MRU GmbH USER MANUAL MFplus Part 2 OPTION TRGI

3

1Table of content

1 Table of content ...................................................................................................................................................................3

2 Introduction .........................................................................................................................................................................5

3 Pipe tests(TRGI)....................................................................................................................................................................6

3.1 Stress test..................................................................................................................................................................7

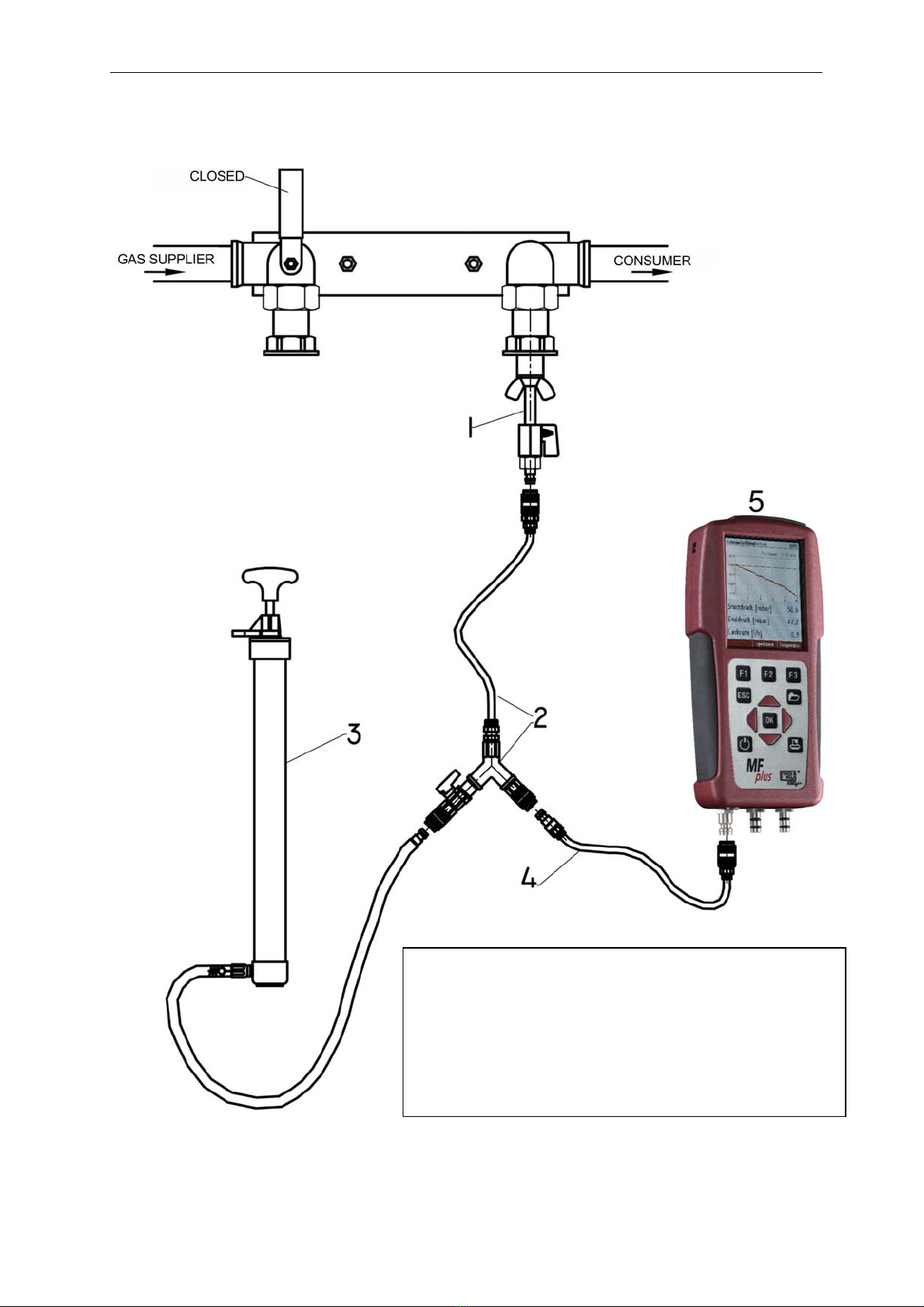

3.1.1 Connection diagram stress test LOAD side only ...................................................................................................8

3.1.2 Connection diagram stress test LOAD side and GAS supplier side .......................................................................9

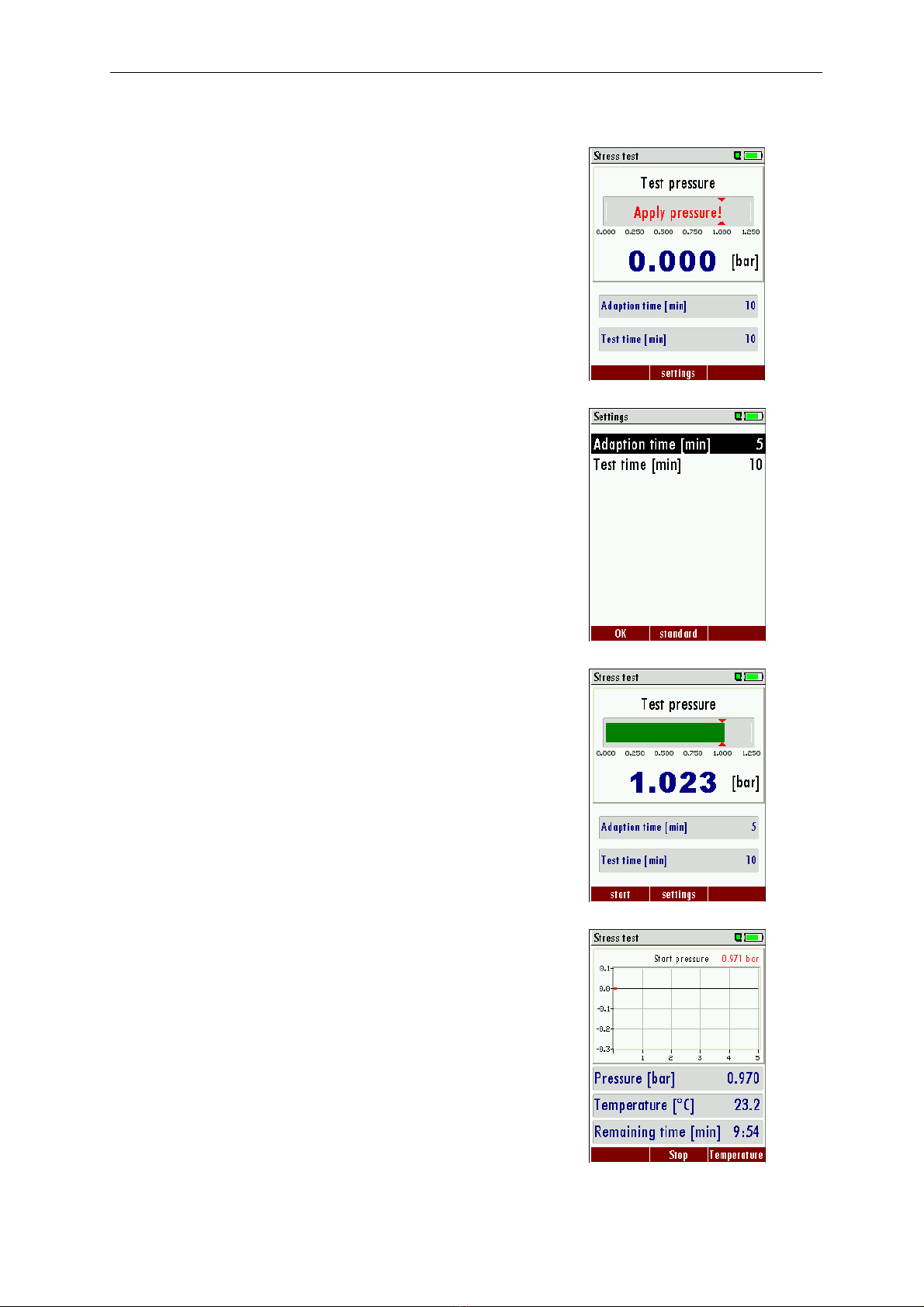

3.1.3 Operation ...........................................................................................................................................................10

3.1.3.1 Apply pressure..........................................................................................................................................10

3.1.3.2 Adaption phase ........................................................................................................................................10

3.1.3.3 Test phase ................................................................................................................................................11

3.1.3.4 View results..............................................................................................................................................11

3.1.3.5 Save results ..............................................................................................................................................12

3.2 Leak-tightness test ..................................................................................................................................................13

3.2.1 Connection diagram leak-tightness test LOAD side only....................................................................................14

3.2.2 Connection diagram leak-tight test Load side and Gas supplier side .................................................................15

3.3 Operation ................................................................................................................................................................16

3.3.1.1 Apply pressure..........................................................................................................................................16

3.3.1.2 Adaption phase ........................................................................................................................................16

3.3.1.3 Test phase ................................................................................................................................................16

3.3.1.4 View results..............................................................................................................................................17

3.4 Usage capability tests..............................................................................................................................................18

3.4.1 Connection diagram usage capability test LOAD side only.................................................................................19

3.4.2 Connection diagram usage capability test without dismounting gas meter.......................................................20

3.4.3 Connection diagram usage capability test LOAD side only test with air.............................................................21

3.4.4 Connection diagram usage capability test LOAD side and Gas supplier side test with air .................................22

3.4.5 Connection diagram example with the optional Black box TRGI........................................................................23

3.4.6 Operation ...........................................................................................................................................................24

3.4.6.1 Automatic capacity determination using the optional Black box TRGI (Option).......................................24

3.4.6.2 Automatic capacity determination ...........................................................................................................25

3.4.6.3 Enter pipe capacity manually ...................................................................................................................26

3.4.6.4 Enter all other parameters........................................................................................................................26

3.4.6.5 Apply test pressure...................................................................................................................................26

3.4.6.6 Adaption phase ........................................................................................................................................27

3.4.6.7 Test phase ................................................................................................................................................27

3.4.6.8 View results..............................................................................................................................................27

3.4.6.9 Save results ..............................................................................................................................................28

3.5 Pipe tests TRGI 50 mbar..........................................................................................................................................30

3.5.1 Connection diagram pipe test ............................................................................................................................30

3.5.2 Operation ...........................................................................................................................................................30

3.5.2.1 Apply pressure..........................................................................................................................................31