User Manual - Test Bench MS111

English

INTRODUCTION.......................................................................................................................................................2

1. PURPOSE.............................................................................................................................................................. 2

2. TECHNICAL CHARACTERISTICS.......................................................................................................................3

3. COMPLETE EQUIPMENT SET............................................................................................................................4

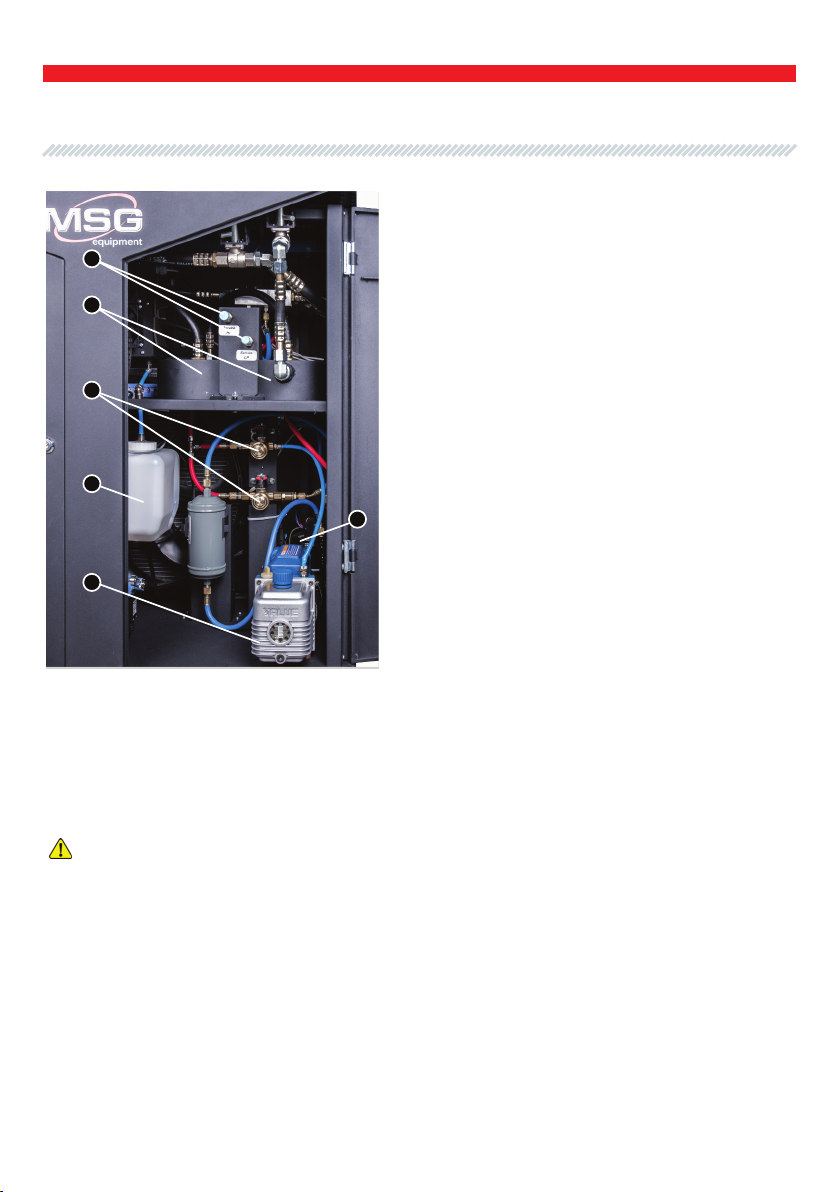

4. TEST BENCH DESCRIPTION............................................................................................................................. 5

5. INTENDED USAGE...............................................................................................................................................8

5.1 Safety regulations......................................................................................................................................9

5.2 Pre-starting procedures........................................................................................................................10

5.2.1 Equipment installation...................................................................................................................10

5.2.2 Test bench lling..............................................................................................................................11

5.2.3 Connection of cables to the test bench terminals................................................................12

6. TEST BENCH MAINTENANCE..........................................................................................................................13

6.1 Cleaning and care....................................................................................................................................14

6.2 Condensate draining..............................................................................................................................14

6.3 Replacement of lters in the test bench hydraulic system.......................................................15

6.4 Firmware update..................................................................................................................................... 19

7. MAJOR FAULTS AND TROUBLESHOOTING.................................................................................................19

8. DISPOSAL OF THE EQUIPMENT.................................................................................................................... 21

CONTENTS

1