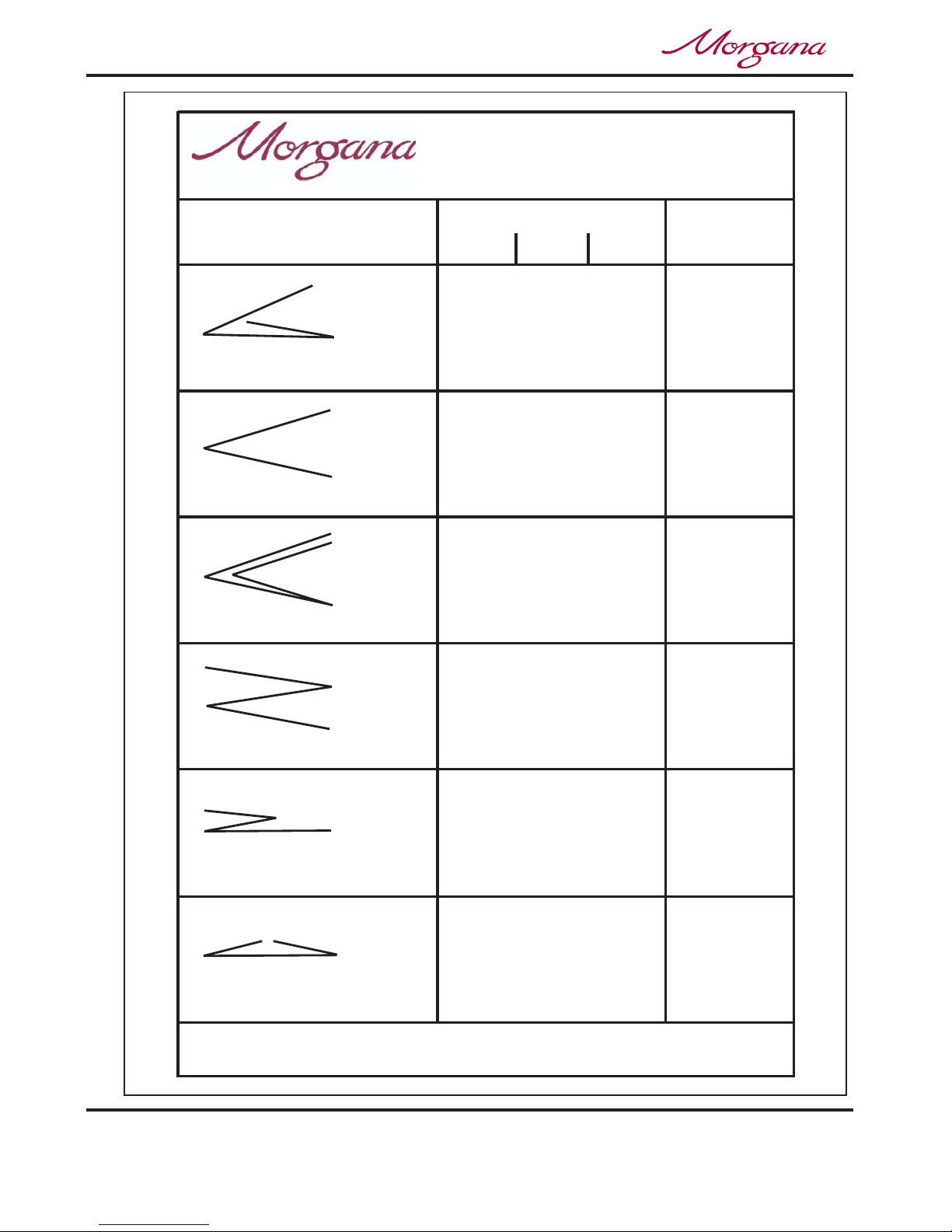

Page 4 PAPER

INTRODUCTION AND SPECIFICATION

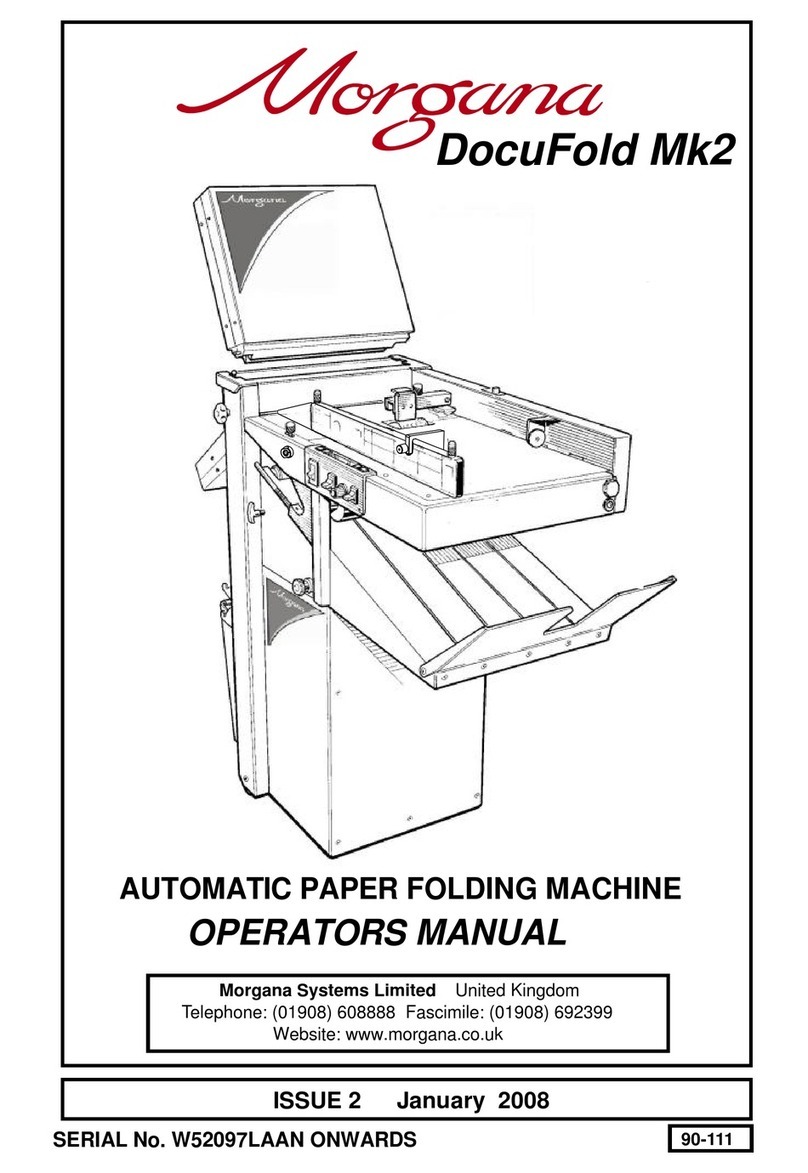

Major is a registered trade mark of Morgana Systems Ltd. The Morgana Major is designed

to be used in today’s environment of document production, the Morgana Major can be

used by non skilled personnel by following this easy to use operators guide. There are very

few operator adjustments required on the machine and our section will get

you started very quickly, but we do recommend that you take a little time to read this

manual, to ensure that you fully understand the machine. We have also included a

section. Be sure to read this section calling a service

engineer to avoid unnecessary expense. A maximum paper weight cannot be specified, as

this can be governed by the hardness of the substrate or the type of fold required to be

produced.

Feeding System .......................................... Bottom suction feed

Max. Sheet Size .......................................... 674mm Long x 365mm Wide (26.5” x 14.37”)

Min. Sheet Size ........................................... 160mm Long x 140mm Wide (6.3” x 5.5”)

Max. Paper Weight ...................................... 240gsm Max. according to hardness, type

of fold, grain direction and substrate

Min. Paper Weight ....................................... 56gsm

Max. No. Folds per Sheet............................. 2

Speed per Hour (A4 Material) ...................... 27,500 sheets (Stream Feed)

QUICK START

TIPS &

TROUBLE SHOOTING before

IMPORTANT

Note:

the operating environment should be controlled to a temperature between

16° C and 27° C Maximum.

Max. Fold Length ......................................... 337mm (13.25”)

17,250 sheets (Pulsed Feed)

Speed per Hour (A3 Material) ...................... 18,000 sheets (Stream Feed)

13,250 sheets (Pulsed Feed)

Dimensions .................................................. L: 1168mm H: 990mm W: 493mm

Weight ..........................................................120Kgs (+11Kgs packing)

Power Requirement ......................................1 phase 220 / 240v

Specification

The production speed varies according to the material size.

Major