3

INSTALLER INSTRUCTIONS

nekos products have been manufactured in accordance with safety standards and conforms to the

stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

DANGER This indication draw the attention about potential dangers for safety and

health of peoples and animals.

Contents

1. Security rules .................................................................................................................. 4

2. Formulas and recommendations for installation .............................................................. 5

2.1. Calculation of opening / closure force ........................................................................ 5

2.2. Maximum opening in accordance with sash height .................................................... 5

3. Technical information about function ............................................................................... 5

4. Construction and standards ............................................................................................ 6

5. Id plate and marking data ............................................................................................... 6

6. Technical specifications .................................................................................................. 7

7. Electrical supply .............................................................................................................. 7

7.1. Section choice of supply cables ................................................................................ 7

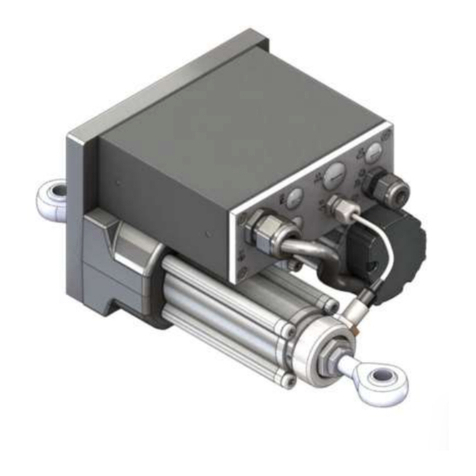

8. Instructions for assembly ................................................................................................ 8

8.1. Preparation of actuator for assembly ......................................................................... 8

8.2. Assembly with outward opening window ................................................................... 9

8.3. Assembly for cupolas or dormer windows ................................................................. 9

8.4. Assembly for transom windows ................................................................................. 9

8.5. Assembly of more than one actuator with connection bar ........................................ 10

9. Electrical connections ................................................................................................... 11

10. Limit switches ............................................................................................................... 12

10.1. Stroke-end at opening and closure ...................................................................... 12

10.2. Stroke adjustment where required ....................................................................... 12

11. Checking for correct assembly ...................................................................................... 12

12. Emergency manoeuvres, maintenance and cleaning ..................................................... 13

13. Troubleshooting ............................................................................................................ 13

14. Environmental protection .............................................................................................. 13

15. Certificate of guarantee ................................................................................................. 13

16. Declaration of incorporation (for a partly completed machine) and EC Declaration of

Conformity .................................................................................................................... 15

4

1. Security rules

CAREFULLY OBSERVE ALL THE FOLLOWING INSTALLATION INSTRUCTIONS TO ENSURE

PERSONAL SAFETY. IMPROPER INSTALLATION CAN SERIOUSLY ENDANGER SAFETY.

MANDATORY RISK ANALYSIS AND PROTECTION MEASURES.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

IEC 60335-2-103 (Particular requirements for drives for gates, doors and windows) and other

directives and regulations indicated in the attached Declarations of Incorporation and CE

Conformity (at the end of the manual). According to the Machinery Directive, actuators are

“partly completed machinery” intended for incorporation into doors and windows. The

manufacturer/supplier of the window is required, with exclusive responsibility, to ensure the

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

any case, the supplier of the complete system retains full liability.

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct risk analysis

regarding potential harm (violent blows, crushing, wounds) caused to people by normal use

or possible malfunction or accidental breakage of the automated windows, and to implement

suitable protective measures in view of these. Such measures include those recommended

by the specified standard:

- controlling the actuators via a “deadman’s button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The

button must be placed at a height of 1.5 m and operated by key if accessible to the

public; or:

- use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

IEC 60335-2-103; or:

- use of non-contact safety systems (lasers, light grids); or:

- use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

- are installed at a height of >2.5 m; or:

- have a leading-edge opening of <200 mm and a closing speed of <15 mm/s; or:

- are part of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or secured in order to prevent them from suddenly

falling or collapsing: e.g. the use of safety arms on bottom-hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow children to play with the fixed controls and keep any remote-control units

out of their reach.

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage on the appliance.

Always request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for

the appliance.

In the event of any problems or queries, consult your agent or contact the

manufacturer directly.