2

[email protected] /

www

.montalvo.com

/

Technical details subject to change without notice. U4-technical manual-us © Montalvo General

1

●Universal 100-240VAC (Optional 24VDC).

●Display of all Information in either English or Metric units.

●Can be used with ultrasonic or laser diameter sensors, rider arms or proximity switches.

●Programmable Soft Start, Anti-coast, and Hold values allow precise control of starting and

stopping during quick Cycle applications.

●Two different alarm settings can be programmed to alert the operator or can be connected

to machine controls to slowdown and stop machine.

●Set up and programming can easily be done using the keypad and display or with free

software through the USB port.

●Stores and re-calls up to 9 sets of control parameters for different materials.

●Can be used with TS torque sensor to display actual calculated Web Tension.

1.1 Overview

1.2 System Operation

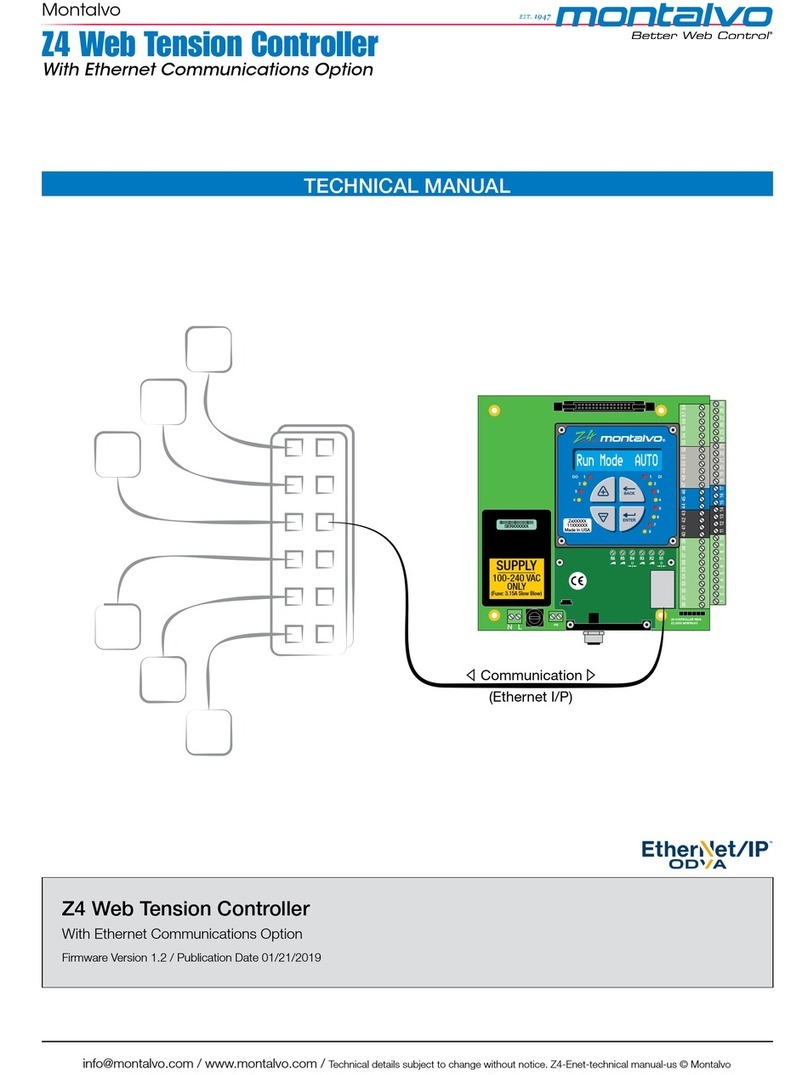

In order to properly set up and program the U4, as well as take advantage of all the available

features, it is important to have a basic understanding of the controller and how it ts into the

tensioning system. Refer to the drawing below.

A typical pneumatic unwind system using an ultrasonic sensor is shown, however the same

principles apply to most open loop tension control systems. The calibrated sensor supplies the

correct diameter to the U4 which applies a proportional output to the brake. The operator sets

the desired amount of tension on the web by increasing or decreasing the trim value to add to

or subtract from the output proportional to the diameter. As the roll diameter decreases, the U4

reduces the output to the brake. Since the output to the brake is proportional to torque, and

since Tension is equal to the Torque divided by the radius, the Tension will automatically remain

the same throughout the roll.

Pneumatic Brake

or Clutch

I/P Converter

Y

Web Direction

Z

Unwind or Rewind

Y

Regulated Air

Air Supply

Z

Y

OUTPUT

U4

US4 Ultrasonic Sensor

INPUT

Z

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

G

24 VDC

-+

U4 Controller Rev #

© Montalvo

Serial #

00000

4

ontroller Rev #

TENSION ONAUTOSTOP

Controller

U4

OUTPUT

TRIM

DIAMETER

TAPERSTART

TAPER%

TENSION

INCREASE SCROLL

TENSION

ON / OFF

DECREASE AUTO / MAN

12345

000000

TYPE

www.montalvo.com

TensionControllers

SN PN

VOLTS AMPS

®

U4

MADEIN USA

207-856-2501 / 800-226-8710

+86-21-52188010

+45 75 57 27 11

+49 (0)511760 69141

IP54

CS100

CS130

V250

V300

V400

MPC4

US4

or

PS1

M4

Tension

Controller

Brake

Web

Unwind

I/P

Converter

Torque

Sensor

Ultrasonic or Proximity

Non-Contact Sensors

Tension

Meter

TS U4

Montalvo TSC™System

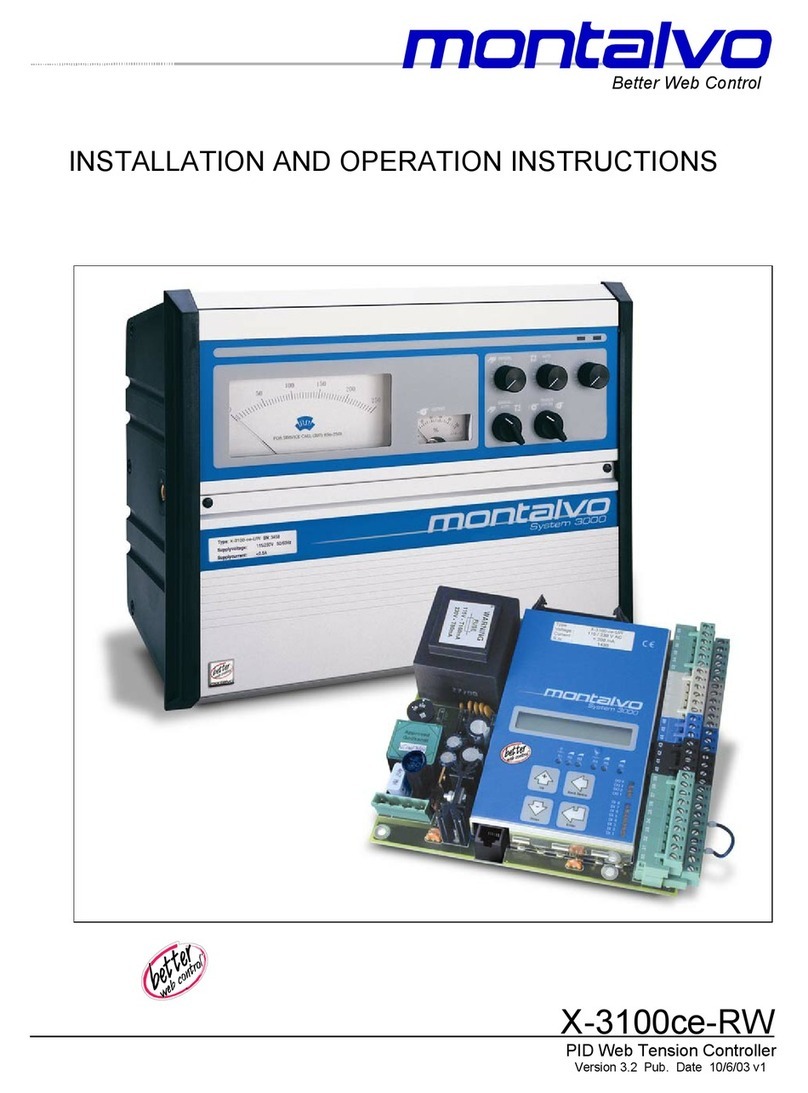

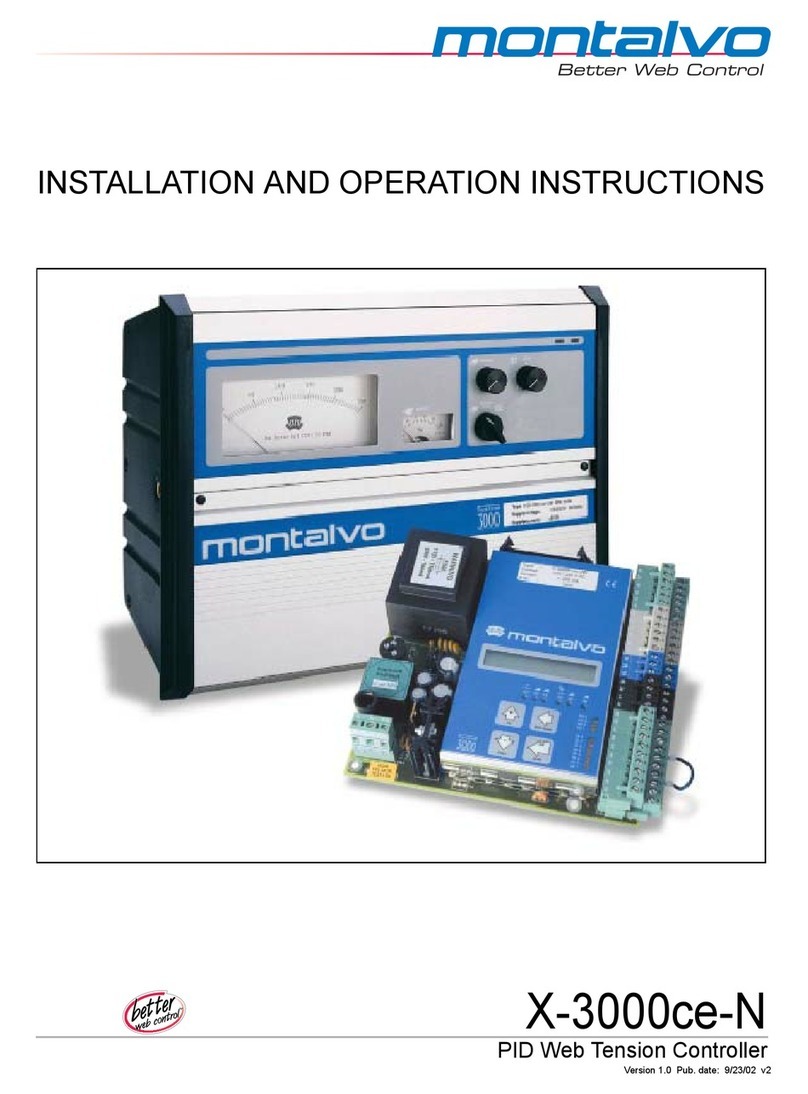

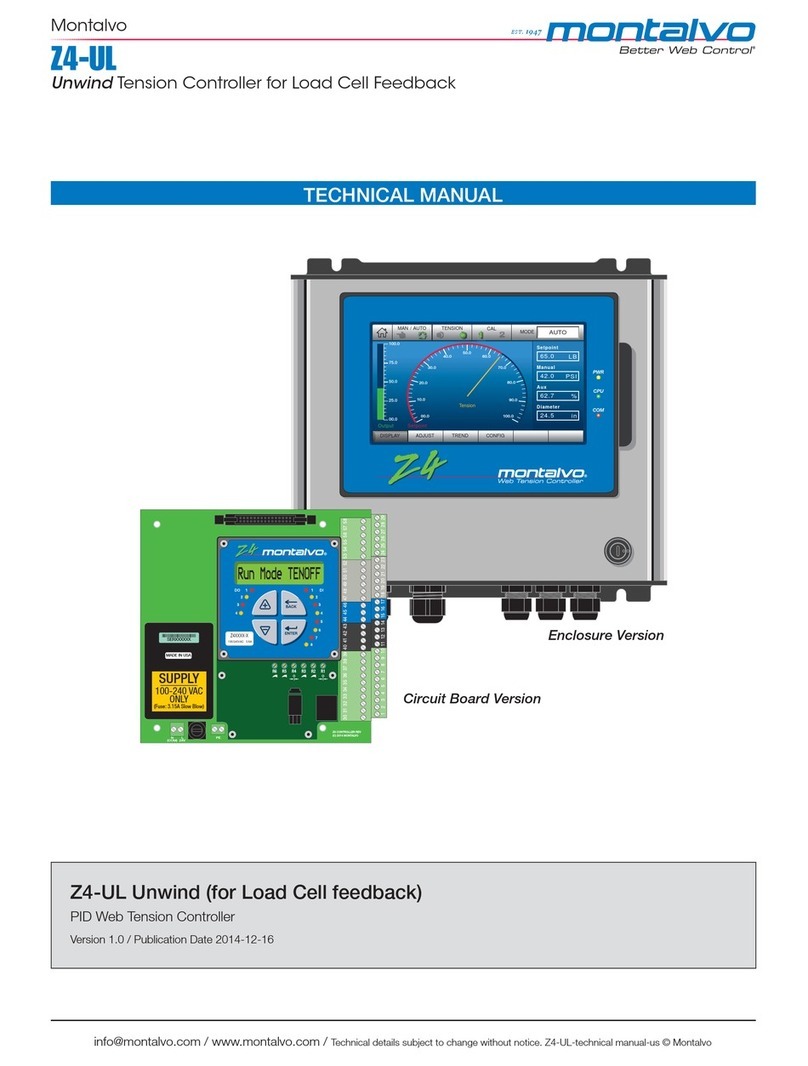

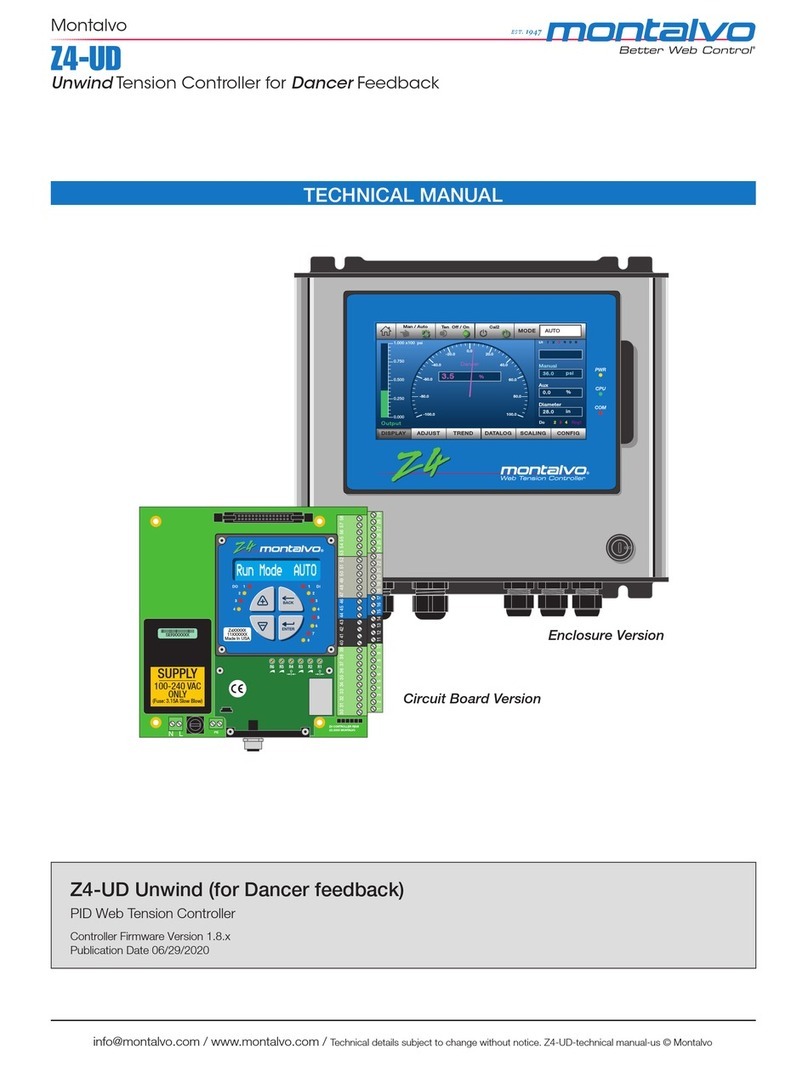

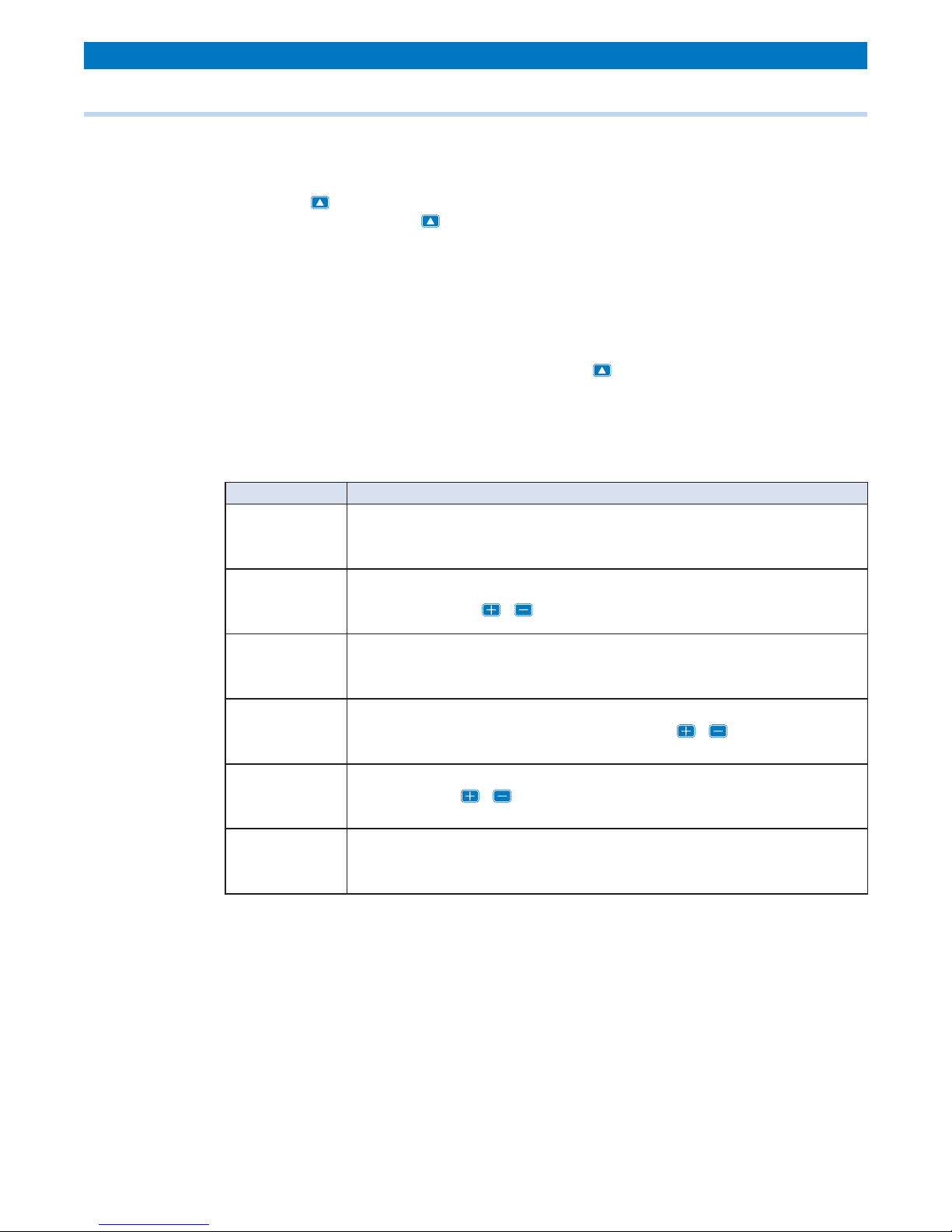

The Montalvo U4 Open Loop Controller provides

precise, accurate control of web tension by

varying torque based on diameter. The control

outputs of 0-10VDC and 4-20mA enable the

U4 to interface with a variety of torque

output devices to control web tensioning

brakes, clutches and motor Drives. The

TSC™ System utilizing a TS Torque Sensor adds

the ability to monitor actual web tension from full

roll to core. Standard U4 features include:

TS