P/N XG0640

Page 4

M40 Series Mobile Home Conversion Kit

Gas Conversion Instructions

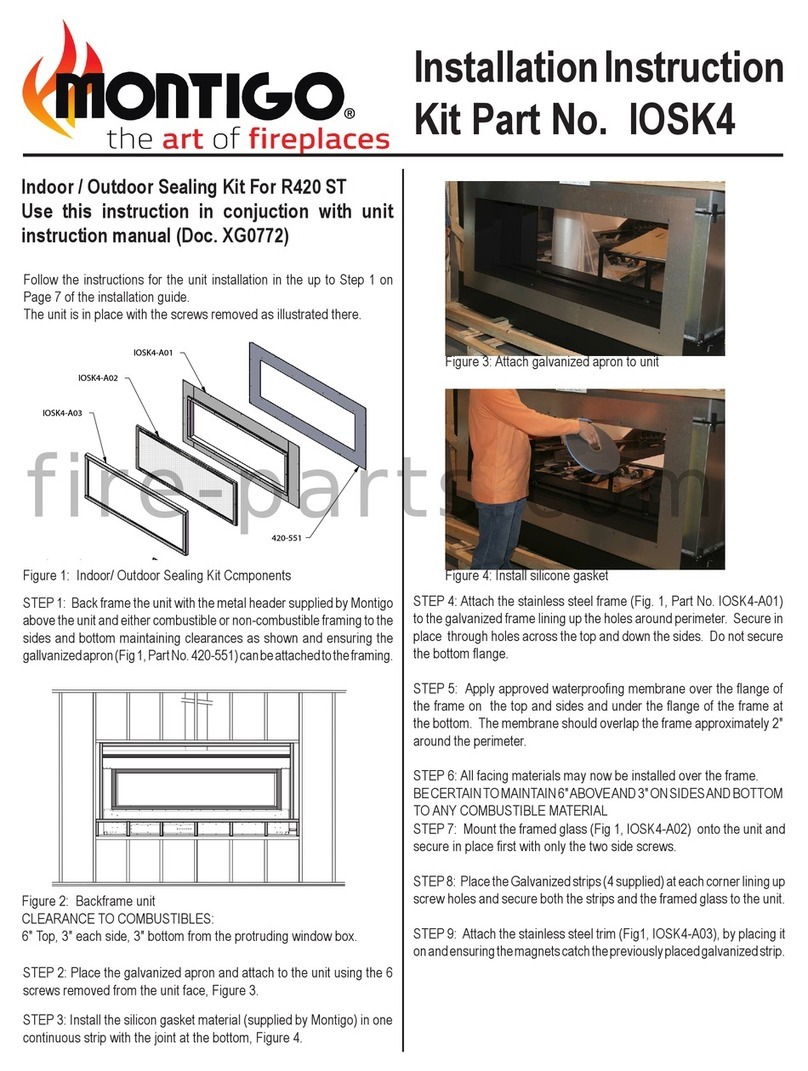

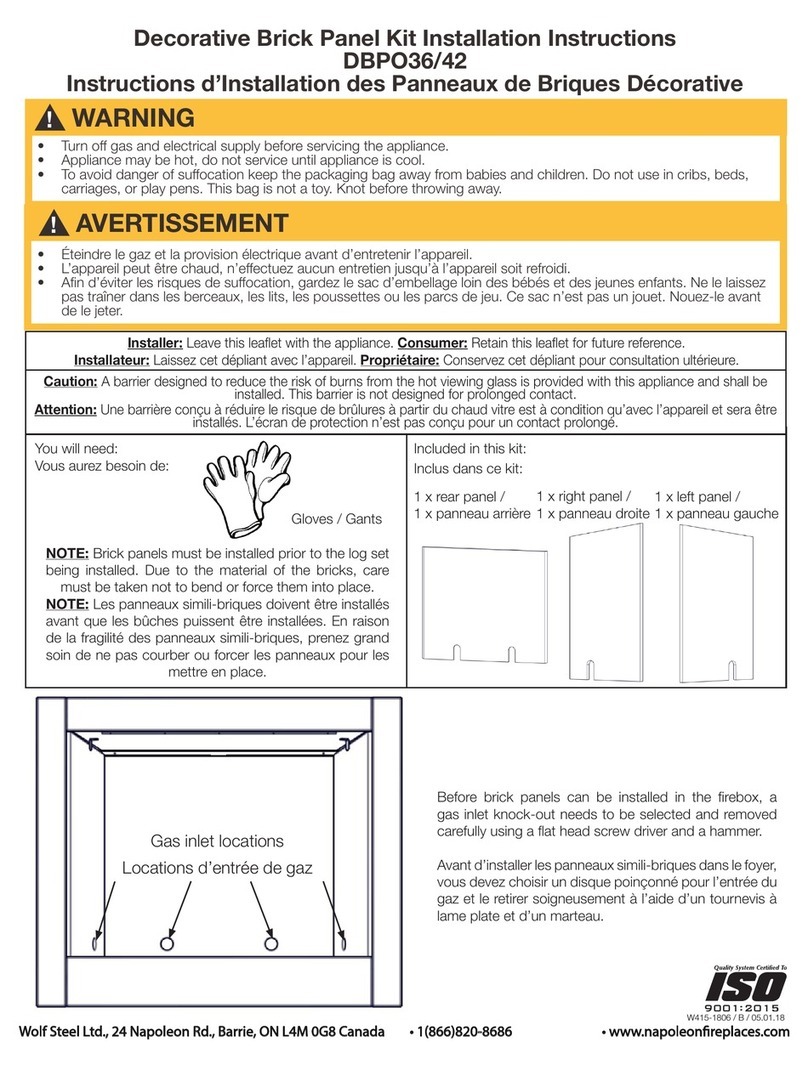

B. Checking the Gas Pressure

1. To check the Inlet and Manifold gas pressures, use a Water

Column Pressure Gauge with 5/16" dia. tubing. Make sure the

gas shut-off valve is closed, then attach the gauge to

the Manifold Pressure Test Connection by loosening the screw

shown in Figure 7. The tubing must be tight in the connection to

prevent gas leaks. Measure the Manifold Pressure and compare

the value against the chart below.

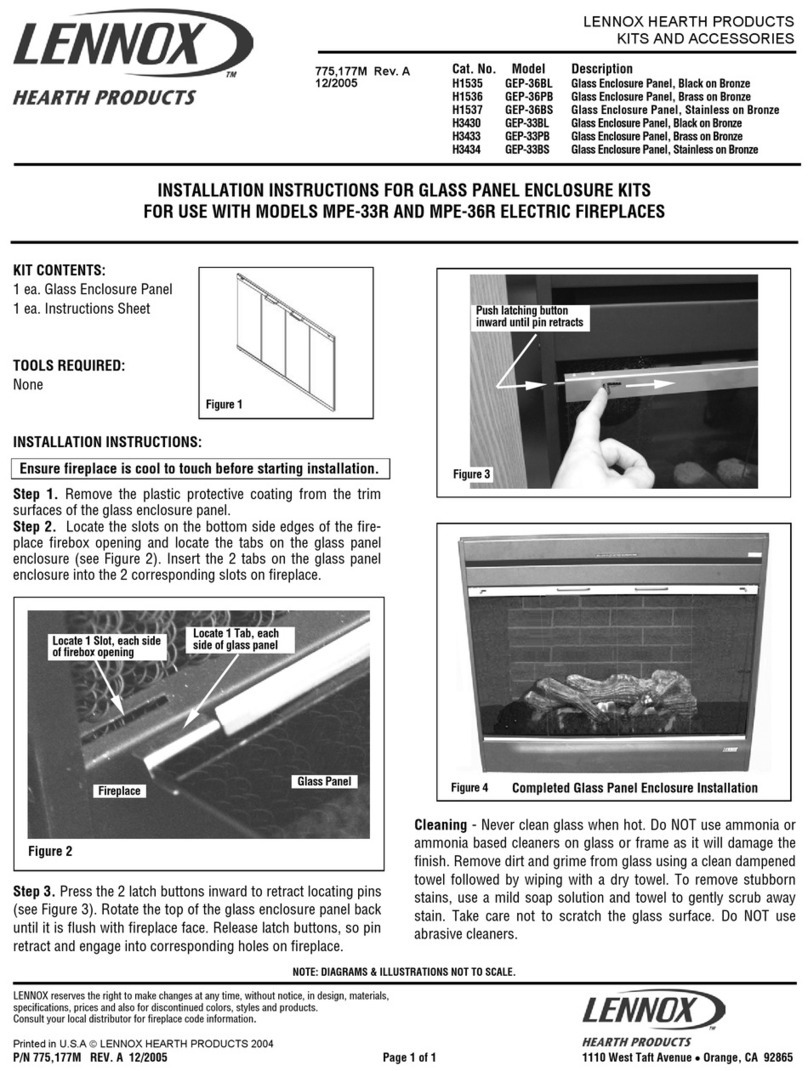

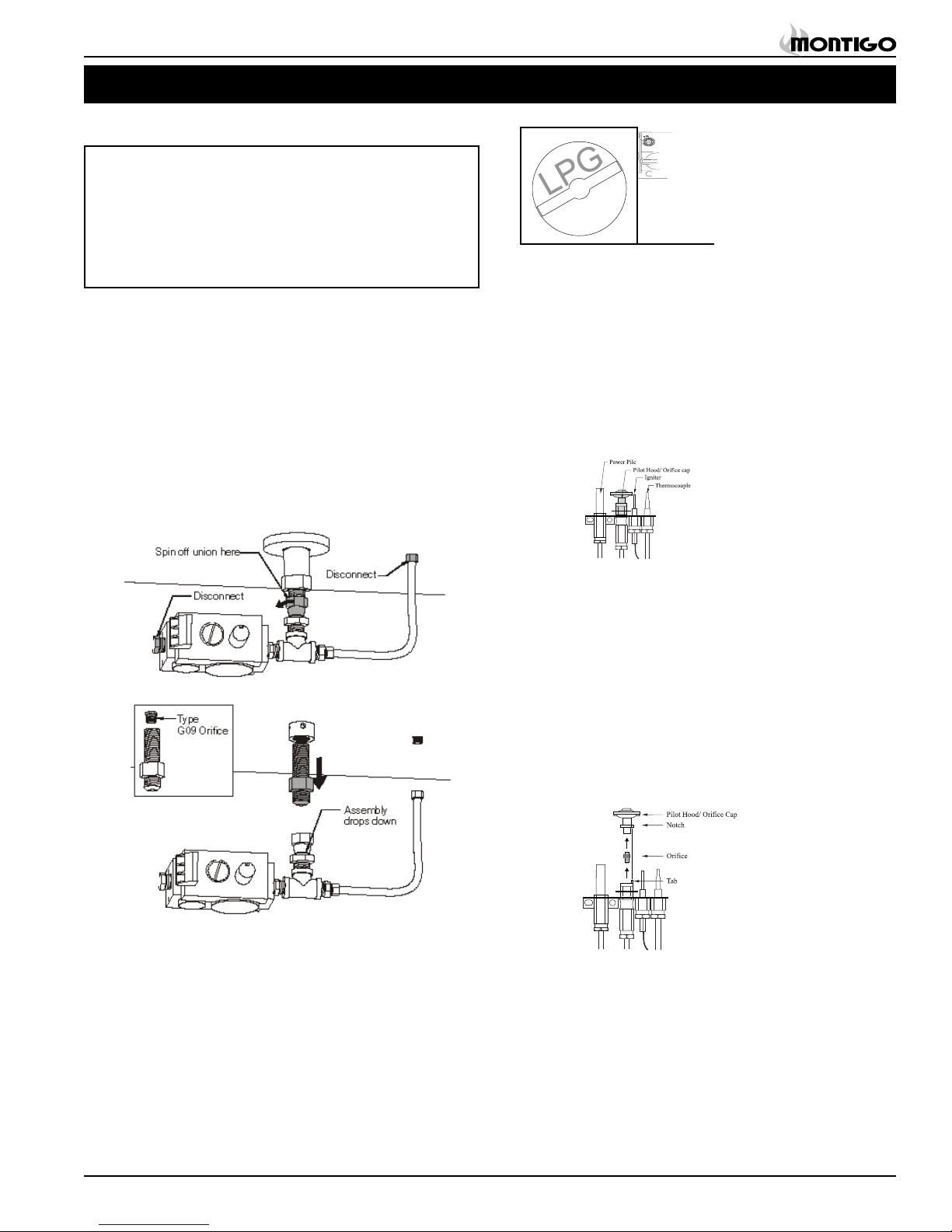

Figure 7. Sit Nova 820 gas valve.

Natural Gas Liquid Propane

Manifold Pressure (min.) 3.5" W.C. 10" W.C.

Inlet Pressure (min.- max.) 5.5" - 14" W.C. 11" - 14" W.C.

" W.C. = inches water column

2. Turn off the fireplace and close the shutoff valve. Remove the

test gauge. Re-tighten the test connection screw to prevent gas

leakage.

3. Repeat the procedure for the Inlet Pressure.

4. If the pressure readings are not within the limits set out, contact

the factory. If the pressure readings are correct, ensure that both

test connection screws are tightened securely, to prevent a gas

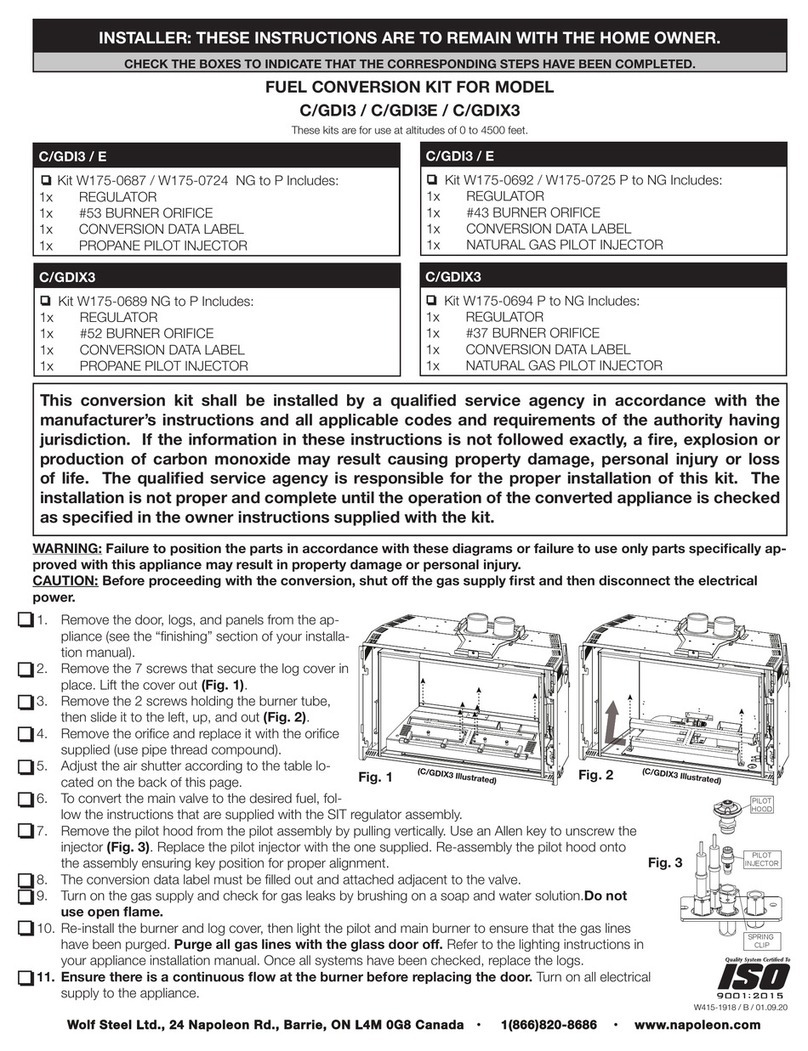

C. Pilot Burner Adjustment

1. Locate the Pilot Adjustment Screw. (See figure 7)

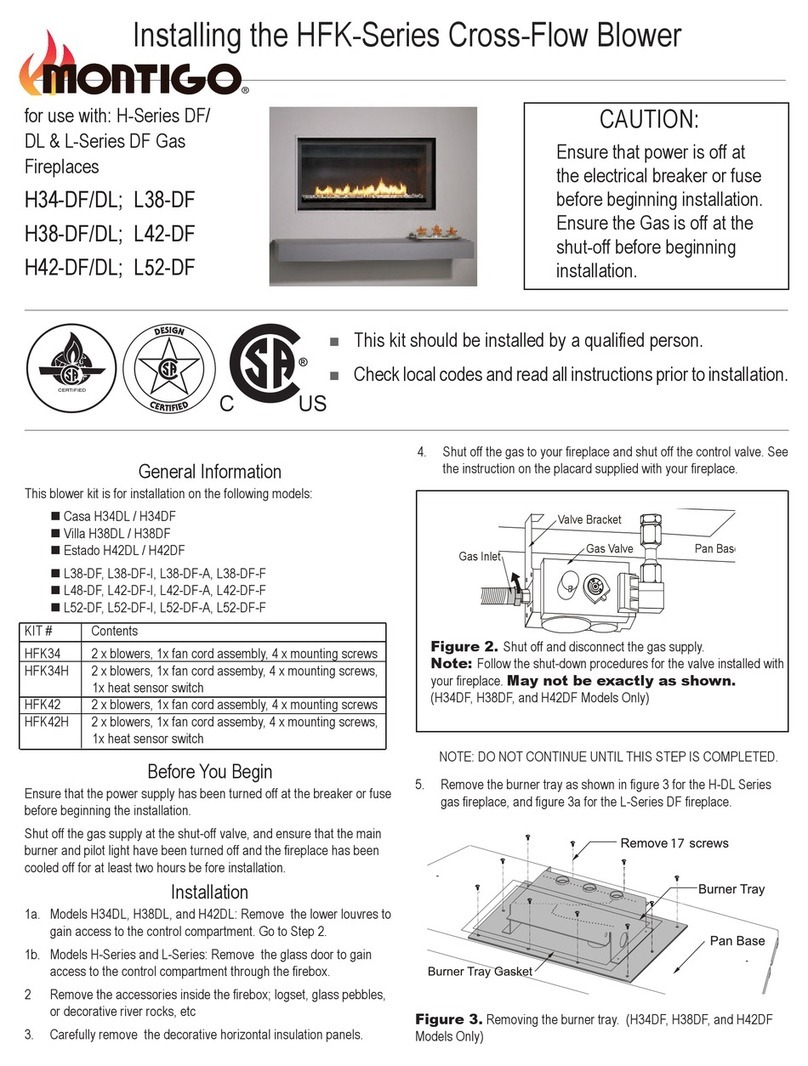

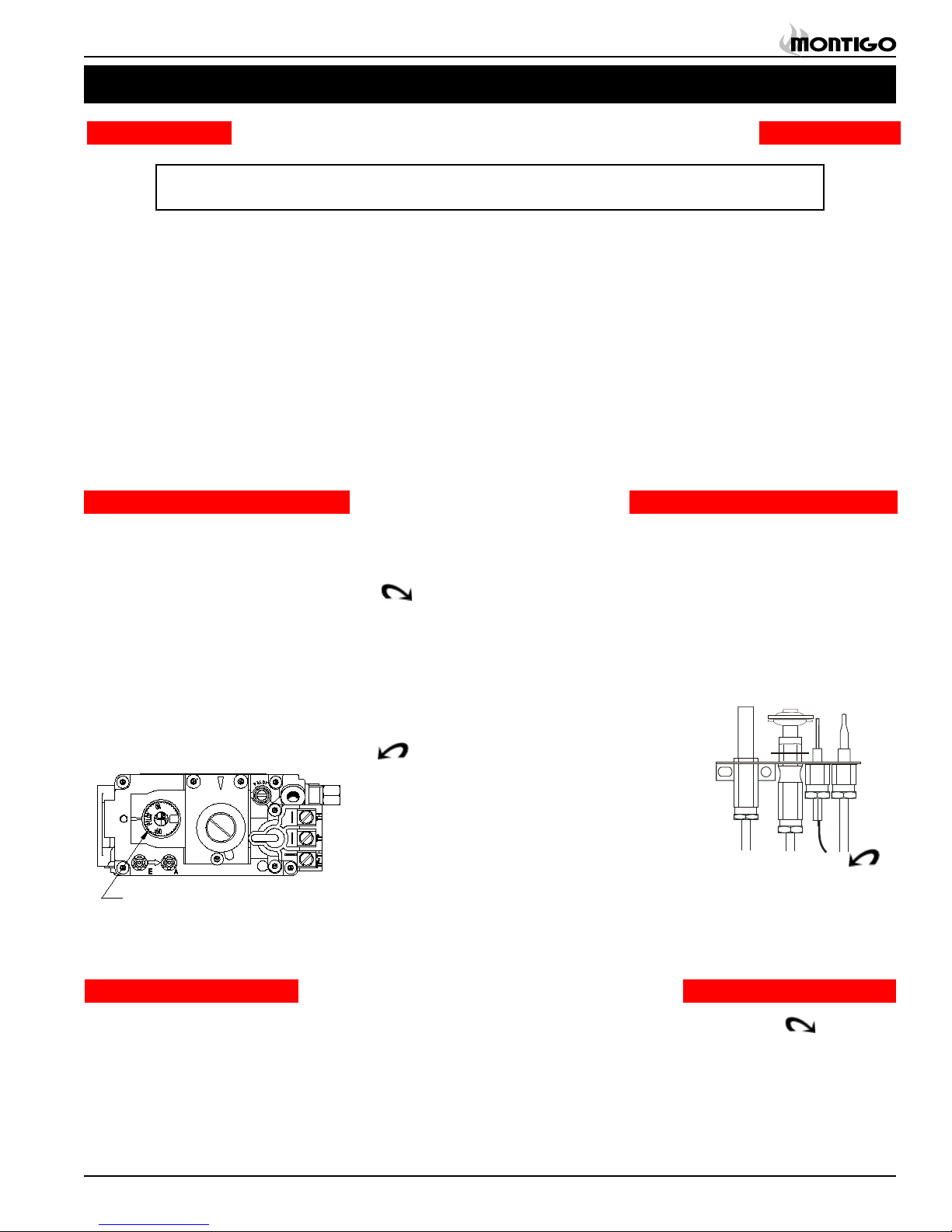

2. Adjust pilot screw to provide properly sized flame. To increase the

flame, turn the screw counterclockwise. To decrease the flame,

turn it clockwise. (The flame should impinge on the thermocouple

and thermopile, as shown in Figure 8)

Figure 8. Pilot Burner

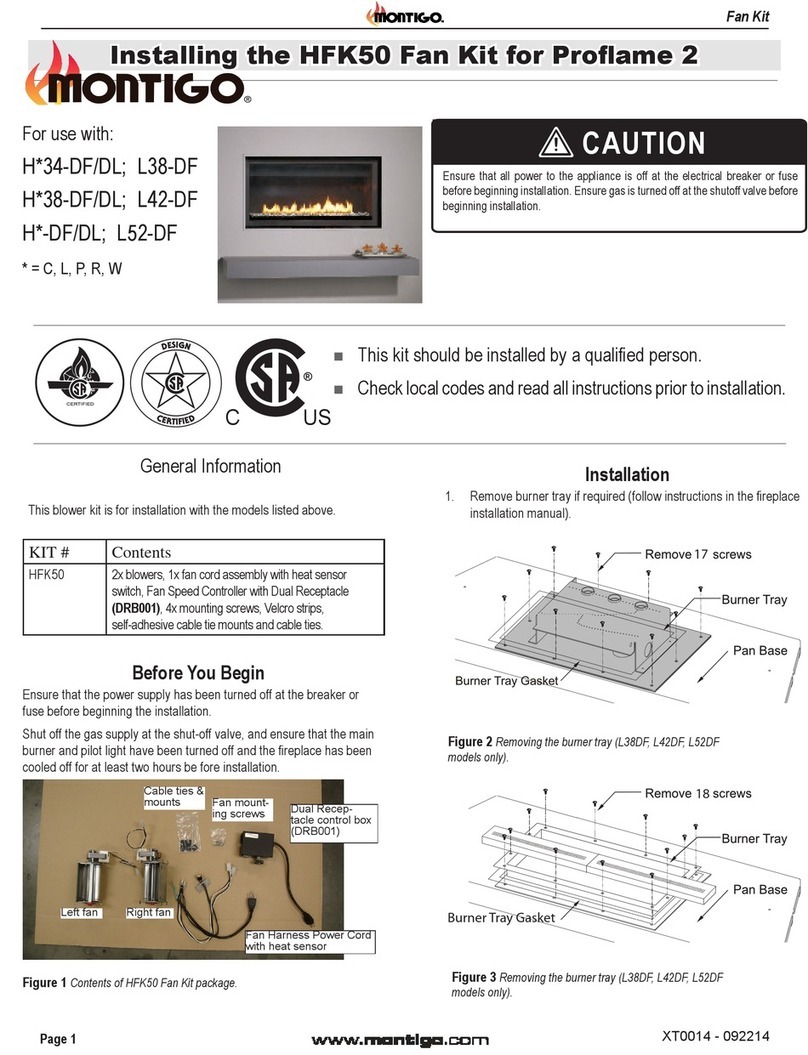

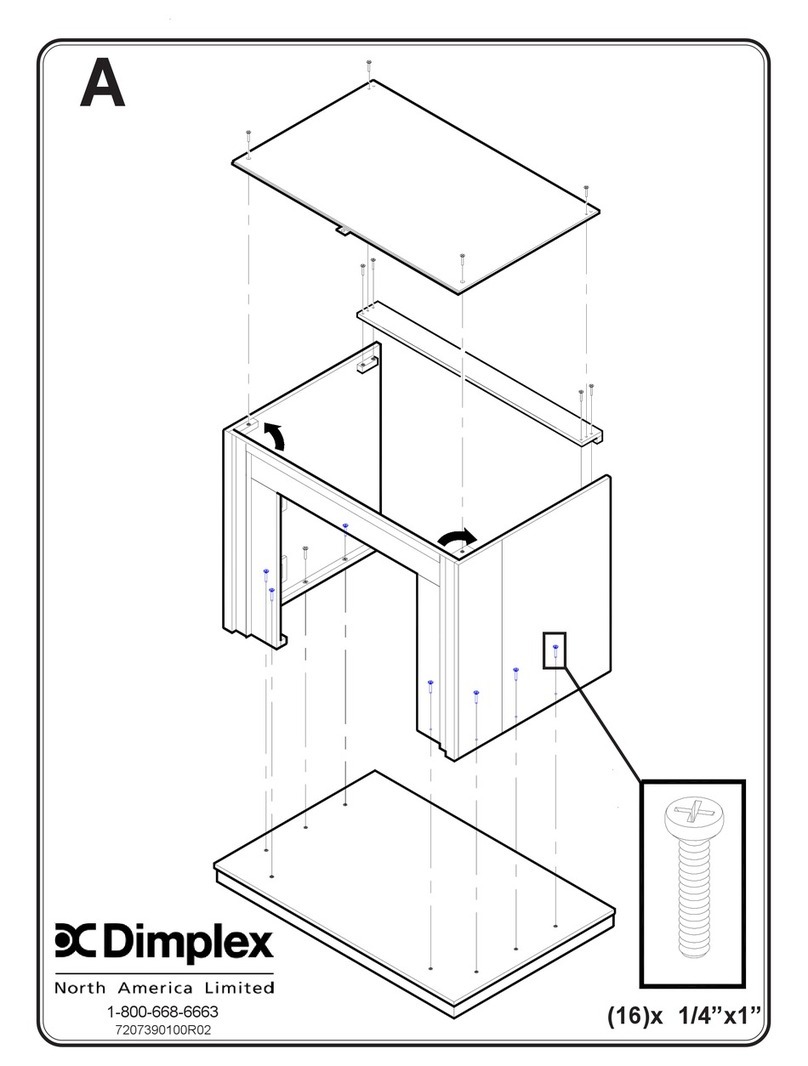

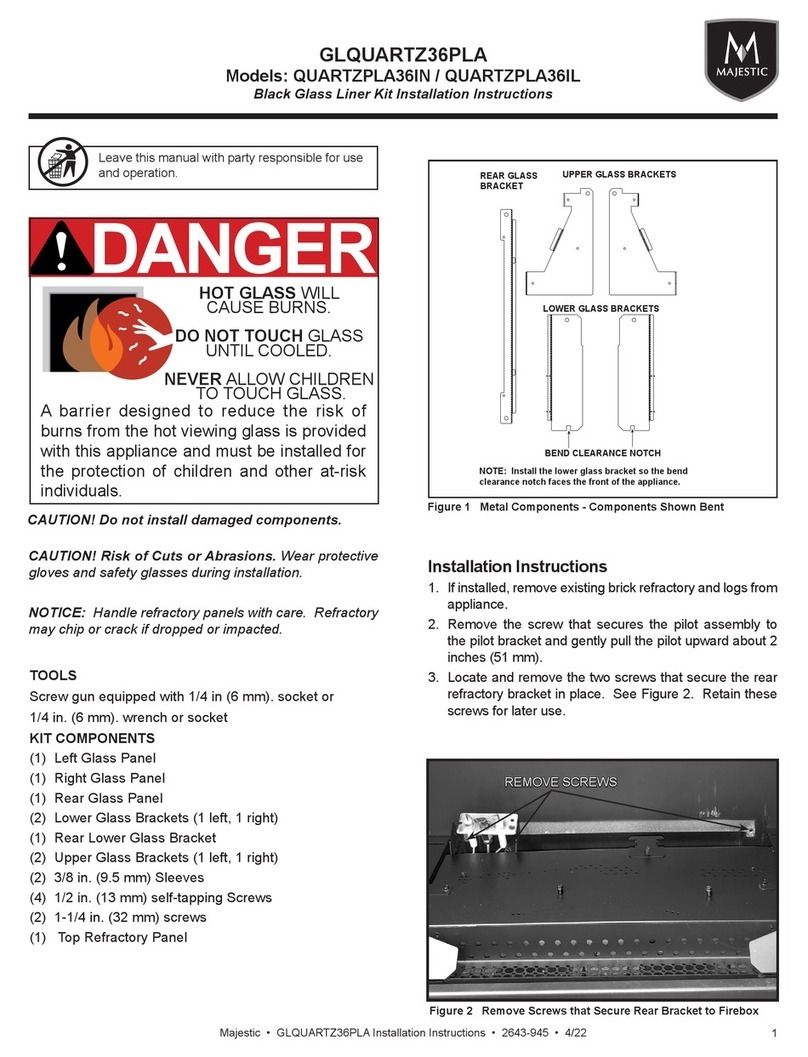

Figure 5. Main Burner.

Main Burner

10. Remove cover plate on both ends of the main (center) burner

and remove main burner tube. (See figure 5)

11. Loosen the set screws at each end of the burner tube. Slide the

sleeves out of each end of the tube and replace them with the

ones from the package marked 'Main Burner Sleeves' in this kit.

(See Inset, Figure 6.) Re-tighten the set screws.

12. Remove the orifices from the orifice holder at each end and

replace them with the new orifices from the package marked

'Main Burner Orifices' in this kit. (See Figure 6.) Make sure the

Orifices are tightened securely to prevent gas leaks.

13. Re-install the main burner, making sure you center the

burner between the two orifices. Ensure that the burner's flame

ports are pointed 90 degrees to the horizontal. Secure the burner

by re-attaching both cover plates.

Checking Your Conversion

14. Leak test using a soap solution with main burner turned on. Coat

pipe and tubing joints, gasket etc. with soap solution. Bubbles

indicate leaks. Tighten any areas where the bubbles appear until

the bubbling stops completely.

15. Light the fireplace pilot, and turn the gas control knob to the ON

position. Ensure all three burners light properly.

Re-Assembly

16. Replace the logs, re-install the door and the door surround.

17. The label (part no. XL0201) indicating that the fireplace has been

converted for use with a different gas must be placed on the

fireplace rating plate over top of the existing fuel type chart.

18. The label (part no. XL0200) indicating who converted the ap-

pliance must be filled out and placed on the base pan, directly

Figure 6. Changing main burner orifice.

Inset. Remove screw

to release sleeve.

under the gas valve.

Manifold Pressure

Test Connection

Pilot Adjustment Screw

Inlet

Pressure

Power

Generator

Wall Switch