Content

1. General Information.......................................................................................................... 6

1.1. Weather and environmental conditions...................................................................... 6

1.2. Installation instructions............................................................................................... 6

1.3. General important instructions for the plant operator................................................. 6

1.4. Important information about the user’s operation manual.......................................... 7

1.5. Safety Information...................................................................................................... 7

1.1. Packing ...................................................................................................................... 9

1.2. Return of hazardous waste........................................................................................ 9

1.3. Return of analyzer...................................................................................................... 9

1.4. MRU guarantee conditions......................................................................................... 9

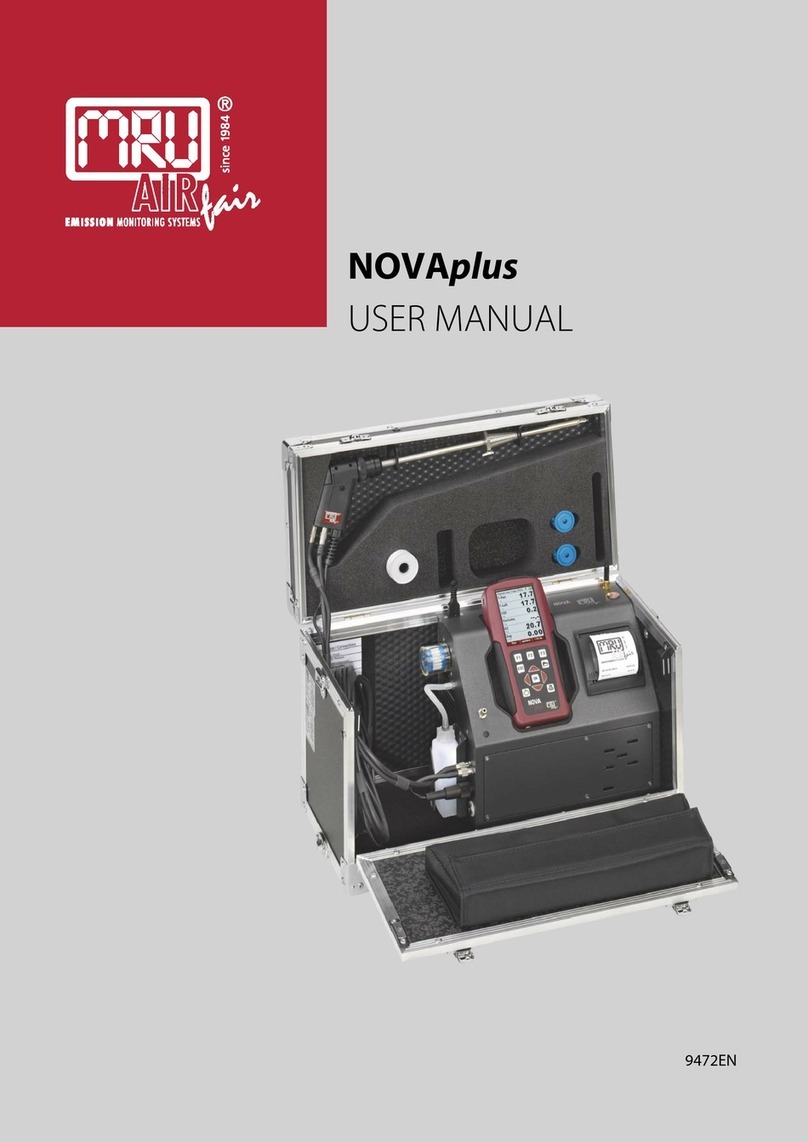

2. Analyzer Description...................................................................................................... 11

2.1. Intended use ............................................................................................................ 11

2.2. Type plate ................................................................................................................ 11

2.3. Possible applications and analyzer options ............................................................. 12

2.1. Principle of operation ............................................................................................... 13

2.2. CO sensor protection (option).................................................................................. 14

2.3. Cabinet ventilation ................................................................................................... 14

2.4. Physical characteristic of the gas analyzer .............................................................. 15

3. Scope of supply and delivery ........................................................................................ 17

4. SD-card content.............................................................................................................. 18

5. Installation manual ......................................................................................................... 19

5.1. Overview.................................................................................................................. 19

5.2. Mounting of the sample measurement point on the stack/chimney ......................... 20

5.3. Installation of the analyzer ....................................................................................... 22

5.4. Installation of the gas inlet/gas outlet and condensate connector (basic)................ 23

5.5. Installation of the sampling line and probe............................................................... 24

5.6. Installation of the gas connections OPTION LOW DUST PROBE WITH UNHEATED

SAMPLE GAS LINE.............................................................................................................. 25

5.7. Installation of the gas connections OPTION LOW DUST PROBE WITH UNHEATED

SAMPLE GAS LINE.............................................................................................................. 28

5.8. Installation of the gas connections OPTION LOW DUST PROBE WITH UNHEATED

SAMPLE GAS LINE.............................................................................................................. 33

5.9. Installation of the gas connections OPTIONS HIGH DUST PROBE WITH HEATED

SAMPLE LINE....................................................................................................................... 39

5.10. Connection of main power supply............................................................................ 44

5.11. I/O modules: Installation and setting........................................................................ 45

6. Operation of the analyzer (HMI)..................................................................................... 47

6.1. Display and keypad.................................................................................................. 47

7. Analyzer commissioning manual.................................................................................. 48

7.1. Check country and language ................................................................................... 48

7.2. Check date and time of the instrument .................................................................... 48

7.3. Configuration of the alarm relays............................................................................. 49

7.4. Configuration of the Modbus.................................................................................... 51

8Binding to a process control system: I/O modules ..................................................... 53

8.1. Position of the IO module inside the analyzer.......................................................... 53