Deif GPC-3 Hydro User manual

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DESIGNER’S REFERENCE HANDBOOK

Generator Paralleling Controller

GPC-3/GPC-3 Gas/GPC-3 Hydro

● Functional description

● Modes and sequences

● General product information

● PID controller

● Additional functions

Document no.: 4189340587L

SW version: 3.09.x or later

1. General information

1.1. Warnings, legal information and safety.................................................................................................. 5

1.1.1. Warnings and notes ......................................................................................................................5

1.1.2. Legal information and disclaimer ..................................................................................................5

1.1.3. Safety issues ................................................................................................................................ 5

1.1.4. Electrostatic discharge awareness ............................................................................................... 5

1.1.5. Factory settings ............................................................................................................................ 6

1.2. About the designer's reference handbook..............................................................................................6

1.2.1. General purpose ...........................................................................................................................6

1.2.2. Intended users ..............................................................................................................................6

1.2.3. Contents and overall structure ......................................................................................................6

2. General product information

2.1. General product information...................................................................................................................7

2.1.1. Introduction....................................................................................................................................7

2.1.2. Type of product..............................................................................................................................7

2.1.3. Options.......................................................................................................................................... 7

2.1.4. PC utility software warning............................................................................................................ 7

3. Functional descriptions

3.1. Standard functions................................................................................................................................. 8

3.2. Regulation modes.................................................................................................................................. 9

3.3. Fixed frequency......................................................................................................................................9

3.4. Fixed power..........................................................................................................................................10

3.5. Frequency droop.................................................................................................................................. 10

3.6. P load sharing...................................................................................................................................... 12

3.7. Measurement systems......................................................................................................................... 13

3.7.1. Three-phase system....................................................................................................................13

3.7.2. Single phase system....................................................................................................................14

3.7.3. Split phase system.......................................................................................................................14

3.8. Scaling..................................................................................................................................................15

3.9. Single-line diagrams.............................................................................................................................16

3.10. Sequences......................................................................................................................................... 18

3.10.1. Sequences.................................................................................................................................18

3.11. Running mode description..................................................................................................................21

3.11.1. Running mode description......................................................................................................... 21

3.12. Password............................................................................................................................................21

3.12.1. Parameter access......................................................................................................................23

4. Additional functions

4.1. Start functions...................................................................................................................................... 24

4.1.1. Start/stop threshold......................................................................................................................24

4.2. Alarm....................................................................................................................................................25

4.2.1. Alarm function..............................................................................................................................25

4.2.2. Alarm inhibit.................................................................................................................................29

4.2.3. Alarm jump...................................................................................................................................31

4.2.4. Alarm test mode...........................................................................................................................31

4.3. Breaker.................................................................................................................................................31

4.3.1. Breaker types...............................................................................................................................31

4.3.2. Breaker spring load time..............................................................................................................31

4.4. Differential measurement..................................................................................................................... 32

4.5. Digital inputs.........................................................................................................................................35

4.5.1. Functional description .................................................................................................................37

4.6. Multi-inputs...........................................................................................................................................42

4.6.1. 4 to 20 mA................................................................................................................................... 43

4.6.2. 0 to 40 V DC................................................................................................................................ 43

4.6.3. Pt100/1000.................................................................................................................................. 43

4.6.4. RMI inputs....................................................................................................................................43

GPC-3 DRH 4189340587 UK

DEIF A/S Page 2 of 122

4.6.5. RMI oil..........................................................................................................................................43

4.6.6. RMI water.................................................................................................................................... 44

4.6.7. RMI fuel....................................................................................................................................... 45

4.6.8. Illustration of configurable inputs................................................................................................. 46

4.6.9. Configuration............................................................................................................................... 47

4.6.10. Scaling of 4 to 20 mA inputs......................................................................................................47

4.6.11. Digital......................................................................................................................................... 50

4.7. Event log.............................................................................................................................................. 50

4.7.1. Logs.............................................................................................................................................50

4.8. External set points................................................................................................................................52

4.8.1. External analogue set point......................................................................................................... 52

4.8.2. Scaling of analogue inputs for external set point control ............................................................ 53

4.8.3. External set point selection..........................................................................................................56

4.9. Fail class.............................................................................................................................................. 58

4.9.1. Fail class configuration................................................................................................................ 59

4.10. Frequency-dependent power droop................................................................................................... 60

4.11. Language selection............................................................................................................................ 63

4.11.1. Language selection....................................................................................................................63

4.12. Memory backup..................................................................................................................................64

4.12.1. Memory backup......................................................................................................................... 64

4.13. Load sharing.......................................................................................................................................64

4.13.1. Load sharing..............................................................................................................................64

4.14. Power limit set point........................................................................................................................... 70

4.14.1. Four-stage power limit set point.................................................................................................70

4.15. M-Logic...............................................................................................................................................70

4.16. Mode configuration.............................................................................................................................71

4.16.1. Manual mode.............................................................................................................................71

4.16.2. Not in remote............................................................................................................................. 72

4.16.3. Modes active..............................................................................................................................72

4.17. Nominal settings.................................................................................................................................73

4.18. Relay setup........................................................................................................................................ 74

4.18.1. Limit relay.................................................................................................................................. 75

4.19. Service menu..................................................................................................................................... 77

4.19.1. Service menu.............................................................................................................................77

4.20. Step-up and step-down transformer...................................................................................................81

4.20.1. Step-up transformer...................................................................................................................81

4.20.2. Vector group for step-up transformer ........................................................................................82

4.20.3. Setup of step-up transformer and measurement transformer ...................................................89

4.20.4. Vector group for step-down transformer ................................................................................... 90

4.20.5. Setup of step-down transformer and measurement transformer ..............................................92

5. Protections

5.1. Protections........................................................................................................................................... 94

5.1.1. General........................................................................................................................................94

5.2. Inverse time over-current..................................................................................................................... 96

5.3. Reverse power..................................................................................................................................... 99

5.4. Trip of Non-Essential Load (NEL).......................................................................................................100

5.5. Reset ratio (hysteresis)...................................................................................................................... 101

6. PID controller

6.1. PID controller......................................................................................................................................102

6.2. Proportional regulator.........................................................................................................................103

6.3. Relay control...................................................................................................................................... 108

7. Synchronisation

7.1. General information............................................................................................................................ 111

7.2. Dynamic synchronisation....................................................................................................................111

7.2.1. Close signal............................................................................................................................... 112

7.2.2. Load picture after synchronising................................................................................................ 112

GPC-3 DRH 4189340587 UK

DEIF A/S Page 3 of 122

7.3. Static synchronisation.........................................................................................................................114

7.3.1. Phase controller.........................................................................................................................115

7.4. Synchronising controller..................................................................................................................... 116

7.5. Synchronising vector mismatch alarm................................................................................................117

7.6. Asynchronous synchronisation ..........................................................................................................118

7.7. Blackout closing .................................................................................................................................118

7.8. Separate synchronising relay............................................................................................................. 119

7.9. Inhibit conditions before synchronising mains breaker.......................................................................121

GPC-3 DRH 4189340587 UK

DEIF A/S Page 4 of 122

1. General information

1.1 Warnings, legal information and safety

1.1.1 Warnings and notes

Throughout this document, a number of warnings and notes with helpful user information will be presented.

To ensure that these are noticed, they will be highlighted as follows in order to separate them from the gener-

al text.

Warnings

Warnings indicate a potentially dangerous situation, which could result in death, personal in-

jury or damaged equipment, if certain guidelines are not followed.

Notes

Notes provide general information, which will be helpful for the reader to bear in mind.

1.1.2 Legal information and disclaimer

DEIF takes no responsibility for installation or operation of the generator set. If there is any doubt about how

to install or operate the engine/generator controlled by the Multi-line 2 unit, the company responsible for the

installation or the operation of the set must be contacted.

The Multi-line 2 unit is not to be opened by unauthorised personnel. If opened anyway, the war-

ranty will be lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information about the

product. DEIF does not take responsibility for the accuracy of translations, and translations might not be up-

dated at the same time as the English document. If there is a discrepancy, the English version prevails.

1.1.3 Safety issues

Installing and operating the Multi-line 2 unit may imply work with dangerous currents and voltages. Therefore,

the installation should only be carried out by authorised personnel who understand the risks involved in work-

ing with live electrical equipment.

Be aware of the hazardous live currents and voltages. Do not touch any AC measurement in-

puts as this could lead to injury or death.

1.1.4 Electrostatic discharge awareness

Sufficient care must be taken to protect the terminal against static discharges during the installation. Once the

unit is installed and connected, these precautions are no longer necessary.

GPC-3 DRH 4189340587 UK General information

DEIF A/S Page 5 of 122

1.1.5 Factory settings

The Multi-line 2 unit is delivered from factory with certain factory settings. These are based on average values

and are not necessarily the correct settings for matching the engine/generator set in question. Precautions

must be taken to check the settings before running the engine/generator set.

1.2 About the designer's reference handbook

1.2.1 General purpose

This Designer's Reference Handbook mainly includes functional descriptions, presentation of display unit and

menu structure, information about the PID controller, the procedure for parameter setup and reference to pa-

rameter lists.

The general purpose of this document is to provide useful overall information about the functionality of the

unit and its applications. This document also offers the user the information he needs in order to successfully

set up the parameters needed in his specific application.

Make sure to read this document before starting to work with the Multi-line 2 unit and the gen-

set to be controlled. Failure to do this could result in human injury or damage to the equip-

ment.

1.2.2 Intended users

This Designer's Reference Handbook is mainly intended for the panel builder designer in charge. On the ba-

sis of this document, the panel builder designer will give the electrician the information he needs in order to

install the Multi-line 2 unit, for example detailed electrical drawings. In some cases, the electrician may use

these installation instructions himself.

1.2.3 Contents and overall structure

This document is divided into chapters, and in order to make the structure simple and easy to use, each

chapter will begin from the top of a new page.

GPC-3 DRH 4189340587 UK General information

DEIF A/S Page 6 of 122

2. General product information

2.1 General product information

2.1.1 Introduction

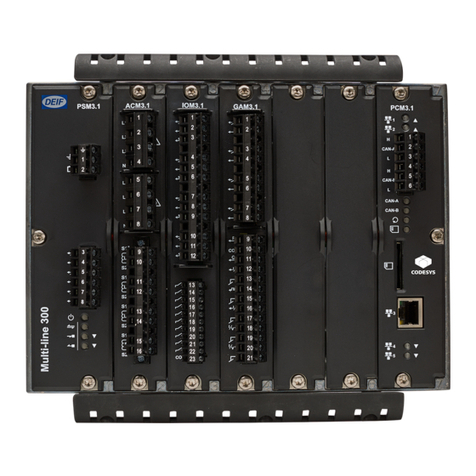

This chapter will deal with the unit in general and its place in the DEIF product range.

The GPC-3 is part of the DEIF Multi-line 2 product family. Multi-line 2 is a complete range of multi-function

generator protection and control products integrating all the functions you need into one compact and attrac-

tive solution.

2.1.2 Type of product

The Generator Paralleling Controller is a microprocessor-based control unit containing all necessary functions

for protection and control of a generator.

It contains all necessary 3-phase measuring circuits, and all values and alarms are presented on the LCD

display.

2.1.3 Options

The Multi-line 2 product range consists of different basic versions which can be supplemented with the flexi-

ble options needed to provide the optimum solution. The options cover, for example, various protections for

generator, busbar and mains, voltage/var/PF control, various outputs, serial communication, and so on.

A complete list of available options is included in the data sheet, document no. 4921240351;

refer to www.deif.com.

2.1.4 PC utility software warning

It is possible to remote-control the genset from the PC utility software, by use of a modem or

TCP/IP. To avoid personal injury, make sure that it is safe to remote-control the genset.

GPC-3 DRH 4189340587 UK General product information

DEIF A/S Page 7 of 122

3. Functional descriptions

3.1 Standard functions

The standard functions are listed in the following paragraphs.

Regulation modes

● Load sharing

● Fixed frequency

● Fixed power

● Frequency droop

Generator protection (ANSI)

● 2 × reverse power (32)

● 5 × overload (32)

● 6 × over-current (50/51)

● Inverse time over-current (51)

● 2 × over-voltage (59)

● 3 × under-voltage (27)

● 3 × over-/under-frequency (81)

● Voltage-dependent over-current (51V)

● Current/voltage unbalance (60)

● Loss of excitation/overexcitation (40/32RV)

Busbar protection (ANSI)

● 3 × over-voltage (59)

● 4 × under-voltage (27)

● 3 × over-frequency (81)

● 4 × under-frequency (81)

● Voltage unbalance (60)

● 3 × NEL groups

M-Logic (Micro PLC)

● Simple logic configuration tool

● Selectable input/output events

Display

● Status texts

● Info messages

● Alarm indication

● Prepared for remote mounting

● Prepared for additional remote displays

General

● USB interface to PC

● Free PC utility software

● Programmable parameters, timers and alarms

● User configurable texts

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 8 of 122

3.2 Regulation modes

The unit can, for example, be used for the applications listed in the table below. This depends on the selec-

tion of the running modes.

Mode selection Select regulation mode

Application Fixed frequency Fixed power Droop Load sharing

Island mode, stand-alone χ χ

Island mode, load sharing with other gensets χ χ

Fixed power, for example to mains χ χ

Regulation modes can be selected via digital inputs, M-Logic or the external communication

protocols.

3.3 Fixed frequency

This regulation mode is typically used when the generator is running in island operation/stand-alone. During

island operation/stand-alone, the load connected to the generator cannot be changed through regulation of

the genset. If the fuel supply to the engine is increased or decreased, the loading of the genset does not

change – only the frequency will increase or decrease as a result of changed fuel supply.

Dependency

Fixed frequency mode is active when:

Input\Active mode Fixed

frequency (sync.)

Fixed

frequency

Fixed

frequency

Control inputs Start sync./control 25 ON ON ON

De-load 43 OFF ON OFF

Breaker feedbacks GB open 26 ON ON OFF

GB closed 27 OFF OFF ON

Mode inputs Fixed frequency 48 Mode inputs are not used when the GB is open ON

To activate the use of “Start sync./control” from M-Logic or external communication (for exam-

ple Modbus), the M-Logic command “Start sync./ctrl enable” must be activated. Alternatively,

you can use the functions “Remote GB ON” and “Remote GB OFF”.

Never mix the two control methods! If "Remote GB ON/OFF" control is used, you must uncon-

figure "Start sync./control", and vice versa.

Regulator

The frequency regulator is active in this mode. During fixed frequency operation, the set point is typically the

nominal frequency.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 9 of 122

3.4 Fixed power

This regulation mode is typically used when the generator is running parallel to the mains. During fixed power

operation, the genset cannot change the frequency because it is maintained by the grid. If the fuel supply to

the engine is increased or decreased, the frequency of the genset does not change – only the load will in-

crease or decrease as a result of changed fuel supply.

Dependency

Fixed power mode is active when:

Input Active mode

Fixed power (w/sync.) Fixed power (de-load)

Control inputs Start sync./control 25 ON ON

De-load 43 OFF ON

Breaker feedbacks GB open 26 OFF OFF

GB closed 27 ON ON

Mode inputs Fixed P User def. ON ON

To activate the use of “Start sync./control” from M-Logic or external communication (for exam-

ple Modbus), the M-Logic command “Start sync./ctrl enable” must be activated. Alternatively,

you can use the functions “Remote GB ON” and “Remote GB OFF”.

Never mix the two control methods! If "Remote GB ON/OFF" control is used, you must uncon-

figure "Start sync./control", and vice versa.

Regulator

The power regulator is active in this mode. During fixed power operation, the set point is typically adjusted in

the display (menu 7051).

3.5 Frequency droop

This regulation mode can be used on various occasions where it is required that the generator frequency

drops with increasing load.

The governor droop has the purpose of applying stability in the regulation of the engine and

does not give an actual droop if a controller (GPC-3) is installed.

The GPC-3 droop has the purpose of causing an actual speed droop. With this droop activated,

the frequency will actually change with changing load.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 10 of 122

Diagram A: high droop setting

In this diagram, the illustrated frequency variation gives a change in the load. This is marked as ΔP.

∆ P

fNOM

Freq (Hz)

P(kW)

This can be used if the generator must operate base-loaded.

Diagram B: low droop setting

In this diagram, the load change (ΔP) is larger than before. This means that the generator will vary more in

loading than with the higher droop setting.

∆ P

fNOM

Freq (Hz)

P(kW)

This can be used if the generator must operate as a peak load machine.

Load sharing with older types of gensets

Droop mode can be used when a new genset is installed in an installation where old gensets are installed

and they operate in droop mode. Then it can be preferred to install the new genset and operate it in droop

mode in order to make equal load sharing with the existing gensets.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 11 of 122

Compensation for isochronous governors

When the genset is equipped with a governor that only provides isochronous operation, the droop in the

GPC-3 can be used to compensate for the missing droop setting possibility on the governor.

Dependency

Droop mode is active when:

Input Active mode

Droop

Control inputs Start sync./control 25 ON

De-load 43 OFF

Breaker feedbacks CB open 54 OFF

CB closed 55 ON

Mode inputs Frequency droop User def. ON

To activate the use of “Start sync./control” from M-Logic or external communication (for exam-

ple Modbus), the M-Logic command “Start sync./ctrl enable” must be activated. Alternatively,

you can use the functions “Remote GB ON” and “Remote GB OFF”.

Regulator

The frequency controller is used in the GPC-3 when operating in frequency droop mode. This means that as

long as the power does not match the frequency, the governor will be controlled up- or downwards. In this

way, the power and the frequency will always end up matching each other according to the adjusted droop

curve.

3.6 P load sharing

This regulation mode is typically used when paralleling two or more gensets. During load sharing operation

with other gensets, the power and frequency of each individual genset can be changed. This means that if the

fuel supply is changed to the engine, the power of the genset – and subsequently the frequency – will

change.

Dependency

P load sharing mode is active when:

Input Active mode

Load sharing

Control inputs Start sync./control 25 ON

De-load 43 OFF

Breaker feedbacks GB open 26 OFF

GB closed 27 ON

Mode inputs P load sharing 49 ON

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 12 of 122

To activate the use of “Start sync./control” from M-Logic or external communication (for exam-

ple Modbus), the M-logic command “Start sync./ctrl enable” must be activated. Alternatively,

you can use the functions “Remote GB ON” and “Remote GB OFF”.

Never mix the two control methods! If "Remote GB ON/OFF" control is used, you must uncon-

figure "Start sync./control", and vice versa.

In case the busbar frequency drops more than the setting in menu 2623 during de-load, the GB

will be opened regardless of the setting in menu 2622 (Breaker open point).

Regulator

The power and the frequency regulators are active when the load sharing mode is selected. The set point is

typically a combination of the signal on the load sharing line and the nominal frequency.

For a detailed description of the load sharing principle, refer to the chapter “Load sharing”.

Analogue load sharing: When a unit is running alone on the busbar, the regulation mode

should be changed to fixed frequency.

Governor mode undefined (menu 2730)

After the breaker has been closed, it is required that one regulation mode is selected. In case no mode is

selected or more than one mode is selected, the following action will be performed regardless of the fail class

selected for “GOV mode undef.” in 2730:

1. No mode input active: The unit is changed to manual mode (regulator OFF), and a “GOV mode undef.”

alarm is raised after the delay has expired.

2. More than one mode input active: The unit is maintained in the first selected running mode and the “GOV

mode undef.” alarm is raised.

3.7 Measurement systems

The GPC is designed for measurement of voltages between 100 and 690 V AC on the terminals. If the volt-

age is higher, voltage transformers are required. For further reference, the AC wiring diagrams are shown in

the Installation Instructions.

In menu 9130, the measurement principle can be changed; the options are three-phase, single phase and

split phase.

Configure the GPC to match the correct measuring system. When in doubt, contact the switch-

board manufacturer for information about the required adjustment.

3.7.1 Three-phase system

When the GPC is delivered from the factory, the three-phase system is selected. When this principle is used,

all three phases must be connected to the GPC.

The table below contains the parameters to make the system ready for split phase measuring.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 13 of 122

Below is an example with 230/400 V AC, which can be connected directly to the GPC's terminals without the

use of a voltage transformer. If a voltage transformer is necessary, the nominal values of the transformer

should be used instead.

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-phase voltage of the generator 400 V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) 400 V AC

6042 G transformer Secondary voltage of the G voltage transformer (if installed) 400 V AC

6051 BB transformer set 1 Primary voltage of the BB voltage transformer (if installed) 400 V AC

6052 BB transformer set 1 Secondary voltage of the BB voltage transformer (if instal-

led)

400 V AC

6053 BB nom. voltage set 1 Phase-phase voltage of the busbar 400 V AC

The GPC has two sets of BB transformer settings, which can be enabled individually in this

measurement system.

3.7.2 Single phase system

The single phase system consists of one phase and the neutral.

The table below contains the parameters to make the system ready for single phase measuring.

Below is an example with 230 V AC, which can be connected directly to the GPC's terminals without the use

of a voltage transformer. If a voltage transformer is necessary, the nominal values of the transformer should

be used instead.

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-neutral voltage of the generator 230 V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) 230 V AC

6042 G transformer Secondary voltage of the G voltage transformer (if installed) 230 V AC

6051 BB transformer set 1 Primary voltage of the BB voltage transformer (if installed) 230 V AC

6052 BB transformer set 1 Secondary voltage of the BB voltage transformer (if instal-

led)

230 V AC

6053 BB nom. voltage set 1 Phase-neutral voltage of the busbar 230 V AC

The voltage alarms refer to UNOM (230 V AC).

The GPC has two sets of BB transformer settings, which can be enabled individually in this

measurement system.

3.7.3 Split phase system

This is a special application where two phases and neutral are connected to the GPC. The GPC shows pha-

ses L1 and L3 in the display. The phase angle between L1 and L3 is 180 degrees. Split phase is possible

between L1-L2 or L1-L3.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 14 of 122

The table below contains the parameters to make the system ready for split phase measuring.

Below is an example with 240/120 V AC, which can be connected directly to the GPC's terminals without the

use of a voltage transformer. If a voltage transformer is necessary, the nominal values of the transformer

should be used instead.

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-neutral voltage of the generator 120 V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) 120 V AC

6042 G transformer Secondary voltage of the G voltage transformer (if installed) 120 V AC

6051 BB transformer set 1 Primary voltage of the BB voltage transformer (if installed) 120 V AC

6052 BB transformer set 1 Secondary voltage of the BB voltage transformer (if instal-

led)

120 V AC

6053 BB nom. voltage set 1 Phase-neutral voltage of the busbar 120 V AC

The measurement UL3L1 shows 240 V AC. The voltage alarm set points refer to the nominal

voltage 120 V AC, and UL3L1 does not activate any alarm.

The GPC has two sets of BB transformer settings, which can be enabled individually in this

measurement system.

3.8 Scaling

Default voltage scaling for the GPC-3 is set to 100 V-25000 V. To be able to handle applications above 25000

V and below 100 V, it is necessary to adjust the input range so it matches the actual value of the primary

voltage transformer. This makes it possible for the GPC-3 to support a wide range of voltage and power val-

ues.

Setup of the scaling can be done from the display by using the jump function or by using the USW.

When changing the voltage scaling in menu 9030, the unit will reset. If it is changed via the

USW, it is necessary to read the parameter again.

Scaling of nominal voltage and voltage read-out is done in menu 9030.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 15 of 122

Changing the voltage scaling will also influence the nominal power scaling:

Scaling parameter

9030

Nom. settings 1 to 4

(power)

Nom. settings 1 to 4

(voltage)

Menu: 6041, 6051 and

6053

10 V-2500 V 1.0-900.0 kW 10.0 V-2500.0 V 10.0 V-2500.0 V

100 V-25000 V 10-20000 kW 100 V-25000 V 100 V-25000 V

1 kV-75 kV 0.10-90.00 MW 1.00 kV-75.00 kV 1.00 kV-75.00 kV

10 kV-160 kV 1.0-900.0 MW 10.0 kV-160.0 kV 10.0 kV-160.0 kV

3.9 Single-line diagrams

The GPC-3 can be used for numerous applications. A few examples are shown below, but due to the flexibili-

ty of the product it is not possible to show all applications. The flexibility is one of the great advantages of this

controller.

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 16 of 122

Stand-alone

G

Diesel generator set

Load

Controller

Display

Parallel to mains

G

Generator

breaker

(GB)

Diesel generator set

Controller

Display

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 17 of 122

Paralleling gensets (load sharing)

G

Generator

breaker

(GB 1)

Diesel generator set 1

Busbar

G

Generator

breaker

(GB 2)

Diesel generator set 2

Analogue

loadsharing

Controller

Display 1

Controller

Display 2

PLC-controlled system

G

Generator

breaker

(GB 1)

Diesel generator set 1

Busbar

Controller

Display 1

G

Generator

breaker

(GB 2)

Diesel generator set 2

Controller

Display 2

G

Generator

breaker

(GB 3)

Diesel generator set 3

Controller

Display 3

Modbus

PLC

Load sharing line

3.10 Sequences

3.10.1 Sequences

The following section contains information about the sequences of the GPC-3.

These sequences will be described:

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 18 of 122

Sequence Description

GB ON Synchronising

GB ON Blackout closing

GB OFF Open breaker

GB OFF De-load/open breaker

GB ON sequence/synchronising

The GB ON sequence can be started when the generator is running and the terminal 25 (start sync./control)

is activated. The regulation will start and control the genset in order to synchronise the breaker.

The busbar voltage must be above 70 % × UNOM in order to initiate the synchronising.

Interruption of the GB ON (synchronising) sequence

Input 25 deactivated

Input 43 activated 25 = ON at the same time

Remote GB ON activated

GB close

UBB measured below 70 % 70 % × UNOM

Synchronising failure

GB close failure

Alarm with Safety stop, Trip GB or Block fail class

When the GB opens, there is a 10 s delay that prevents it from closing immediately after it has

opened. This is to ensure that there is sufficient time to change mode and control inputs.

GB ON sequence/blackout closing

In order to make a blackout closing, terminal 25 must be activated and the measurements from the busbar

must be missing. The breaker will close if the generator voltage is within the settings of 2110 sync. blackout.

The busbar voltage must be below 30 % × UNOM in order to initiate the black busbar closing.

Interruption of the GB ON (blackout close) sequence

Input 25 deactivated

Input 43 activated 25 = ON at the same time

Remote GB ON activated

U gen. not OK Limit set in menu 2112

f gen. not OK Limit set in menu 2111

Black closing not enabled Input function configured and input not activated

GB close

UBB measured above 30 %

General failure

Alarm with Safety stop, Trip GB or Block fail class

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 19 of 122

When the GB opens, there is a 10 s delay that prevents it from closing immediately after it has

opened. This is to ensure that there is sufficient time to change mode and control inputs.

GB OFF/open breaker

The GB can be opened instantly by the GPC-3. The sequence is started by this selection of the control in-

puts:

Terminal Description Input state

25 Start sync./control ON ON

43 De-load ON ON

48 Fixed frequency ON OFF

User def. Frequency droop OFF ON

The GB open signal will be issued immediately when the combination of the control inputs are as mentioned

in the table above.

GB OFF/de-load

The GB can be opened by the GPC-3 after a smooth de-load period where the load has decreased to the

breaker open point (menu 2622). The sequence is started by one of the following combinations of inputs:

Terminal Description Input state

25 Start sync./control ON ON

43 De-load ON ON

49 Load sharing ON OFF

User def. Fixed P OFF ON

The GB open signal will be issued when the load has been below the breaker open point for 1 second. In

order to interrupt the de-load sequence, the input 43 must be deactivated. Then the GPC-3 will continue the

operation according to the present mode selection. The de-load sequence can also be interrupted if the input

“Start sync./control” is deactivated. But then the entire regulation is deactivated.

Remote GB ON

The generator breaker ON sequence will be initiated and the breaker will synchronise if voltage and frequen-

cy at the BB are OK, or close without synchronising if the BB voltage is below 30 % × UNOM.

Remote GB OFF

The generator breaker OFF sequence will be initiated. Whether the breaker is de-loaded before opening de-

pends on the active regulation mode.

Mode De-load Comment

Fixed frequency No GB will be opened immediately

Frequency droop No

P load sharing Yes GB will be de-loaded to the GB open point (menu 2622)

In case de-load is not possible, the breaker will be opened when BB frequen-

cy has dropped to fNOM - 0.5 Hz

Fixed P Yes GB will be de-loaded to the GB open point (menu 2622)

GPC-3 DRH 4189340587 UK Functional descriptions

DEIF A/S Page 20 of 122

Other manuals for GPC-3 Hydro

3

This manual suits for next models

2

Table of contents

Other Deif Controllers manuals

Deif

Deif AGC 150 User manual

Deif

Deif Multi-line 2 User manual

Deif

Deif AGC 200 Series User manual

Deif

Deif AGC-4 User manual

Deif

Deif AGC 200 Series User manual

Deif

Deif AWC 500 Quick start guide

Deif

Deif PICUS PPM 300 User manual

Deif

Deif SGC 121 User manual

Deif

Deif AGC-4 User manual

Deif

Deif AGC 150 User manual

Popular Controllers manuals by other brands

Frequency Devices

Frequency Devices ASC-50 Operation manual

CVS Controls Ltd.

CVS Controls Ltd. 1301F product manual

Emerson

Emerson Bettis CBB Series Disassembly and Reassembly

TIS

TIS DALI-64 installation manual

Velleman

Velleman Vellight LEDC25 user manual

Honeywell

Honeywell Novar ES3.S Mounting and wiring instructions