USER MANUAL SWG

Page 3of129

Content

1. Information for product and safety............................................................................ 5

1.1. Safety manual ...................................................................................................... 5

1.2. Safety precautions................................................................................................ 5

1.3. Weather and environmental conditions ................................................................ 7

1.4. General important instructions for the plant operator ........................................... 7

1.5. Packing................................................................................................................. 8

1.6. Return of hazardous waste................................................................................... 8

1.7. Return of analyser................................................................................................ 8

1.8. MRU Warranty conditions..................................................................................... 8

2. Analyser Description 0004 ......................................................................................... 9

2.1. Intended use......................................................................................................... 9

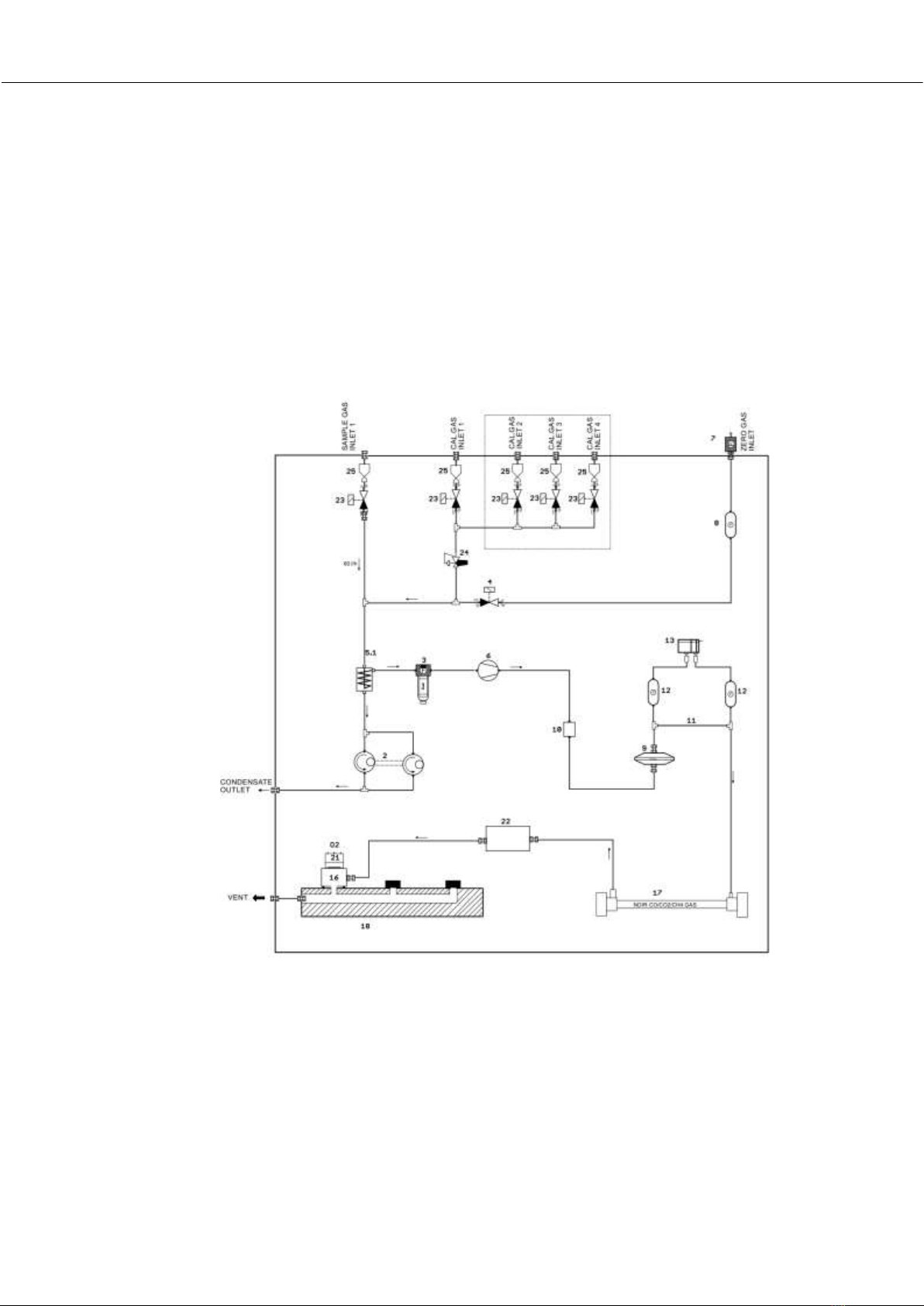

2.2. Principle of operation............................................................................................ 9

2.3. Packing dimensions and designations 0005..................................................... 11

2.4. SD-Card: Position and content........................................................................... 14

1. Safety concept of syngas analyser 0016............................................................... 15

2.5. Fan monitoring ................................................................................................... 15

2.6. Internal LEL sensor ............................................................................................ 15

2.7. Gas reducing unit ............................................................................................... 15

2.8. External switching unit........................................................................................ 15

3. Installation manual 0006.......................................................................................... 16

3.1. Overview ............................................................................................................ 16

3.2. Select measurement point.................................................................................. 18

3.3. Installation of the analyzer.................................................................................. 18

3.4. Installation of pressure reducer unit ................................................................... 20

3.5. Connection of main power supply ...................................................................... 22

3.6. I/O modules: Installation and setting .................................................................. 25

3.7. Installation: Calibration gas / zero gas and condensate outlet ........................... 27

4. Operation of the analyser (HMI) 0007..................... Fehler! Textmarke nicht definiert.

4.1. Display and keypad........................................Fehler! Textmarke nicht definiert.

5. Binding to a process control system: I/O modules 0008...................................... 33

5.1. Position of the IO module inside the analyzer .................................................... 33

5.2. Pin assignment................................................................................................... 34

5.3. Analog outputs 4-20 mA..................................................................................... 36

5.4. Alarm outputs ..................................................................................................... 42

5.5. Analog inputs (4-20 mA)..................................................................................... 47

5.6. Configuration of the external control (Option: IO module) .................................. 52

1. Analyser commissioning manual0009................................................................... 59

5.7. Power up the analyser........................................................................................ 59

5.8. Checking list for commissioning ......................................................................... 60

5.9. Check country and language.............................................................................. 60

5.10. Check date and time of the instrument............................................................... 61

5.11. Configuration of the alarm relays........................................................................ 62

5.12. Configuration of the Modbus .............................................................................. 65

6. Cycle configuration 0010......................................................................................... 69

6.1. Path and default setting...................................................................................... 69

6.2. General information............................................................................................ 69