SECOND STAGE REGULATOR REASSEMBLY

ADJUSTING THE VALVE FORK HEIGHT FOR PROPER

PERFORMANCE

Note: All calibrations will be performed with the bypass

handwheel facing away and with the valve fork’s slots fac-

ing in. The regulator must be depressurized.

Ensure the U-clip holding the bypass and hose assem-

bly in the regulator housing is not removed or lost.

ADJUSTMENT FOR VALVE FORK MAXIMUM RANGE

Note: Clockwise rotation of the lever adjuster knob

(wheel) lowers the lever fork.

Note: All calibrations will be performed with the bypass

handwheel facing away and with the valve fork’sslots fac-

ing in.

Ensure the U-clip holding the bypass and hose assem-

bly in the regulator housing is not removed or lost.

•Press on the top of the valve fork assembly to ensure

the valve fork assembly moves up and down freely.

• Place a jeweler’s screwdriver on the flats of the lever

adjuster knob.

• Turn the lever adjuster knob (wheel) clockwise to lower

the valve fork. Be certain adjuster knob clicks into

position.

• The top surface of the valve fork should be along the

grooved surface of the lever height gauge without

exerting pressure on the valve fork assembly for nor-

mal valve fork height.

ADJUSTMENT FOR VALVE FORK MINIMUM RANGE

Note: Counter-clockwise rotation of lever adjuster knob

(wheel) raises the lever fork.

Note: All calibrations will be performed with the bypass

handwheel facing out.

Check that the U-clip holding bypass and hose

assembly in the regulator housing is properly

engaged. Pull on the bypass and hose assembly to

ensure that the bypass and hose assembly are secure-

ly attached to the regulator housing with the U-clip.

• Press on the top of the valve fork assembly to ensure

the valve fork assembly moves up and down freely.

• Place a jeweler’s screwdriver on the flats of the lever

adjuster knob.

• Turn the lever adjuster knob counter-clockwise to

raise the valve fork. Be certain adjuster knob clicks

into position.

• The top of the valve fork should be along the grooved

surface of the Lever Height Gauge without exerting

pressureon the valve fork assembly for normal valve

fork height.

•Press on the top of the valve fork assembly to ensure

the valve fork assembly moves up and down freely.

DISASSEMBLING THE VALVE ASSEMBLY

1. Remove the regulator cover, spring, and spring retainer.

2. Remove the diaphragm.

3. Remove the U-clip from the regulator housing.

Note: Use the bypass body as a tool to remove the

bypass insert.

8

TAL 502 (L) Rev. 0 - 10064393

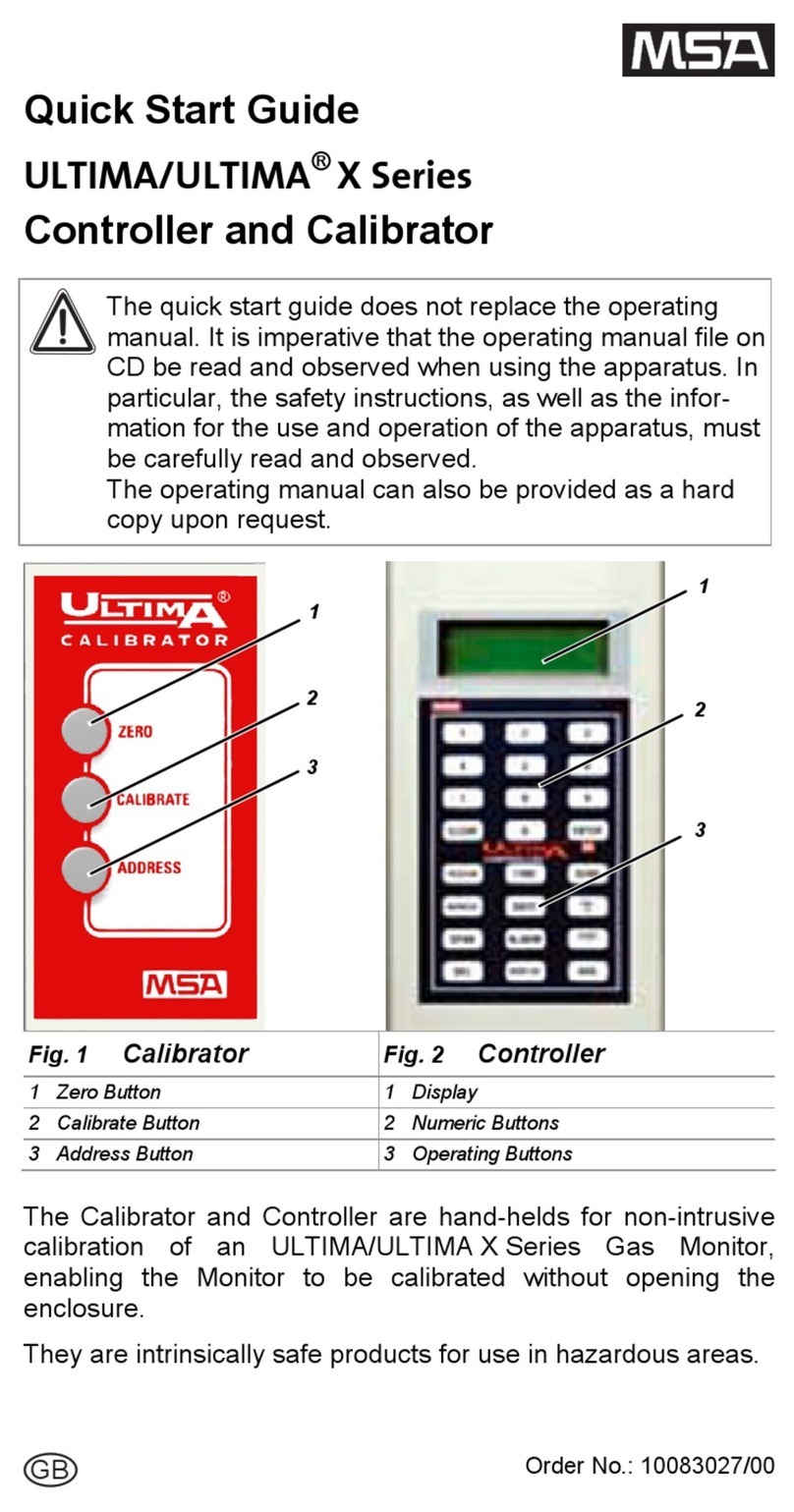

Lever

Adjuster Knob

(wheel)