2

3

1

2

24 Months

1

Do not use anything except ethanol. Do not use too much ethanol; it could seep inside and damage the handpiece.

Rotation and spray delivery will be impaired if debris gets inside the water or air lines.

Do not immerse the handpiece in or wipe it with any of the following: functional water (acidic electrolyzed water,

strong alkaline solution, and ozone water), medical agents (glutaral, etc.), or any other special types of water or

commercial cleaning liquids. Such liquids may result in metal corrosion and adhesion of the residual medical agent to

the handpiece.

Unit Name Mode Detergent

(concentration)

Neutralizer*

(concentration)

Rinse

(concentration)

Miele G7881 Vario TD neodisher MediClean

(0.3 – 0.5%)

neodisher Z

(0.1 – 0.2%)

neodisher Mielclear

(0.02 – 0.04%)

* After cleaning there may be streaks or white spots on the instrument.

Use a neutralizer only if there are streaks or white spots.

* When using a high-temperature washer-disinfector to clean the handpiece, strictly adhere to the

conditions specified below.

High-temperature cleaning conditions

Operating conditions for high-temperature washer-disinfectors

Operating Precautions

• Always use a handpiece holder when washing the handpiece, making sure to rinse the inside of the handpiece

thoroughly.

• For details on handling medical agents or adjusting their concentration, refer to the user manual for the washing device.

• After washing is complete, check to see if the handpiece, including its inside, is completely dry. If any water

remains inside the handpiece, expel it with an air gun or another such tool. Failure to do so could result in the

remaining water coming out during use and cause poor lubrication or sterilization.

• Always lubricate the handpiece after washing.

Always use a handpiece holder when washing the handpiece; otherwise any medical agent remains inside the

handpiece, it may corrode or clog the air or water pipe, resulting in a malfunction of the handpiece.

Inappropriate cleaning methods and solutions will damage the handpiece.

Do not clean the handpiece using strong acidic or alkaline solutions that could cause the metal to corrode.

Any moisture left inside the handpiece could result in the remaining water coming out during use and cause

corrosion, or poor lubrication and sterilization.

Do not leave a handpiece inside the high-temperature washer-disinfector.

Failure to lubricate the handpiece will result in a malfunction.

Never use any spray other than the LS SPRAY or MORITA MULTI SPRAY.

The head could get quite cold if the spray is applied for more than 5 seconds. In this case, wait awhile

before operating the handpiece; otherwise the bearings could be damaged.

Always use the spray can in an upright position. Use only the special spray nozzle provided.

• Do not point the spray can at anyone.

• Do not use the spray in a closed space without proper ventilation. Open windows and turn on

exhaust fans to make sure the room is well ventilated.

• Do not get the spray in your eyes. If you accidentally get it in your eyes, wash your eyes with

plenty of water and see a doctor.

• Do not get the spray on your skin. If it gets on your skin, wash it off with soap and water.

• If used in a sink or other enclosed space, a flammable mist could permeate the air; keep the area

free of open flames or other ignition sources.

• To prevent the spread of serious, life-threatening infections such as HIV and hepatitis B, the handpiece must be

autoclaved after finishing the treatment of each patient.

• Instruments are extremely hot after autoclaving; do not touch them until they cool off.

Do not sterilize the handpiece by any method other than autoclaving.

Remove the bur or point before autoclaving.

Failure to clean and lubricate the handpiece before autoclaving will lead to a malfunction of the handpiece.

The sterilization and drying temperatures must not exceed +135°C (+275°F). A drying temperature in excess of

+135°C (+275°F) will result in contamination of the handpiece or cause it to malfunction.

When autoclaving the handpiece, do not let it come into contact with the heat source or the body of the autoclave to

avoid damage to the O-rings or other parts due to the high temperature.

Do not leave the handpiece in the autoclave.

Place the handpiece in a sterilization pouch and autoclave it.

After autoclaving, store the handpiece in a dry environment.

* Autoclaving and drying temperatures must not exceed +135° C

(+275° F)

* Minimum drying time after sterilization: 10 minutes.

Recommended Temperature and Time:

In a sterilization pouch, minimum 6 minutes at +134°C (+273.2°F) or

minimum 60 minutes at +121°C (+249.8°F)

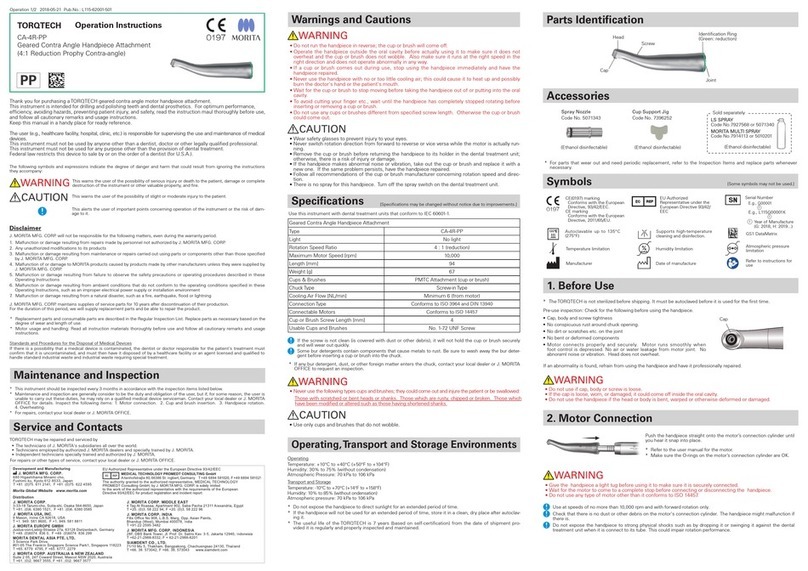

< Remove >

< Insert >

• Always insert burs and points all the way in and give them a light tug to make sure they will not come out.

Otherwise, a bur or point could come out and injure the patient or be swallowed.

• Wait for the handpiece to completely stop rotating before inserting or removing a bur or point.

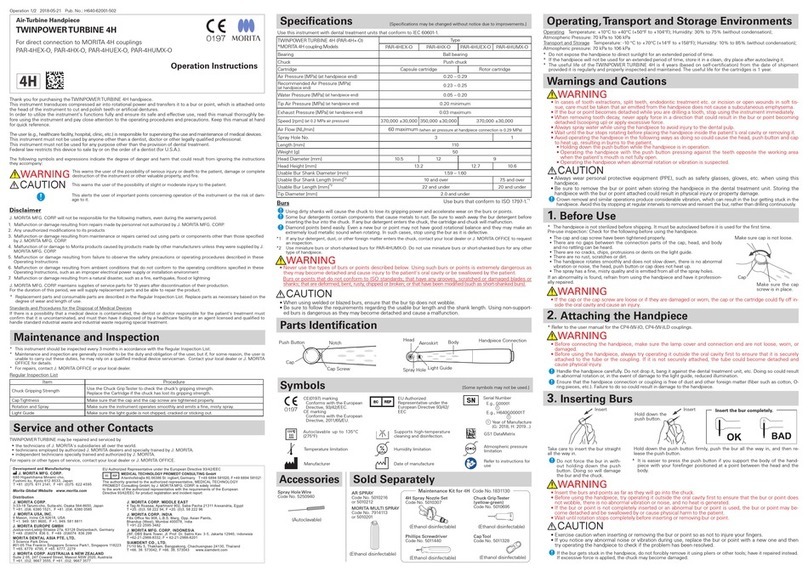

3. Inserting and Removing Burs and Points

• Protect your fingers from being cut by wearing gloves whenever you put in or take out a bur or point.

Operation 2/2

Take out the bur or point and disconnect the handpiece from the motor.

* Refer to the user manual for the motor.

* It may be hard to remove a bur or point if it is left in the handpiece.

4. After Use

5. Cleaning

Wipe the handpiece with a piece of gauze that has been dampened with

Ethanol for Disinfection (ethanol 70 vol% to 80 vol%) and wrung out

thoroughly.

6. Disinfection

7. Lubrication

Put the spray nozzle on the spray can.

8. Removing Excess Oil

• After lubricating the handpiece, do not fail to remove excess oil. The motor could malfunction if any oil

get inside of it. Also excess oil inside the handpiece could cause it to overheat.

10. Troubleshooting

If water does not come out

Refer to the accompany user manual for the motor.

If water comes out

Check the o-ring on the motor joint. Replace it if it is worn or damaged and coat it with oil. If the o-ring is OK, clean

out the air and water holes on the handpiece. If the spray still doesn’t work, have the handpiece repaired.

◆Overheating

Never rotate the handpiece with the chuck open (e.g., if the match marks are not lined up properly). Internal chuck

components will rub against each other; this could wear them out and cause the chuck to fail.

Lock sheath

1. Turn the lock sheath in the direction shown by the

arrow until the chuck is completely open.

2. Pull out the bur or point.

Closed Open

1. Turn the lock sheath in the direction shown by the

arrow to open the chuck.

2. Insert a bur or point all the way in.

3. Turn the lock sheath in the direction shown by the

arrow until the match marks are lined up to close

the chuck all the way.

Insert the bur completely.

9. Packing and Sterilization

Open the chuck.

(The spray will not be effectively delivered if the chuck is

closed.)

Open

Insert the nozzle into the connection end of the hand-

piece, hold it firmly and then spray for about 2 seconds.

Close the lock sheath and point the handpiece down.

Connect it to its motor and rotate it for about 30 sec-

onds. Use a piece of gauze to wipe off any oil that

gets on the outside of the handpiece .

TERMS AND CONDITIONS

J. MORITA MFG. CORP. warrants the Product as follows:

1. Warranty Term.

J. MORITA MFG. CORP. warrants that the Product will be free from defects in materials and workmanship for 24 months.

2. Items Not Covered by Warranty.

This Warranty will not cover parts of the Product or consumables which normally need to be replaced such as glass or rubber components,

and the like. Further, this warranty will not cover defects or damage caused by:

a. Failure to operate or use the Product in accordance with the Operation Instructions or warning/cautionary labels.

b. Modifications of the Product, connecting the Product to other products, or using components or replacement parts not specified

or approved by J. MORITA MFG. CORP.

c. Repairs performed by parties not designated by J. MORITA MFG. CORP.

d. Accidents or forces outside of J. MORITA MFG. CORP.’s control, such as dropping the Product or collision of the Product with

other objects, fire, flood, natural disaster, etc.

e. Use or operation of the Product in settings or under conditions not specified by J. MORITA MFG. CORP. or set forth in the

Operation Instructions including, without limitation, unauthorized changes in equipment settings, connection to unauthorized

devices.

3. Remedies of Customer.

Customer must present this Warranty when claiming coverage or application thereof, and either ship or deliver the Product to an

authorized location of J. MORITA MFG. CORP. or its subsidiaries or authorized dealers. Upon receipt and verification of this Warranty,

inspection of the Product, and determination of coverage by this Warranty, J. MORITA MFG. CORP. will, at its sole option, supply the

parts or components either replaced or repaired free of charge to the Customer. Delivery and shipping charges are the responsibility

of the Customer.

4. LIMITATIONS AND EXCLUSIONS FROM WARRANTY.

The remedy set forth in paragraph 3 is the sole and exclusive remedy of Customer. J. MORITA MFG. CORP. MAKES NO OTHER

EXPRESS OR IMPLIED WARRANTIES AND SPECIFICALLY EXCLUDES ALL OTHER WARRANTIES INCLUDING, WITHOUT LIMITA-

TION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL J.

MORITA MFG. CORP. BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL, DIRECT OR INDIRECT, OR SPECIAL DAMAGES

OF ANY KIND INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF REVENUE, LOSS OF BUSINESS OR BUSINESS

OPPORTUNITY, OR OTHER SIMILAR FINANCIAL LOSS ARISING OUT OF THE PERFORMANCE, USE OR INTERRUPTED USE OF

THE PRODUCT.

5. Repairs Not Covered by Warranty.

With respect to repairs not within the period of this Warranty or otherwise not covered by this Warranty, J. MORITA MFG. CORP. will

perform the same, timely, efficiently, and for an appropriate cost.

Make sure flows for cooling air and spray are up to specifications. Also make sure the motor is operating properly.

2018.05.PrintedinJapan

If a medical agent being used for the treatment has adhered to

the handpiece, wash it off in running water.

Do not perform ultra sonic cleaning.

Clean drilling and polishing debris off the head with a brush and

running water.

Clean the spray hole with the spray hole wire provided.

After cleaning, use the syringe or an air blow gun to get rid of any

moisture left inside the handpiece.

Lubricate with the LS Spray (sold separately) or MORITA MULTI SPRAY (sold separately) before autoclav-

ing and after morning and afternoon treatment sessions.

Using an air blow gun, blow the handpiece connection for

20 to 30 seconds to get rid of any moisture left inside the

handpiece. Wipe the excess oil from the handpiece with a

gauze.

You can use MORITA's threeway syringe instead of an air

blow gun.

(In this case, attach the air nozzle to the tip of the threeway

syringe. The air nozzle comes with a micromotor or its

optional accessory.)

Before inspecting or adjusting the handpiece, make sure the main power switch is turned on and that the main air and

water valves are open. If the handpiece does not work properly even after inspection and adjustment, contact your local

dealer or J. MORITA OFFICE and have it repaired.

◆Cannot insert burs or points

Take the handpiece off the motor and step on the foot pedal. Does water come out of the motor joint?

◆Poor water delivery

◆Poor rotation

Lubricate the handpiece, and then use a new bur or point to check if the problem has been resolved.

If this does not resolve the problem, have the handpiece repaired.

Make sure the motor is properly connected to its tube. Remove the handpiece from the motor and step on the foot

control. Does the motor run?

If motor runs

Make sure the handpiece is connected to the motor correctly, then step on the foot control to see the bur runs. If

the bur does not run, have the handpiece repaired.

If motor does not run

Refer to the accompany user manual for the motor.

2018-05-21 Pub. No.: L101-62001-501