To reduce the risk of serious or fatal injury from

breathing toxic fumes, ensure proper ventilation

when working in trenches, hollows or other con‐

fined locations.

Stop work immediately if you start suffering from

nausea, headaches, impaired vision (e.g. your

field of vision gets smaller), impaired hearing,

dizziness, or impaired concentration – these

symptoms may possibly be the result of too-high

exhaust gas concentration – Risk of accidents!

Operate your power tool so that it produces a

minimum of noise and emissions – do not run the

engine unnecessarily, accelerate the engine only

when working.

To reduce the risk of fire, do not smoke while

operating or standing near your power tool. Com‐

bustible fuel vapor may escape from the fuel sys‐

tem.

Dusts, mist and fumes emissions during the work

may be hazardous to your health. Wear respira‐

tory protection in case of heavy dust or smoke

emission.

The gear head becomes hot during

operation. To reduce the risk of burn

injury, do not touch the gear housing!

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting". Check in particular that the fuel

system has no leaks and the safety equipment is

fully operative. Never use a power tool that is no

longer safe to operate. In case of doubt, contact

a dealer.

Do not operate your power tool in the starting

throttle position – engine speed cannot be con‐

trolled in this position.

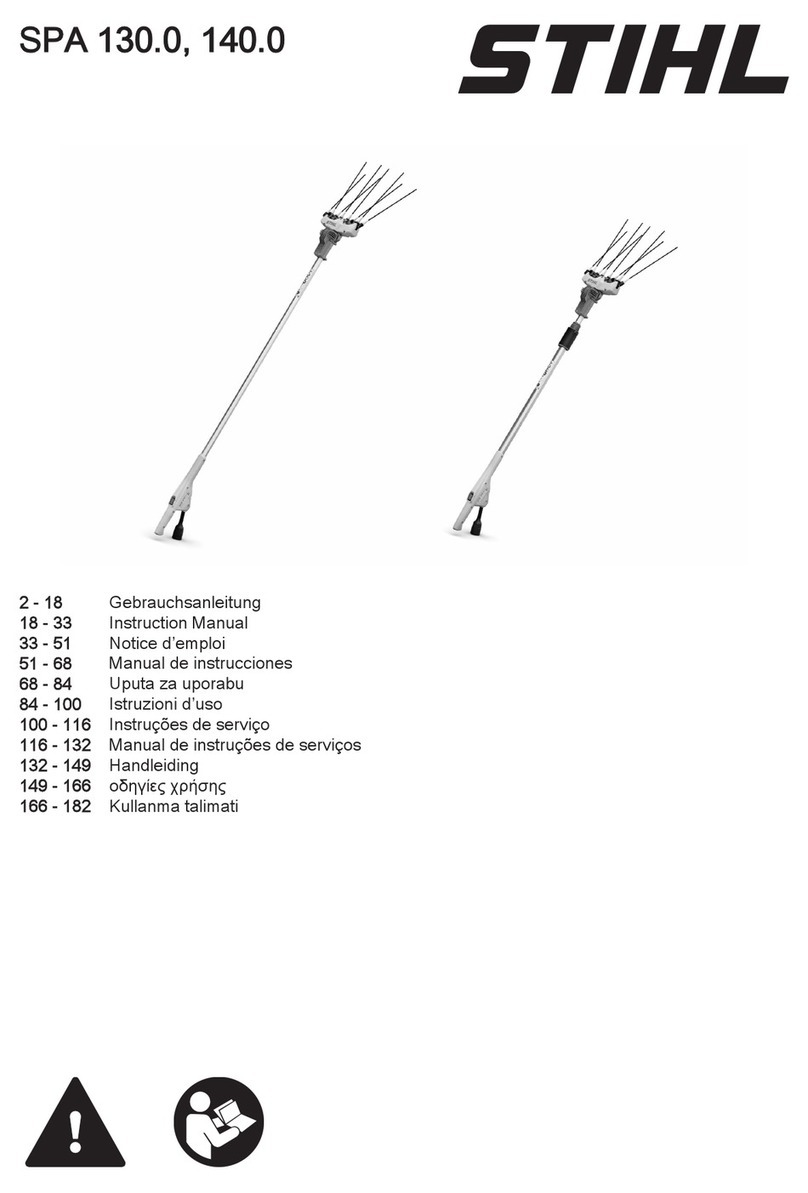

Inspect the hedge and work area to avoid dam‐

aging the cutting blades:

–Remove stones, rocks, pieces of metal and

other solid objects

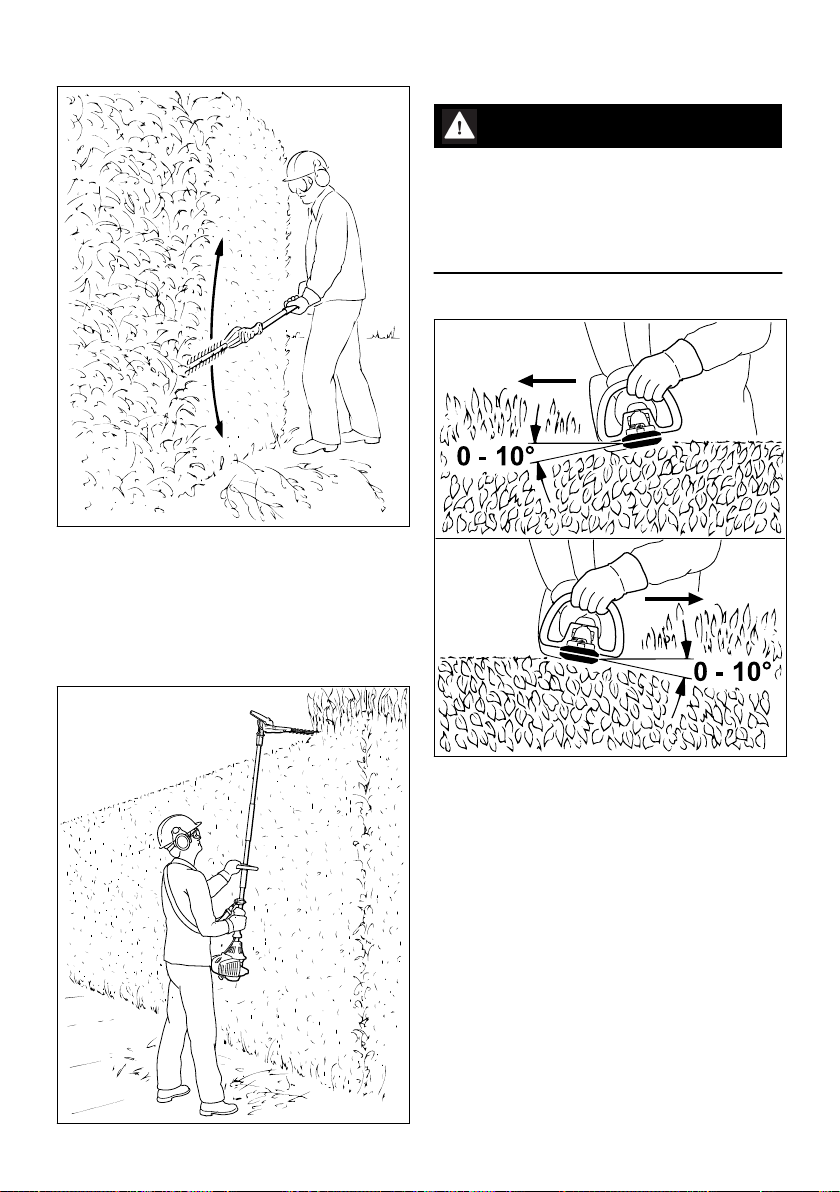

–When working close to the ground, make sure

that no sand, grit or stones get between the

cutting blades

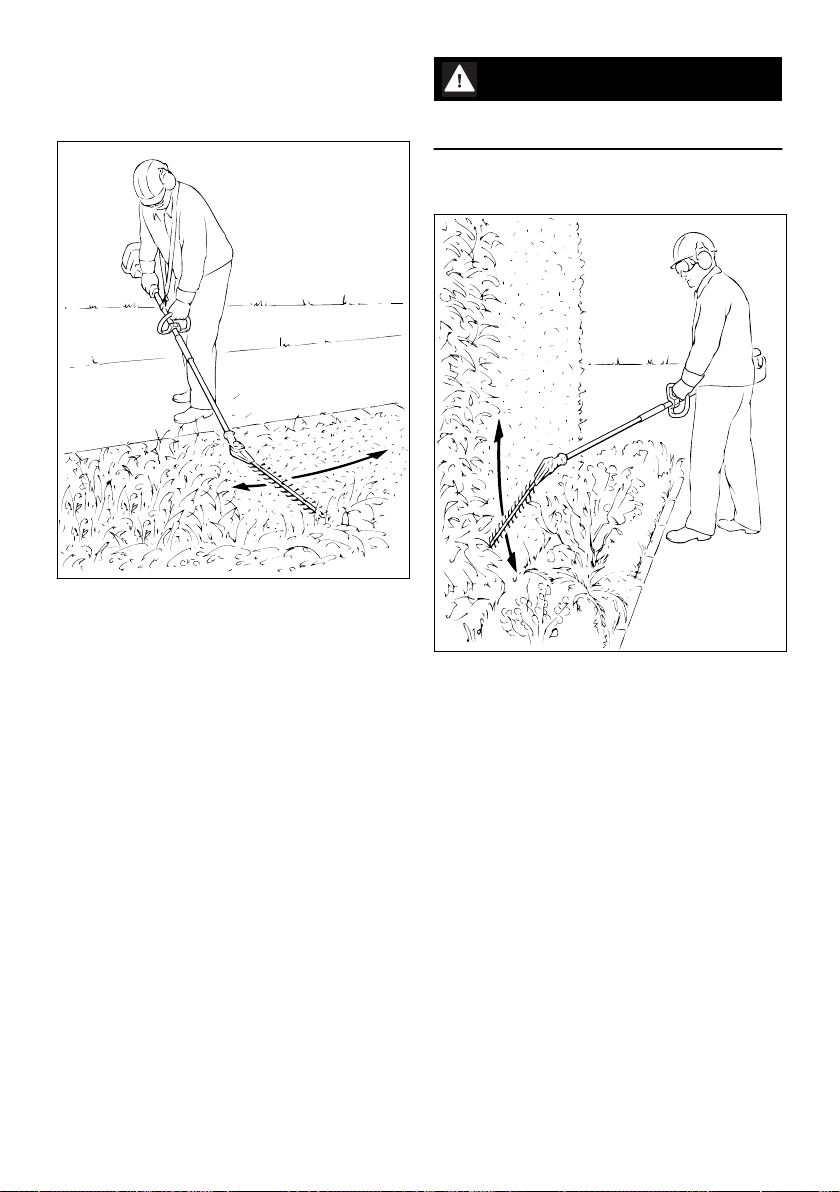

–Take particular care when cutting hedges next

to or against wire fences

Do not touch electric power lines – never cut

through electric power lines – risk of electrocu‐

tion!

Do not touch the cutting blades.while

the engine is running. If the cutting

blades become jammed by an object,

switch off the engine immediately

before attempting to remove the

object – risk of injury!

Opening the throttle when the cutting blades are

jammed increases the load and reduces the

working speed of the engine. The constant slip‐

ping of the clutch causes overheating and dam‐

age to important components (e.g. coupling,

plastic housing parts) – thus e.g. due to the cut‐

ting blade moving during idling – risk of injury!

If the hedge is very dusty or dirty, spray the cut‐

ting blades with STIHL resin solvent from time to

time during cutting. This helps reduce blade fric‐

tion as well as the aggressive effects of sap and

the build-up of dirt particles.

Before you leave the machine: Shut the engine

off.

Check the cutting blades at regular, frequent

intervals during operation or immediately if there

is a noticeable change in cutting behavior:

–Shut off the engine

–Wait for cutting blades to come to a standstill

–Check condition and tightness of connections,

look out for fine cracks

–Ensure that the cutting blades are sharp

Always clean plant residue, chips, leaves and

excess lubricant off the engine and muffler – risk

of fire!

2.8 After finishing work

Always clean dust and dirt off the machine – do

not use any grease solvents for this purpose.

Spray the cutting blades with STIHL resin sol‐

vent. Run the motor briefly so that the solvent is

evenly distributed.

2.9 Vibrations

Prolonged use of the power tool may result in

vibration-induced circulation problems in the

hands (whitefinger disease).

No general recommendation can be given for the

length of usage because it depends on several

factors.

The period of usage is prolonged by:

–Hand protection (wearing warm gloves)

–Work breaks

The period of usage is shortened by:

English 2 Safety Precautions and Working Techniques

6 0458-519-8321-D