MSA 10033170 User manual

Other MSA Controllers manuals

MSA

MSA FireHawk M7 Setup guide

MSA

MSA SMC Sentry-IT NEMA Retrofit Kit User manual

MSA

MSA M1 User manual

MSA

MSA PremAire System User manual

MSA

MSA General Motions MC600 User manual

MSA

MSA BVC-650 User manual

MSA

MSA SENTRY io User manual

MSA

MSA Firehawk 10043892 Setup guide

MSA

MSA ZGARD CX II User manual

MSA

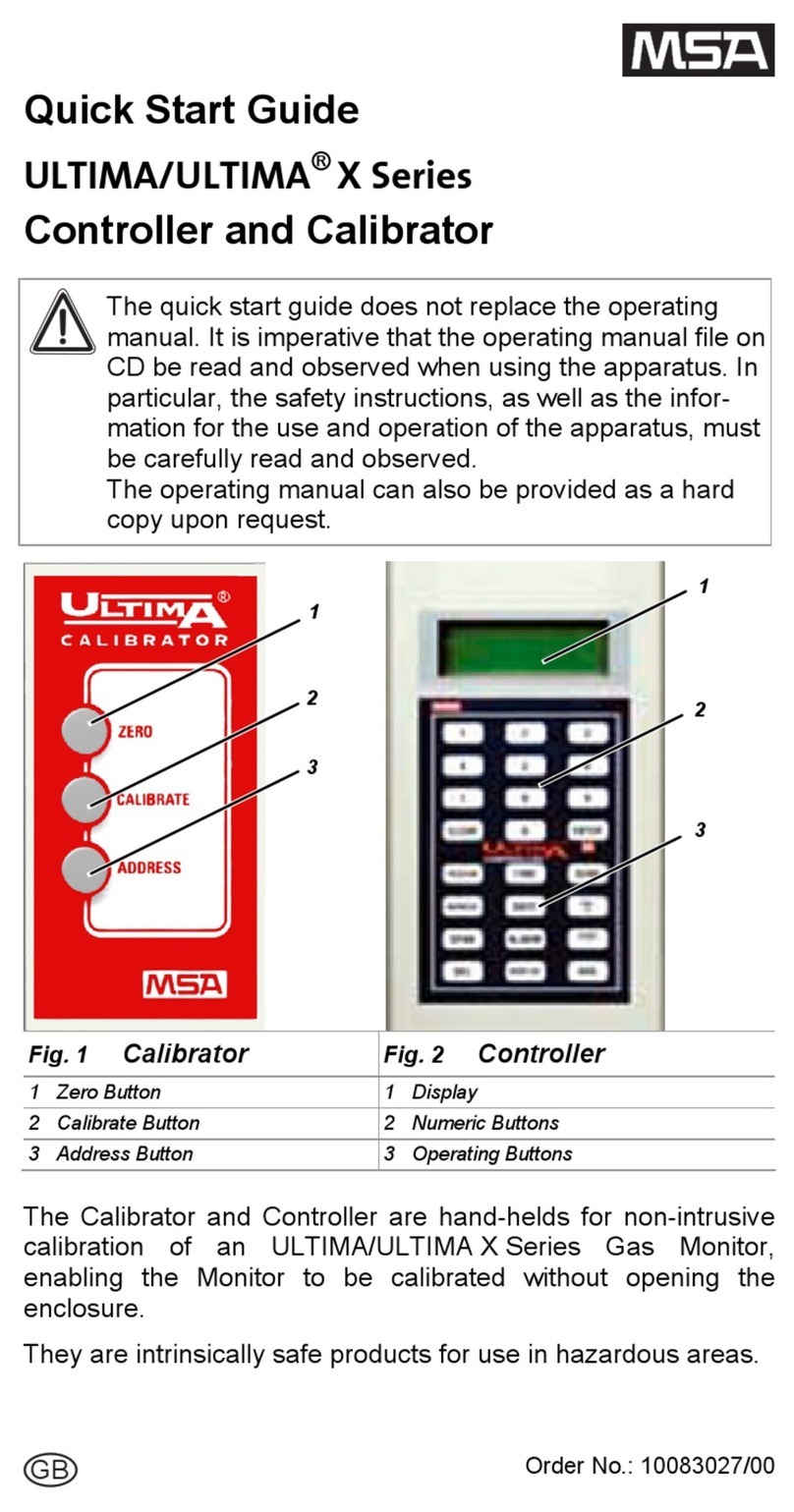

MSA Ultima User manual

MSA

MSA GasGard XL User manual

MSA

MSA GasGard XL User manual

MSA

MSA ModCon 75 User manual

MSA

MSA GasGard XL Operating and maintenance instructions

MSA

MSA Ultima Series User manual

MSA

MSA Ultima Series User manual

MSA

MSA Firehawk Responder Series Operating instructions

MSA

MSA 10033170 User manual

MSA

MSA SUPREMA Touch Installation and operating instructions

MSA

MSA ZGARD C User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions