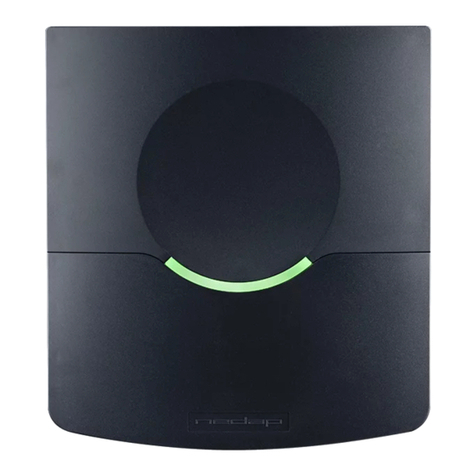

Nedap TRANSIT Entry User manual

Other Nedap RFID System manuals

Nedap

Nedap NVITE User manual

Nedap

Nedap PROX-BOOSTER 2G User manual

Nedap

Nedap uPASS Access User manual

Nedap

Nedap LibAssist User manual

Nedap

Nedap uPASS TARGET User manual

Nedap

Nedap MidRanger + Antenna Set User manual

Nedap

Nedap TRANSIT User manual

Nedap

Nedap uPASS REACH User manual

Nedap

Nedap TRANSIT Entry User manual

Nedap

Nedap VP1007-B User manual

Popular RFID System manuals by other brands

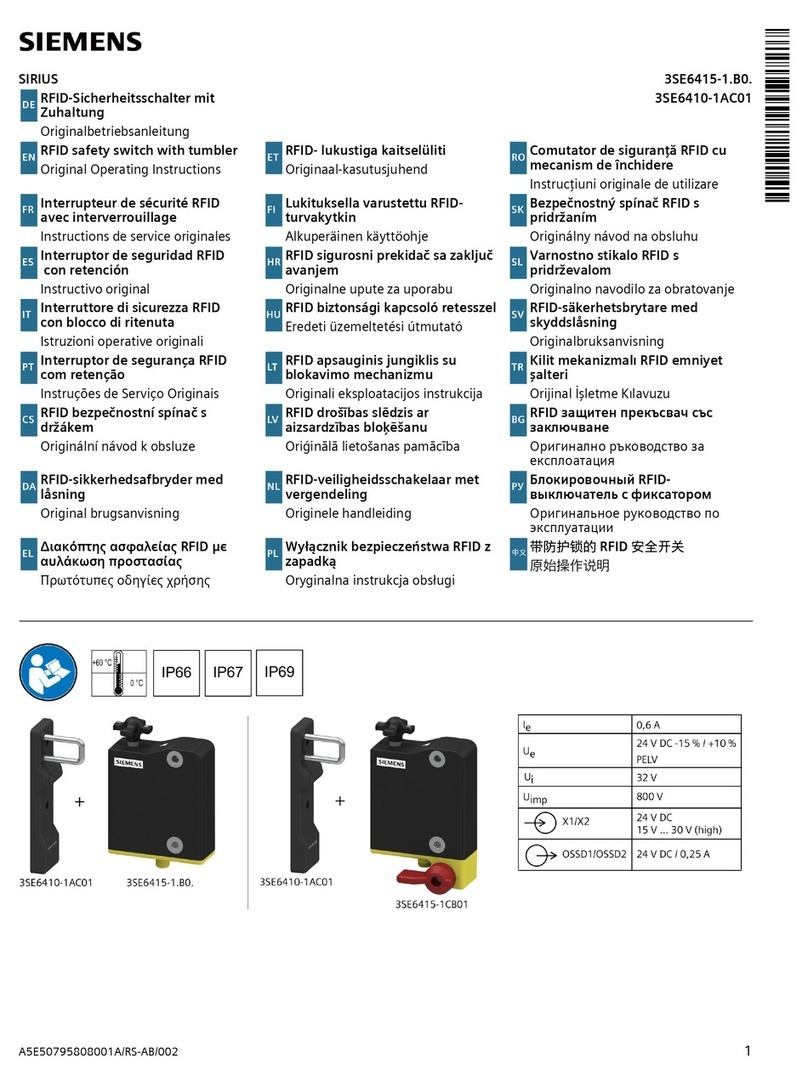

Siemens

Siemens SIRIUS 3SE6415-1 B0 Series Original operating instructions

Dormakaba

Dormakaba Quantum II RFID ECU installation instructions

RAK

RAK WisBlock RAK13600 quick start guide

Dahua Technology

Dahua Technology DH-ASR1200A user manual

Elatec

Elatec TWN4 MultiTech 2 HF Integration manual

GeoVision

GeoVision GV-RU9003 manual

LEGRAND

LEGRAND Bticino FL4649 quick start guide

ThingMagic

ThingMagic Sargas user guide

Dormakaba

Dormakaba access manager 92 30 Technical manual

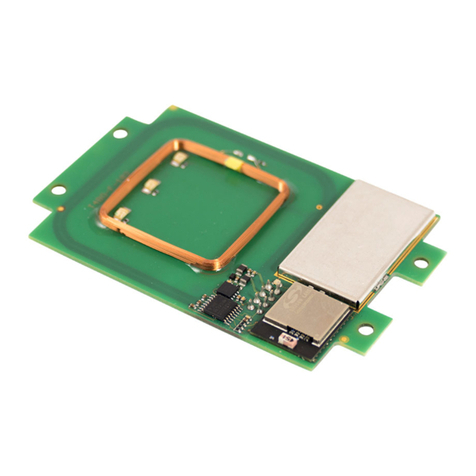

Convergence System Limited

Convergence System Limited CS108 quick start guide

United Technologies

United Technologies interlogix ACL805SUW-RDPX Installation sheet

XPR Access

XPR Access MTPX-RS-MF user manual