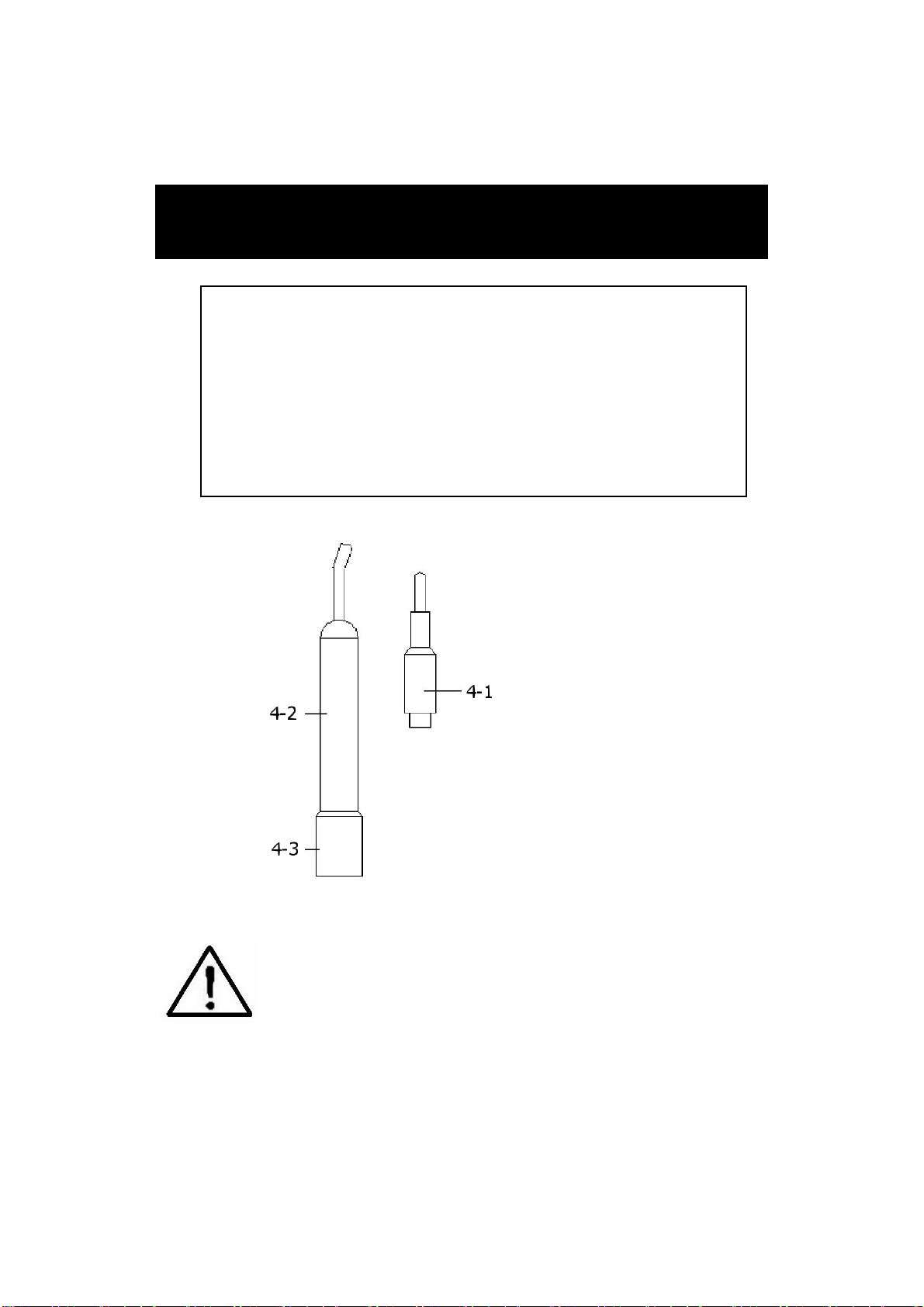

4-1 uS, mS measurement

1)Prepare the Conductivity Probe ( included, CDPB-03 ),

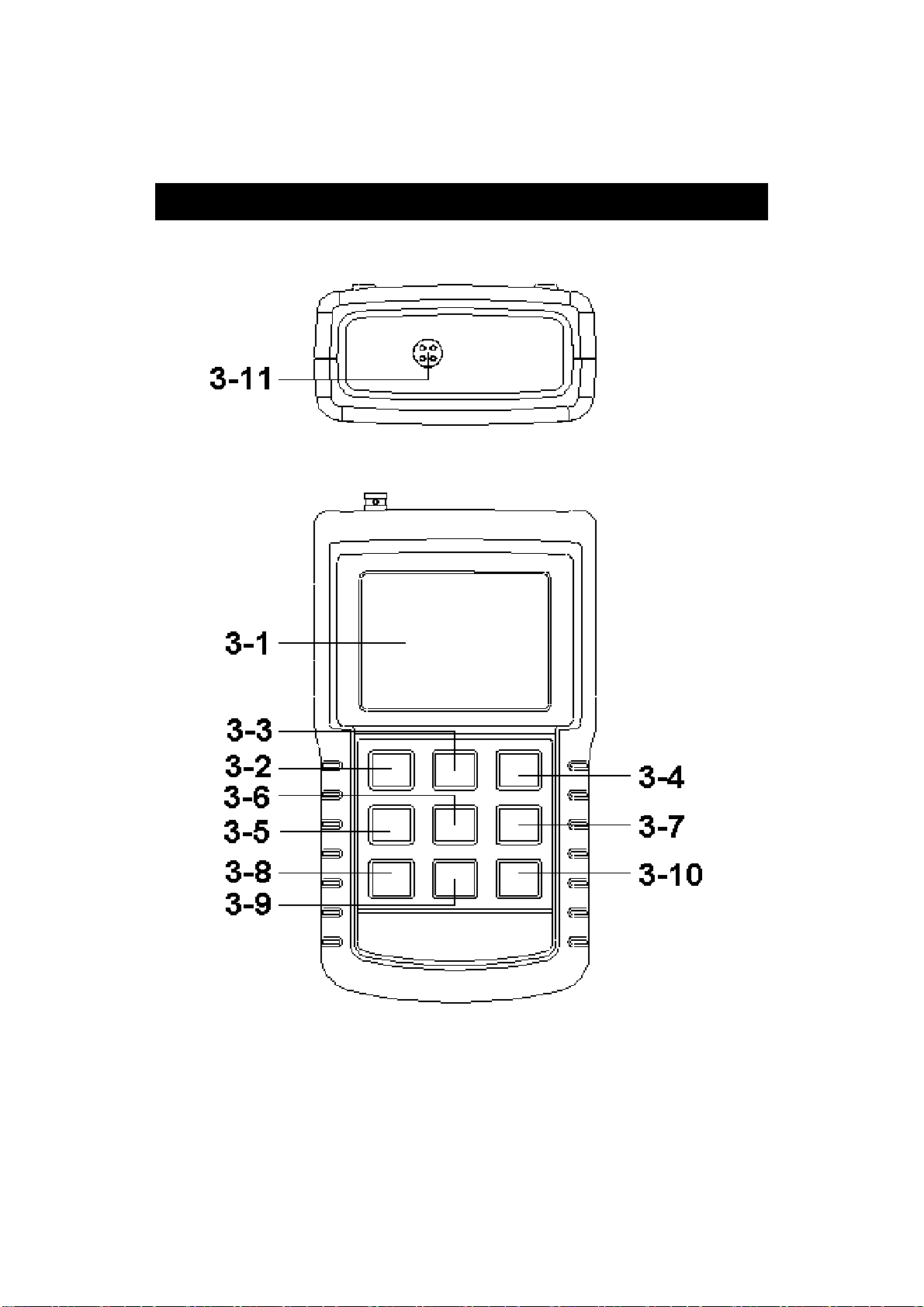

install the " Probe Plug " ( 4-1, Fig. 2 ) into the

" CD Socket " ( 3-11, Fig. 1 ).

2)Power on the meter by pressing " Power Button "

( 3-2, Fig. 1 ) once.

The Display will show " uS " and " Temp. " indicator.

3)Hold the " Probe Handle " ( 4-2, Fig. 2 ) by hand

and let the " Sensing head " ( 4-3, Fig. 2 )

immersed wholly into the measured solution. Shake

the probe to let the probe's internal air bubble drift

out from the sensing head.

4)Display will show the conductivity mS ( uS ) values.

at the same time the left bottom display will show the

Temp. value of the measured solution.

Manual range operation

The meter is default to be used for the auto range

mode.

If intend to let the meter be used under the

manual range mode, the procedures are following :

*

Press the " Range Button " once a while, it can

change the range, the range name ( Auto, 200 uS, 2

mS, 20 mS, 200 mS ) will show under the

measurement value.

* If the display shows " ", it indicates an

overload condition, select the next higher range.

* If the display shows " ", it indicates an

out-of-range, select the next lower range.

* If intend to change the operation mode from Manual

range back to Auto Range, press the " Range Button

" ( 3-6, Fig. 1 ) once in sequence until the Display

show the text " Auto ", release the " Range Button ",

the meter is ready for the Auto range mode again.

8