moyes LITESPEED User manual

Moyes Delta Gliders Pty. Ltd. Version 1.01

LITESPEED

owners

manua

l

LITESPEED OWNERS MANUAL

Version 1.01 1

CONTENTS

Amendments ..........................................................................................2

Introduction.............................................................................................3

Description of Design.............................................................................4

Specifications .........................................................................................5

Operating Limitations .............................................................................6

Disclaimer...............................................................................................7

Getting Started .......................................................................................8

Assembly Procedures ..........................................................................11

Pre-Flight Check...................................................................................16

De-Rigging the Litespeed.....................................................................18

Flying the Moyes Litespeed .................................................................22

Tuning Hints..........................................................................................26

Performance Tuning.............................................................................28

Glider Care ...........................................................................................30

Maintenance Schedule.........................................................................32

Sail Removal ........................................................................................33

List of Fasteners & Airframe Bolts .......................................................34

AN Bolt Index...................................................................................34

Checking The Litespeed Stability System ...........................................35

Purchase Record..................................................................................37

Maintenance Log..................................................................................37

LITESPEED OWNERS MANUAL

Version 1.01 2

AMENDMENTS

Version Date Chan

g

es

1.00 24/12/2002 Converted Owners Manual to new format.

1.01 28/7/2003 1. Updated all assembly drawings.

2. Corrected page 9 paragraph 4 – referring to the positioning of the

sail webbing.

LITESPEED OWNERS MANUAL

Version 1.01 3

Moyes Delta Gliders Pty. Ltd.

1144 Botan

y

Road, Botan

y

NSW 2019 Australia T: +61

(

0

)

2 9316-6466 F: +61

(

0

)

2 9316-8488 E: mo

y

es

@

mo

y

es.com.au

INTRODUCTION

Thank you for choosing the Moyes Litespeed. You have chosen wisely.

The Litespeed incorporates the latest high performance hang gliding

design technology.

Since 1967, Moyes Delta Gliders has strived to be on the cutting edge of

developing hang gliders of the highest calibre. A family owned business

operating under homespun values, we aim to provide a comprehensive

international network to service all pilots. Even further, we work with some of

the best pilots in the world to ensure that our gliders are stringently made and

tested in order to improve their performance, handling, and safety.

We wish you the very best flying,

The Moyes Team

LITESPEED OWNERS MANUAL

Version 1.01 4

DESCRIPTION OF DESIGN

The Moyes Litespeed is a glider designed by elite competition pilots for competition and

enjoyable high performance cross country flying. The Litespeed utilises a similar plan

form as its predecessors the Xtralite and CSX, and has improved other facets of the

glider to provide better performance, safety and handling.

The Litespeed features a 7075 aluminium airframe which allows minimum weight with

excellent flex characteristics. The leading edge features a step down taper design with

revised sleeving and tube diameters to produce a lighter weight outer leading edge with

improved flex distribution across the length. The weight reduction provides considerable

reduction of inertia and thus roll pressures are minimal.

The elliptical fibre glass wing tip has been a feature of Moyes high performance gliders

since the early 80’s. The fibre glass tip creates a washout distribution allowing better

turning coordination than conventional designs. With the full tight VG setting, the fibre

glass tip allows for a tighter mainsail and a more desirable washout distribution.

The Litespeed features a revised sail design which allows for minimum twist without

losing pitch stability. The double surface has been increased to 92% which provides

better washout control under positive load and allows the enclosed stability system to be

mounted further rearward for better support. The leading edge tension has been markedly

increased to minimise airfoil distortion at high speeds. Many design steps have been

taken to produce a low minimum flying speed and allow easycontrol at these speeds.

The pitch stability system utilises cable braced inner and outer aluminium sprogs

providing support for battens 7 to 11 via two transversal battens. The inner sprog

features a unique compensator system operating from the geometrical change of the

X-bar to leading edge angle. This allows for the inner sprog to rise 80mm when the VG

is released. The stability system was designed with maximum strength and stiffness in

mind, and demonstrates excellent structural integrity under any flight load.

The Litespeed sail has a total of 8 internal cloth ribs. These internal ribs restrict the

under surface from ‘blowing out’ which prevents pilot induced oscillations. The internal

ribs are cut to a specific airfoil, which produces the desired under surface camber for low

drag high speed gliding.

The Litespeed features a spar constructed entirely of pre-impregnated carbon fibrecloth.

The pre-impregnated carbon provides maximum consistency in production. The spar

utilises combinations of biaxial fibre and unidirectional fibre to produce load absorbing

flexibility and maximum impact resistance.

LITESPEED OWNERS MANUAL

Version 1.01 5

SPECIFICATIONS

Model Size Litespeed 3 Litespeed 4 Litespeed 5

Area 12.6sq m

136 sq ft 13.6sq m

146 sq ft 14.5sq m

156 sq ft

Span 9.6 m

31.5 ft 10.0 m

32.8 ft 10.4 m

34.1 ft

Nose Angle 130 to 132 deg 130 to 132 deg 130 to 132 deg

Aspect Ratio 7.2 7.4 7.5

Glider Weight 31.9 kg

70.4 lb 33.6 kg

74 lb 34.5 kg

76 lb

Hook-In-Weight 55-95kg

120-210 lb 68-110kg

150-240 lb 75-120kg

165-265 lb

Packed-Length 4845mm

15’11” 4950mm

16’3” 5150mm

16’11”

Short-Packed Length 4200mm

13’9” 4330mm

14’2” 4500mm

14’9”

C of G Front of Keel 1310mm

51.57” 1363mm

53.66” 1370mm

51.94”

Number of Battens:

Mainsail

Undersurface

21

6

23

6

23

6

VNE 53mph

85kph 53mph

85kph 53mph

85kph

VA 46mph

74kph 46mph

74kph 46mph

74kph

Trim Speed 21mph

34kph 21mph

34kph 21mph

34kph

Stall Speed 16mph

26kph 16mph

26kph 16mph

26kph

Max Speed 77mph

124kph 77mph

124kph 77mph

124kph

Best Glide Speed 28mph

45kph 28mph

45kph 28mph

45kph

Best Glide Angle 15:1 15:1 15:1

Glide Angle 10:1 43mph

69kph 46mph

75kph 45mph

73kph

LITESPEED OWNERS MANUAL

Version 1.01 6

OPERATING LIMITATIONS

Your Moyes Litespeed is a sophisticated state of the art high performance hang glider.

If maintained correctly it will give you years of safe enjoyable soaring. However, it is

important that you display a healthy respect for all aspects of aviation and that you

especially understand the increased risks of flying in dangerous conditions or in a

manner that exceeds the glider’s operating limitations.

•Flight operation should be limited to non-aerobatic manoeuvres where the pitch

angle doesn’t exceed 30 degrees up and down to the horizon and bank angles don’t

exceed 60 degrees

•The Moyes Litespeed has been designed for footlaunched soaring flight and should

not be flown by more than one person at a time

•It should not be flown backwards or inverted

•The recommended minimum pilot skill level is Advanced (Hang 4)

•The Moyes Litespeed should not be flown with auxiliary power

•The Moyes Litespeed should not be flown in excess of the placarded VNE or VA

•VNE (speed never to exceed): 53 mph / 84.8 kph

•VA (maximum rough air manoeuvring speed): 46 mph / 73.6 kph

•Stall speed with maximum pilot weight: Less than 25 mph / 40 kph

•Maximum speed with minimum pilot weight: Less than 55 mph / 80 kph

The Moyes Litespeed will resist spinning and will recover quickly if control pressures are

relaxed. Recovery from a stalled turn can be achieved without extreme height loss or

without extreme attitude change if the angle of attack is reduced. Recovery from such an

incipient spin will be achieved within half a turn if the angle of attack is lowered to a

normal flyingangle.

The Moyes Litespeed has been tested and certified to the USHGMA and DHV

standards. These standards require ultimate load tests at:

•Maximum lift angle of attack at a speed of 65 mph / 104 kph

•Negative 30 degrees angle of attack at a speed of 46 mph / 73.6 kph

•Negative 150 degrees angle of attack at a speed of 32 mph / 51.2 kph

•Pitching moment tests at 20/32, 37/59 and 54/86 mph/kph respectively, to display

the gliders inherentpositive pitch stability through a broad range of angles of attack

The Moyes Litespeed is capable of easily flying at speeds greater than the VA and VNE.

We recommend you use an accurate airspeed indicator and familiarise yourself with

control bar positions at these speeds and normal flying speeds.

LITESPEED OWNERS MANUAL

Version 1.01 7

DISCLAIMER

The owner and operator must understand that due to the inherent risk involved in flying

such a unique vehicle, no warranty is made or implied of any kind against accidents,

bodily injury or death. Operations such as aerobatic manoeuvres or erratic pilot

technique may ultimately produce equipment failure, and are specifically excluded from

the warranty.

This glider is not covered by product liability insurance, nor has it been designed,

manufactured or tested to any state or federal government airworthiness standards

or regulations.

LITESPEED OWNERS MANUAL

Version 1.01 8

GETTING STARTED

Your new Moyes Litespeed may have been shipped to you in the 4.5 metre breakdown

form. If so, you can assemble your glider to its full length by following the assembly

procedures. All references to ‘top’ & ‘bottom’ and ‘left’ and ‘right’ are referred to with the

glider in flying mode.

Please check your packing list.

•Glider

•2 x Back section leading edges: note that the back sections are different between

left and right

•1 x Batten Set: Right=Green/Left=Red/Blue=Undersurface

•1 x Speed Bar

•2 x Tip Bags

•3 x Padding Pieces: A-Frame top& bottom, Keel sleeve

•1 x Batten Pattern

•1 x Snack Pack with owner’s manual and Batten Profile

Assembly from 4.5m Breakdown Form

1. Open the glider bag and roll the glider onto its undersurface.

Undo the straps and extend the sail.

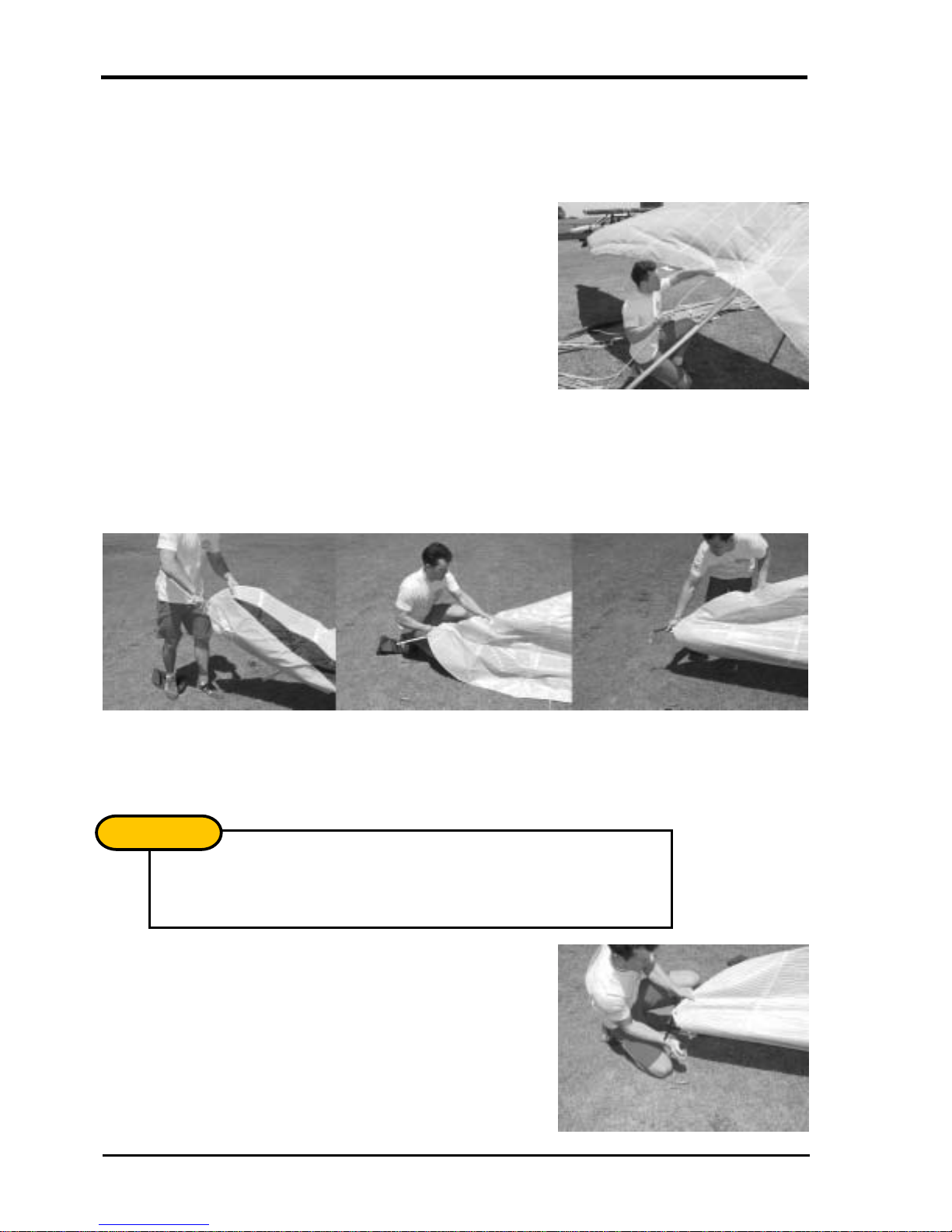

Picture 1

Lay the glider on

its undersurface

and unfold the sail.

2. Expose the leading edge/cross bar junction through the inspection zip. Remove the

bubble wrap and tape from the leading edge/cross bar junction and the end of the

middle sleeve.

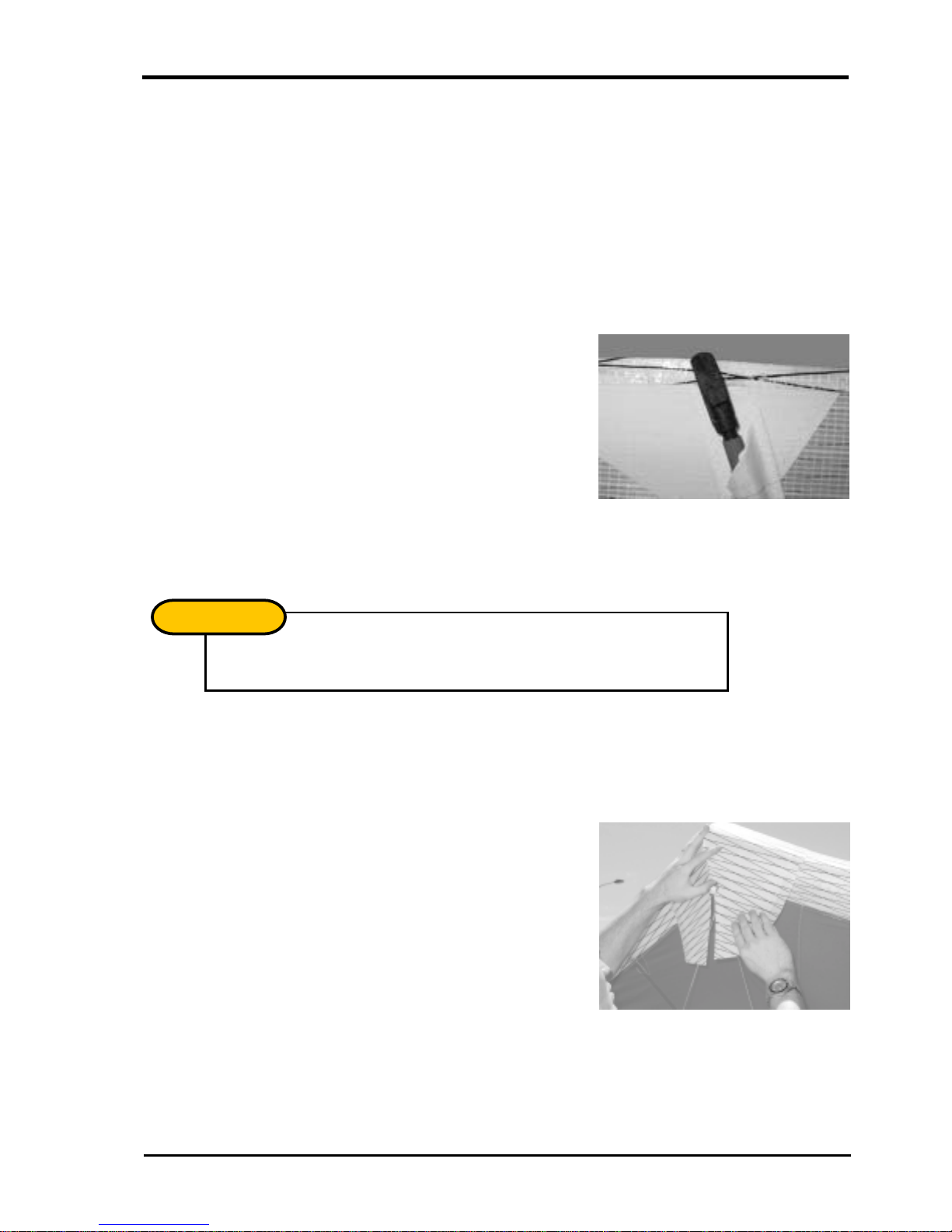

Picture 2

Remove packing materials from leading edge end.

LITESPEED OWNERS MANUAL

Version 1.01 9

3. Insert the right hand back section of leading edge. The right hand back section

differs from the left in the mounting of the outer sprog. You can check this by

picturing that the cable must be on the top side of the leading edge and the sprog

must fold inboard. Push the back section into the mid sleeve while depressing the

push button pin. Continue to push the back section in until it reaches its stop, then

rotate the back section until the mid sleeve location holes align with the push

button pin. Closely check that the push button pin has fully released and that the

back section is secure against rotation forces.

Picture 3

Insert the back

ends of the

leading edge.

4. Secure the sail by attaching to the tip webbing using the clevis pin and ring supplied.

Insert the pin through the webbing and into the bottom hole at an angle. Straighten

the clevis pin while sliding the webbing towards the leading edge as shown in

Picture 4. Ensure the tip webbing is not twisted and is on the bottom of the leading

edge.

Picture 4

Insert sail pin into end of leading edge.

LITESPEED OWNERS MANUAL

Version 1.01 10

5. Repeat steps 1-4 to install the left hand back section of leading edge.

Your Litespeed will now be ready for the standard assembly. Before flight, make

a thorough inspection of all tubing and nuts and bolts to ensure no damage has

occurred during transportation. (refer to section on pre-flight check).

Picture 5

Assembled glider

showing dive sticks

extruding from under

surface zippers.

The inner and outer sprogs must exit the sail from the large cord wise zippers.

The zippers must be opened when the glider is in standard break down form

with both sprogs folding toward the wing tip outside the sail.

IMPORTANT

!

LITESPEED OWNERS MANUAL

Version 1.01 11

ASSEMBLY PROCEDURES

1. Place the glider on the ground, zipper up. Open the bag, undo ties, remove A-frame

bottom padding and battens.

2. Assembly the A-Frame.

Picture 6

Standard uprights and

base bar assembly.

Roll the glider over so that

it is standing on the

control frame.

3. Roll the glider over so that it is standing on the control frame.

Picture 7

Roll the glider onto the

A-frame and attach the

front wire to the Bailey Block.

Take special care with the wires, the Litespeed features 1x19 cable which can

easily be kinked unless special care is taken.

N

O

TE

!

With standard uprights, the uprights will naturally toe-in as shown in

Picture 6. Hold the base bar and the upright, twisting the upright so the

connection lines up.

N

O

TE

!

LITESPEED OWNERS MANUAL

Version 1.01 12

After initial assembly it is suggested that the nose batten be left in but pulled

out slightly and left beside the nose plate for pack-up. Check that the nose

batten sits over the lug on the keel securely.

N

O

TE

!

4. Insert the ring of the lower front wires in the Bailey Block making sure that the spring

is firmly locked and the wires untwisted.

Picture 8

Attaching the front wires to the Baileys Block.

5. Insert the nose batten. The batten may need some “feeding” through the Sail by

pulling the sail forward to remove any wrinkles as the batten slides into its pocket.

Picture 9

Insert nose batten.

6. Carefully spread each wing making sure thatyou do not raise them above the keel.

Picture 10

Spread the wings.

Check bottom wires are not twisted or kinked.

N

O

TE

!

LITESPEED OWNERS MANUAL

Version 1.01 13

DO NOT USE EXCESSIVE FORCE WHEN TENSIONING THE GLIDER.

If excess force is encounteredcheck:

!The side wires are not twisted or kinked

!The cross bar retainer wire is not caught on the nose plate assembly

!The floating crossbar centring wire is notcaught on a cross bar

assembly junction

!The pull back wire or VG pulleys are not caught in the hang loop assembly

7. To tension the crossbar, pull the cord coming out of the keel aft of the sail.

Check that the cable and rope are not twisted and that the spring lock is firmly

locked. In strong winds the glider can be particularly difficult to tension. Have a

helper gently raise and pull one wing, this reduces the pressure on the centre

section andallows it toslide more freely.

Picture 11

Tension the glider.

8. The Litespeed is equipped with a removable keel aft section. The glider can be left

resting on it, facilitating the fitment of the washout struts, and battens. If desired, the

glider may now be raised onto its keel to complete the assembly. This also assists

with keeping the sail clean by keeping the tips off the ground.

Picture 12

Raising the glider ontothe keel can make assembly

easier and keeps the sail clean.

WARNIN

G

!

The glider may fall to one side if pushed or blown by the wind - this may result in

wing tip damage. It is recommended that you only use in flat level ground and in

nil wind. Use with care!

WARNIN

G

!

LITESPEED OWNERS MANUAL

Version 1.01 14

9. Insert battens gently from the root towards the mid span, battens 1-6 only for the

Litespeed 4 & 5, battens 1-5 only for the Litespeed 3. Use only gentle pressure

when inserting the battens, this will greatly extend the longevity of the batten

pockets. Red tipped numbered battens are for the left wing, green for the right, and

blue the under surface.

Picture 13

Insert battens #1 to #6

10. Open zipper at sail tip to allow access to inside of sail. Slide fibre glass rod through

end of sail and locate in the end of the leading edge. Ensure that the fibre glass rod

is pushed hard against its stop.

Picture 14

Inserting tip and fitting aluminium cap.

11. Fit aluminium cup of the tip lever to the end of the tip rod and tension tip by rotating

the flat end of the tip lever inboard. For extra leverage, place your thumb through the

loop that is attached to the end of the tip lever. Make sure the tip lever is locked

against the tip rod. Close the zipper.

Picture 15

Tension the fibre glass wing tip.

Make sure the tip lever is consistent on both sides. The tip lever should either

be above or below the tip rod when locked in place.

NOTE

!

LITESPEED OWNERS MANUAL

Version 1.01 15

12. Insert the remaining mainsail battens, 7 to 11 on the Litespeed 4 & 5 and 6 to 10 on

the Litespeed 3.

13. The battens have been adjusted in the factory, but may need to be readjusted upon

initial assembly. The batten tips simply screw into the end of the batten, therefore

the batten tension can be adjusted by either screwing the tip in or out.

The outer batten on each wing should be fitted with additional tension. Continue to

make minor adjustments to the outer batten tension until any wrinkles have been

removed from the upper surface.

Picture 16

Adjust the batten end so that it slightly

extends past the trailing edge.

14. Locate the inner and outer wire braced dive struts by placing them inside the sail,

below the webbing loop. Note that the action of closing the cord-wise zipper creates

the loop necessary to hold the strutin place.

15. Insert the under surface battens (blue) into their respective pockets.

16. Fit the nose fairing using the Velcro to keep a clean trim finish.

Picture 17

Fitting the nose nappy.

Do not forget this step as it is necessary for stability.

IMP

O

RTANT

!

LITESPEED OWNERS MANUAL

Version 1.01 16

PRE-FLIGHT CHECK

As with most high performance hang gliders, much of the hardware and structure is well

enclosed to give a streamlined finish to the wing. This means that you must look inside

the sail to check many of the important structural components. You should develop a

consistent routine that incorporates all the necessary checks. If you are distracted during

the routine, you should start again to ensure nothing has been missed.

1. As you should have already attached your harness to the glider, check that it is set

up correctly. Ensure that your parachute is well maintained and stowed appropriately

and that the bridle runs cleanly to the carabineer which is attached vertically to the

hang loops. If your harness height from base bar needs adjustment, it is best to

acquire the correct length loop from your Moyes dealer.

2. Move up to the suspension system and verify that the dingle-dangle is rotated

perpendicular to the keel and is free from the nose batten pocket. Check hang loop

and backup.

3. Open the under surface zip and inspect the cross-bar retainer wire. Pull the VG on

and off a few times to check that the crossbars are moving freely and the VG system

is operating smoothly and is tied firmly to the clip. Inspect the interior of each wing,

looking at the back side of the leading edges, the crossbar, and the crossbar

junctions. Check that the cross bar centring wire is free. This wire is partly loose in

VG full off and should become tightwhen VG is 3/4 on.

4.

5. Check the apex of the control frame ensuring all nuts are secure and thread is

showing beyondthe nut on the bolt end.

6. Sight along keel and move to the nose section, checking all nuts and bolts.

Test nose catch and ensure keel batten is located correctly. Re-attach nose fairing.

7. Sight along each leading edge to confirm a similar amount of leading edge

deflection (curve). Uneven curves will indicate a bent or damaged leading edge.

While sighting down the leading edges check each wing for dive stick symmetry, ie.

equal twist for left and right wing.

Check that all internal Velcro’s are attached and are of equal length. If one

side is disconnectedor too loose, it may cause a significant turn.

IMP

O

RTANT

!

It is easiest to inspect for tube damage when wings are slightly opened with

no battens in the sail. The entire length of the leading edge tubes can be

easily seen at this stage of the set up procedure through the under surface

zippers and centre zip. It is recommended to check for dents or bends at this

stage of set up before each flight.

N

O

TE

!

LITESPEED OWNERS MANUAL

Version 1.01 17

8. Move out along the wing looking and feeling for any damage. Open the zip where

the side wires enter the sail and check that bottom wires are not kinked, twisted or

damaged. Check the cross-bar/leading edge junction bolts and nuts and check that

the ball joint is not bent. Close zip on inspection port.

9. Open the long cord-wise zippers at sprog location and check both the front and rear

of each dive strut. Check that the wires are not kinked or twisted and check that the

ball joint thread is not bent. Close zip.

10. Continue out to wing tip and make sure the tip levers are properly installed and that

the zipper is closed.

11. Check all battens as you move along the trailing edge and be sure that the spring

tips are secure inside of the trailing edge pocket.

12. At the keel, check the top VG rope and the cross-bar restaining wire. Check that

rear wires are properly secured by the Bailey Block bolt.

13. Moving across to the other wing, repeat the process as you work your way back to

the nose of the glider. Carefully check the front bottom wires and nose catch before

inspecting the base of the control bar. Check bottom side wires for frayed strands

between thimbleand inner nico, and just outboard of the outer nico.

14. Ensure that the control frame assembly bolt passes through the base bar and the

corner knuckle.

15. Check the rigging, nuts, and bolts are in good order and that the VG rope is

threaded through the jam cleat and is secure.

16. Re-check harness, hang loops, and carabineer.

17. When finally preparing to fly, do a proper hang check ensuring that legs are through

leg loops, that harness zippers work, and that all buckles or clips etc. are closed and

working. Look again at your hangloops and carabineer(s).

LITESPEED OWNERS MANUAL

Version 1.01 18

DE-RIGGING THE LITESPEED

Disassembly of the Litespeed is virtually an exact reversal of the set-up procedure,

however, a few important points must be remembered to avoid unnecessary damage.

1. If desired, the Litespeed can be disassembled on its keel.

Picture 18

Removing the keel assists with assembly

and disassembly of the glider

2. Remove all battens starting from the tips, all the under surface battens, and the

glass tips. Place all battens in the batten bag.

3. Fold the sail tips

There are a number of ways to fold the sail tips. Two such ways are shown below.

Folding the Sail Tips - METHOD 1

•Fold the leading edge back onto itself.

•Roll the sail up from the trailing edge towards the leading edge.

•Fit the sail and theouter dive strut intothe boot.

The glider may fall to one side if pushed or blown by the wind. This may result in

wing tip damage. It is recommended that you only use it on flat level ground and

in nil wind. Use with care!

WARNIN

G

!

Other manuals for LITESPEED

1

Table of contents

Other moyes Aircraft manuals