SFH-30 Quick Start Guide

iii

SFH-30 Quick Start GuideSFH-30Quick Start Guide

Contents

Chapter 1 Quick Start..................................................................... 1

Safety........................................................................................1

Overview ................................................................................. 1

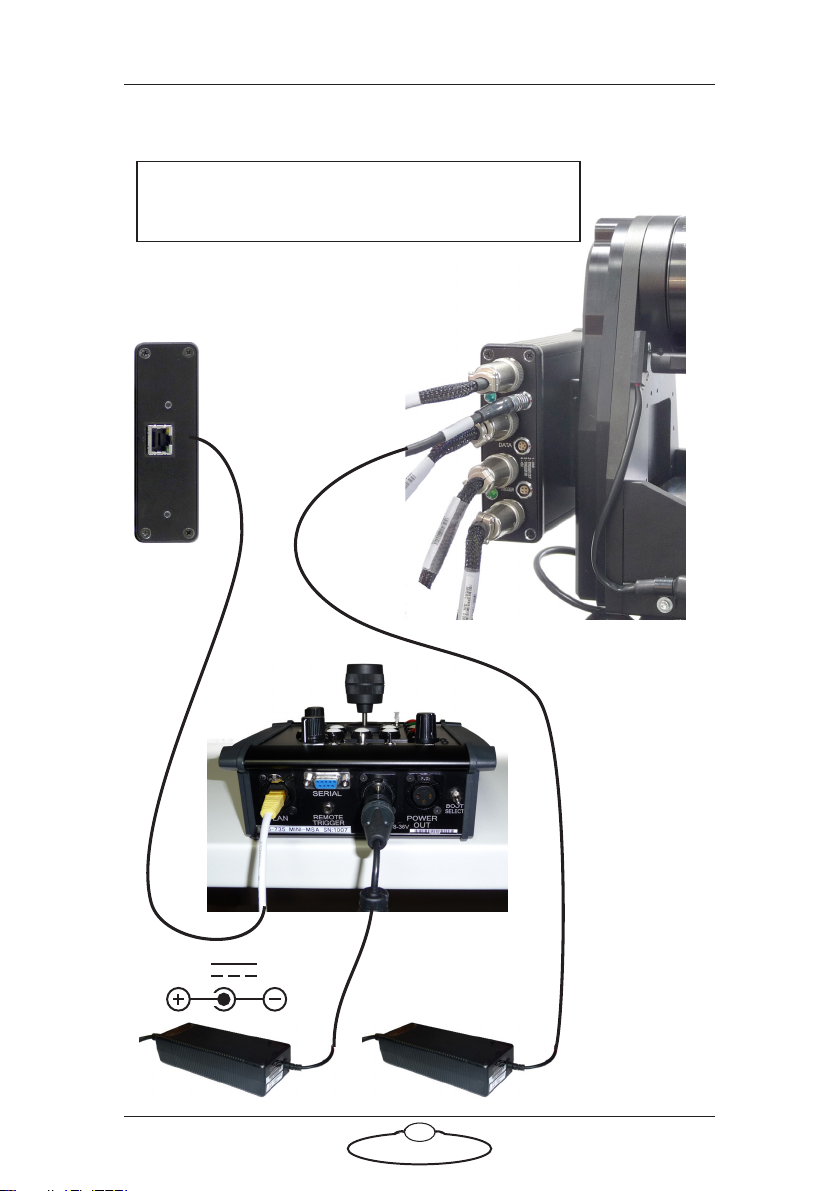

Setting up the hardware ........................................................2

Connecting the cables ...........................................................5

Your first session ....................................................................7

Subsequent sessions.............................................................10

Appendix 1 Troubleshooting........................................................... 11

Typical symptoms, causes, and actions .............................11

Working with Local Area Networks..................................12

Introduction to LAN addresses ................................12

Managing LAN addresses with Flair........................14

Appendix 2 SFH-30 Panel ............................................................... 18

Introduction to SFH-30 connections ................................18

Quad-box connector summary..........................................19

Quad-box connector pin-out information .......................21

Stepper motor connector...........................................21

Power 18-36 Volts connector ....................................21

Serial RS232 connector ..............................................21

Trigger connector (trigger out and in).....................22

Appendix 3 Specifications............................................................... 24