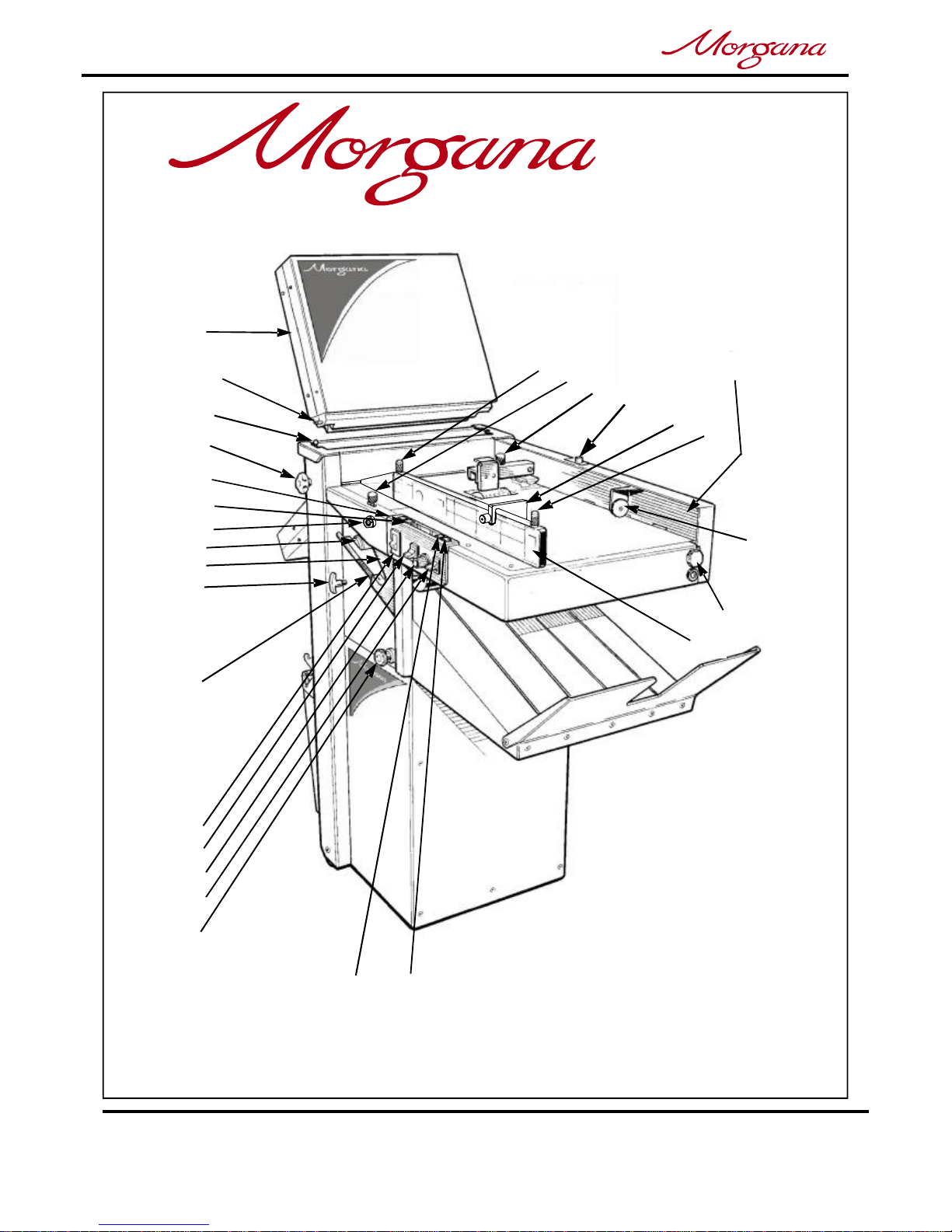

Page8 PAPER

Manual&FineAdjustment

Thefoldplatelengthcanbeadjustedmanually.Youmayneedtomakethisadjustmentto

achievetheexactcorrectlengthoffold.Button(CC)willselecttheupperfoldplate&button

(DD)thelowerfoldplate.Tomakeamanualadjustmenttothepositionoftheupperfoldplate,

pressandholdtheupperfoldplatebutton(CC).Thedimensionoftheupperfoldplatewillnow

bedisplayedinthecontrolpanel.

Note: -Theupperfoldplateshowsthedimensionofthefrontedgeofthe papertothefirstfold,

thelowerfoldplateshowsthedimensionfromthefirstfoldtothesecondfold.

Byturningtheselectknob(V)whilststillpressingandholdingtheupperfoldplatebutton(CC)

thefoldlengthoftheupperplatecanbelengthenedorshortened.Turningtheselectknob(V)

clockwisewilllengthenthefoldplatelengthandbyturninganti-clockwiseitwillshortenthe

foldplatelength.

Thedigitsbeforethedecimalpointshowninthedisplayareinmillimetres,each‘click’ofthe

selectknob(V)representsincrementsof0.1ofamillimetre.

Toadjustthepositionofthelowerfoldplate,press&holdthelowerfoldplatebutton(DD)and

adjustthelengthasdescribedabove.

Whenyouhaveadjustedthefoldlengthdimension,moveswitch(W)uptotheRunposition.

Theplateswillthenpositionthemselvesaccordingtothefoldlengthsyouhaveselected.

Withswitch(W)intheRunpositionthelefthandsideofthecontrolpanelwilldisplaytheletter

‘U’whichindicatesausersettingfollowedbyaletterthatindicatedthefoldtype.Forexample

theletters‘UL’wouldindicateaUsersettingbasedonaLetterfoldandtheletters‘UH’would

indicateaUsersettingbasedonaHalffold.

Tocheckthefoldpositionaftermakingamanualorfineadjustment,pressthesystemswitch

(T)andthenpressthefeedswitch(U)down.Themachinewillfeed3checksheetsandstop.

Aftercheckingthe3-rdsheet,ifthefoldpositioniscorrect,movethefeedswitchuptotheoff

positionandthen immediatelydowntothepulsepositionandthemachinewillstarttooperate.

Ifaftercheckingandfurtherplatepositioningisrequired,repeattheaboveprocedure.

Thefinalfoldplateanddeliverystackersettingscanbe‘stored’forretrievalatalaterdate,see

‘ToStoreAProgramme’.