MULTISPAN PI-54 User manual

Other MULTISPAN Measuring Instrument manuals

MULTISPAN

MULTISPAN AVF-133 User manual

MULTISPAN

MULTISPAN MPD-19N User manual

MULTISPAN

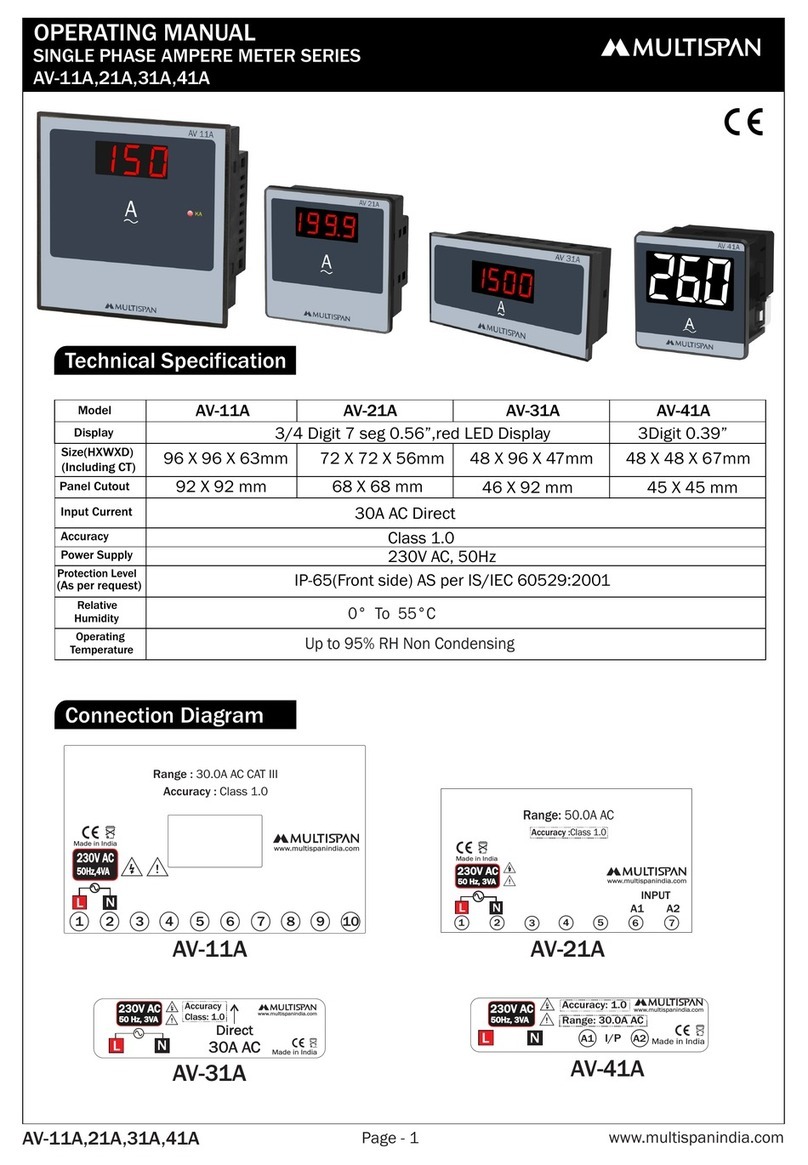

MULTISPAN AV-11A User manual

MULTISPAN

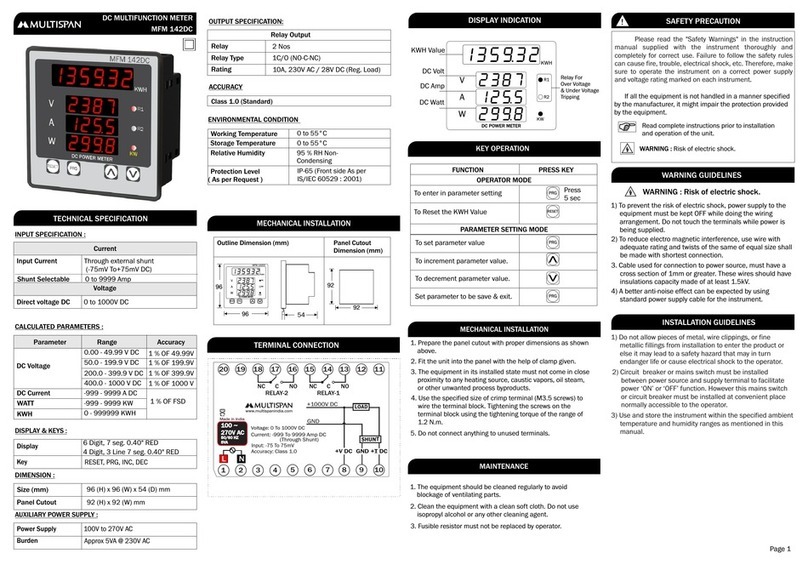

MULTISPAN MFM 142DC User manual

MULTISPAN

MULTISPAN EM-1P User manual

MULTISPAN

MULTISPAN AVH 13N User manual

MULTISPAN

MULTISPAN PIC-38 User manual

MULTISPAN

MULTISPAN AVH-14 User manual

MULTISPAN

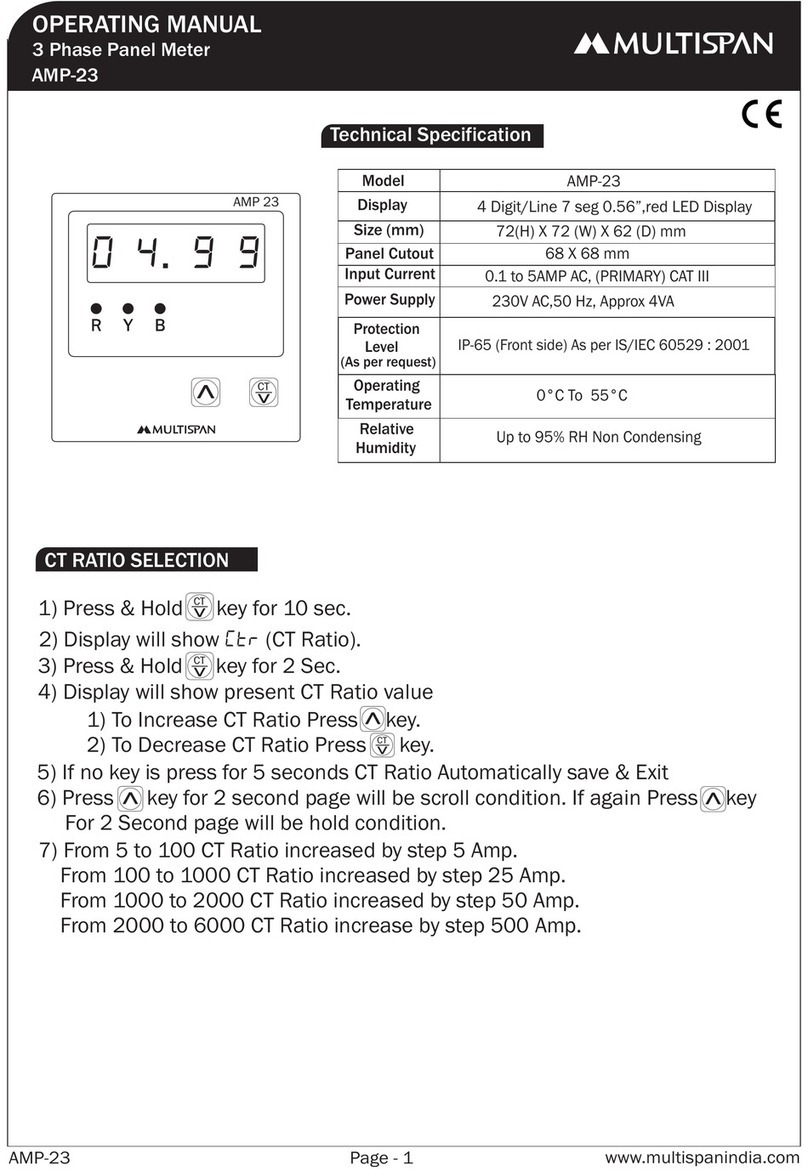

MULTISPAN AMP-23 User manual

MULTISPAN

MULTISPAN AVF-19N User manual

MULTISPAN

MULTISPAN AVF-19N User manual

MULTISPAN

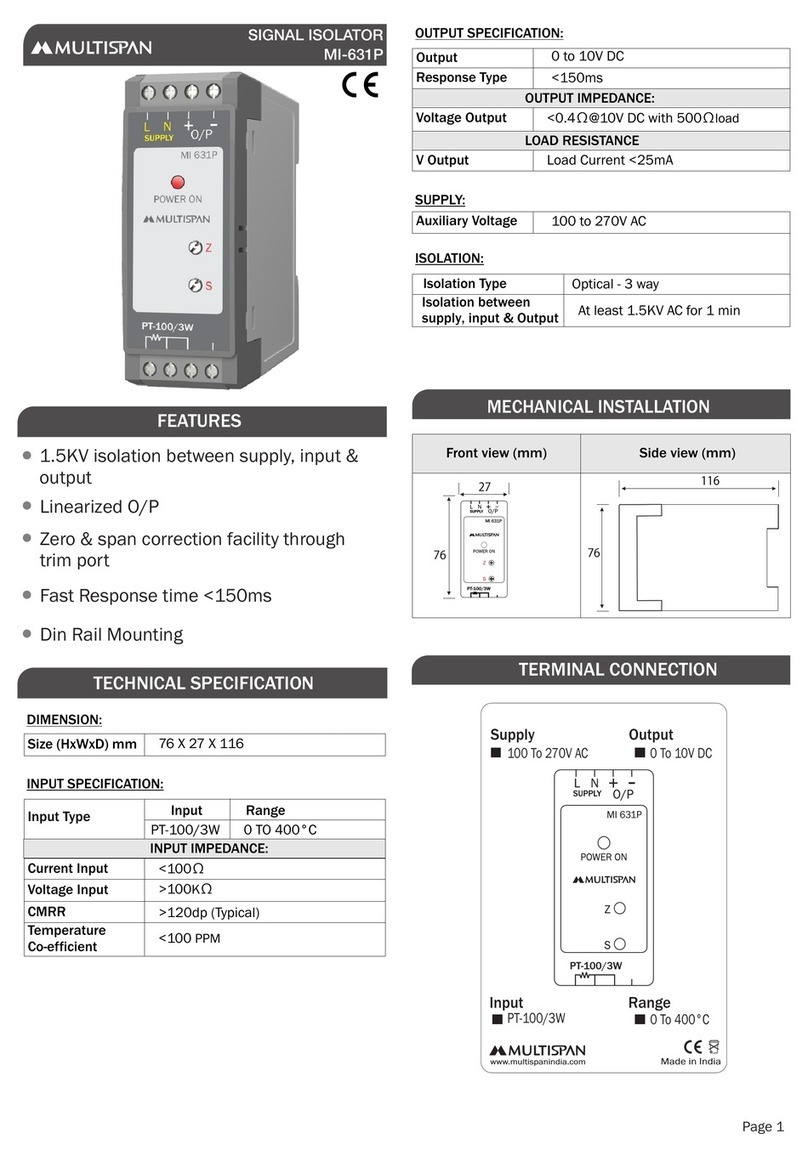

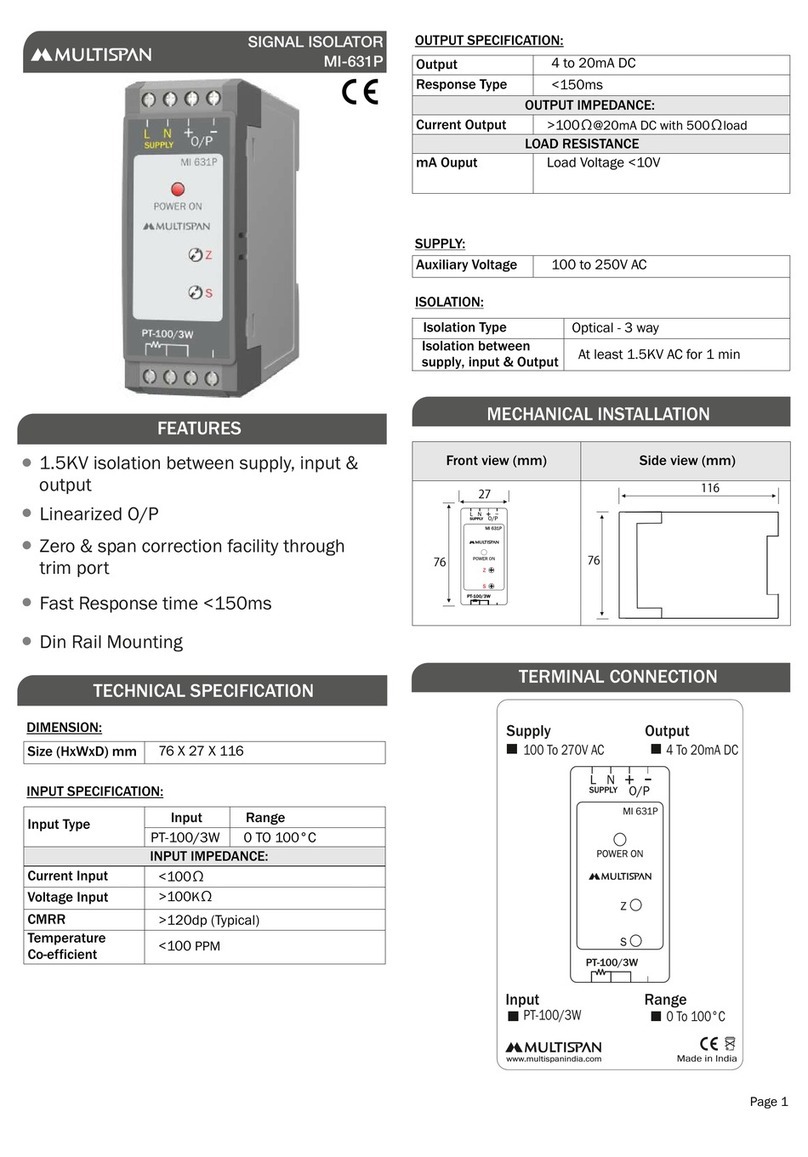

MULTISPAN MI-631P User manual

MULTISPAN

MULTISPAN AV-41CT User manual

MULTISPAN

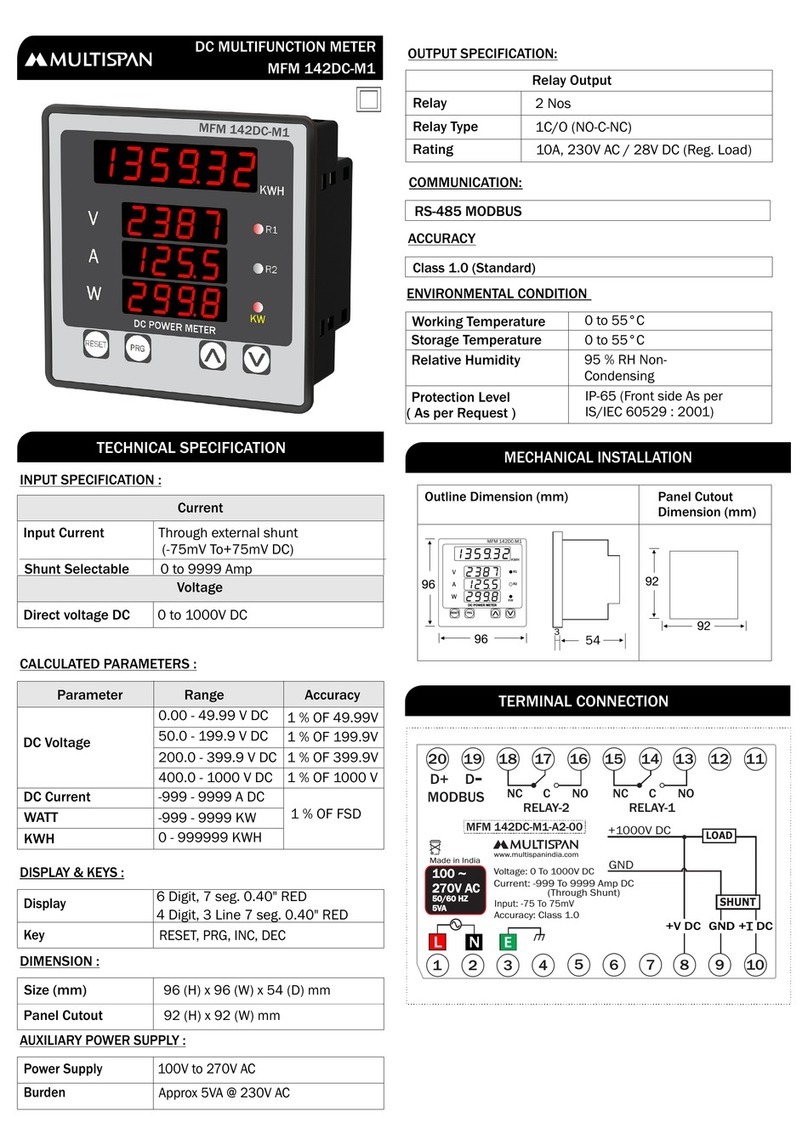

MULTISPAN MFM 142DC-M1 User manual

MULTISPAN

MULTISPAN LC-3006 User manual

MULTISPAN

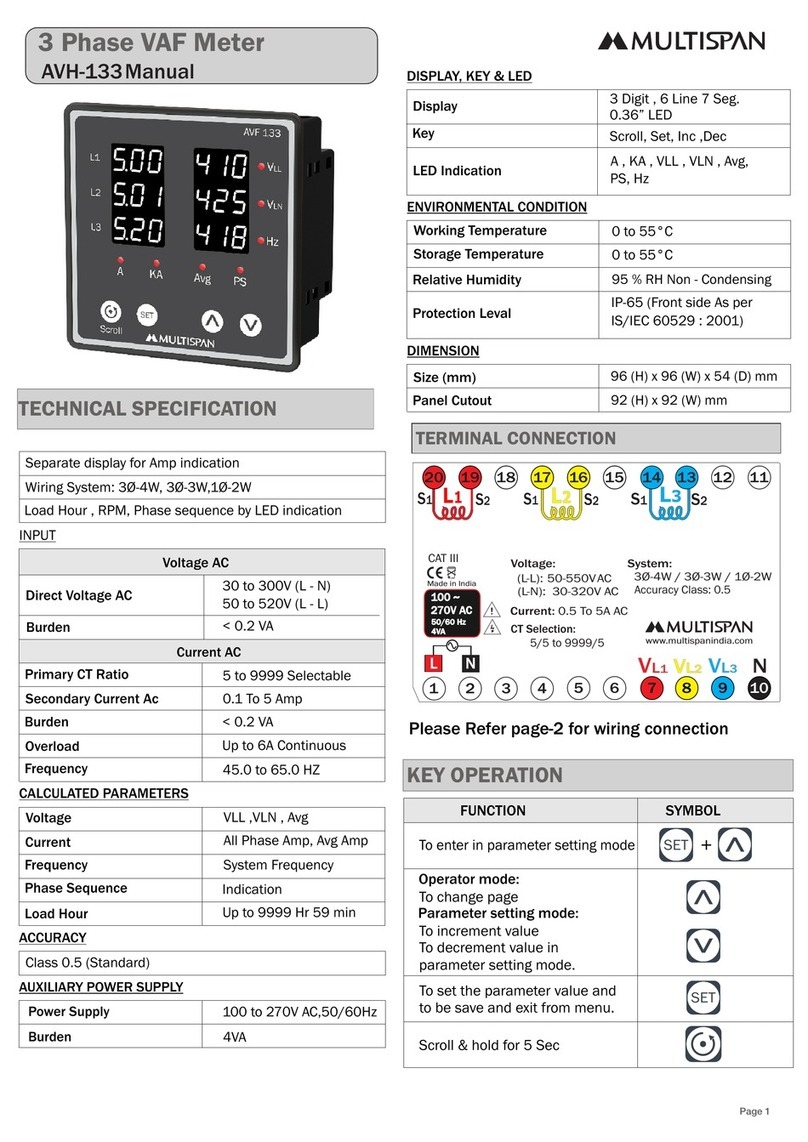

MULTISPAN AVH-133 Manual User manual

MULTISPAN

MULTISPAN EPM-13N User manual

MULTISPAN

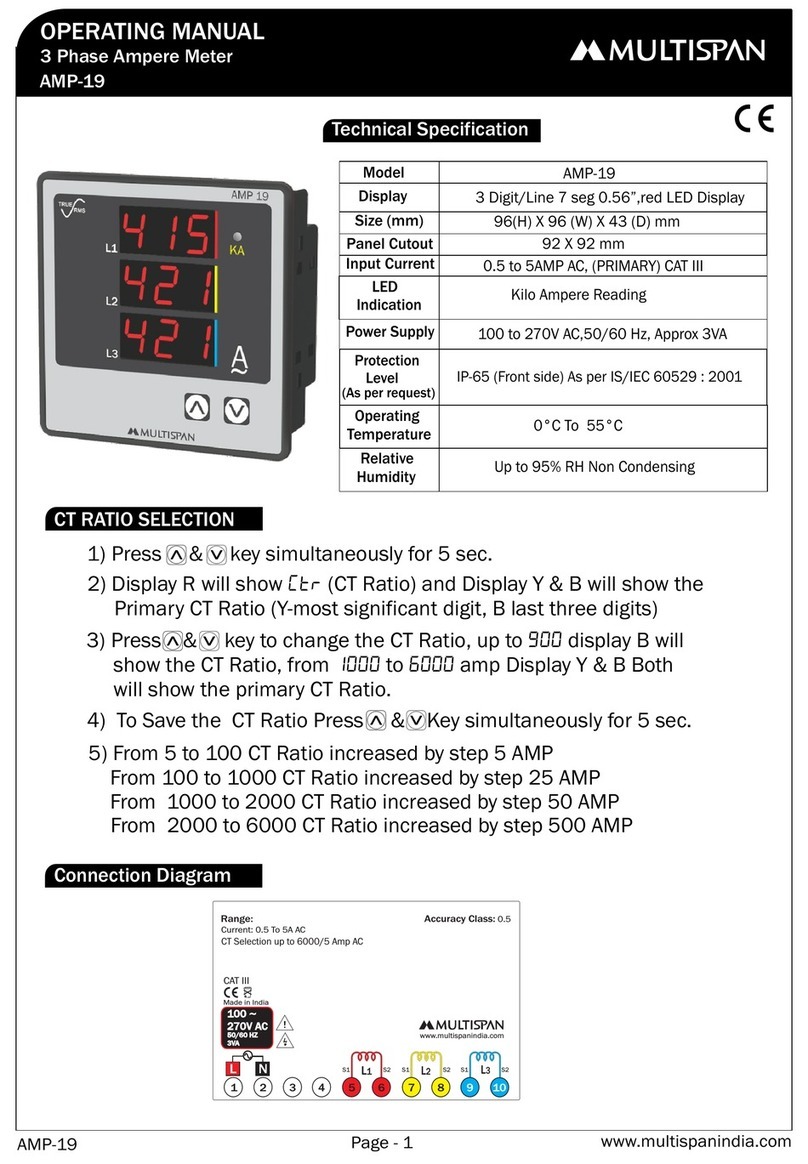

MULTISPAN AMP-19 User manual

MULTISPAN

MULTISPAN AVH-14N User manual

MULTISPAN

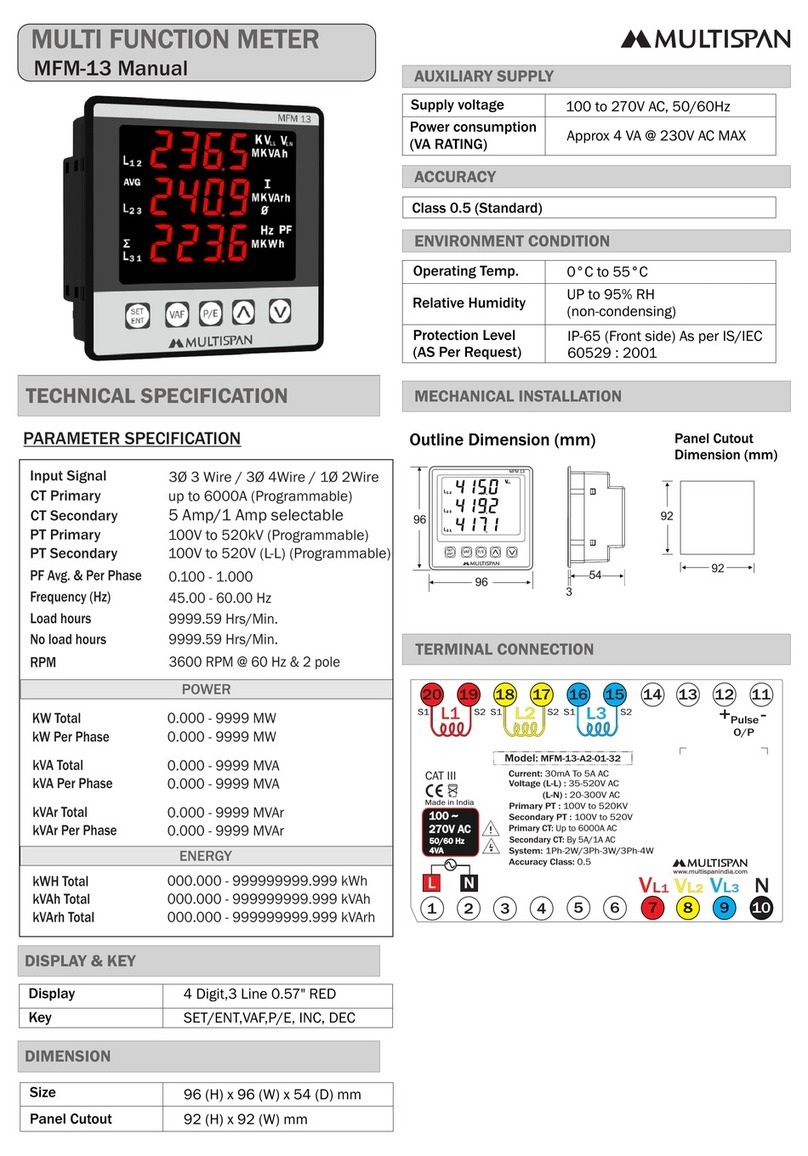

MULTISPAN MFM-13 User manual

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual