25% Step Current Output

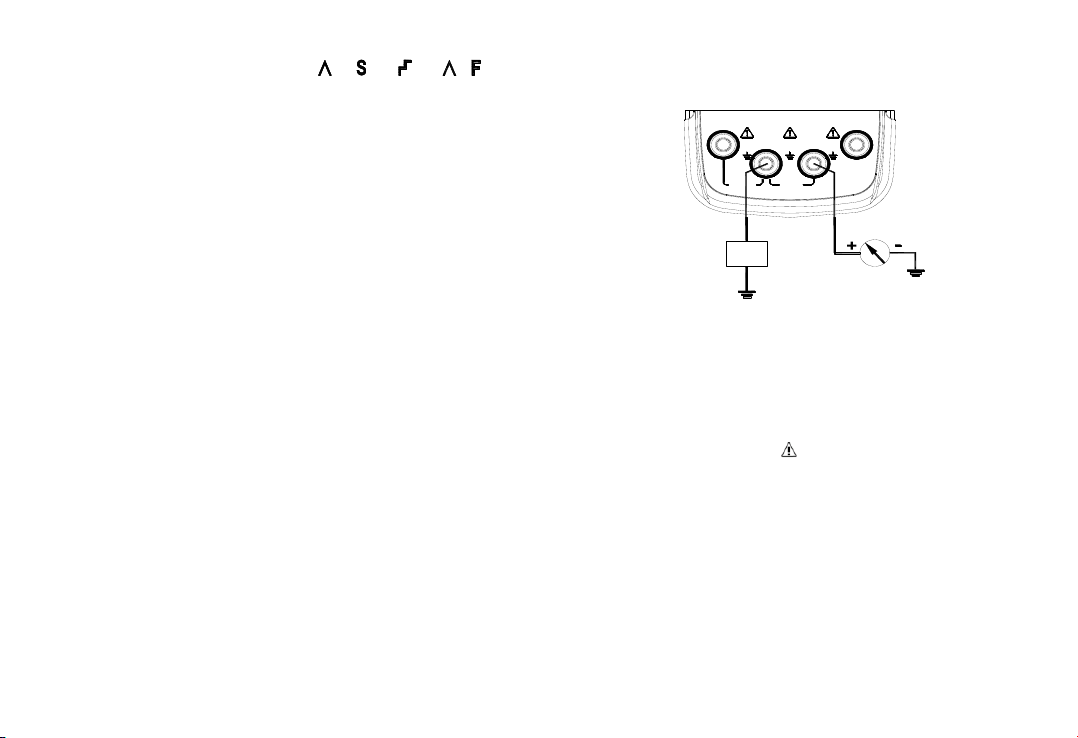

1) Connect to the Instrument as shown in Figure

5-1;

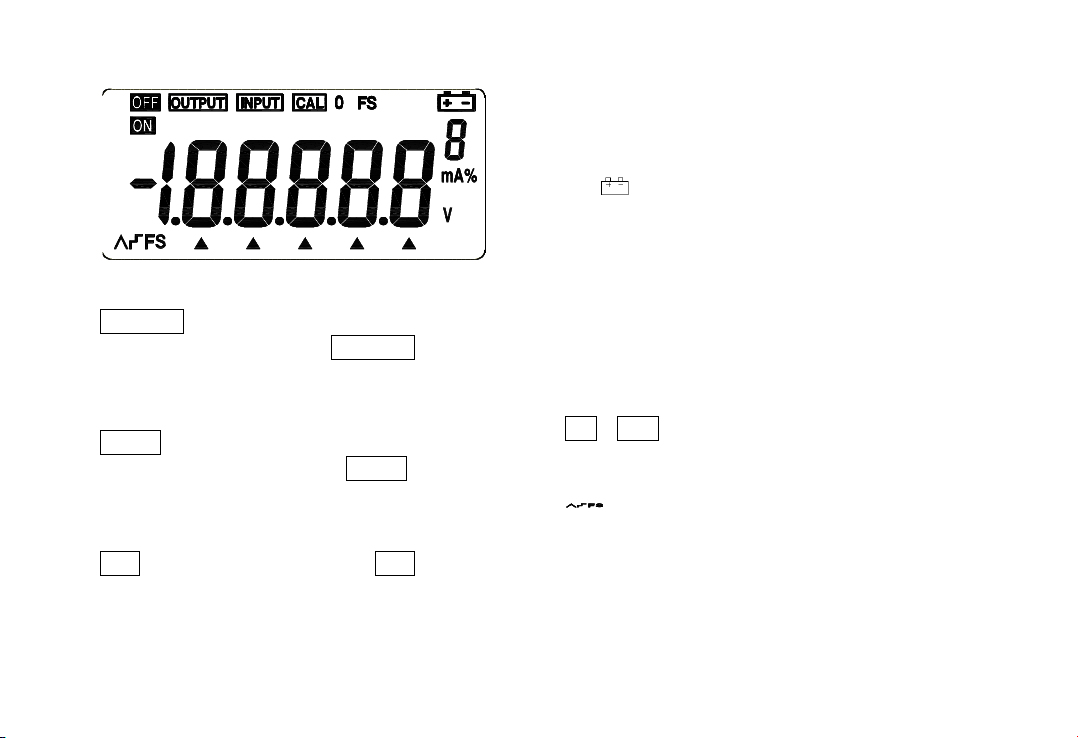

2) When the key〔OUTPUT/IN〕is pressed, the

OUTPUT appears in the LCD, it denotes the

Instrument is in an output state;

3) Press the key〔25%/RAMP〕and the

symbols‘ ’ and ‘’will appear;

4) Press the key 〔mA%/ V〕to select the

output to be set in mA or %, and then the unit

‘mA’or‘mA % appears;

5) Press the key 〔〕/〔〕to change the

output in a value of 25%, in which 0% denotes

4mA and 100% denotes 20mA;

6) Repress the key〔25%/RAMP〕so as to exit

the step current output.

Current Output Set for Zero Point & Full Scale

1) Connect to the Instrument as shown in Figure

5-1;

2) When the〔OUTPUT/IN〕key is pressed, the

OUTPUT appears in the LCD, it denotes the

Instrument is in an output state;

3) Press the key 〔100%/START〕and the

symbols ‘ ’、‘’、‘0’、‘FS’ will appear in the

display;

4) Press the key〔〕to be set to 100% and the

current output will be 20mA. Press the

key〔〕to be set to 0% and the current

output will be 4mA;

5) Repress the key〔100%/START〕so as to exit

the step current output.

Auto-ramp Output

1) Connect as shown in Figure 5-1;

2) When the key〔OUTPUT/IN〕is pressed, the

OUTPUT appears in the LCD, it denotes the

Instrument is in an output state;

3) When the key〔STEP/AUTO〕is pressed, the

symbols ‘OUTPUT’, ‘OFF’, ‘ ’along with

‘4mA’ appear in the LCD. If so, it denotes that

the Instrument is getting into the mode of

RAMP;

4) Repress the key〔25%/RAMP〕again so as to

change the type of the output ramp, which

finds itself in the lower left of the LCD. The