9/23/02 5

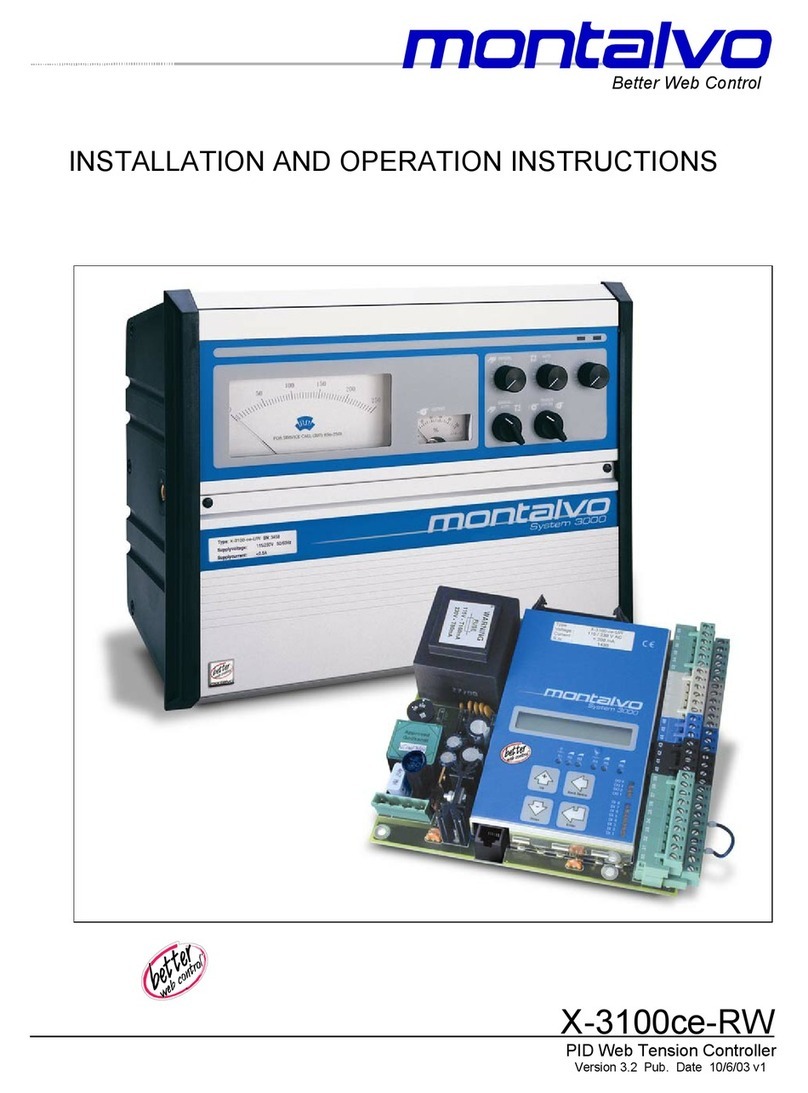

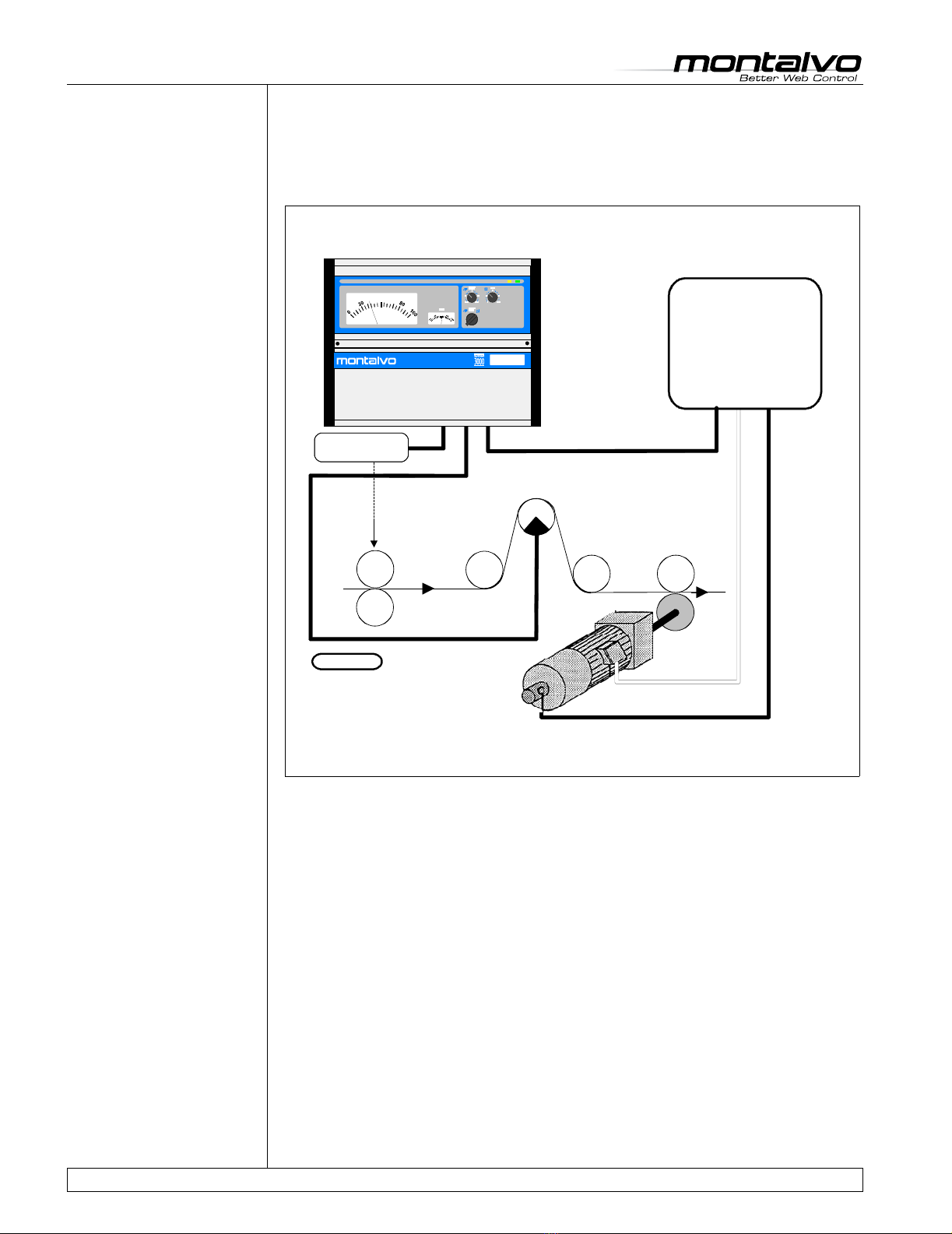

1 General Description

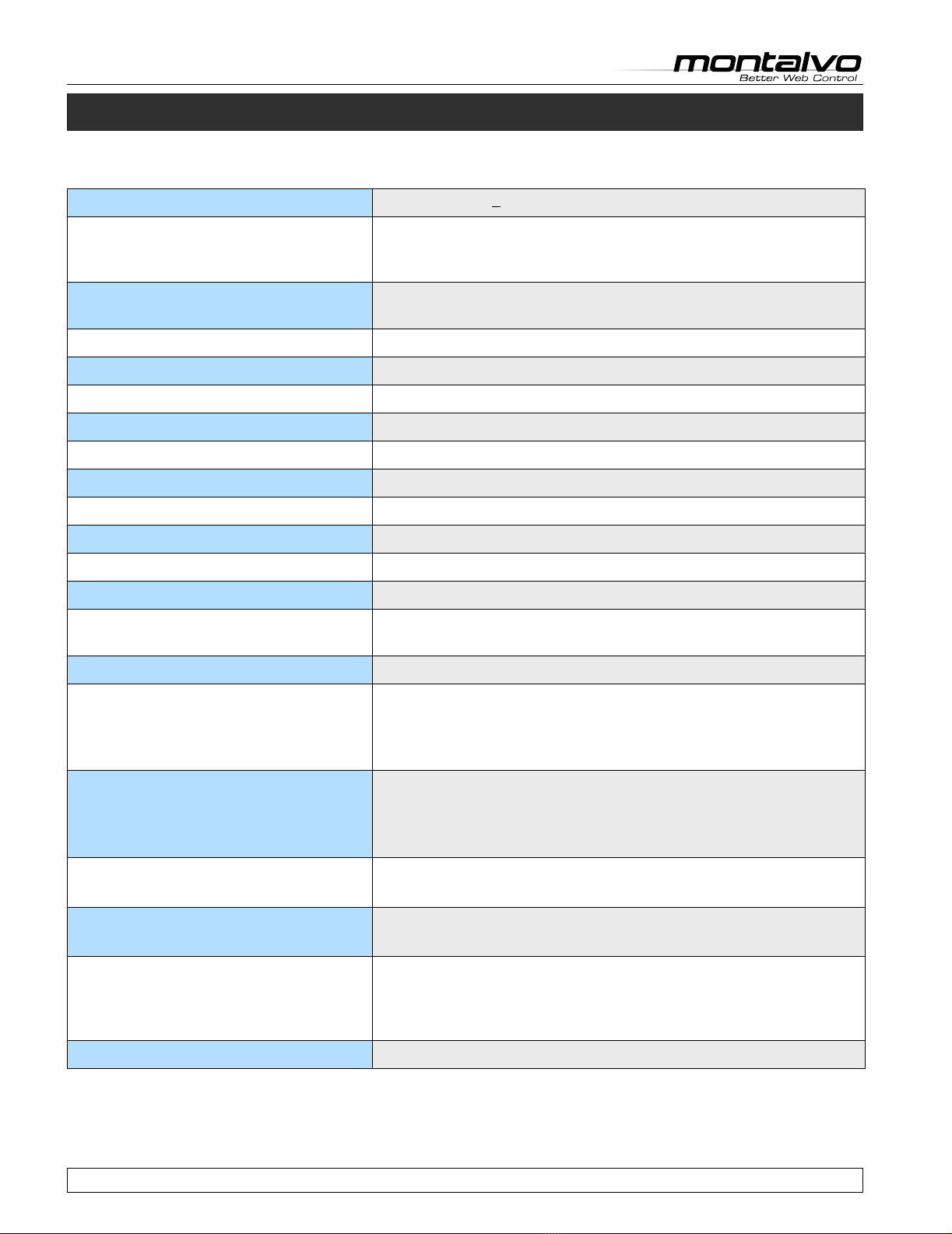

The Montalvo X-3000ce-N analog controller provides precise automatic control of

web tension. The X-3000ce-N is used in a closed loop that includes a load cell roll, a

motor, and a motor controller.

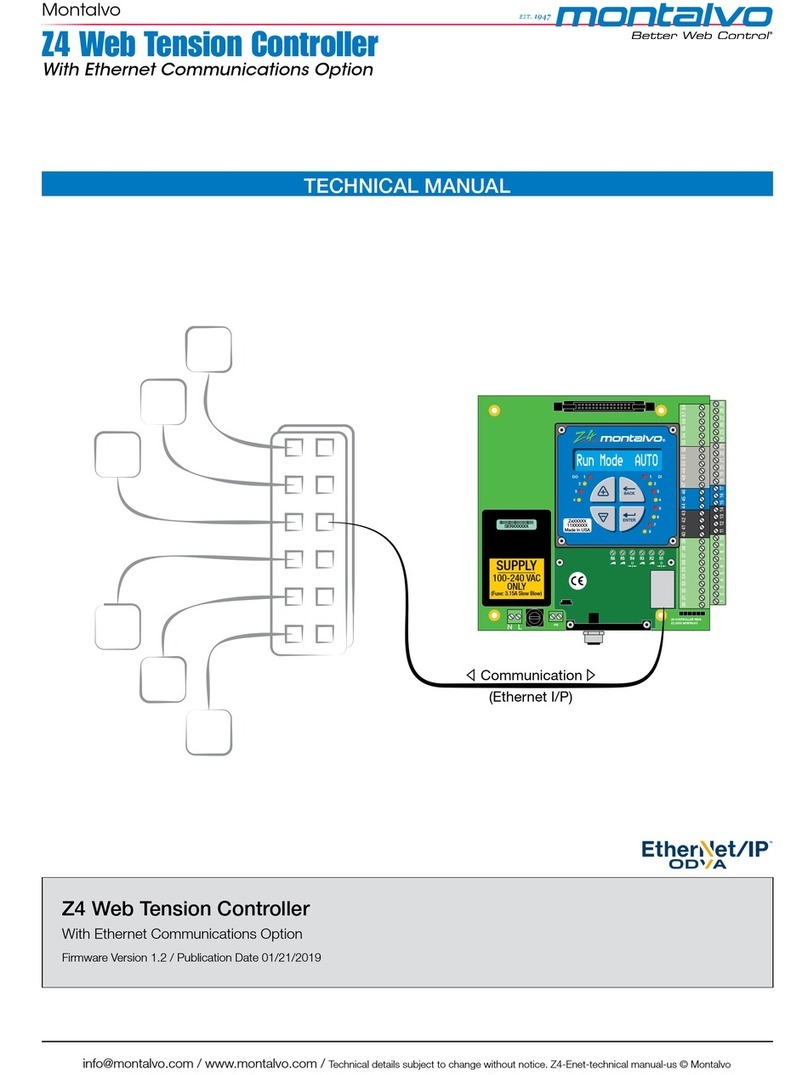

To properly set up and operate the X-3000ce-N and to take advantage of all its

available features, it is important to have a general understanding of the controller

and its place in the tensioning system (please refer to the diagram on the following

page). The control outputs of 4 to 20 mA and 0 to 10 volts DC enable the X-3000ce-N

to interface with a variety of variable speed drives to control web tensioning motors.

Load Cell Function

Two load cells (also called transducers) are normally used. The signals from the load

cells are summed together to indicate total web tension across the entire web. Each

load cell contains two strain gauges connected in a series. The two load cells are

connected so that the four strain gauges form a Wheatstone bridge configuration

supplied with + 2.5 VDC. The web tension transfers a force to the load cell roll,

changing the resistance values in the bridge. The resulting voltage change is

amplified and calibrated to display actual web tension.

Motor Controller and Motor Function

The motor controller converts the 0 to 10 volt signal from the X-3000ce-N into the

output appropriate to regulating the speed of the nip motor. The nip motor tracks the

line speed of the main drive motor.

Auto Mode Function (Closed Loop)

In auto mode, the speed of the NIP motor follows line speed. The signal from the load

cells is calibrated to display the actual web tension. When this signal is compared to

the desired tension (or setpoint), the regulator automatically trims the line speed until

the setpoint and actual tension are equal. Because the web itself is part of the

feedback loop, the X-3000ce-N can quickly compensate for changes in speed, and for

other factors that affect tension during the process.