Murata ZRB157R61E225KE11 Series User manual

Other Murata Industrial Electrical manuals

Murata

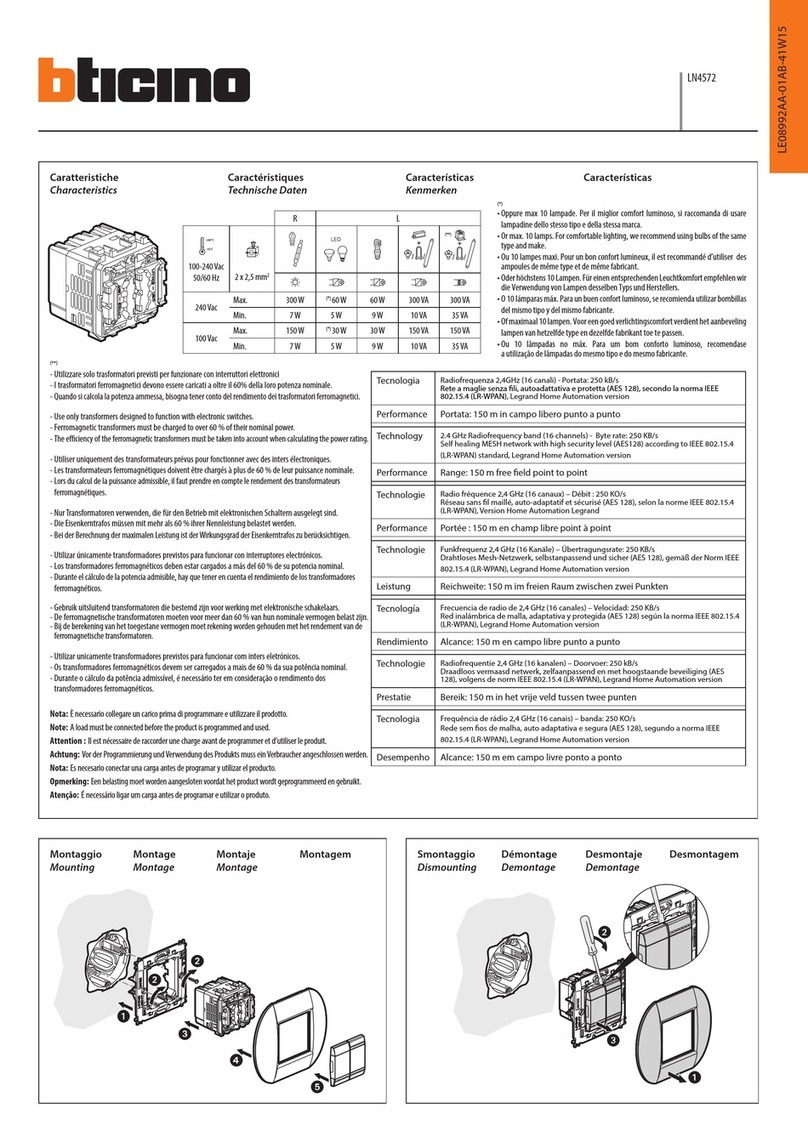

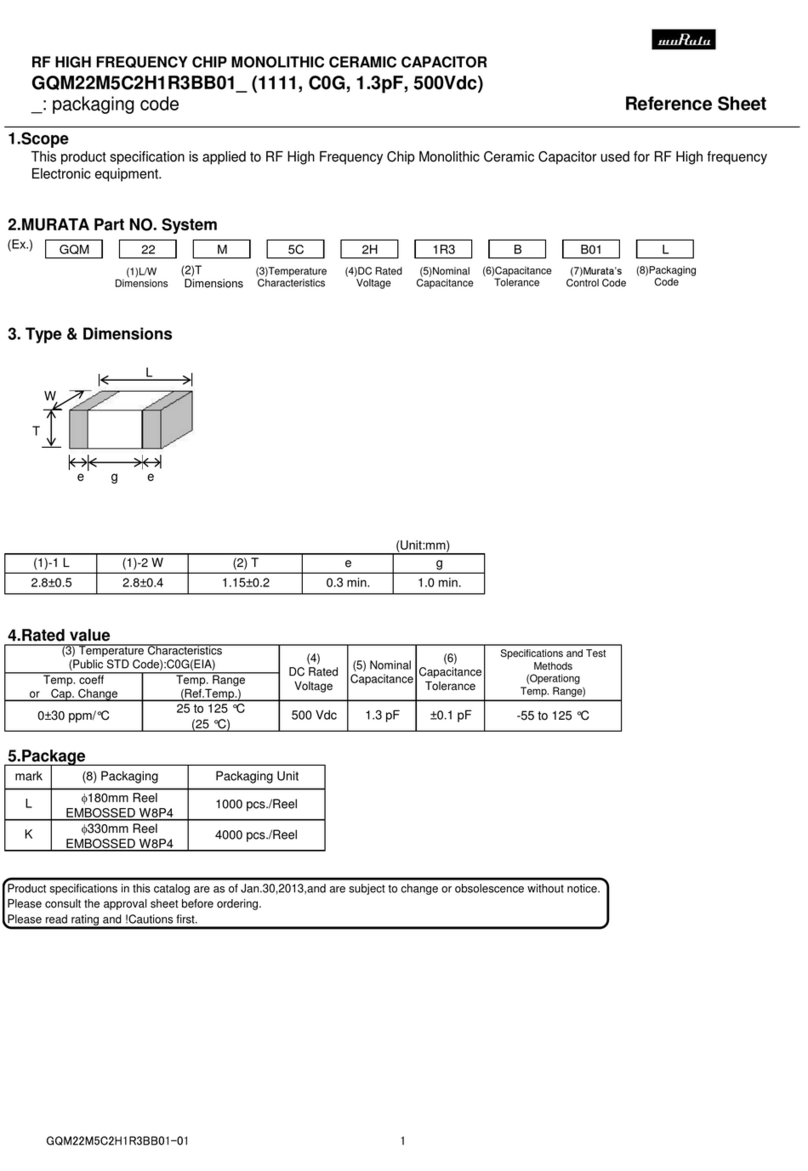

Murata GQM22M5C2H1R3BB01 Series User manual

Murata

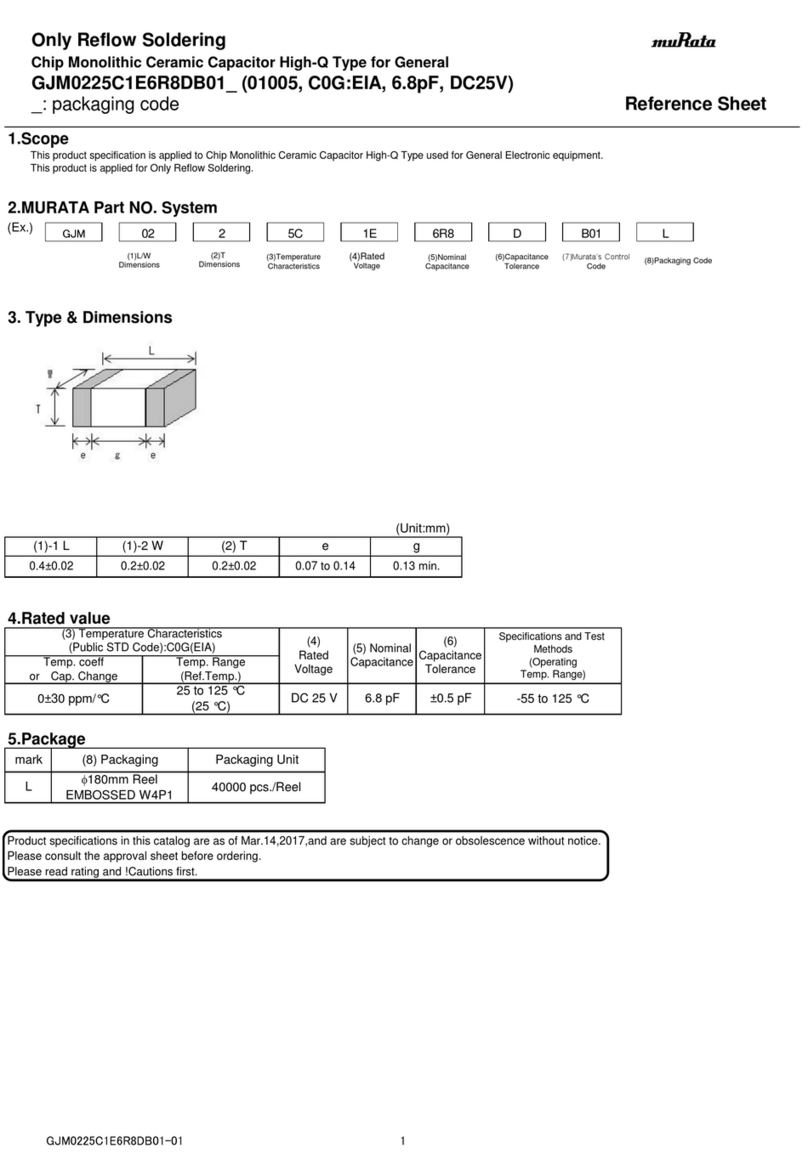

Murata GJM0225C1E6R8DB01 Series User manual

Murata

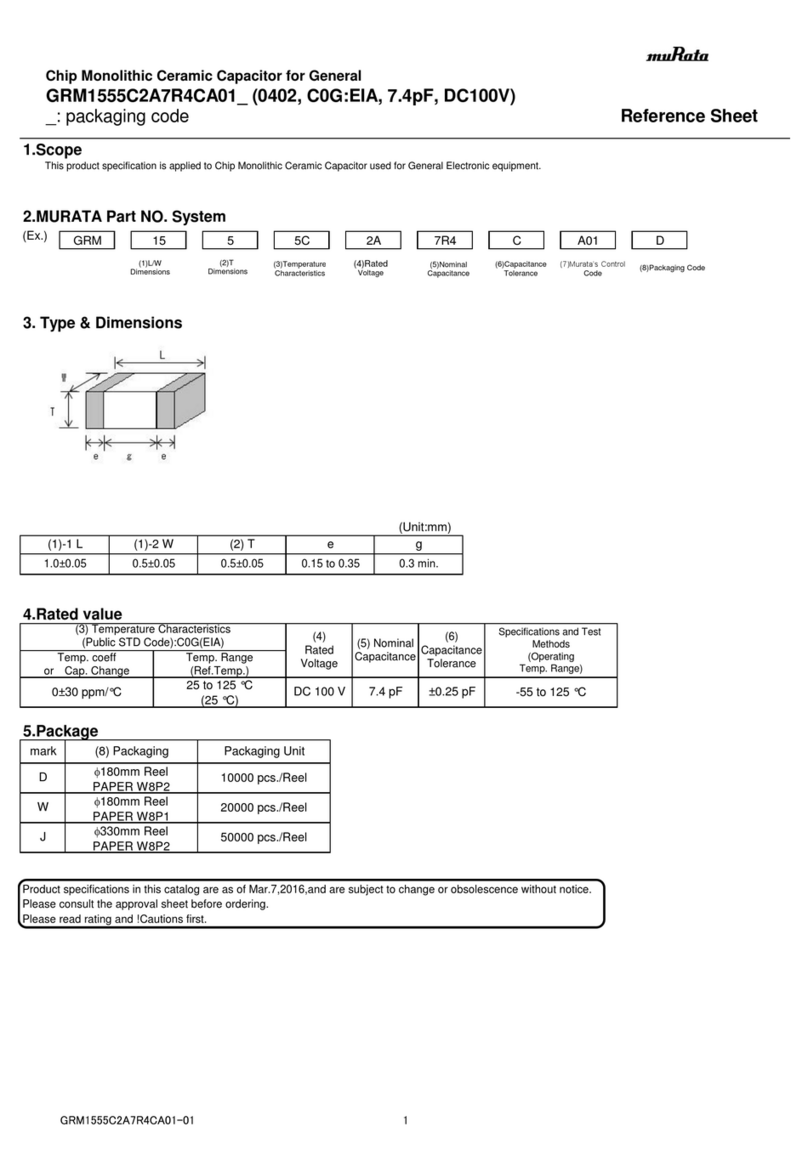

Murata GRM1555C2A7R4CA01 Series User manual

Murata

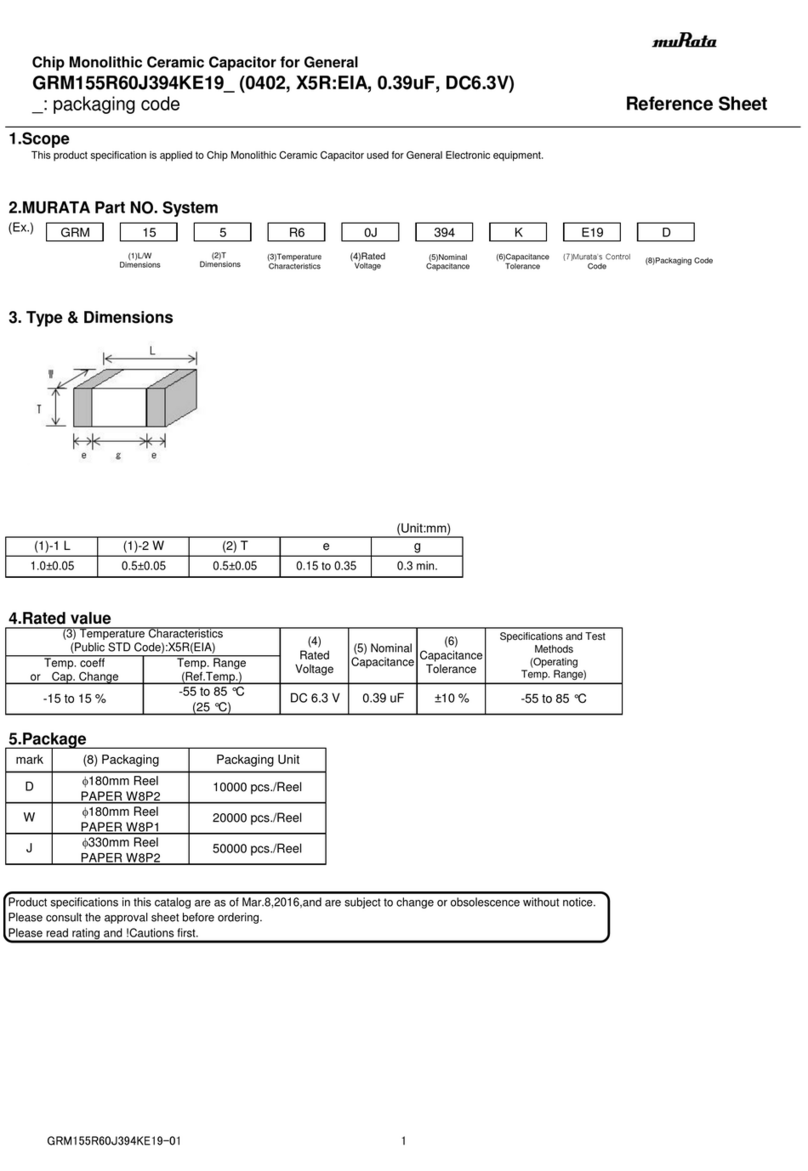

Murata GRM155R60J394KE19 Series User manual

Murata

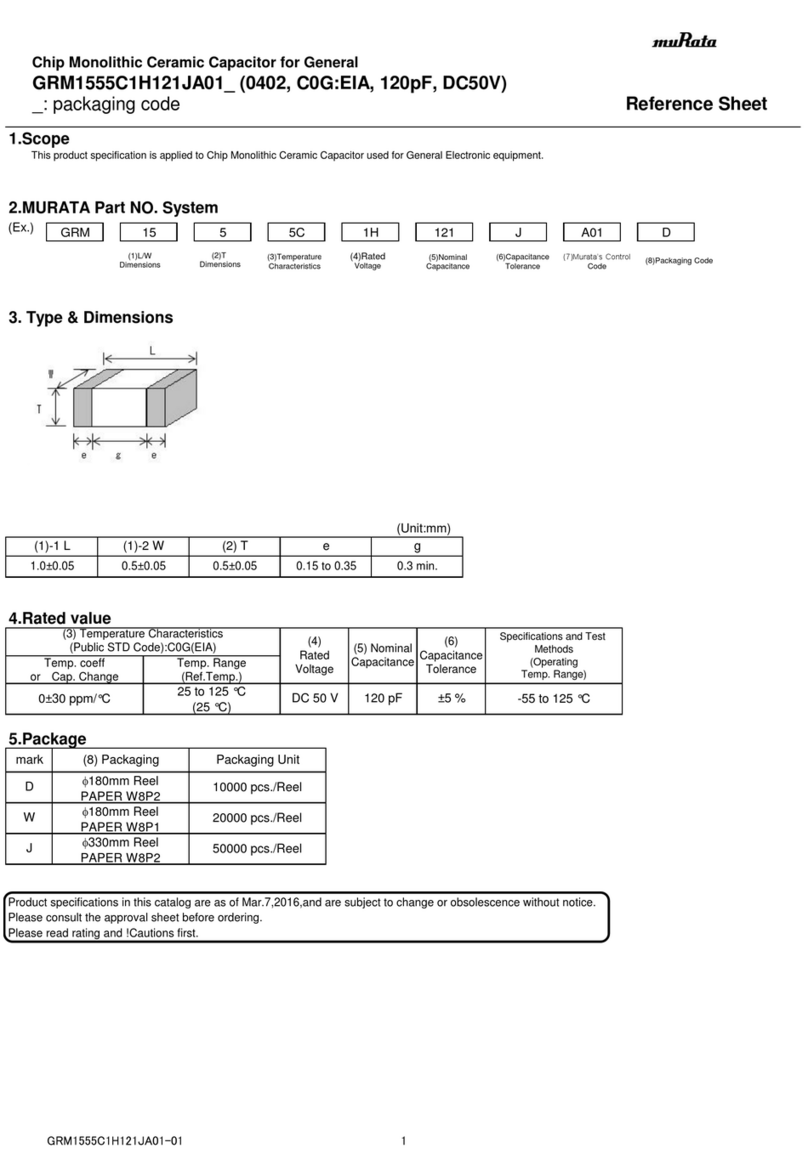

Murata GRM1555C1H121JA01 Series User manual

Murata

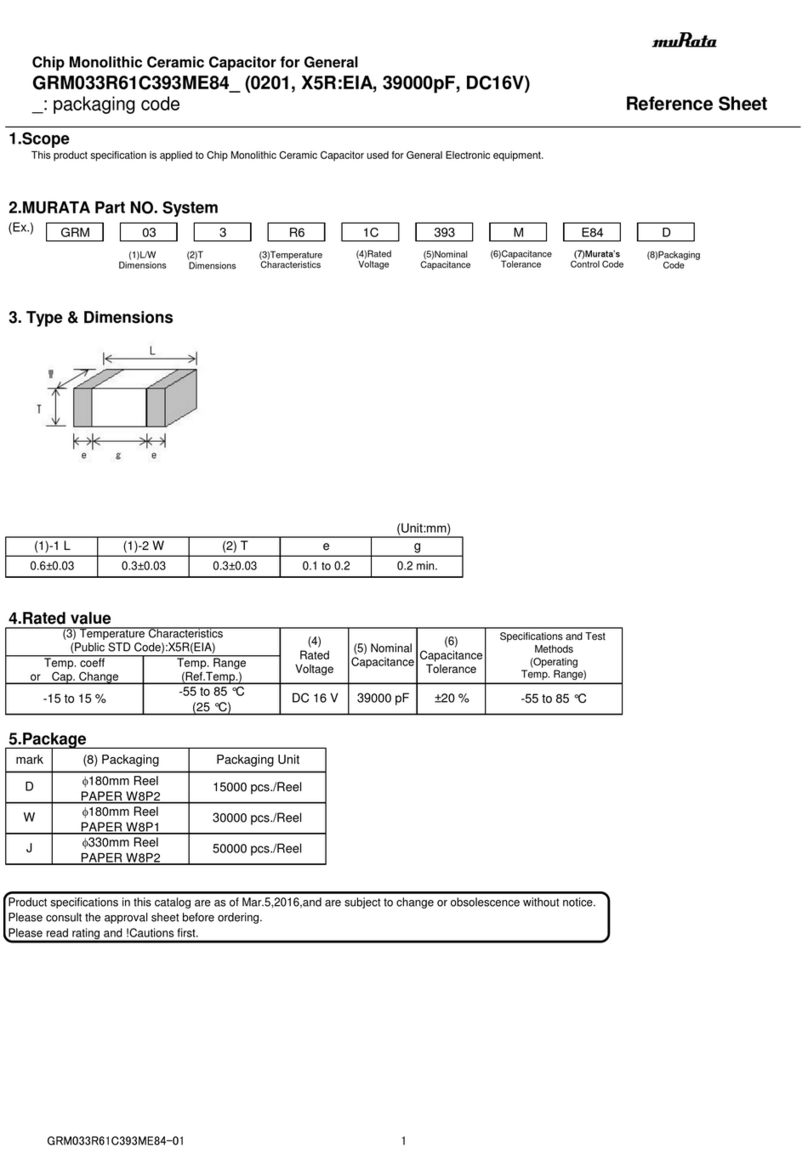

Murata GRM033R61C393ME84 Series User manual

Murata

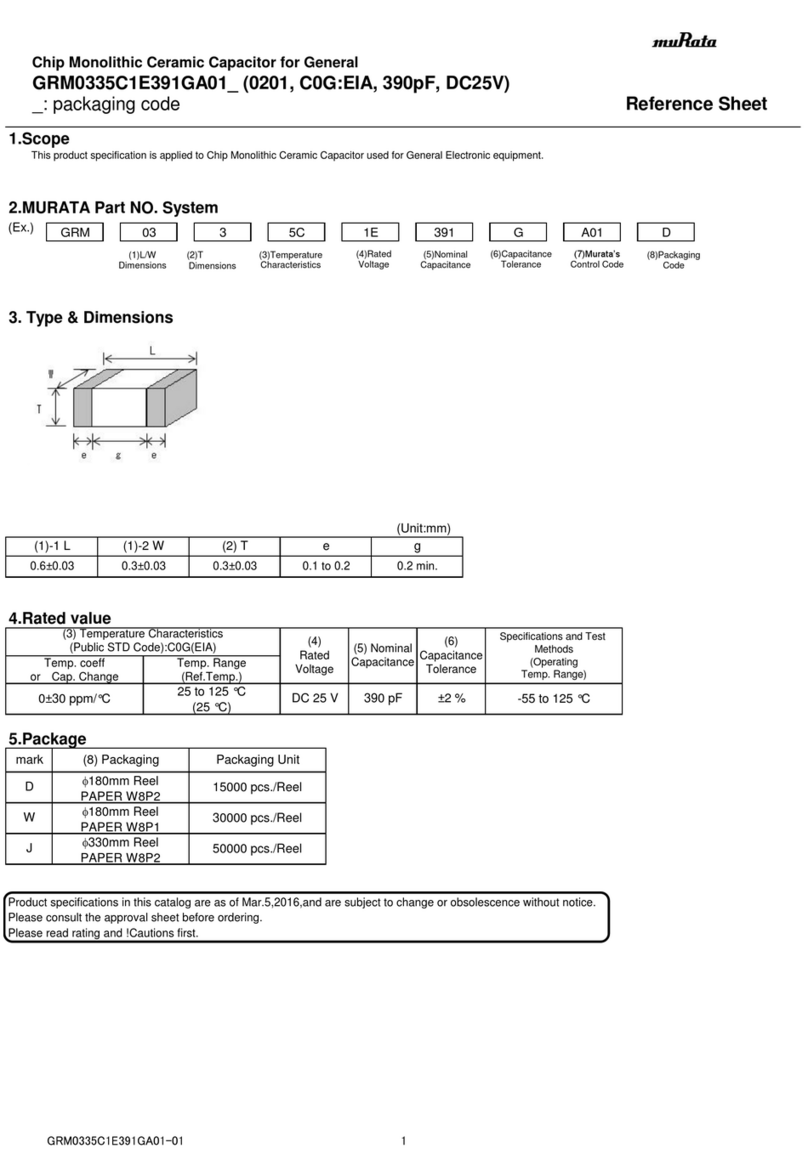

Murata GRM0335C1E391GA01 Series User manual

Murata

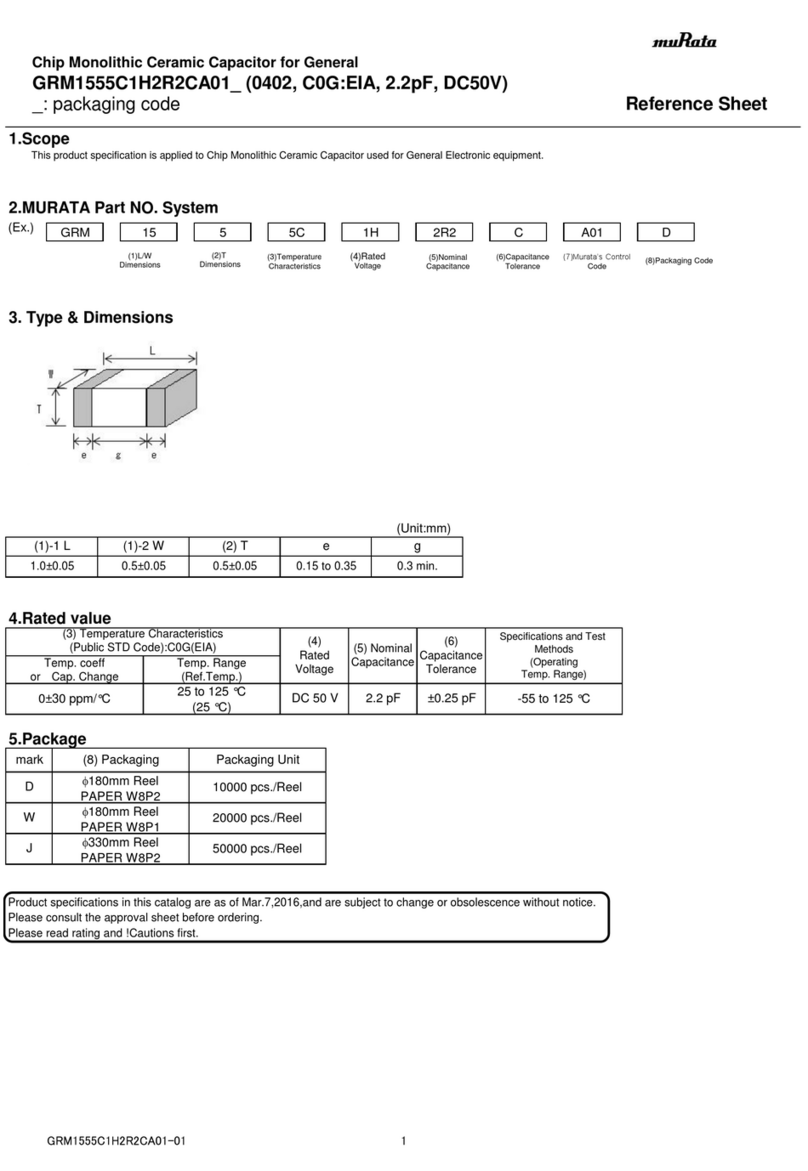

Murata GRM1555C1H2R2CA01 Series User manual

Murata

Murata GQM22M5C2H6R2DB01 Series User manual

Murata

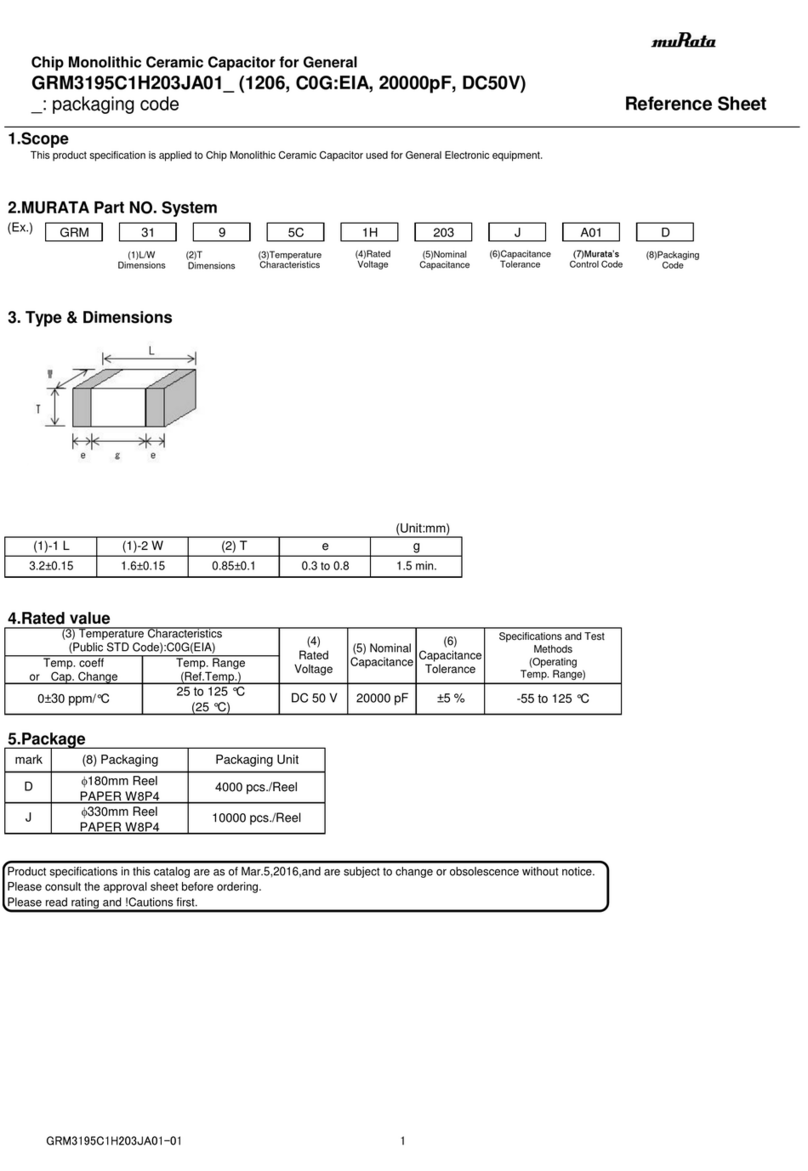

Murata GRM3195C1H203JA01 Series User manual

Murata

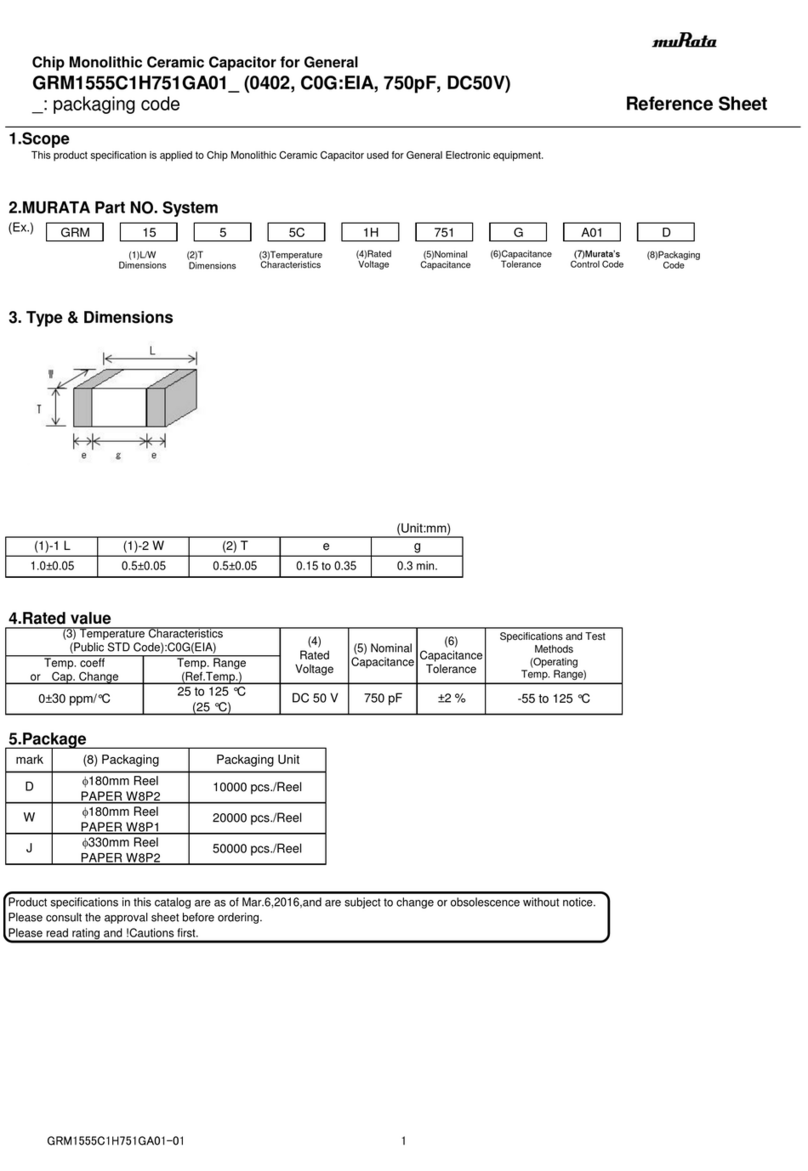

Murata GRM1555C1H751GA01 Series User manual

Murata

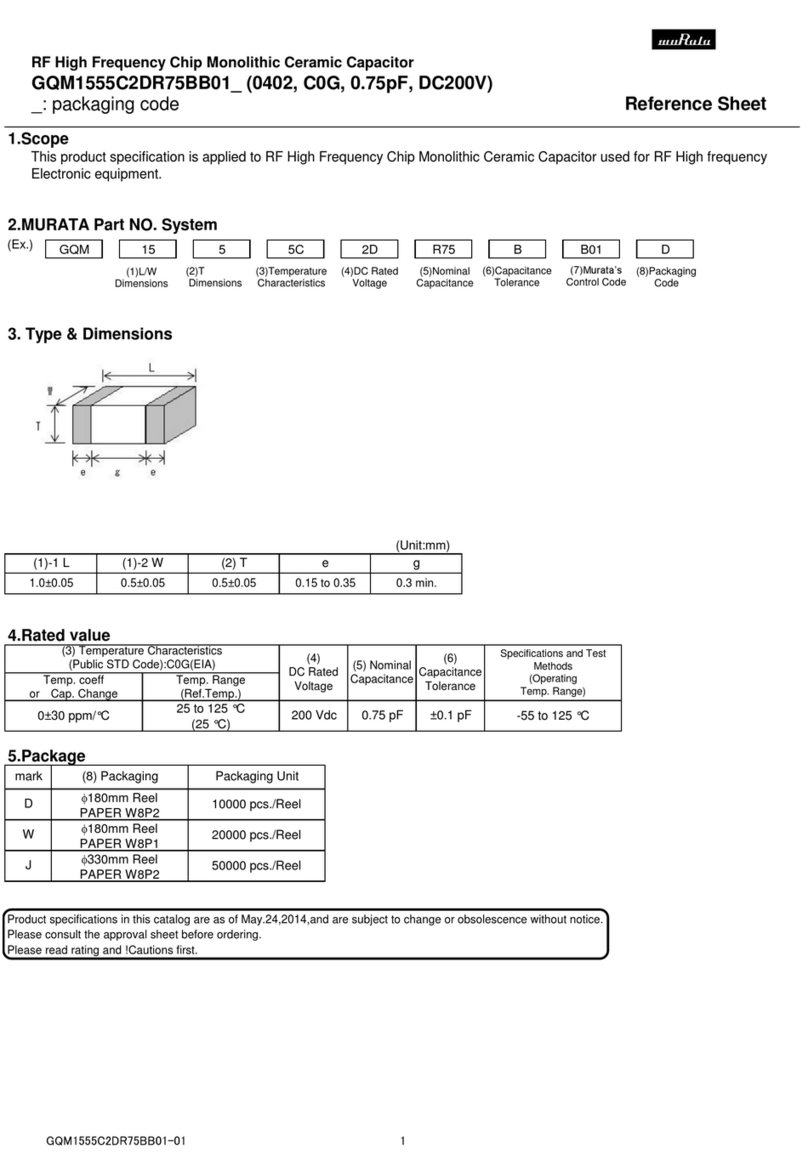

Murata GQM1555C2DR75BB01 Series User manual

Murata

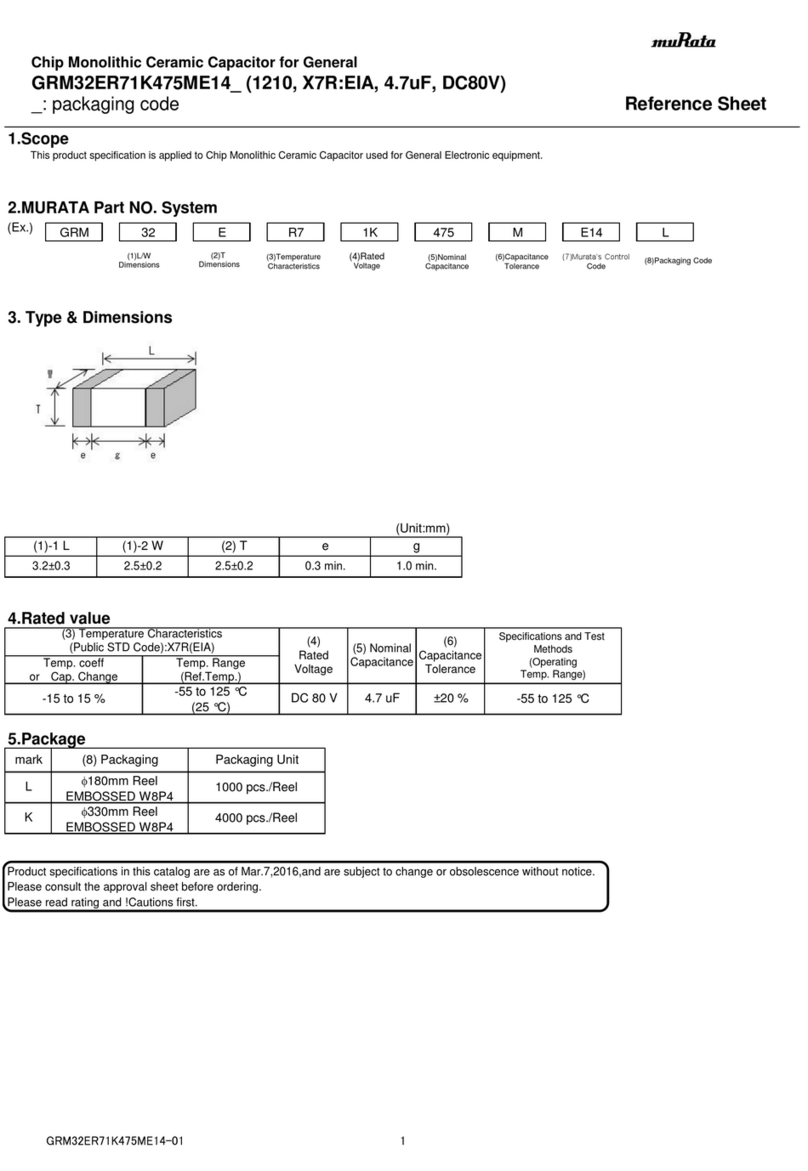

Murata GRM32ER71K475ME14 Series User manual

Murata

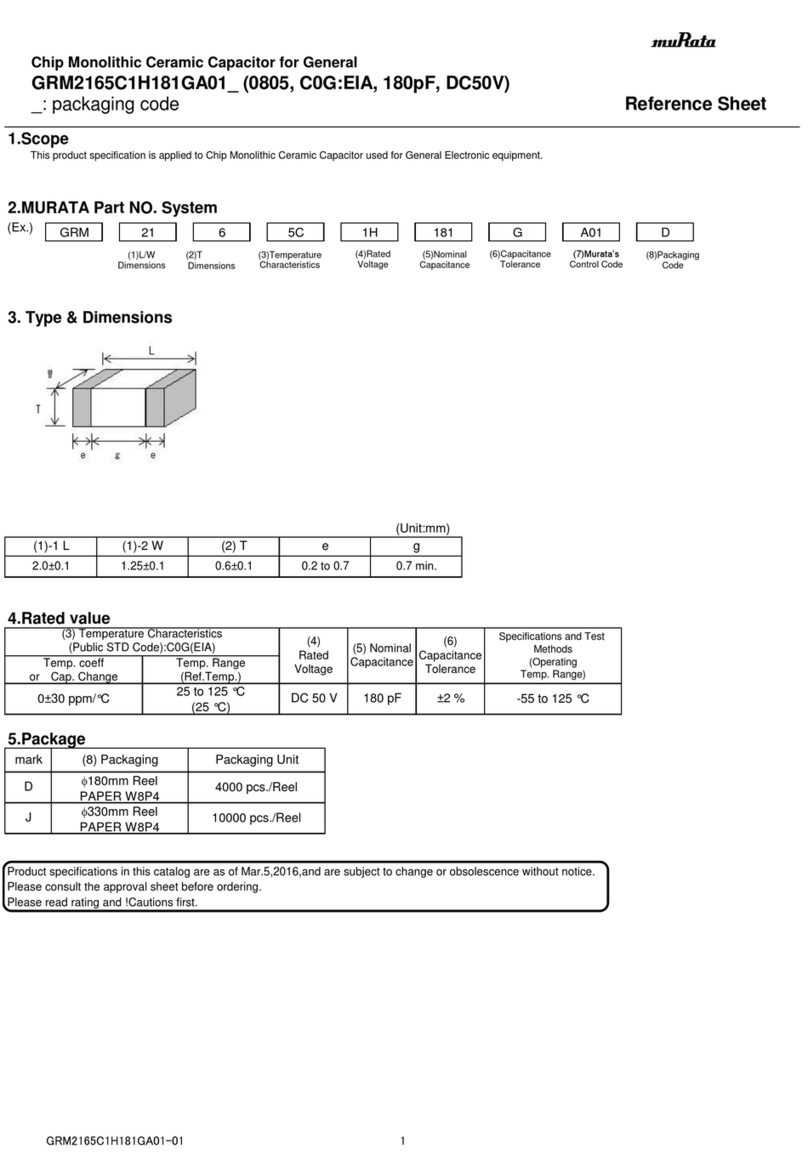

Murata GRM2165C1H181GA01 Series User manual

Murata

Murata GRM319R71H124KA01 Series User manual

Murata

Murata GRM21BF51E225ZA01 Series User manual

Murata

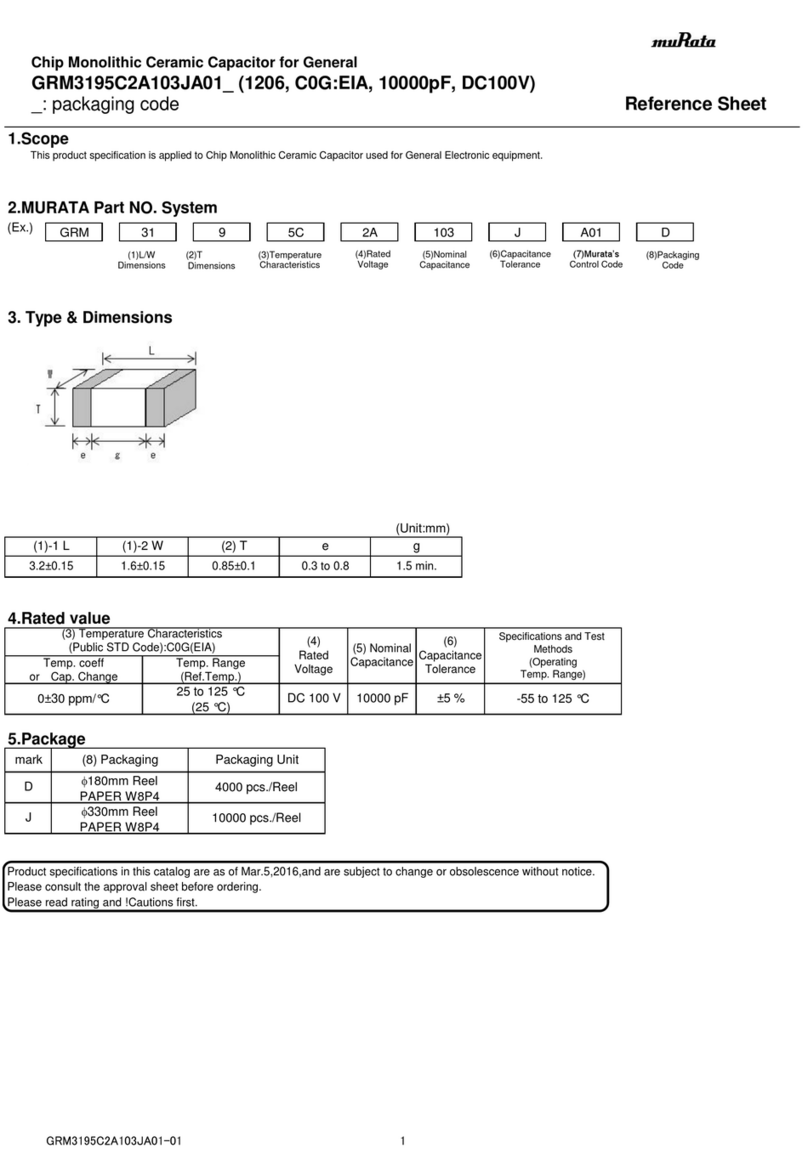

Murata GRM3195C2A103JA01 Series User manual

Murata

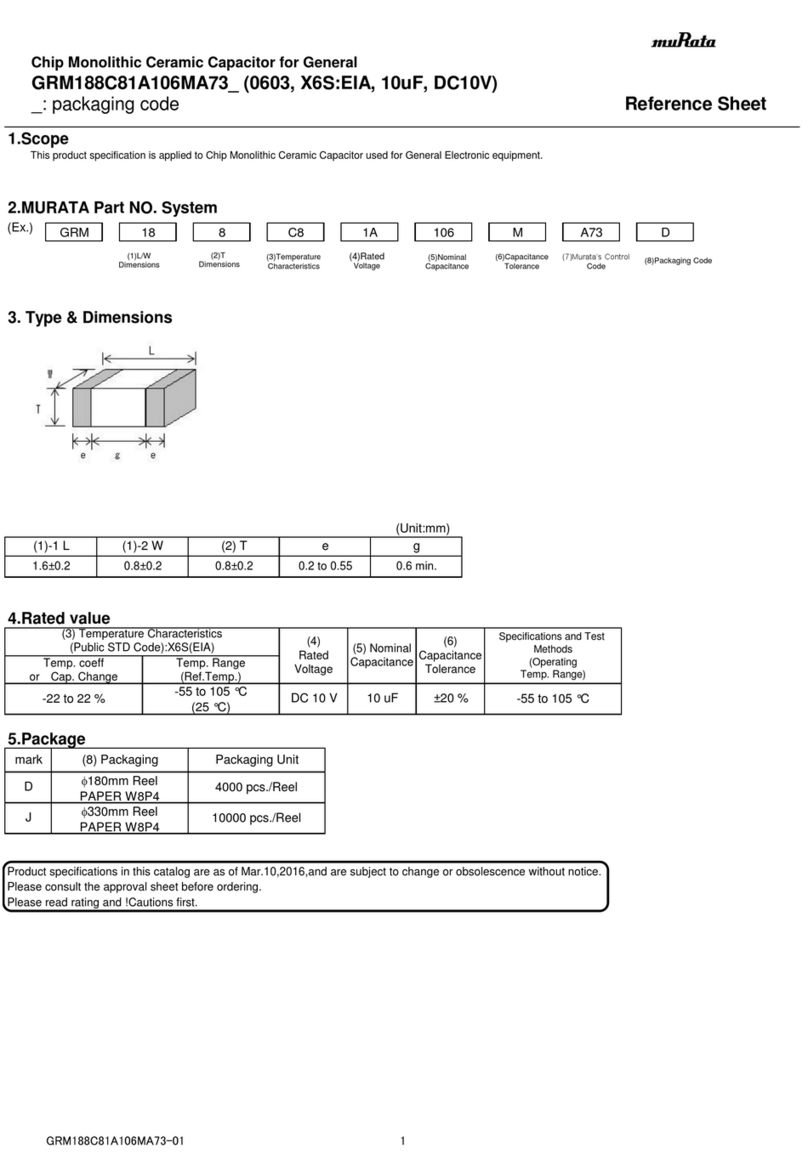

Murata GRM188C81A106MA73 Series User manual

Murata

Murata GQM2195C2E120GB12 Series User manual

Murata

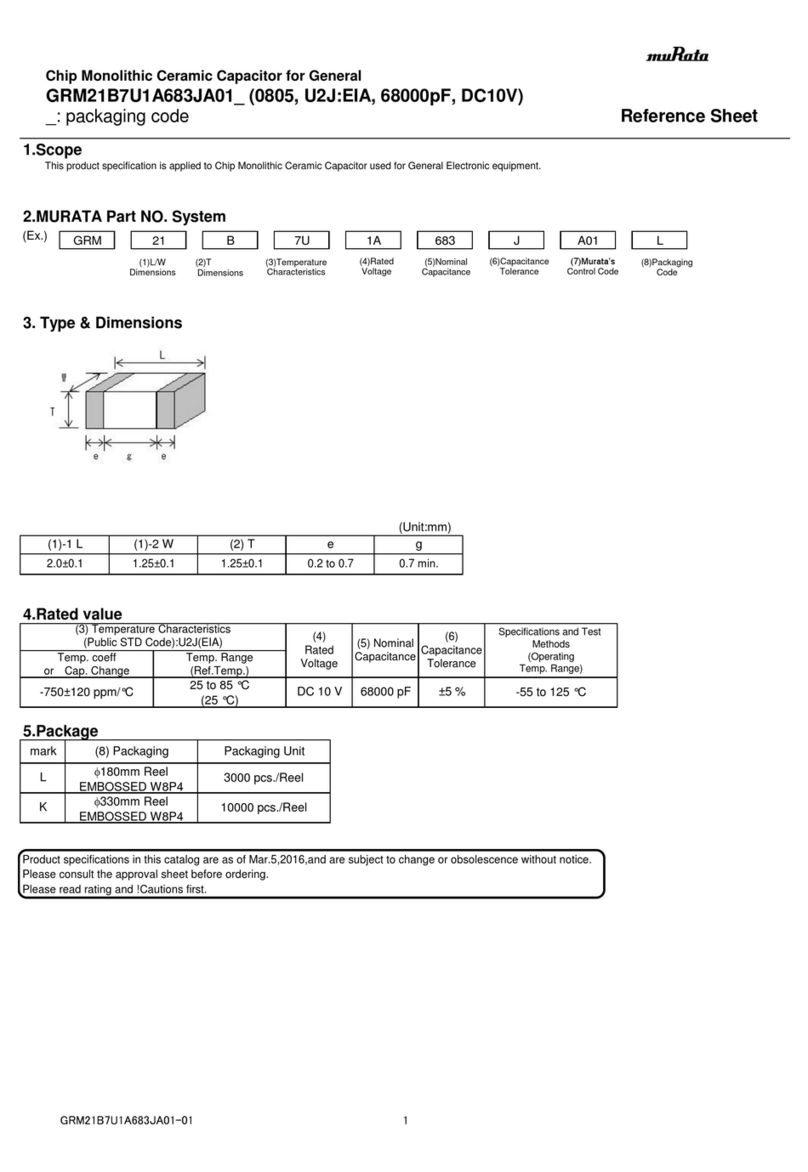

Murata GRM21B7U1A683JA01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

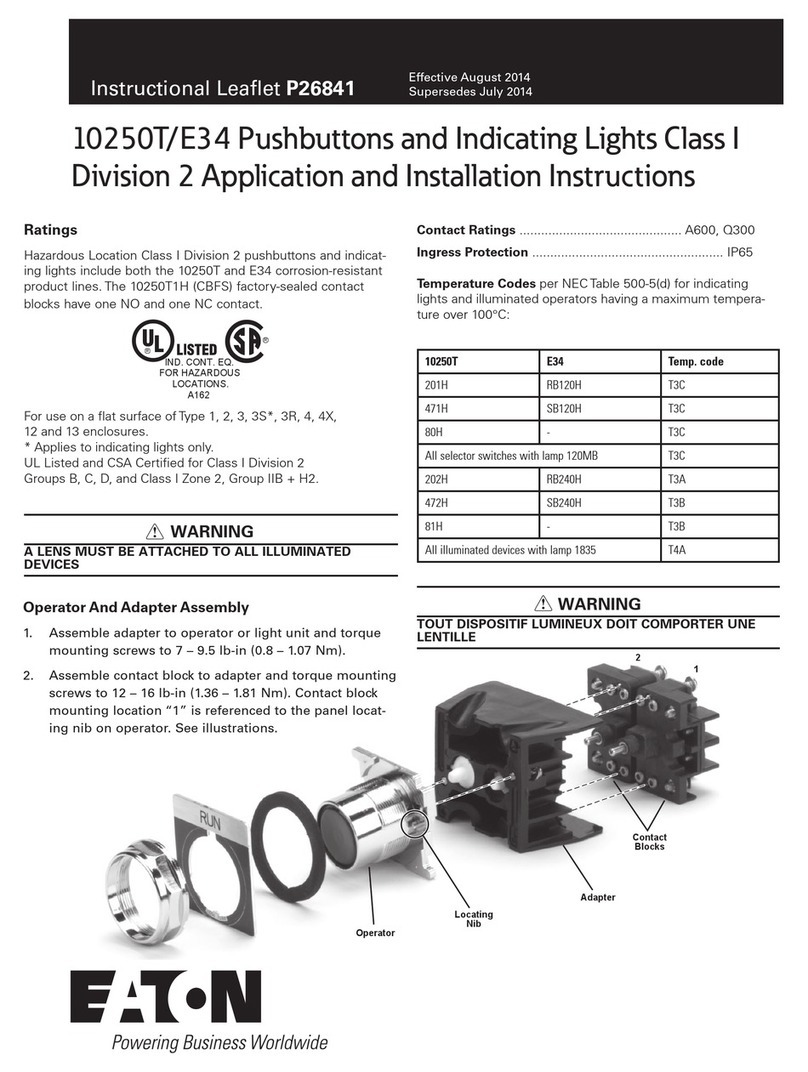

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

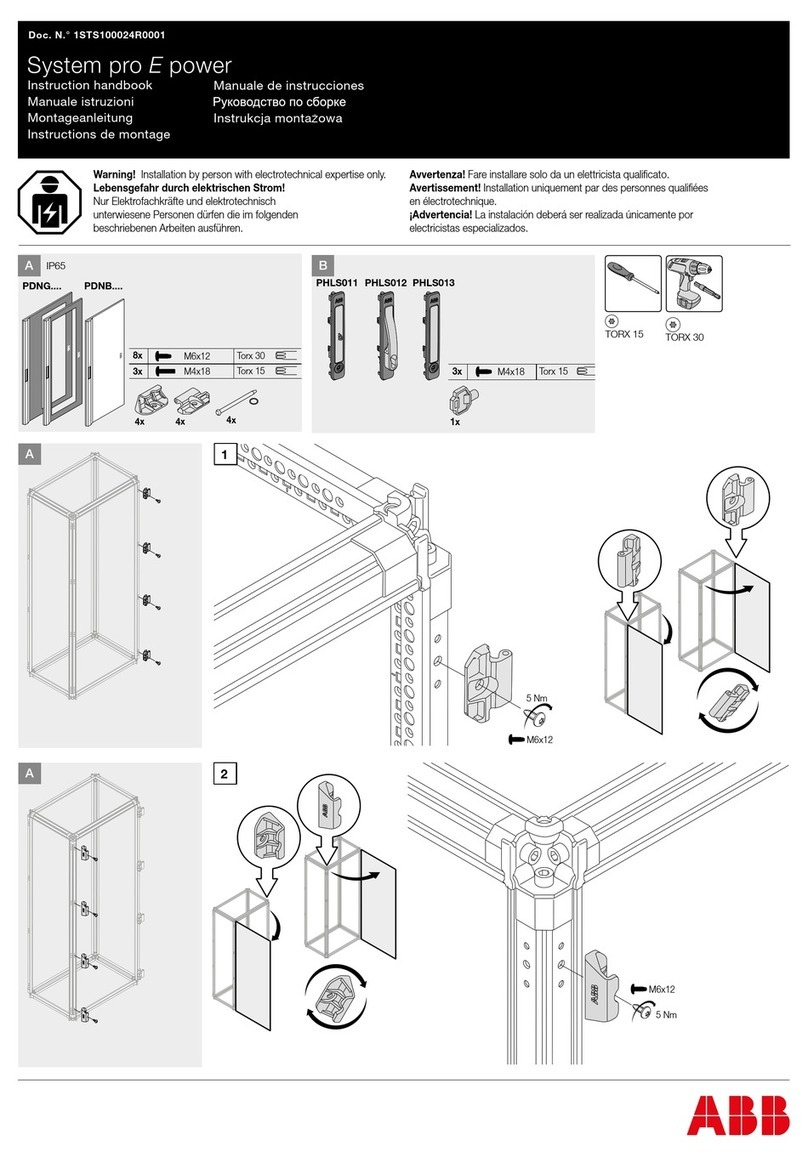

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions