Operating Instructions | GPM 450

5

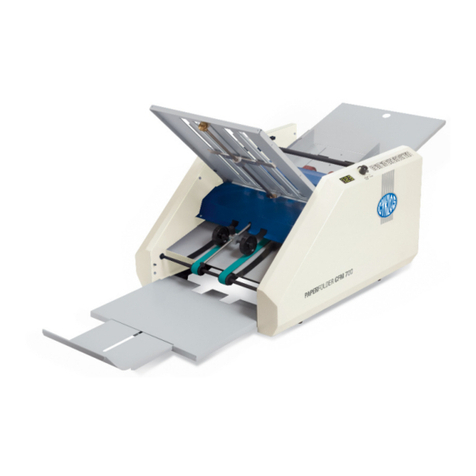

4. MACHINE DESCRIPTION, INSTALLATION AND ADJUSTMENT

Electrical creasing and perforating machine is suited for final processing of graphical material up to 450 mm

width. Creasing enables to fold paper easily without cracking. Perforation can be done simply by a blade

change, and turning the lower tool (8) without further adjustment. Waste-free perforation allows easy paper

separation. Millimeter scales, which are used to adjust paper stops, are placed on the sides of the both

tables (3, 4). The machine is controlled, either by a hand-operated switch on the cover (2), or by a foot

pedal (13).

When the machine is unpacked, it is placed on a solid flat surface. First the rear table (3) has to be installed

and secured, and also the foot pedal if needed. Then, after the machine has been plugged in, it is set in a

working condition and the control indicator (5) shines constantly.

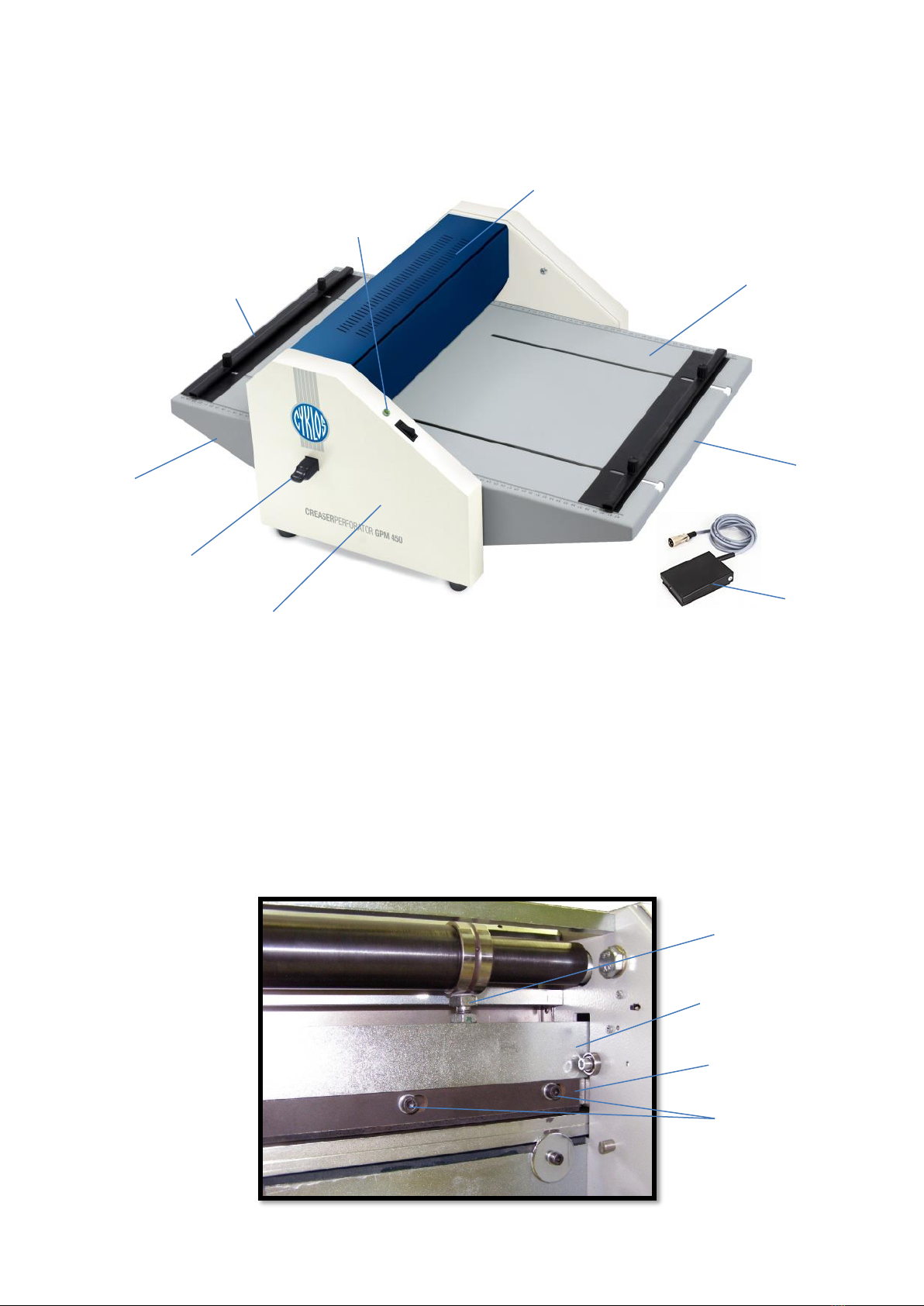

For perforation the lower tool (8) has to be turned by the smooth (no groove) surface faced upwards and

beside that it is necessary to replace the creasing knife with a perforating knife (separate packing). To

achieve this, the machine has to be unplugged first. Then we tilt up the top cover (1). There are 5 screws

(9) and clamp (11) holding the knife inside the machine. These need to be dismounted. After knife

replacement screws should not be tightened completely until the check test is carried out. Plug the machine

in, press once electric switch. The knife goes down and aligns itself with respect to the bottom tool. Then

plug the machine out again and tighten the screws completely. This way crease/perf knife and lower tool

are parallel.

In case of poor quality of perforating, or while having trouble with separation of the paper after perforating

has been completed, it is necessary to adjust the pressure of upper bar.

4.1 Adjustment of Upper Bar Stroke

Unless the depth of a crease on both sides of the sheet is identical or unless the sheet is torn away evenly

after perforation, the upper bar (10) can be moved down using the tool thrust regulation screws (12). The

screws should be loosened anticlockwise by 1/12 (30°) of the revolution (the bar moves downwards) and

then secure them with a nut. Try the quality of perforation after each turn of the screw by 30° and, if

satisfactory, do not turn the screws any more. When adjustment of perforation is finished, the machine is

also to be adjusted for creasing.

5. THE MOST COMMON FAULTS (TROUBLESHOOTING)

- control indicator flickers approx. 1x /sec: the top cover (1) is open or the rear table (3) is pushed out

- control indicator flickers approx. 2x /sec: the upper bar mechanism has been blocked, it is necessary to

unplug the machine, to loosen locking nuts and then to turn the tool thrust regulating screw (9) clockwise

(approx. 2 turns) and then the upper bar moves up. After the machine has been turned back on, the

unfinished working cycle finish automatically. It is necessary to readjust the upper bar (see Section 4.1).