6

OPERATING INSTRUCTIONS

A.CONTROLS

1. Engine Choke

There are usually two moving levers on the side of

an engine near the carburetor. One of these is the

choke, the other is the throttle. The choke lever

should be moved all the way to the "CHOKE"

position when starting a cold engine. After the

engine starts, slowly move the lever all the way

back to the "RUN" position as the engine warms

up. A warm engine should not be choked.

2. Engine Throttle

The second moving lever on the side of an engine

near the carburetor is the throttle. For starting,

place the lever at 50% of the maximum RPM. For

pump pressures up to about 100 psi, the throttle

should be set at 30% of the maximum RPM. For

maximum pressures, the throttle should be set at

"FAST" or 100% of the maximum RPM.

3. Ignition Switch

NOTE: Make sure the pump is not under

pressure before trying to start the engine.

a. Recoil-Start Engines

On some engines, moving the throttle lever to

"OFF" or "STOP", while the engine is running

will short out the magneto and stop the

engine. On other engines, a separate lever or

knob on the side or top of the engine functions

as an ignition switch. They have two positions:

"OFF" and "START". They must be placed in

the "START" position before trying to start the

engine. Moving the lever or turning the knob

back to the "OFF" position while the engine is

running will short out the magneto and stop

the engine.

b. Electric-Start Engines

Automotive-type key switches are used as

ignition switches and are usually found on the

side or top of the engine. A clockwise 45° turn

closes the ignition circuit and turning the

switch further against spring pressure starts

the engine. The key should always be

removed from the switch if the sprayer is to be

left unattended.

4. Rewind Pull-Cord Starter

Located on the right side of the engine. To start

the engine, set the choke and the throttle and

grasp the starter grip and pull slowly until the

starter engages. Then pull the cord rapidly to

overcome compression, prevent kickback and start

the engine. Repeat if necessary with the choke

opened slightly. When the engine starts, slowly

open the choke all the way.

5. Valves

There are several ball valves used on the

sprayers. They serve as pump outlets and are

mounted under the pressure regulator. Ball valves

operate with a quarter turn movement of the

handle. When the handle lines up with the

direction of flow, the valve is open. When the

handle is at a 90° angle to the direction of flow, the

valve is closed. There is a gate valve in the suction

line at the front of the engine plate near the drain

fitting. The handle should be turned all the way

counterclockwise to open the valve and all the way

clockwise to close the valve. To drain the tank, the

cap must be removed from the drain fitting and the

gate valve must be opened.

6. Pressure Gauge

Mounted in the pressure regulator housing, the

pressure gauge indicates the pressure in the

output line to the spray gun, wand or boom and the

line to the hydraulic agitator, if used. The gauge is

graduated in pounds per square inch (psi) and

kilopascals (kPa).

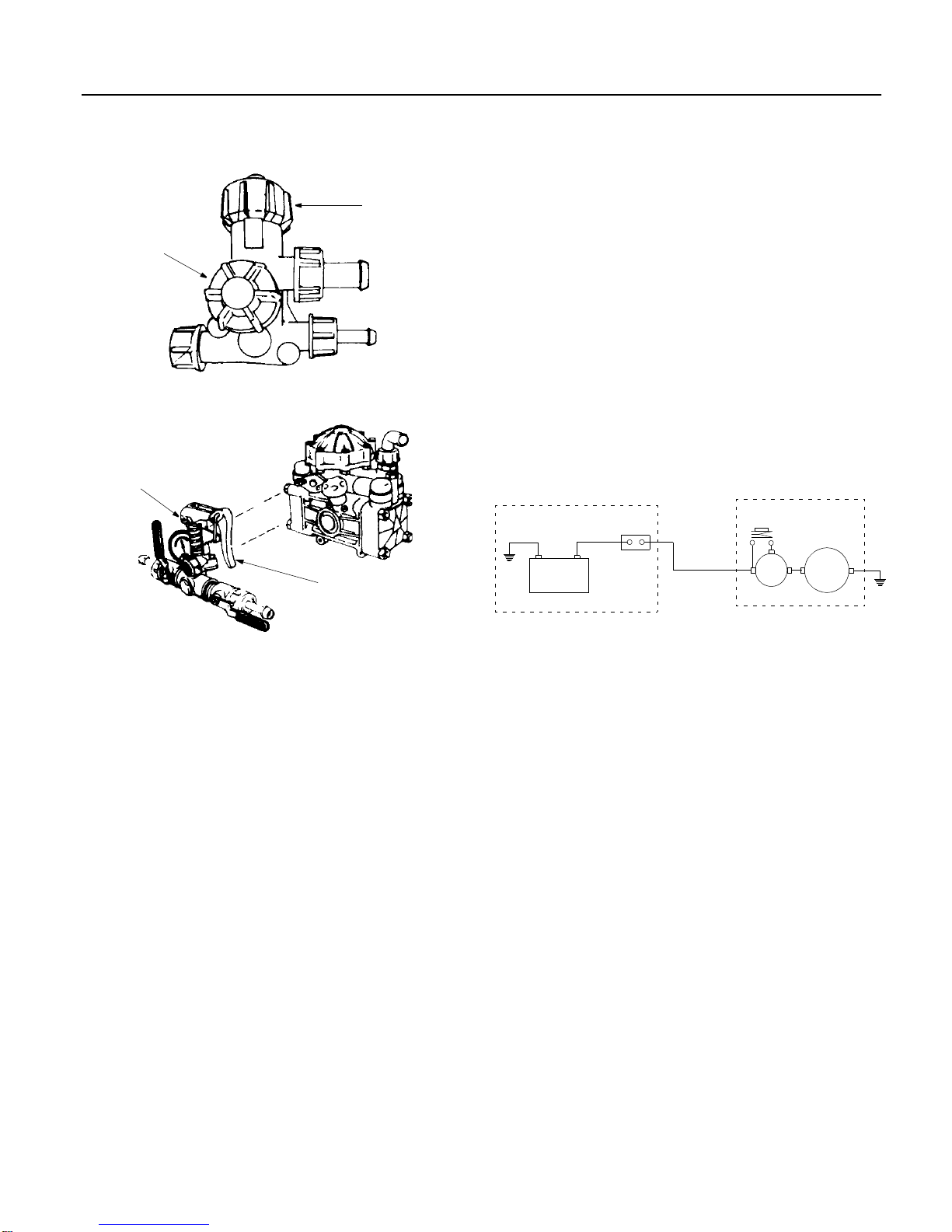

7. Pressure Regulator

Located on the side of the pump opposite the drive

shaft. There are different styles of regulators, but

they all function in the same way. A spring-loaded

plunger rests against a valve seat which forces the

pump flow to the outlets. The springs are opposed

by the hydraulic pressure generated by the pump.

If this pressure exceeds the spring pressure, the

plunger is lifted off of its seat and part or all of the

flow goes to bypass. All of the pressure regulators

have operating levers which in one position,

remove the spring pressure from the plunger and

permit the pump's flow to dump to bypass and in

the other position, apply the spring pressure to the

plunger and force the pump's flow to the outlets.

One valve has a toggle-type operating lever with a

ball which can be hooked in different notches for

adjustment. Another regulator has a knob that

turns about 90° from "OFF" to "ON". Still another

has a hinged part of the plunger shaft work as the

operating lever. All of the regulators also have a

means for adjusting the operating pressure. This is

a threaded knob, a ring or a brass adjustment nut

which when threaded down toward the base of the

pressure regulator, increases the spring pressure.

Normally, the regulator should be set to provide

about 100 psi with both output ball valves closed.

Then the output ball valve to the application device

is opened completely and with bypass or

pressurized jet agitation, the output ball valve to

the agitator line is adjusted to provide the desired