ROTARY

PAGE 10

3.2 .......Numbering

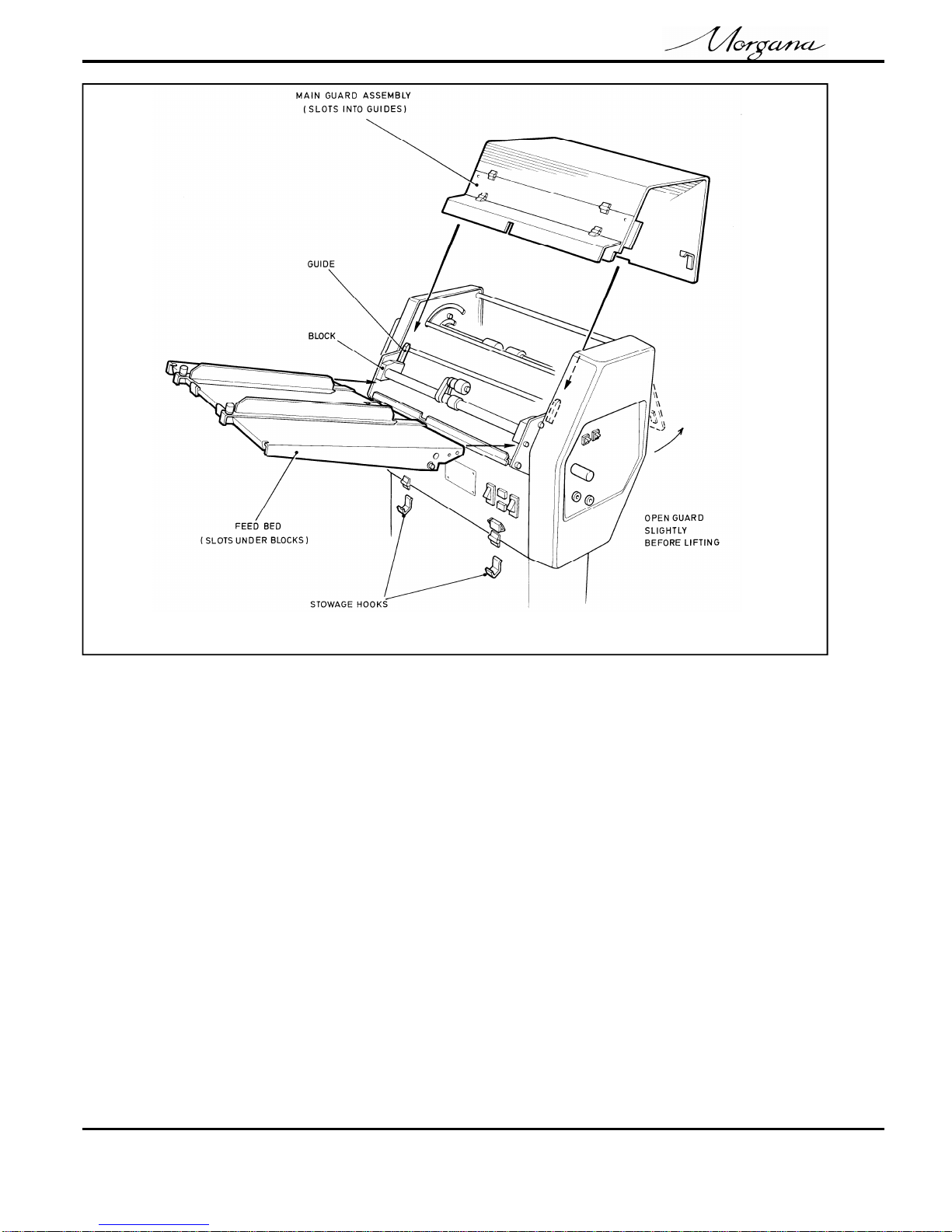

Fit a Numbering Head to a collar, using the scale on the collar to

obtain the correct position. The scale relates to the distance from

the top of the sheet, to the top of the number. Line up the back

edge of the Numbering Head with the scale. (To make the scale

position accessible, operate the Auto/Man switch and turn the

machine using the handwheel at the rear of the machine See Fig

2.11)

Position the Numbering Head sideways, by releasing the collar

locking screw. This locking screw is only accessible by operating

the auto/man switch, (see 2.1) and rotating the machine by hand.

NOTE .....Every time the collars are moved, the advance cam will

need moving and the hold-down wheels checked , by

rotating the machine by hand. NEVER operate the

machine under power until the auto/man switch has been

released, and the Numbering Head has been turned one

complete revolution by hand, to ensure that the hold-

down wheels and advance cams are positioned correctly.

3.3 .......Setting Numbering Digits

Set the Numbering Head digit wheels using the pointed stylus,

supplied with your Numbering Head. The wheels can only be

turned in the direction shown in Fig. 3.21

To avoid having to reset the digit wheels after make-ready, set

them to a number somewhat lower than, (forward heads) or higher

than, (backward heads) your jobs required starting number.

Standard heads have seven digits. If less than seven digits are to

be printed, up to six zero's may be depressed so that they do not

print. ( This feature may not apply to all Numbering Heads )

To depress the digits, turn the digit wheel until the zero is at the top

of the head. Turn the wheel further while pressing the zero down

into the head. The zero will drop down and remain down.

To release the zero, turn the wheel further in the normal direction.

Section 3 SETTING