nekos KATO RADIO 230V User manual

Table of contents

Other nekos Controllers manuals

nekos

nekos KIMO 202 User manual

nekos

nekos SKY 650 User manual

nekos

nekos SKYRO 650 User manual

nekos

nekos ROCK 230 V User manual

nekos

nekos KATO 253 Reference manual

nekos

nekos KIMO User manual

nekos

nekos SKYRO 850 User manual

nekos

nekos KATO ADV RADIO User manual

nekos

nekos SKY 650 User manual

nekos

nekos INKA 356 Series User manual

Popular Controllers manuals by other brands

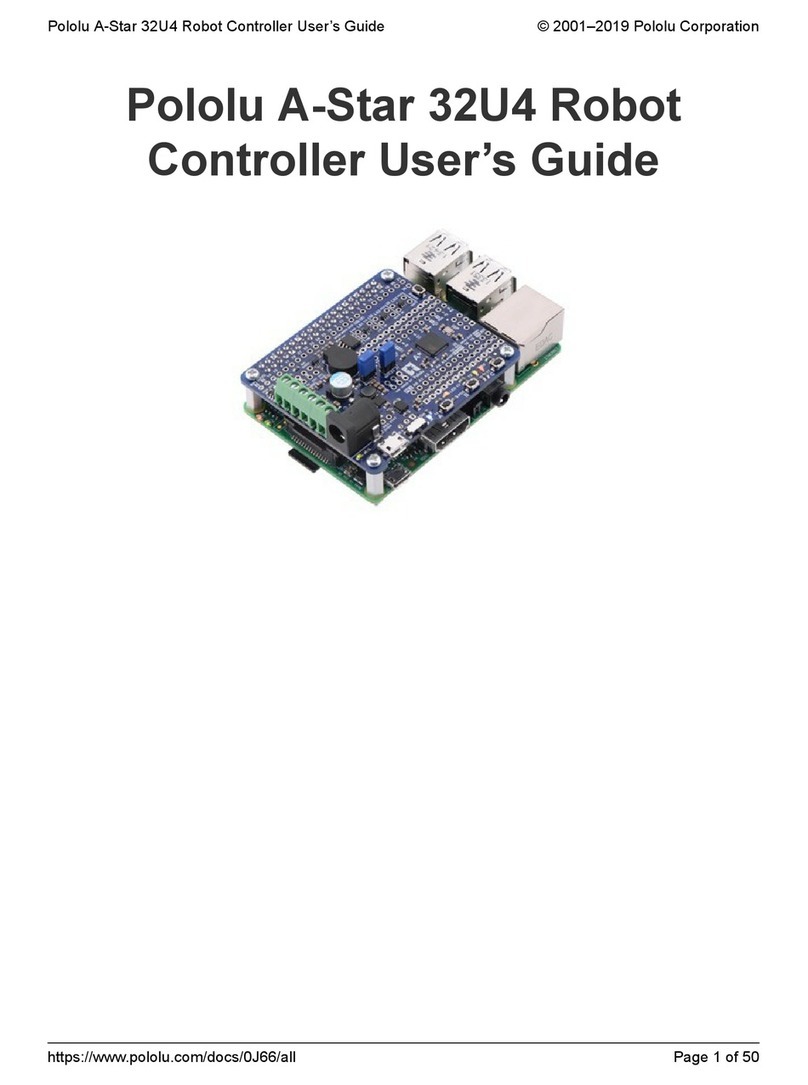

Texas Instruments

Texas Instruments Stellaris MDL-BDC24 Getting started guide

Yamaha

Yamaha TS-P user manual

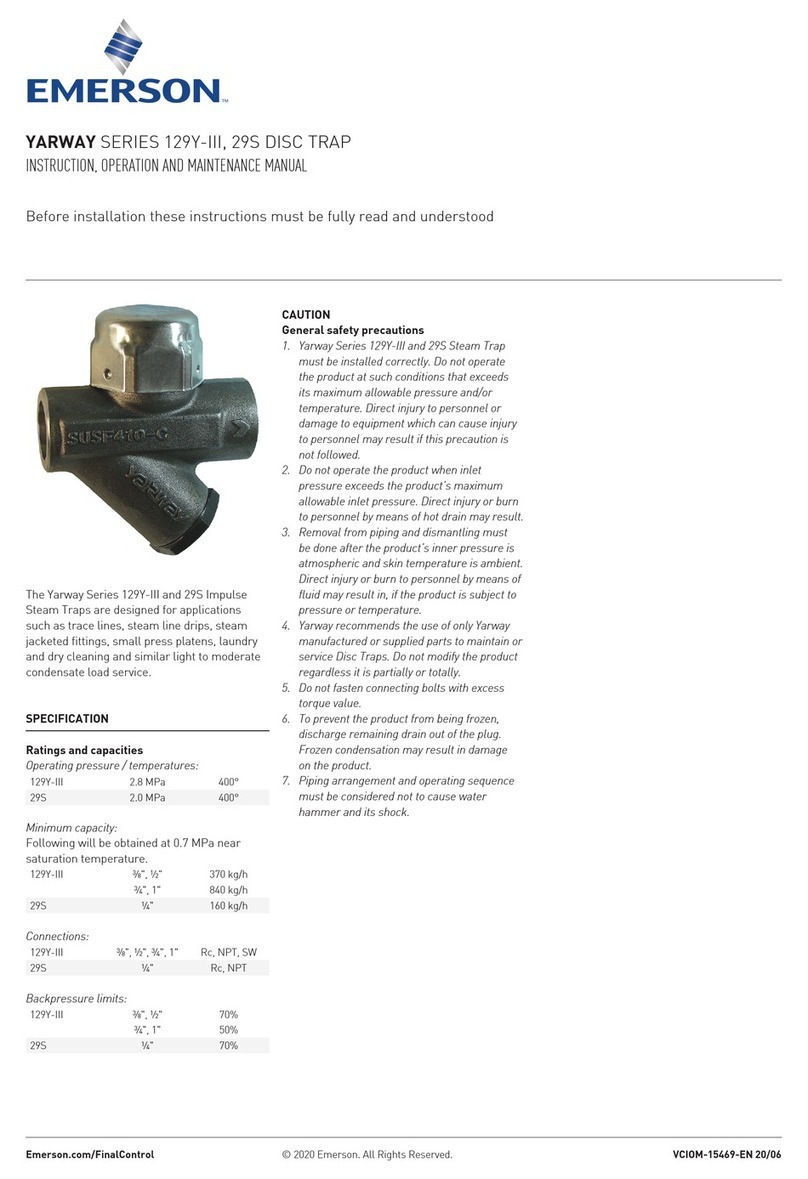

Emerson

Emerson YARWAY Series Instruction, Operation and Maintenance Manual

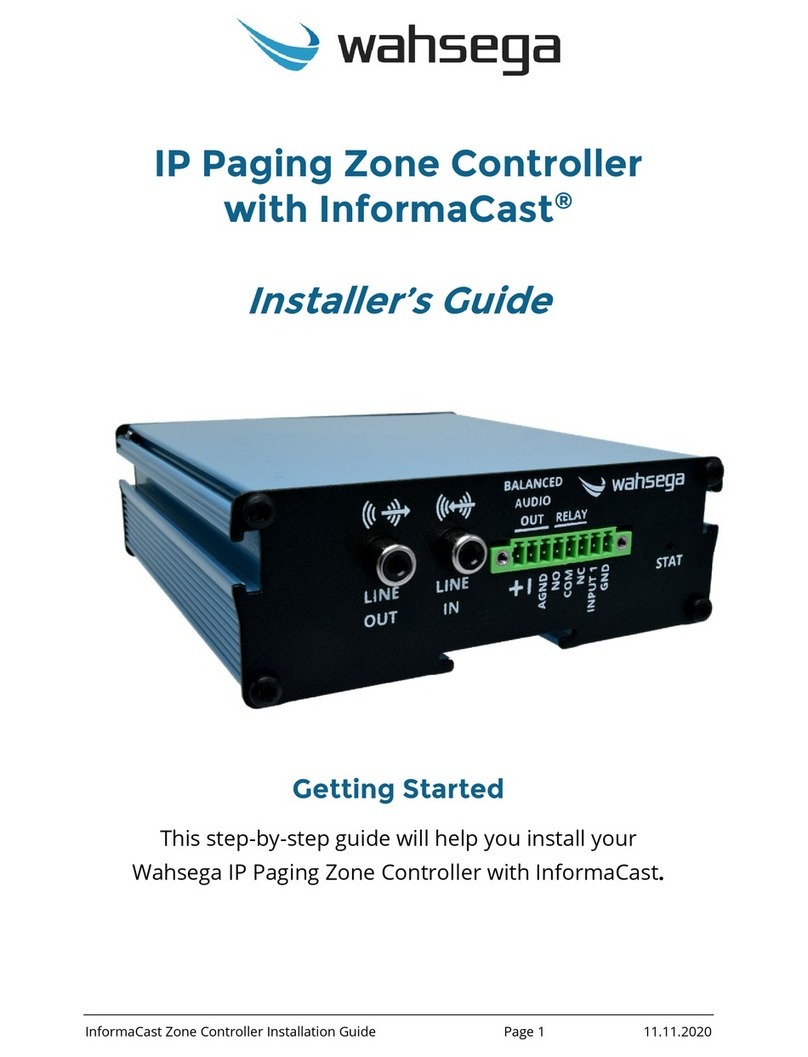

Wahsega

Wahsega WL-ZN-CTR-1CH-INF-R Installer's guide

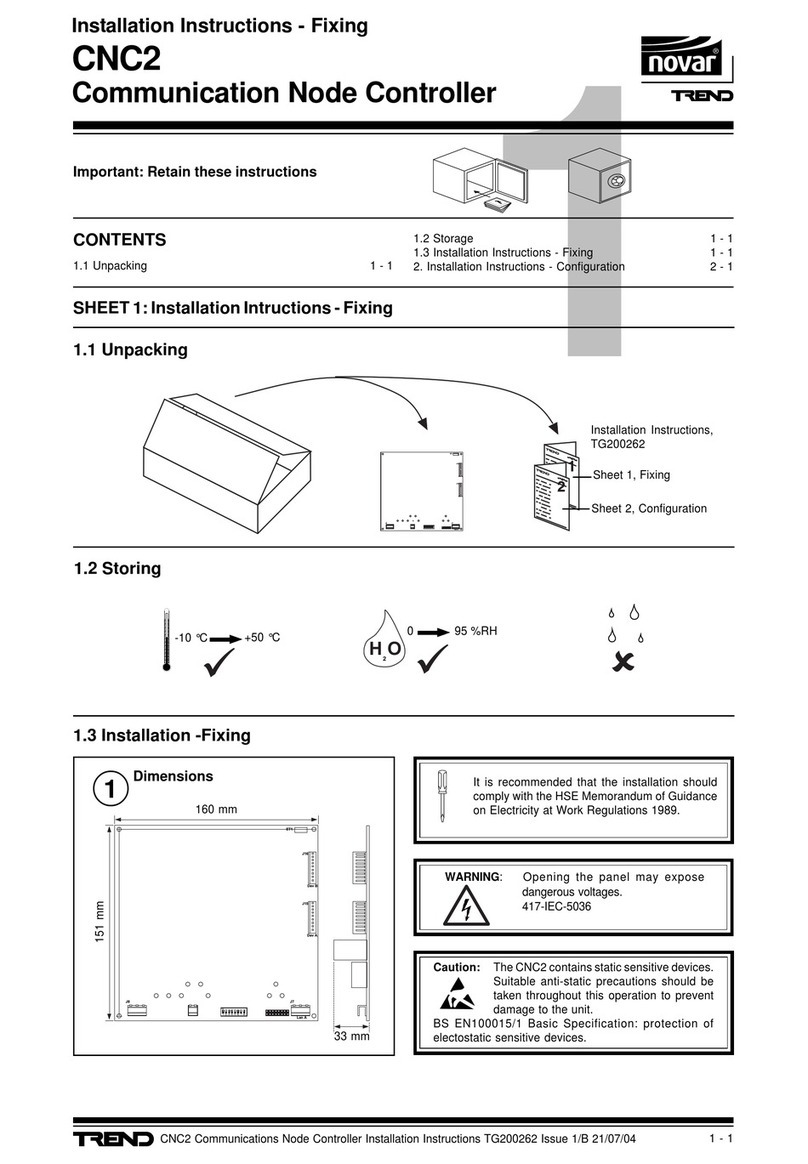

TREND

TREND CNC2 Installation Instructions - Fixing

Larson Electronics

Larson Electronics Golight 2020 instruction manual

Danfoss

Danfoss VLT HVAC operating instructions

Screen Innovations

Screen Innovations LinkPro Z installation instructions

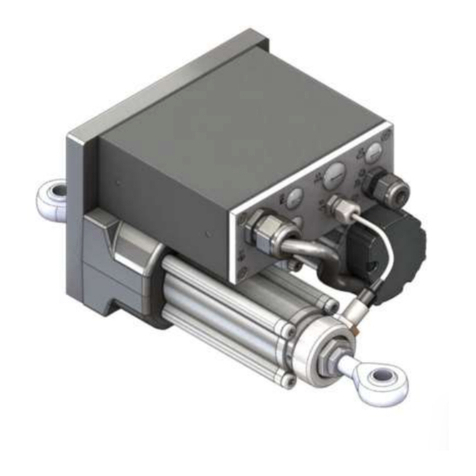

Maxcess

Maxcess GMA-BL-1-1 Installation and service manual

Dakota Digital

Dakota Digital PAC-2750 Installation

Xantrex

Xantrex XW owner's guide

Varian

Varian Turbo-V 81-AG instruction manual