Version 1.06 IMC01 Maintenance Manua

Munbyn,More choice for your growing business

Page 13 of 26 Version 1.06 IMC01 Maintenance Manua Page 14 of 26

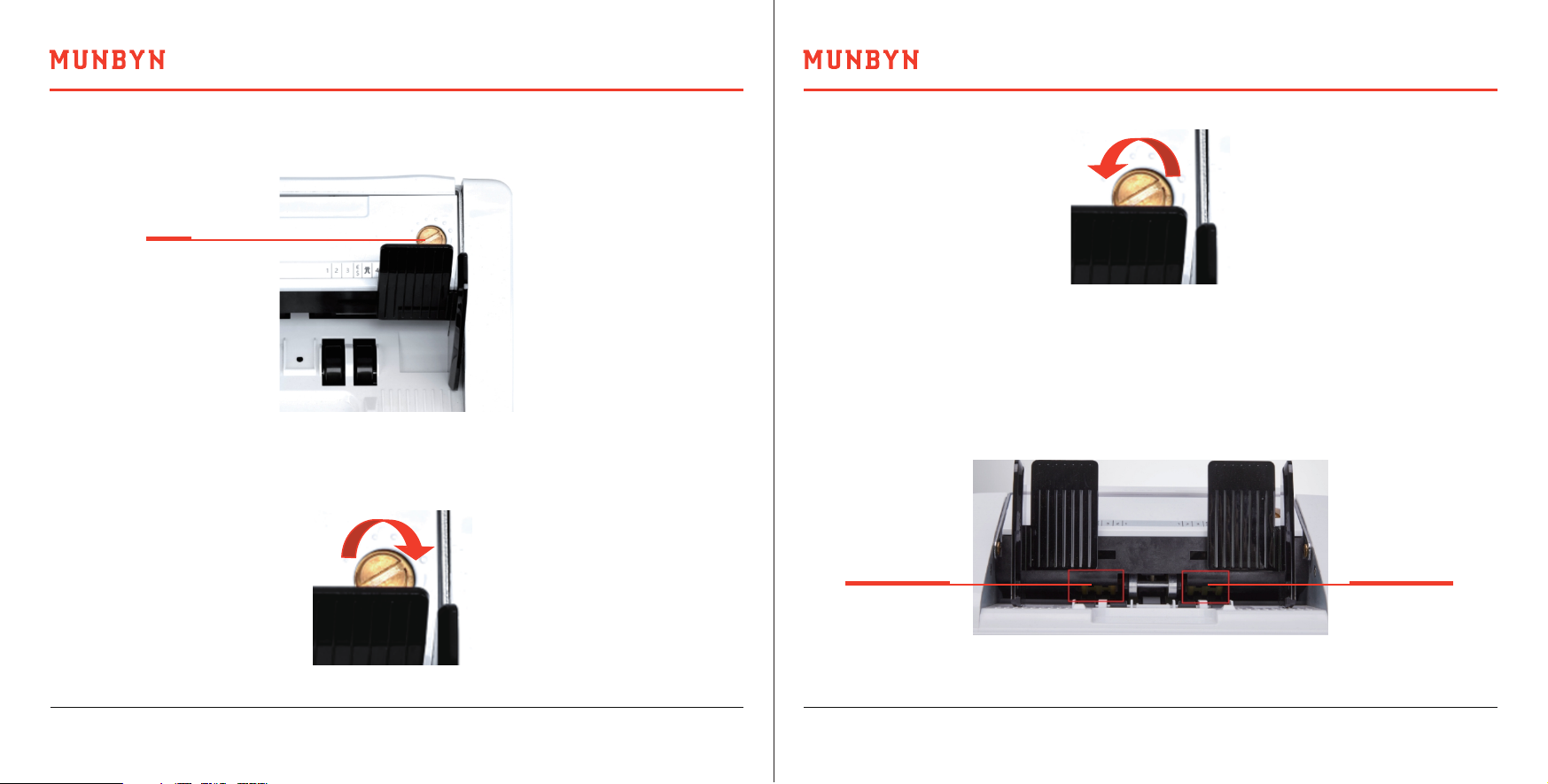

3) If the banknote is hard to inserted, that means the feeding gap is too small, please rotate

the screw clockwise until the banknote can be inserted smoothly. If the feeding gap is

so large that two or more banknotes can be inserted to the feeding gap, please rotate

the screw counterclockwise until the gap can just allow one banknote inserted.

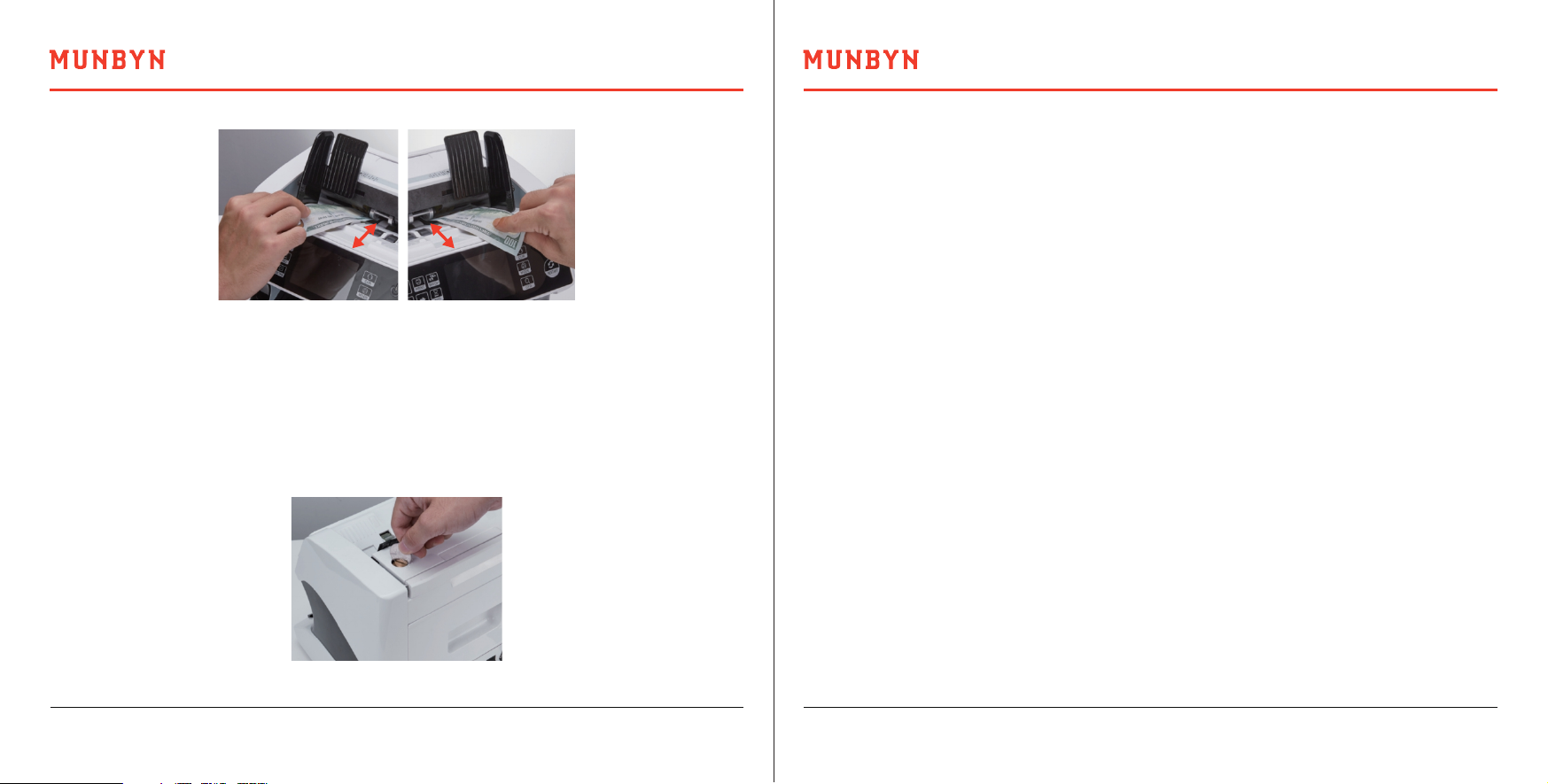

4) Use the banknote to check the other sides of the gap between rollers, to make sure the

banknote can be inserted into both sides of the feeding gap smoothly.

Having the correct feeding gap adjusted will ensure a smooth counting as well as

a trouble-free operation. Trial and error attempts are recommended before you make

the final adjustment and start the count.

You may also perform this adjustment when the banknotes are not fed smoothly through

the machine or several error messages are occurring too often like Bill Double Error,

Chain Notes Error or Half Notes Error.

Other reasons that might require to readjust the feeding gap are:

- The counting of new or mint condition notes

- The counting of poor or bad fitness condition notes

- Polymer notes and Paper-made notes counted together

Tips : you can just use one coin to rotate the screw.

Figure 5-5 One banknote to Check the Gap between the Rollers

Figure 5-6 One Coin to Rotate the Screw

Munbyn,More choice for your growing business