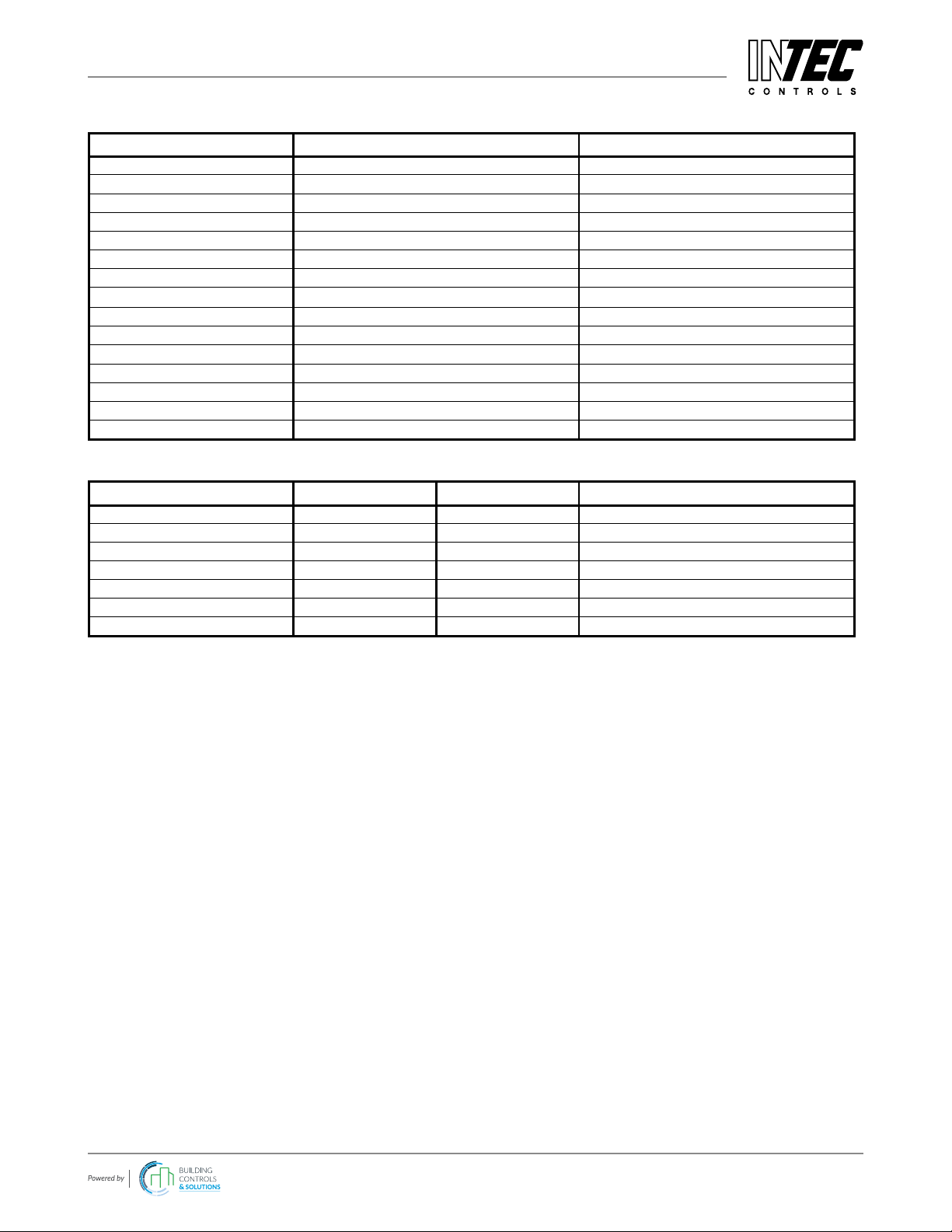

Table of Contents

1 General................................................................................................................................... 5

1.1 Intended Use...........................................................................................................................................5

1.2 Safety........................................................................................................................................................5

1.3 Installers‘ and Operators‘ Responsibilities......................................................................................5

1.4 Services ....................................................................................................................................................6

1.5 Limited Warranty ...................................................................................................................................6

1.6 Part Disposal ...........................................................................................................................................6

2 Functional Description ........................................................................................................... 6

2.1 General .....................................................................................................................................................6

2.2 Measuring Mode.....................................................................................................................................6

2.3 Special Mode...........................................................................................................................................6

2.4 Sensor Element.......................................................................................................................................7

A: Catalytic Sensor Element (Pellistor) for Combustible Gases ...............................................7

B: Electrochemical Sensor Element for Toxic Gases and Oxygen ............................................7

C: Semiconductor Sensor Element for Freon Gases, Ethylene and Ammonia.......................8

D: Infrared Sensor Element for Methane, Propane and Carbon Dioxide................................8

3 Installation ............................................................................................................................. 9

3.1 Mounting Instructions...........................................................................................................................9

3.2 Mounting of Sensors .......................................................................................................................... 10

4 Electrical Connection ........................................................................................................... 11

4.1 Plug Connection (SC2) in DT6, DC6, SGC6, SCM6 ....................................................................... 11

4.2 Terminal Connection (AT6)............................................................................................................... 11

4.3 Registration of the Sensors SC2/AT6............................................................................................. 11

5 Commissioning..................................................................................................................... 12

5.1 General .................................................................................................................................................. 12

5.2 Required Instruments for Commissioning (Calibration)............................................................ 12

6 Calibration............................................................................................................................ 12

6.1 Run-in Time .......................................................................................................................................... 13

6.2 Calibration Work ................................................................................................................................. 14

6.2.1 Zero Calibration.................................................................................................................... 14

6.2.2 Gain Calibration.................................................................................................................... 14

6.2.3 Calibration (Gain) with Surrogate Gas for Catalytic Sensor Element (Pellistor)... 15

6.2.4 Extended Calibration for Semiconductor Sensor Element ........................................ 15

6.3 Calibration Analog Output................................................................................................................ 15

6.4 Exchange of Sensors .......................................................................................................................... 16

6.4.1 Sensor SC2............................................................................................................................. 16

6.4.2 Sensor AT6............................................................................................................................. 16

6.4.3 Perform Function Test......................................................................................................... 16

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | GA_MC2_SC2_E, 2022-05-31 | USA 220907 | Page 3of 28

SC2-AT6 – UserManual