9.

End of the procedure. In the event of errors in the previous steps, repeat the

procedure

This procedure is carried out the first time the device performs a complete stroke and it

stored as an operating parameter

IMPORTANT

.

If a K-

Lock electromechanical lock is connected at a later moment, i.e.

after acquisition of the stroke end positions, a new setting procedure

operation

CAUTION. In

the event that, for whatever reason, the gearmotor has not closed the

door/sash correctly, stopping before completing its stroke, the setting procedure

reset operation

In the case of window sash automation, check, with the sash closed, that the

properly compressed, otherwise there is no certainty that the window is fully closed and the

lock properly engaged. Check also that the brackets are firmly attached to t

the screws properly tightened.

13.

CORRECT INSTALLATION CHECK

After completing the installation, it is always necessary to check that the work has been

done professionally, with no completion tasks left pending, and that the equipment is

working

properly. Therefore, ensure that:

The window or sunscreen blades should close perfectly and there should be no

hindrances due to inaccurate mounting positions.

When the window is closed, the gaskets should be properly compressed, otherwise

there is no cert

ainty of a proper seal against atmospheric agents.

The brackets should be firmly attached to the frame and the screws properly tightened.

Where the K-

LOCK electric lock is also installed, check that the lock is activated at the

close stroke end position,

with a closing time of around 4 seconds.

Any casing covering the mechanisms is fitted so that it does not hinder the proper

opening / closing operation of the door/sash.

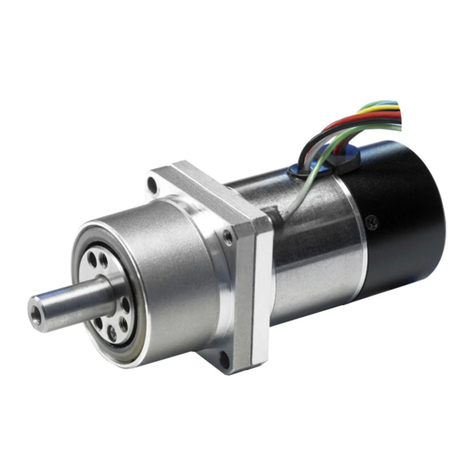

The power cables of the gearmotor and any locks are secured and protected in order to

prevent dangling or interference with moving parts.

14.

EMERGENCY MANOEUVRE AND MAINTENANCE

To open the window manually in the event of a power failure or fault in the mechanism,

follow the procedure described below.

If an electromechanical

lock

the relevant instruction manual.

1.

Remove the bolt securing the rod attachment bracket and remove the rod from its

housing.

2.

To facilitate the operation, move the window with small jolts in order to f

extraction of the bolt from its housing.

3.

Open the window or blades manually.

4.

Once the emergency is resolved or the maintenance completed, car

in reverse.

13

End of the procedure. In the event of errors in the previous steps, repeat the

This procedure is carried out the first time the device performs a complete stroke and it

stored as an operating parameter

.

Lock electromechanical lock is connected at a later moment, i.e.

after acquisition of the stroke end positions, a new setting procedure

the event that, for whatever reason, the gearmotor has not closed the

door/sash correctly, stopping before completing its stroke, the setting procedure

In the case of window sash automation, check, with the sash closed, that the

properly compressed, otherwise there is no certainty that the window is fully closed and the

lock properly engaged. Check also that the brackets are firmly attached to t

the screws properly tightened.

CORRECT INSTALLATION CHECK

After completing the installation, it is always necessary to check that the work has been

done professionally, with no completion tasks left pending, and that the equipment is

properly. Therefore, ensure that:

The window or sunscreen blades should close perfectly and there should be no

hindrances due to inaccurate mounting positions.

When the window is closed, the gaskets should be properly compressed, otherwise

ainty of a proper seal against atmospheric agents.

The brackets should be firmly attached to the frame and the screws properly tightened.

LOCK electric lock is also installed, check that the lock is activated at the

with a closing time of around 4 seconds.

Any casing covering the mechanisms is fitted so that it does not hinder the proper

opening / closing operation of the door/sash.

The power cables of the gearmotor and any locks are secured and protected in order to

prevent dangling or interference with moving parts.

EMERGENCY MANOEUVRE AND MAINTENANCE

To open the window manually in the event of a power failure or fault in the mechanism,

follow the procedure described below.

-LOCK

is installed, to release it, see the indications given in

the relevant instruction manual.

Remove the bolt securing the rod attachment bracket and remove the rod from its

To facilitate the operation, move the window with small jolts in order to f

extraction of the bolt from its housing.

Open the window or blades manually.

Once the emergency is resolved or the maintenance completed, car

End of the procedure. In the event of errors in the previous steps, repeat the

This procedure is carried out the first time the device performs a complete stroke and it

is

Lock electromechanical lock is connected at a later moment, i.e.

after acquisition of the stroke end positions, a new setting procedure

or a new reset

the event that, for whatever reason, the gearmotor has not closed the

door/sash correctly, stopping before completing its stroke, the setting procedure

or a

In the case of window sash automation, check, with the sash closed, that the

gasket is

properly compressed, otherwise there is no certainty that the window is fully closed and the

lock properly engaged. Check also that the brackets are firmly attached to t

he frame and

After completing the installation, it is always necessary to check that the work has been

done professionally, with no completion tasks left pending, and that the equipment is

The window or sunscreen blades should close perfectly and there should be no

When the window is closed, the gaskets should be properly compressed, otherwise

ainty of a proper seal against atmospheric agents.

The brackets should be firmly attached to the frame and the screws properly tightened.

LOCK electric lock is also installed, check that the lock is activated at the

with a closing time of around 4 seconds.

Any casing covering the mechanisms is fitted so that it does not hinder the proper

The power cables of the gearmotor and any locks are secured and protected in order to

To open the window manually in the event of a power failure or fault in the mechanism,

is installed, to release it, see the indications given in

Remove the bolt securing the rod attachment bracket and remove the rod from its

To facilitate the operation, move the window with small jolts in order to f

acilitate the

Once the emergency is resolved or the maintenance completed, car

ry out the operation

CAUTION

To prevent damage to persons and property, observe the

-

Before performing cleaning and maintenance operations, disconnect the

actuator from the power outlet, without pulling on the power cord, to quickly

disconnect the appliance.

-

Disconnect the power supply to all terminals; remove the fuses if neces

15.

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to a

centre for ecological recycling as established from laws in

mainly made from the following materials: aluminium, zinc, iron, plastic of various type,

cuprum.

Dispose materials in conformity with local regulations about removal.

16.

The manufacturer will guarant

undertake to replace defective parts due to poor quality materials or manufacturing defects

in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for

The latter is valid as long as the purchaser possesses proof of purchase and completion of

all agreed conditions of payment. Guarantee of good function of appliances agreed by the

manufacturer implies that the latter und

the shortest period possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage

or other expenses incurred. Attempt to repa

manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

for eventual damage incurred by erroneous assembly, manoeuvre or insertion, excessive

stress or inexpert use.

Repairs performed under guarantee are always "

Respective transport expenses (out/back) are the res

14

To prevent damage to persons and property, observe the

Before performing cleaning and maintenance operations, disconnect the

actuator from the power outlet, without pulling on the power cord, to quickly

disconnect the appliance.

Disconnect the power supply to all terminals; remove the fuses if neces

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to a

centre for ecological recycling as established from laws in

force on recycling. The device is

mainly made from the following materials: aluminium, zinc, iron, plastic of various type,

Dispose materials in conformity with local regulations about removal.

The manufacturer will guarant

ee good function of the appliance. The manufacturer shall

undertake to replace defective parts due to poor quality materials or manufacturing defects

in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for

2 years

from the date of purchase.

The latter is valid as long as the purchaser possesses proof of purchase and completion of

all agreed conditions of payment. Guarantee of good function of appliances agreed by the

manufacturer implies that the latter und

ertakes to repair or replace free of charge and in

the shortest period possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage

or other expenses incurred. Attempt to repa

ir by personnel unauthorised by the

manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

for eventual damage incurred by erroneous assembly, manoeuvre or insertion, excessive

Repairs performed under guarantee are always "

ex factory of the manufacturer

Respective transport expenses (out/back) are the res

ponsibility of the purchaser.

To prevent damage to persons and property, observe the

following:

Before performing cleaning and maintenance operations, disconnect the

actuator from the power outlet, without pulling on the power cord, to quickly

Disconnect the power supply to all terminals; remove the fuses if neces

sary.

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to a

force on recycling. The device is

mainly made from the following materials: aluminium, zinc, iron, plastic of various type,

Dispose materials in conformity with local regulations about removal.

ee good function of the appliance. The manufacturer shall

undertake to replace defective parts due to poor quality materials or manufacturing defects

from the date of purchase.

The latter is valid as long as the purchaser possesses proof of purchase and completion of

all agreed conditions of payment. Guarantee of good function of appliances agreed by the

ertakes to repair or replace free of charge and in

the shortest period possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage

ir by personnel unauthorised by the

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

responsibility

for eventual damage incurred by erroneous assembly, manoeuvre or insertion, excessive

ex factory of the manufacturer

".

ponsibility of the purchaser.