INTRODUCTION

USING THIS

MANUAL

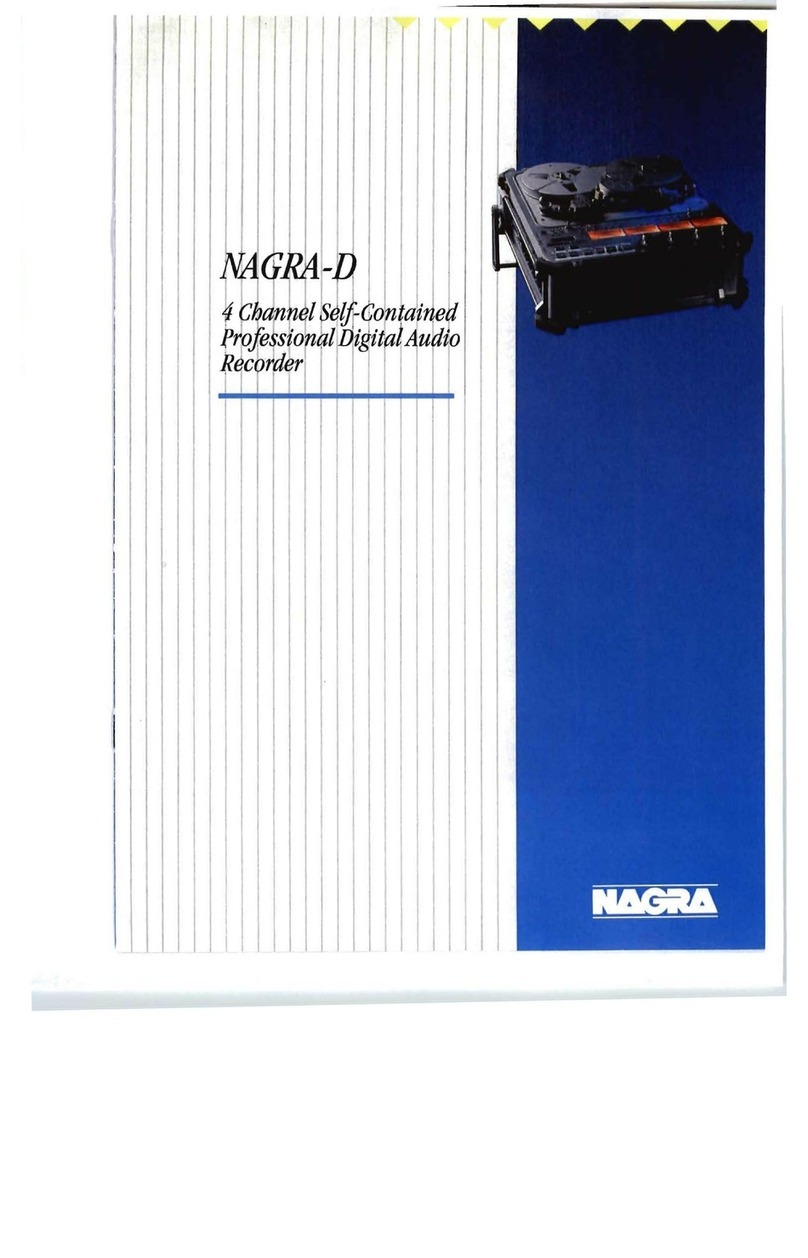

This instruction manual is designed to enable the operator to understand, and use the NAGRA-D.

The basic principles

of

audio recording or digital technology are not covered, except where the

concept within the

NAGRA-D

is different from that normally app'lied. The manual is broken down into

chapters covering different aspects of the machine. At the end

of

the manual there is a

comprehensive index, which should guide the operator to the correct page quickly. The pages are

numbered from 1 to N for each chapter.

If

in

the future there is a page to be added in the middle

of

a

chapter, then the new page to

be

added will have a page number followed by a decimal point and

then

1,

2 or 3 etc. For example

if

a page is to

be

added between pages 5 and 6

of

a particular

chapter then the new page will be numbered 5.1. This manual covering Version 2.X software for the

NAGRA-D replaces all previous editions.

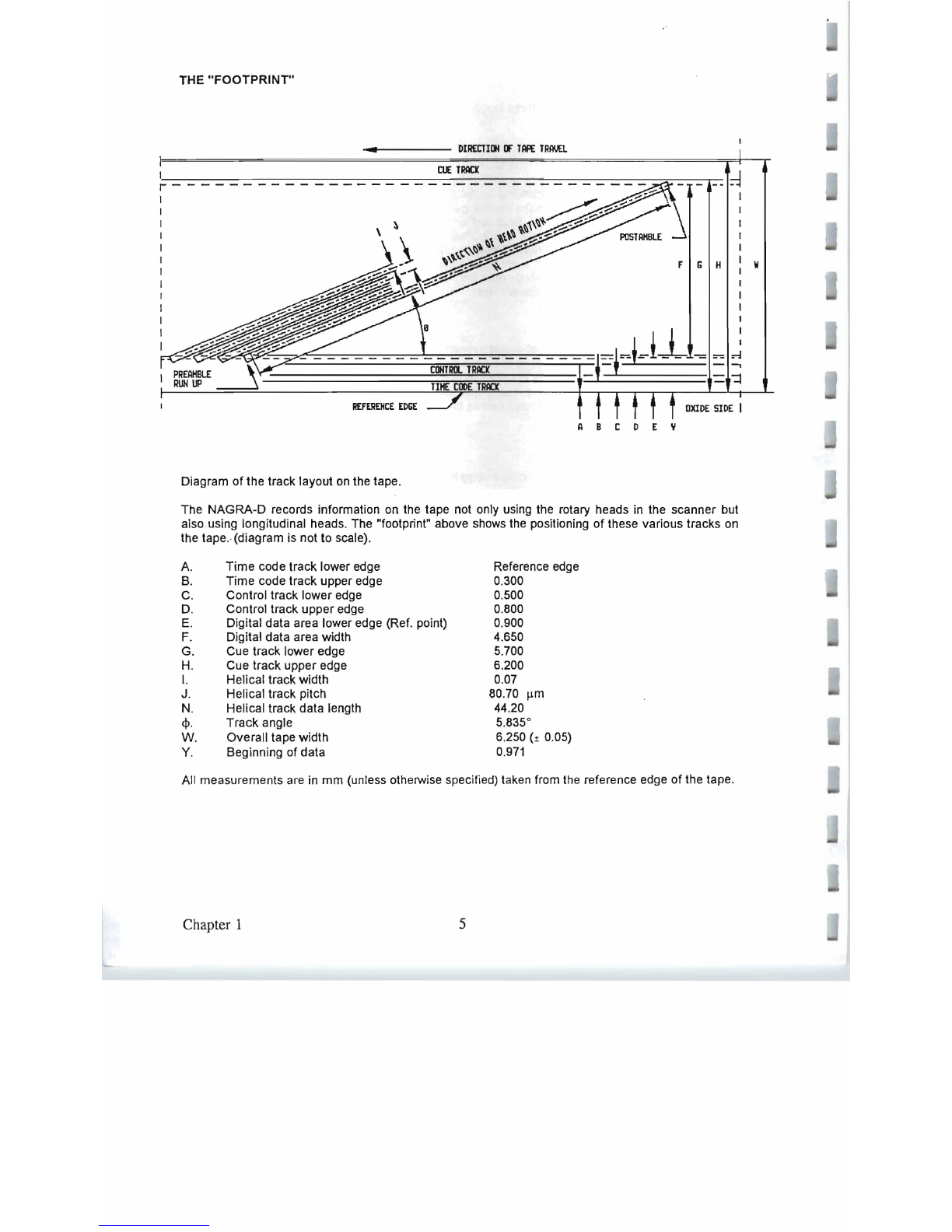

GENERAL

DESCRIPTION

The concept

of

the NAGRA-D was to build a truly professional machine based

on

a

format

that is

reliable and lends itself well to archiving. The arguments regarding the format, choice

of

tape etc. are

not covered here.

The NAGRA-D is a

four

channel digital audio recorder having 24 bits per sample recording

on

6.35mm metal oxide tape. It accommodates the sampling frequencies

of

32 kHz, 44.1 kHz and 48

kHz (with the on-board AID converters) rendering it suitable for all types

of

professional recording

applications. The NAGRA-D is transparent to the AES bus giving connection possibilities to a wide

range

of

external digital equipment, which even give it the possibility

of

recording at sampling

106

frequencies

of

64, 88.2 and 96 kHz. The format of the NAGRA-D records 4.608 x bits per

second, meaning that on a 5" reel

of

tape contains 16.03 x 109 bits (16 giga bits)

of

data. The

combination

of

selected tape speed and number of channels to be recorded gives tape durations to

satisfy all applications.

TAPE

DURATIONS

48

kHz

44.1

kHz

32

kHz

5" reel 4 channel mode 1 hr. 1

hr.

05 mins. 1 hr 30 mins.

2 channel mode 2 hrs. 2 hrs. 10 mins. 3 hrs.

7" reel 4 channel mode 2 hrs. 2 hrs. 10 mins. 3 hrs.

2 channel mode 4 hrs. 4 hrs. 20 mins. 6 hrs.

Apart from the two AES digital inputs, four analog inputs are available for either line

or

microphone

input sources.

When

in microphone operation each of the four inputs is switchable between Dynamic,

"T" powering,

+12V

phantom and +48V phantom. The Signal levels are adjusted using the input

sensitivity potentiometers, and the levels are indicated

on

the four microprocessor controlled meters.

The four head scanner

(2

for recording and 2 for playback) allows read after write (off tape

monitoring) which can be heard through the two, level adjustable, headphone outputs.

The three longitudinal tracks (Control, CUE

and

Time Code) give flexibility

of

operation and

additional features

never

before seen

in

a professional recorder.

Microprocessor control

of

the entire machine gives almost limitless possibilities, not only as far as the

digital recording is concerned, but also for external control, fault diagnosis, tape directory

management etc., from a PC equipped with the NADCOM software (KSA # 10514)

Chapter 1