Nagra III User manual

Other Nagra Recording Equipment manuals

Nagra

Nagra Ares-M Audio Recorder User manual

Nagra

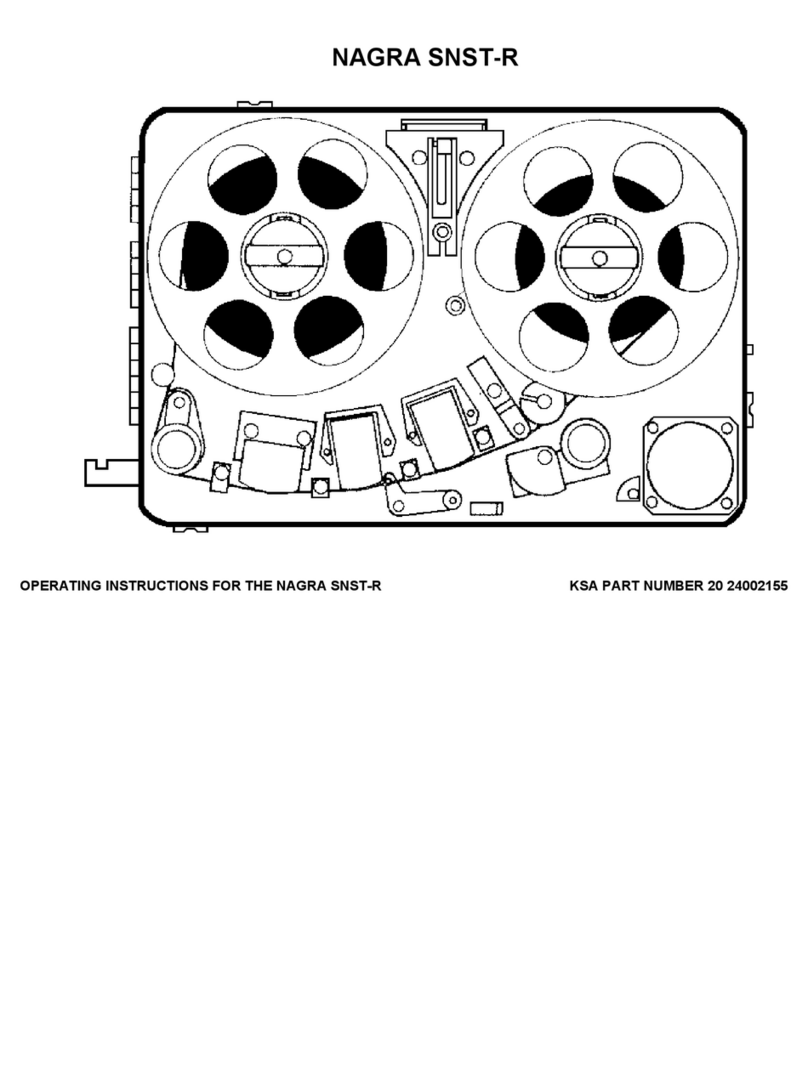

Nagra SNST-R User manual

Nagra

Nagra NAGRA-V User manual

Nagra

Nagra IV-S User manual

Nagra

Nagra LB User manual

Nagra

Nagra Nagra-D User manual

Nagra

Nagra Seven User manual

Nagra

Nagra IV D User manual

Nagra

Nagra IV-SJ User manual

Nagra

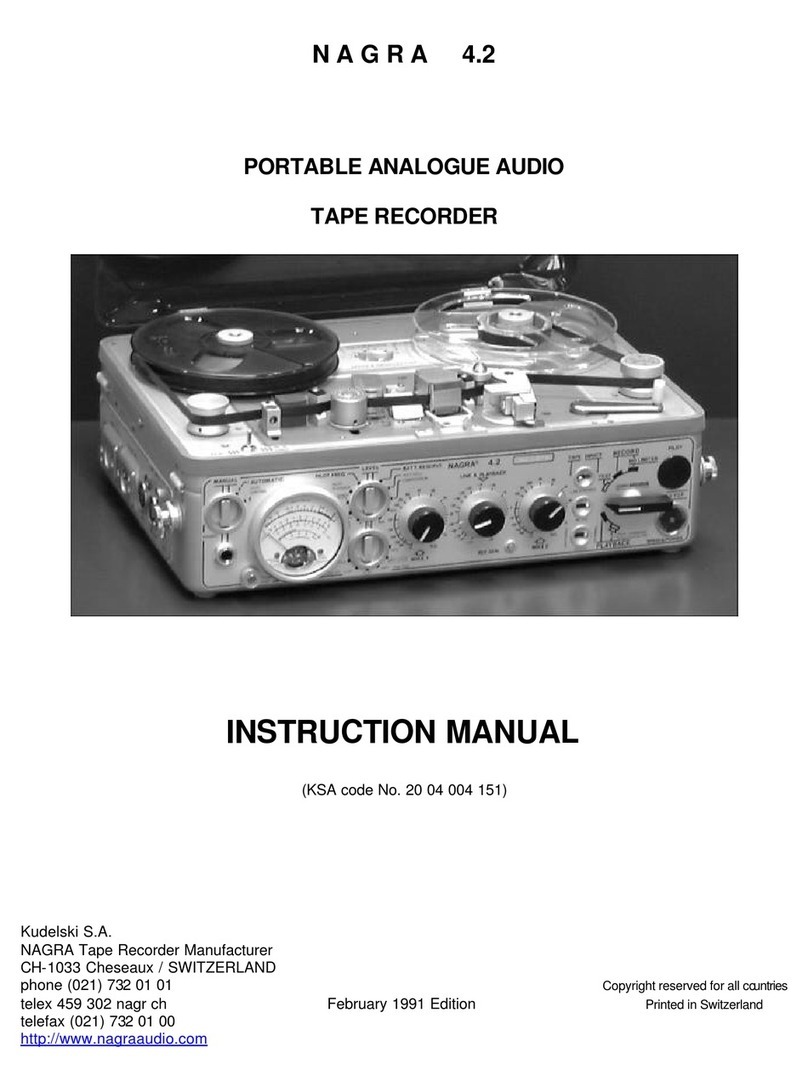

Nagra NAGRA 4.2 User manual

Nagra

Nagra Nagra-D User manual

Nagra

Nagra IV-SJ User manual

Nagra

Nagra ARES-C User manual

Nagra

Nagra ARES-BB Plus User manual

Nagra

Nagra E User manual

Nagra

Nagra IV-SJ User manual

Nagra

Nagra PORTABLE ANALOGUE AUDIO TAPE RECORDER User manual

Nagra

Nagra NAGRA-SD User manual

Nagra

Nagra Ares-M User manual

Nagra

Nagra NAGRA 4.2 User manual