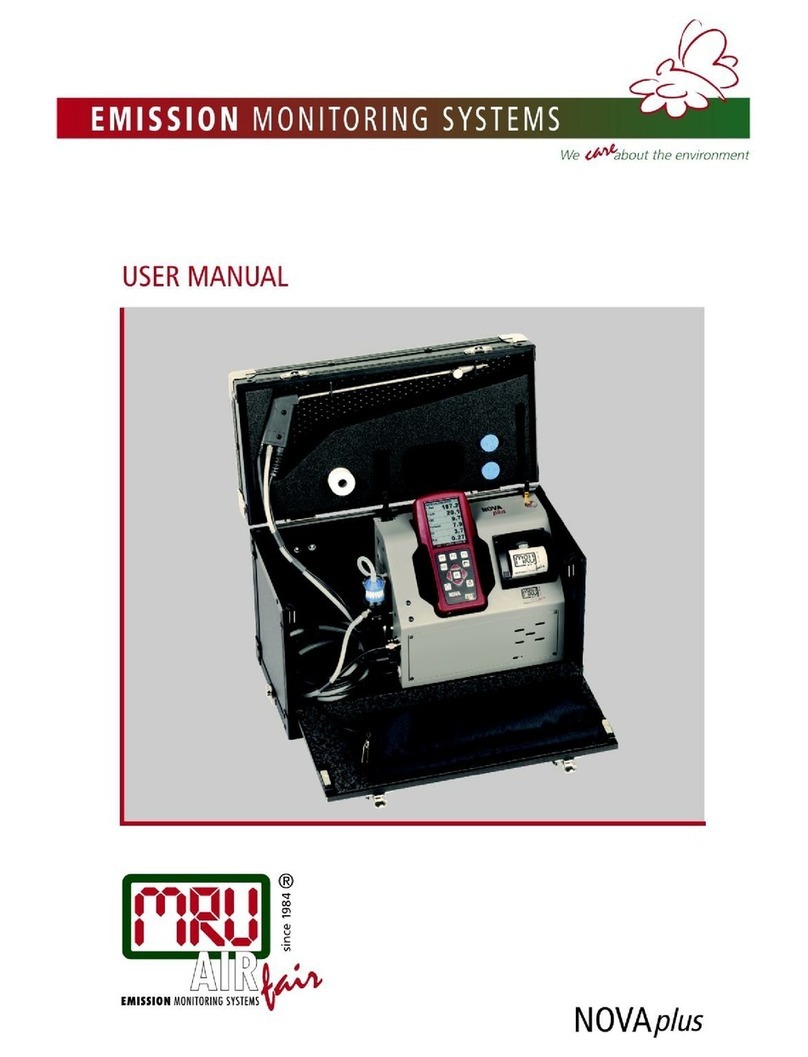

User Manual

VARIO

luxx

SYNGAS

MRU GmbH, D-74172 Neckarsulm 3 / 50

Content

1Introduction ...........................................................................................5

1.1. Intended use .........................................................................................................5

1.2. About us..................................................................................................................6

2Information for product and safety .....................................................7

2.1. Safety manual .......................................................................................................7

2.2. Safety precautions...............................................................................................7

3Description.............................................................................................8

3.1. Task...........................................................................................................................8

3.2. Gas flow diagram.................................................................................................8

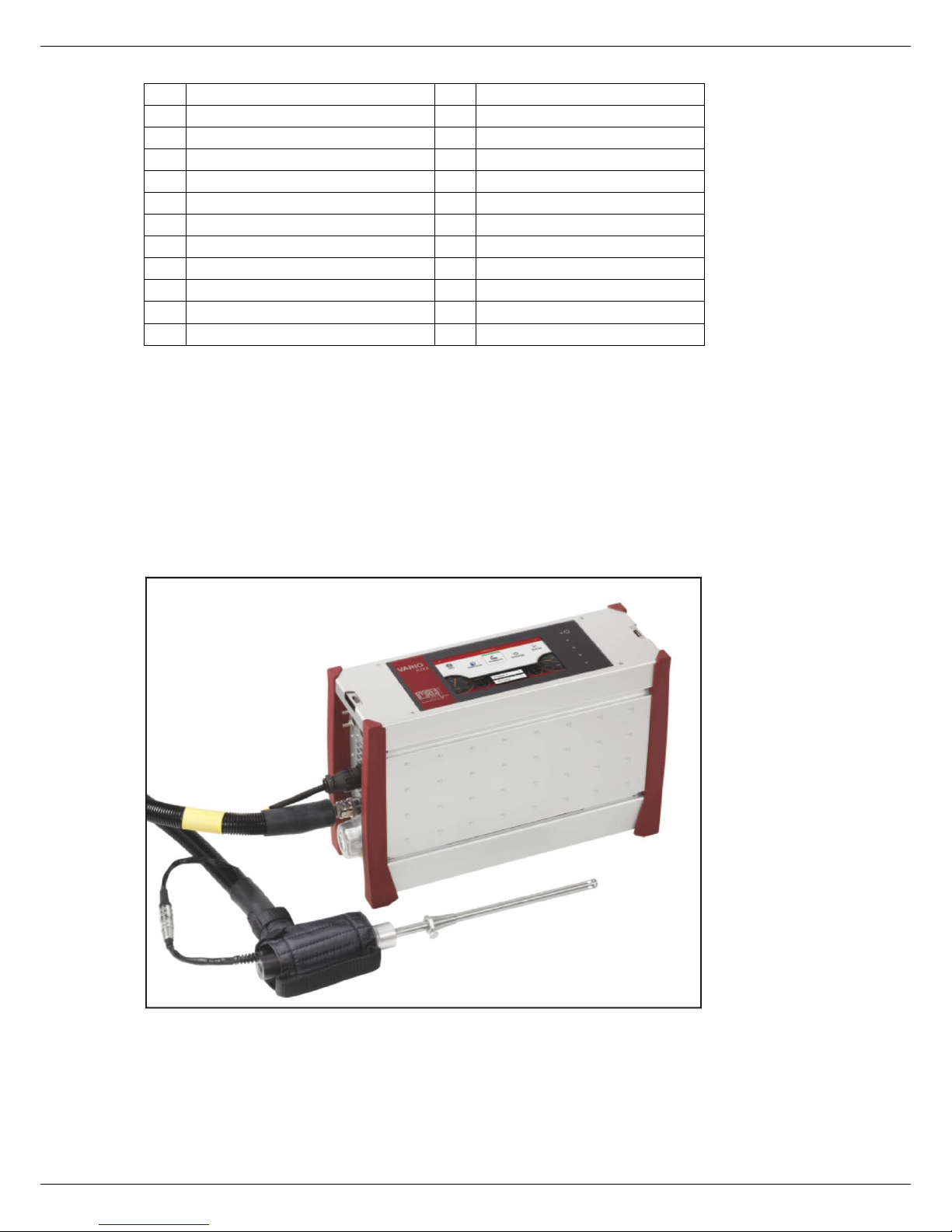

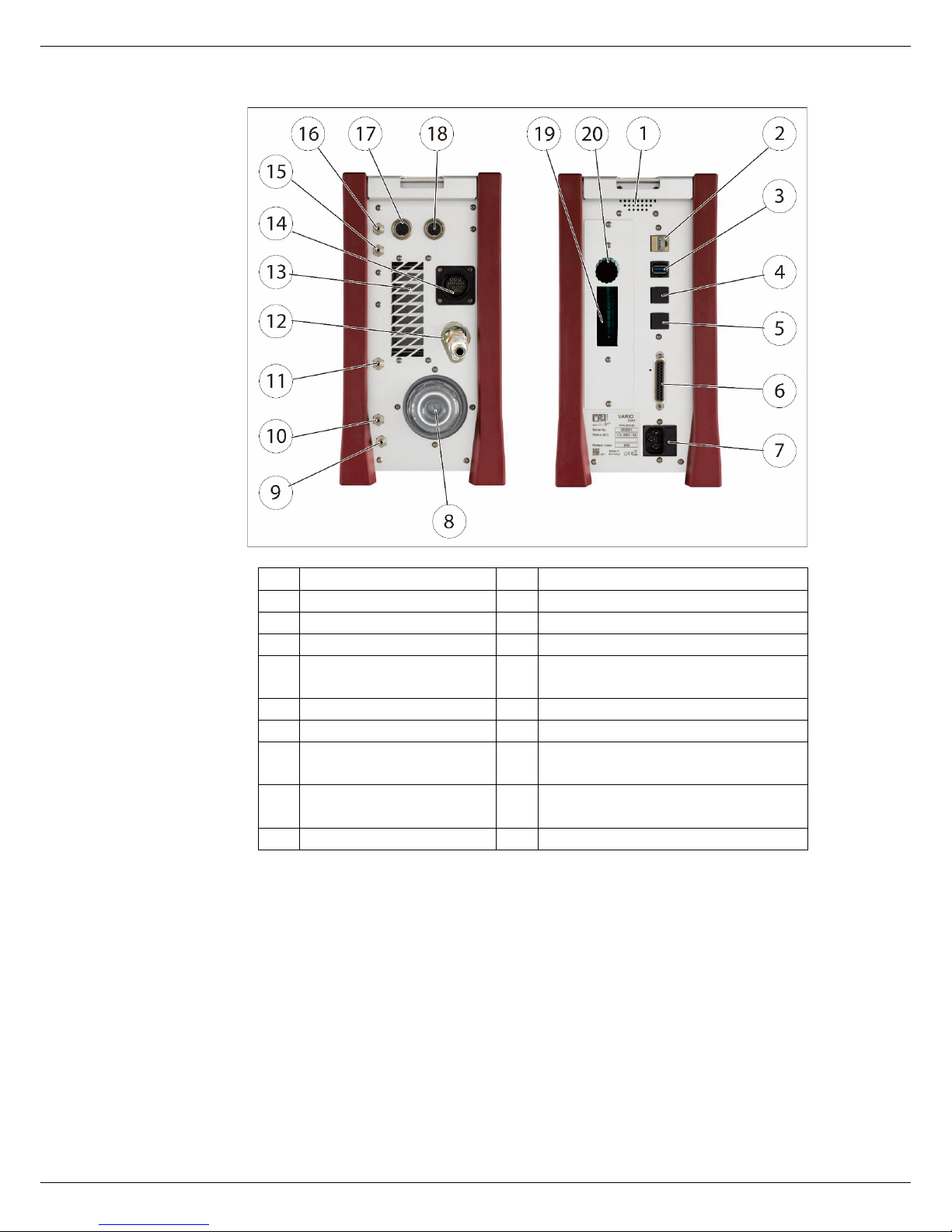

3.3. The measuring instrument...............................................................................9

3.4. Connectors.......................................................................................................... 10

3.5. Probes................................................................................................................... 10

3.6. Gas sampling probe “TR”................................................................................ 11

3.7. Gas conditioning............................................................................................... 11

3.8. Electrochemical measuring principle ........................................................ 12

3.9. IR measurement ................................................................................................ 13

4Operation ............................................................................................ 14

4.1. Commissioning ................................................................................................. 14

4.2. Switch on............................................................................................................. 14

4.3. Switching on after automatic emergency stop...................................... 14

4.4. Switch off............................................................................................................. 14

4.5. Reset...................................................................................................................... 15

4.6. Operating panel................................................................................................ 15

5Settings................................................................................................ 16

5.1. Analyzer settings............................................................................................... 16

5.2. Setting time and date...................................................................................... 17

5.3. Configuration of measurement program................................................. 17

5.4. Gas flow measurement................................................................................... 19

5.5. Setting of CO purge limit ............................................................................... 20

6Measurement ...................................................................................... 21

6.1. Preparation of each measurement............................................................. 21

6.2. How to take a Measurement......................................................................... 23

7Maintenance and cleaning................................................................. 26

7.1. Cleaning and maintenance........................................................................... 26

7.2. Maintenance....................................................................................................... 26

8Data memory ...................................................................................... 27

8.1. Organization of the Data memory.............................................................. 27

8.2. Information about the data memory......................................................... 27

8.3. Site administration........................................................................................... 27

8.4. Data transfer via USB (CSV export).............................................................. 29

8.5. Export of measurements................................................................................ 29