1. General Description

5

1 General Description

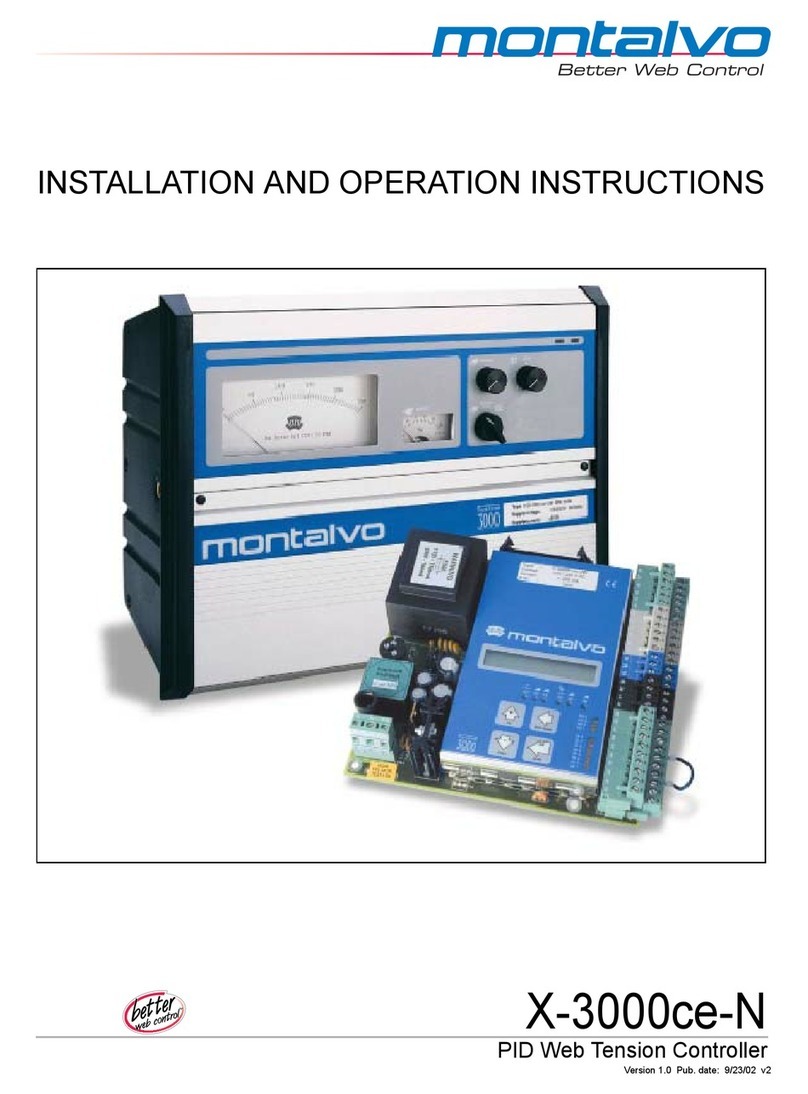

The Montalvo X-3100ce-RW PID analog controller provides precise

automatic control of web tension. The progressive PID regulator

automatically compensates for roll diameter. The controller is used in a

closed loop, of which the load cell, motor and motor regulator are a part.

To properly set up and operate the X-3100ce-RW and to take advantage of

all its available features, it is important to have a general understanding of

the controller and its place in the tensioning system (please refer to the

diagram on the following page). A typical rewinder system is displayed;

however, the same principles apply to any other closed-loop control

system. The control outputs of 4 to 20 mA and 0 to 10 volts DC enable the

X-3100ce-RW to interface with a variety of output devices to control web

tensioning brakes, clutches, and motors.

Load Cell Function

Two load cells (also called transducers) are normally used. The signals

from the loadcells are summed together to indicate total web tension across

the entire web. Each load cell contains two strain gauges connected in a

series. The two load cells are connected so that the four strain gauges form

a Wheatstone bridge configuration supplied with + 2.5 VDC. The web

tension transfers a force to the load cell roll, changing the resistance values

in the bridge. The resulting voltage change is amplified and calibrated to

display actual web tension.

Torque control

The X3110ce system is based on “torque” control. This is a regulation type

that is used for soft regulation and machines with a “long” ramp up and

down time.

Motor Function

The Rewinder shaft is driven directly by the rewinder motor. If a gearing is

used, the maximum gear ratio recommended is 1:10.

Motor controller

It is possible to use a “simple” motor controller for the rewind motor. This is

because that the X3110ce has many special features that are required for

the “perfect” rewinder system.

Line speed

The line speed can be used in different ways. For the simple rewinder the

line speed is connected directly into the motor controller. For the more

advanced system the line speed has to be connected to the X3110ce. The

X3110ce will then control the “speed” setpoint for the rewinder as well.