netvox R718UBD Series User manual

Wireless Multifunctional CO2 Sensor

R718UBD Series

Wireless Multifunctional

CO2 Sensor

R718UBD Series

User Manual

Copyright©Netvox Technology Co., Ltd.

This document contains proprietary technical information which is the property of NETVOX Technology. It shall be

maintained in strict confidence and shall not be disclosed to other parties, in whole or in part, without written

permission of NETVOX Technology. The specifications are subject to change without prior notice.

1

Table of Content

1. Introduction..........................................................................................................................................2

2. Appearance...........................................................................................................................................4

3. Main Feature.........................................................................................................................................4

4. Set up Instruction..................................................................................................................................5

5. Data Report ..........................................................................................................................................6

5.1 Example of ReportDataCmd..........................................................................................................7

5.2 Example of ConfigureCmd............................................................................................................8

5.3 Example of calibration configuration...........................................................................................10

6. Installation..........................................................................................................................................12

6-1 Precautions for use of dust sensor................................................................................................12

6-2. Precautions for use of TVOC sensor...........................................................................................12

6-3 Precautions for outdoor installation.............................................................................................13

7. Important Maintenance Instruction.....................................................................................................14

2

1. Introduction

R718UBD all-in-one series is a ClassA type of netvox based on LoRaWAN open protocol, which can support a variety of combined

detection devices composed of temperature and humidity, CO2, vibration, atmospheric pressure, illumination, TVOC and dust, and is

compatible with LoRaWAN protocol.

LoRa Wireless Technology:

LoRa is a wireless communication technology dedicated to long distance and low power consumption. Compared with other

communication methods, LoRa spread spectrum modulation method greatly increases to expand the communication distance. Widely

used in long-distance, low-data wireless communications. For example, automatic meter reading, building automation device,

wireless security systems, industrial monitoring. Main features include small size, low power consumption, transmission distance,

anti-interference ability and so on.

LoRaWAN:

LoRaWAN uses LoRa technology to define end-to-end standard specifications to ensure interoperability between devices and

gateways from different manufacturers.

3

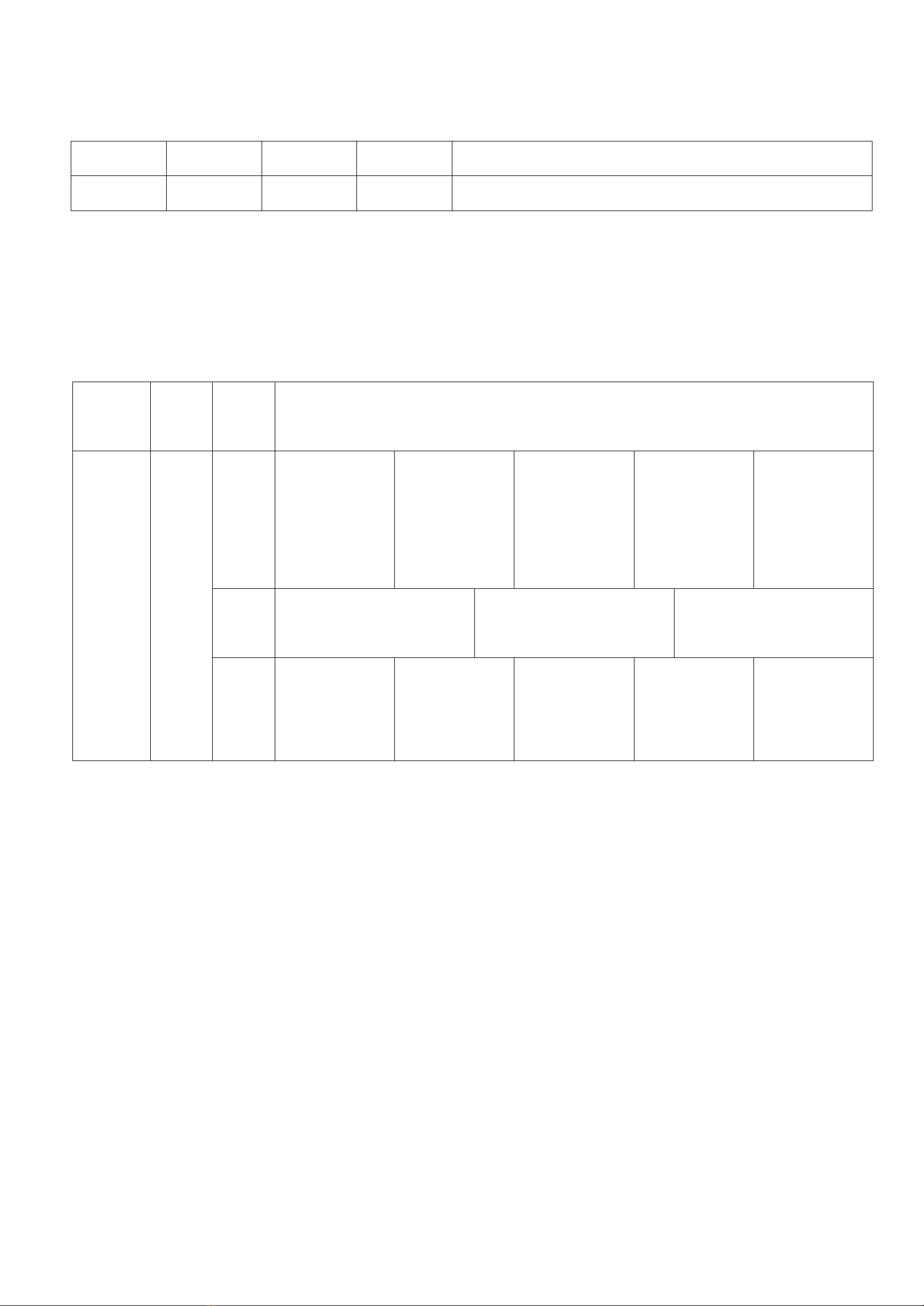

The specific model of R718UBD all-in-one is shown in the following table:

UBD represents the basic function CO2 of DC power supply

“1” represents temperature and humidity,

“2” represents vibration

“3” represents air pressure

“5” represents light

“6” represents TVOC

“7” represents PM2.5

Device Model Product functions

R718UBD CO2

R718UBD1 CO2, temperature and humidity

R718UBD12 CO2, temperature and humidity, vibration

R718UBD123 CO2, temperature and humidity, vibration, air pressure

R718UBD23 CO2, vibration, air pressure

R718UBD25 CO2, vibration, light

R718UBD125 CO2, temperature and humidity, vibration, light

R718UBD235 CO2, vibration, air pressure, light

R718UBD1235 CO2, temperature and humidity, vibration, air pressure, light

R718UBD126 CO2, temperature and humidity, vibration, TVOC

R718UBD1236 CO2, temperature and humidity, vibration, air pressure, TVOC

R718UBD127 CO2, temperature and humidity, vibration, PM2.5

R718UBD1237 CO2, temperature and humidity, vibration, air pressure, PM2.5

R718UBD12357 CO2, temperature and humidity, vibration, air pressure, light, PM2.5

R718UBD1257 CO2, temperature and humidity, vibration, light, PM2.5/10

R718UBD256 CO2, vibration, light, TVOC

R718UBD257 CO2, vibration, light, PM2.5/10

R718UBD236 CO2, vibration, air pressure, TVOC

R718UBD237 CO2, vibration, air pressure, PM2.5/10

R718UBD2356 CO2, vibration, air pressure, light, TVOC

R718UBD2357 CO2, vibration, air pressure, light, PM2.5/10

4

2. Appearance

3. Main Feature

Apply SX1276 wireless communication module

DC 12V power supply

It can detect temperature and humidity, CO2, vibration, atmospheric pressure, illumination, TVOC and dust

The base is attached with a magnet, which can be adsorbed on iron objects

Host Body Protection Level: IP65

Compatible with LoRaWANTM Class A

Frequency Hopping Spread Spectrum (FHSS) technology

Configuration parameters can be configured through third-party software platforms, data can be read and alarms can be set via

SMS text and email (optional)

Available third-party platform: Actility / ThingPark, TTN, MyDevices/Cayenne

Indicator

Temperature and humidity

Function Key

Dust sensor

(PM2.5 / PM10)

Light Sensor

5

4. Set up Instruction

On/Off

Power on Power on

Restore to factory setting Press and hold the function key for 5 seconds till green indicator flashes 20 times.

Power off Remove adapter

Note:

1. On/off interval is suggested to be about 10 seconds to avoid the interference of capacitor

inductance and other energy storage components.

2. In the first 5 seconds after power on, the device will be in engineering test mode.

Network Joining

Never joined the network

Turn on the device to search the network to join.

The green indicator stays on for 5 seconds: success

The green indicator remains off: fail

Had joined the network

(not at factory setting)

Turn on the device to search the previous network to join.

The green indicator stays on for 5 seconds: success

The green indicator remains off: fail

Fail to Join The Network Suggest to check the device verification information on the gateway or consult your platform

server provider.

Function Key

Press and hold for 5 seconds

Restore to factory setting

The green indicator rapidly flashes for 20 times: success

The green indicator remains off: fail

Press once The device is in the network: green indicator flashes once and sends a report

The device is not in the network: green indicator remains off

Sleeping Mode

The device is on and in the network

Sleeping period: Max Interval.

When the reportchange exceeds setting value or the state changes: send a data report according

to Max Interval.

6

5. Data Report

When the device is powered on, it will immediately send a version package report and then report the device data.

Default setting:

Min interval = 10s // The interval between multiple data packets

Max interval = 900s

Report count=1, R718UBD, R718UBD1, R718UBD12

Report count=2, R718UBD123, R718UBD23, R718UBD25, R718UBD125, R718UBD235, R718UBD 1235

R718UBD126, R718UBD127

Report count=3, R718UBD1236, R718UBD1237, R718UBD12357, R718UBD1257, R718UBD256, R718UBD257,

R718UBD236, R718UBD237

Data detection:

When the device is in a network state, the light flashes once after pressing the key, and then reads the data. When the time to

return the corresponding data or configure is up, it will also detect and return the corresponding data information.

(Note: The interval between multiple data packets is mintime)

Note:

1. Before any configuration, the device sends data according to the default configuration.

2. Do not send any configuration before turn on the device.

3. CO2 data will be unstable due to transportation relations, long storage time and other factors.

If the CO2 value which customers test is inconsistent ,or there is large discrepancy of the primary standard,

it can be recalibrated. For specific calibration methods,please refer to command 0x03 CalibrateType.

Refer to Netvox LoRaWan Application Command documents and for data analysis reported by the device

http://www.netvox.com.cn:8888/page/index Instruction parsing

The report configuration and sending time are as follows:

Min Interval (Unit: s) Max Interval (Unit: s) Sending interval of multiple data packets Report cycle

Not 0 Mintime * reportcount ~ 65535 By Min Time Report Report by Max Time

7

5.1 Example of ReportDataCmd

FPort:0x06

Bytes 1 1 1 Var(Fix=8 Bytes)

Version DeviceType ReportType NetvoxPayLoadData

Version– 1 byte –0x01——the Version of NetvoxLoRaWAN Application Command Version

DeviceType– 1 byte – Device Type of Device

The devicetype is listed in Netvox LoRaWAN Application Devicetype doc

ReportType – 1 byte –the presentation of the NetvoxPayLoadData,according the devicetype

NetvoxPayLoadData– Fixed bytes (Fixed =8bytes)

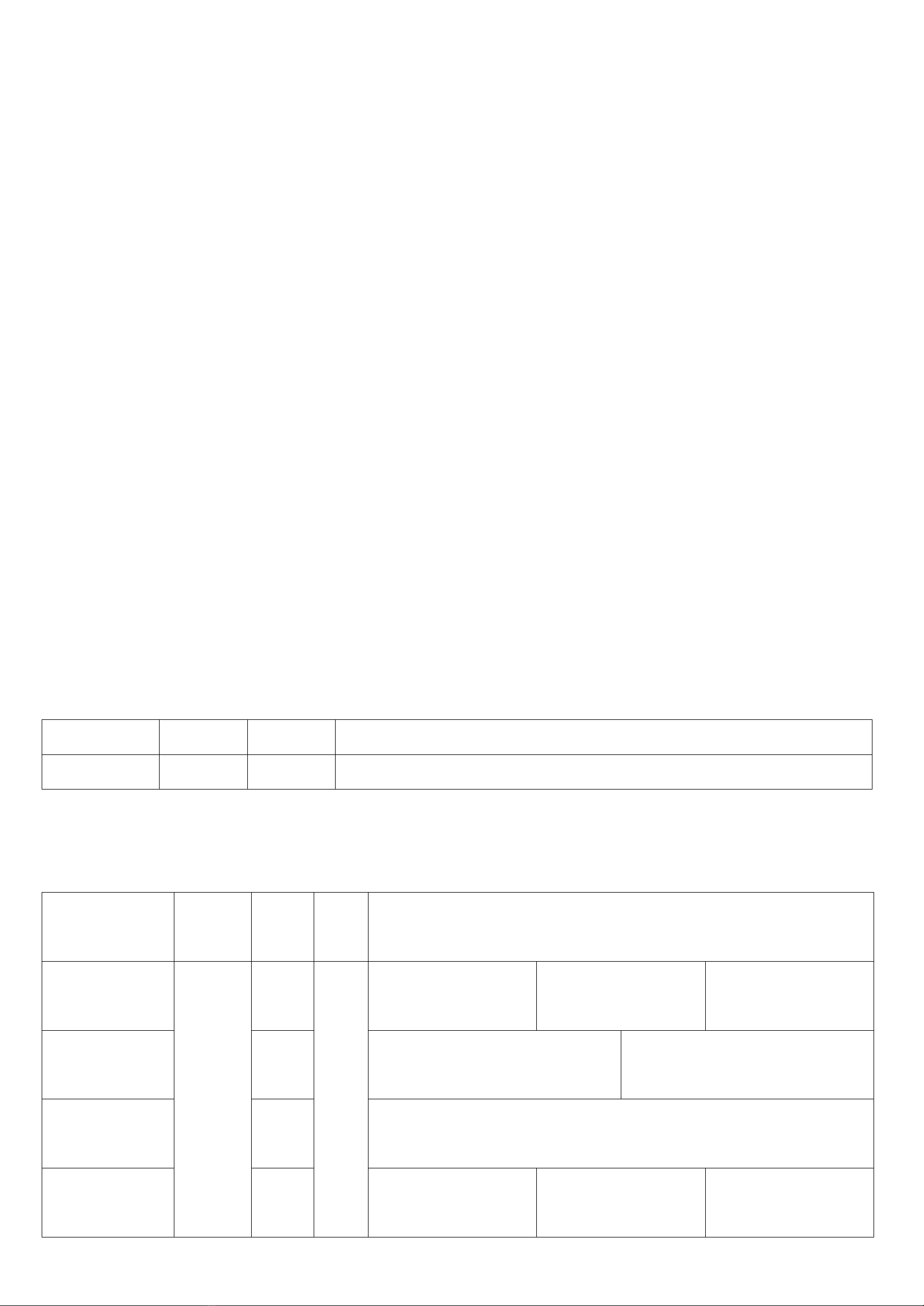

Device Device

type

Report

type NetvoxPayloadData

R718UBD 0xBB

0x01

Battery

(1Byte)

unit:0.1V)

Temperature

(Signed 2Bytes)

unit:0.01°C

Humidity

(2Bytes)

unit:0.01%

CO2

(2Bytes)

unit:1ppm

ShockEvent

(1Byte)

0x00_NoShock

0x01_ Shock

0x02 Battery

(1Byte, unit:0.1V)

AirPressure

(4Bytes,unit:0.01hPa)

illuminance

(3Bytes,unit:1Lux)

0x03

Battery

(1Byte)

unit:0.1V

PM2.5

(2Bytes)

Unit:1 ug/m3

PM10

(2Bytes)

Unit: 1ug/m3

TVOC

(2Bytes)

Unit:1ppb

Reserved

(1Byte)

fixed 0x00

R718UBD12357 report example:

# Report data 1: 01BB0100097A151F020C01

1st byte (01): Version

2nd byte (BB): DeviceType 0xBB -R718UBD Series

3rd byte (01): ReportType

4th byte (00): Battery-0x00 means is powered by DC power source

5th 6th byte (097A): Temperature-24.6°C ,097A(HEX)=2426(DEC),2426*0.01°C =24.26°C

7th 8th byte (151F): Humidity-54.07% , 151F(HEX)=5407(DEC),5407*0.01%=54.07%

9th 10th byte (020C): CO2-524ppm , 020C(HEX)=524(DEC),524*1ppm=524ppm

11th byte (01): Shock Event-1 , Shock

# Report data 2: 01BB02000001870F000032

1st byte (01): Version

2nd byte (BB): DeviceType 0xBB -R718UBD Series

8

3rd byte (02): ReportType

4th byte (00): Battery-0x00 means is powered by DC power source

5th ~ 8th byte (0001870F): AirPressure-1001.11hPa,1870F(HEX)=100111(DEC),100111*0.01hPa=1001.11hPa

9th ~11th byte (000032): Illuminance-50 Lux ,000032(HEX)=50(DEC),50*1Lux=50Lux

# Report data 3: 01BB030000110011FFFF00

1st byte (01): Version

2nd byte (BB): DeviceType 0xBB -R718UBD Series

3rd byte (03): ReportType

4th byte (00): Battery-0x00 means is powered by DC power source

5th 6th byte (0011):PM2.5-17ug/m3, 11(HEX)=17(DEC)

7th 8th byte (0011): PM10-17ug/m3, 11(HEX)=17(DEC)

9th 10th byte (FFFF): TVOC

11th byte (00): Reserved

Note:

Unsupported sensor detection item data is 0xFF/0xFFFF/0xFFFFFF/0xFFFFFFFF

5.2 Example of ConfigureCmd

FPort:0x07

Bytes 1 1 Var (Fix =9 Bytes)

CmdID DeviceType NetvoxPayLoadData

CmdID– 1 byte

DeviceType– 1 byte – Device Type of Device

NetvoxPayLoadData– var bytes (Max=9bytes)

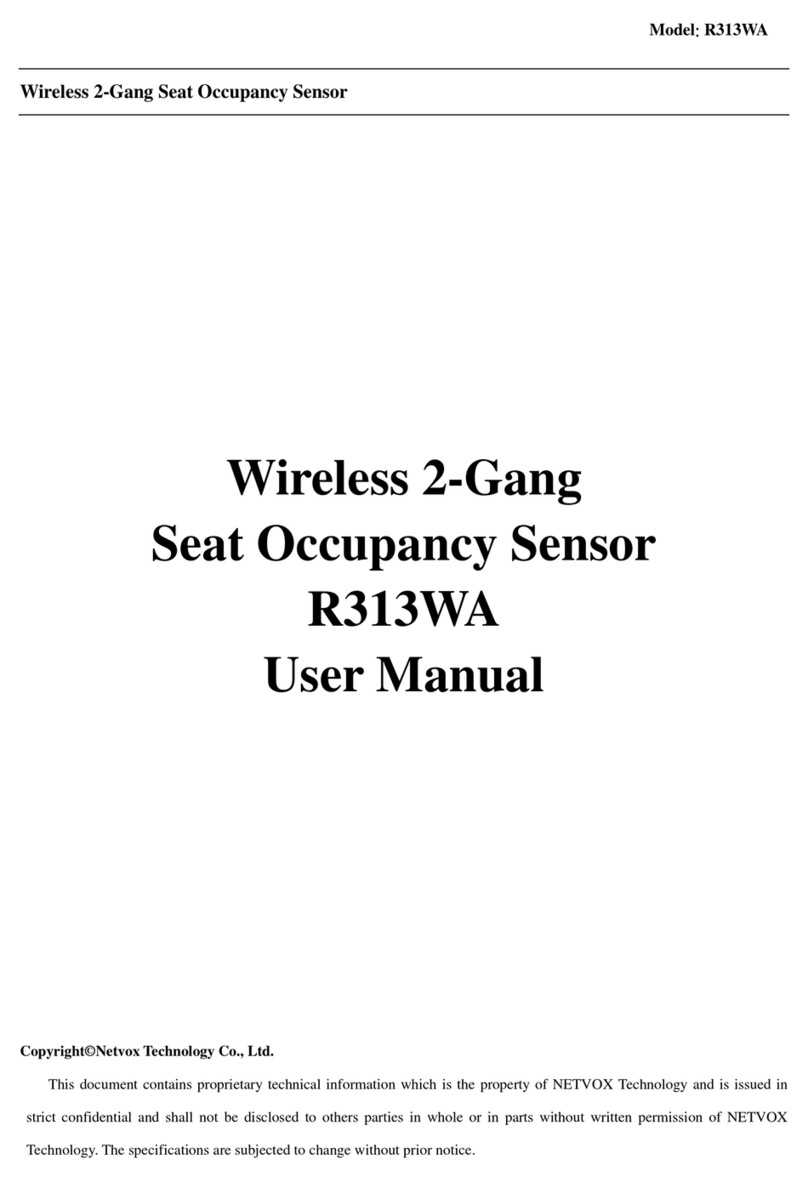

Description Device CMD

ID

Report

type NetvoxPayloadData

Config

ReportReq

R718UBD

0x01

0xBB

MinTime

(2bytes Unit:s)

MaxTime

(2bytes Unit:s)

Reserved

(2Bytes,Fixed 0x00)

Config

ReportRsp 0x81 Status

(0x00_suBBess)

Reserved

(8Bytes,Fixed 0x00)

ReadConfig

ReportReq 0x02 Reserved

(9Bytes,Fixed 0x00)

ReadConfig

ReportRsp 0x82 MinTime

(2bytes Unit:s)

MaxTime

(2bytes Unit:s)

Reserved

(2Bytes,Fixed 0x00)

9

Calibrate

CO2Req 0x03

CalibrateType (1Byte)

0x01_TargetCalibrate

0x02_ZeroCalibrate

0x03_BackgroudCalibrate

0x04_ABCCalibrate

CalibratePoint

(2Bytes,Unit:1ppm)

Only valid in

targetCalibrateType

Reserved

(6Bytes,Fixed 0x00)

Calibrate

CO2Rsp 0x83 Status

(0x00_suBBess)

Reserved

(8Bytes,Fixed 0x00)

SetShockSensor

SensitivityReq 0x04 ShockSensorSensitivity

(1Byte)

Reserved

(8Bytes,Fixed 0x00)

SetShockSensor

SensitivityRsp 0x84 Status

(0x00_success)

Reserved

(8Bytes,Fixed 0x00)

GetShockSensor

SensitivityReq 0x05 Reserved

(9Bytes,Fixed 0x00)

GetShockSensor

SensitivityRsp 0x85 ShockSensorSensitivity

(1Byte )

Reserved

(8Bytes,Fixed 0x00)

(1)Configure the device parameter MinTime = 300s, MaxTime = 900s

Downlink: 01BB012C03840000000000//12C(Hex)=300(Dec), 384(Hex)=900(Dec)

Device return:

81BB000000000000000000 (configuration successful)

81BB010000000000000000 (configuration failed)

(2) Read the device parameter

Downlink: 02BB000000000000000000

Device Return:

82BB012C03840000000000 (device current parameter)

(3) Set CO2 calibration

Downlink:

03BB0103E8000000000000 // Select Target-calibrations

(calibrate when the known CO2 concentration is 1000ppm (concentration optional))

03BB020000000000000000 // Select Zero-calibrations

(Calibration in an environment with a CO2 concentration of 0 ppm)

03BB030000000000000000 // Select Background calibrations

(calibration shall be carried out in a stable environment in fresh air, i.e. 400 ppm concentration)

03BB040000000000000000 // Select ABC calibrations

10

(self calibration is default when power on, and 8 days is a cycle of self calibration. The sensor must be exposed to

fresh air at least once (well ventilated) for calibration)

Device return:

83BB000000000000000000 (configuration successful)

// Successfully configured, (Target/Zero/Background/ABC-alignments)

83BB010000000000000000 (configuration failed)

//After calibration, the returned CO2 value is not within the error range

(4) SetShockSensorSensitivityReq:

The effective range of the configuration is 0x01~0x14, and the vibration function is turned off when it is set to 0xFF

Downlink: 04BB0A0000000000000000 //Set ShockSensorSensitivity = 10 (Dec)

Device return:

84BB000000000000000000 (device current parameter)

(5) GetShockSensorSensitivityReq:

Downlink: 05BB000000000000000000

Device return:

85BB0A0000000000000000 (device current parameter)

5.3 Example of calibration configuration

FPort:0x0E

Description Cmd

ID

Sensor

Type PayLoad(Fix =9 Bytes)

SetGlobal

CalibrateReq 0x01

See

below

Channel (1Byte)

0_Channel1

1_Channel2,etc

Multiplier

(2bytes,Unsigned)

Divisor

(2bytes,Unsigned)

DeltValue

(2bytes,Signed)

Reserved

(2Bytes,Fixed 0x00)

SetGlobal

CalibrateRsp 0x81

Channel (1Byte)

0_Channel1

1_Channel2,etc

Status

(1Byte,0x00_success)

Reserved

(7Bytes,Fixed 0x00)

GetGlobal

CalibrateReq 0x02

Channel (1Byte)

0_Channel1

1_Channel2,etc

Reserved

(8Bytes,Fixed 0x00)

GetGlobal

CalibrateRsp 0x82

Channel (1Byte)

0_Channel1

1_Channel2,etc

Multiplier

(2bytes,Unsigned)

Divisor

(2bytes,Unsigned)

DeltValue

(2bytes,Signed)

Reserved

(2Bytes,Fixed 0x00)

ClearGlobal 0x03 Reserved 10Bytes,Fixed 0x00)

11

CalibrateReq

ClearGlobal

CalibrateRsp 0x83 Status

(1Byte,0x00_success)

Reserved

(9Bytes,Fixed 0x00)

The calibrationsensor type and channel corresponding to each sensor :

Sensor Sensor Type Channel

Temperature 0x01 0x03

Humidity 0x02 0x04

Light 0x03 0x05

PM2.5 0x04 0x01

PM10 0x02

CO2 0x06 0x00

Air Press 0x35 0x06

TVOC 0x40 0x07

(1)Assume that the reported original value of CO2 is 500ppm, the calibration increases by 100ppm, and the reported value is

600ppm.

SetGlobalCalibrateReq: Calibration increased by 100ppm,Multiplier =0x0001,Divisor = 0x0001,DeltValue = 0x0064

Downlink: 0106000001000100640000

Device return:8106000000000000000000 (configuration successful)

8106000100000000000000 (configuration failed)

(2)GetGlobalCalibrateReq:

Downlink:0206000000000000000000

Device return:8206000001000100640000

(3)Assume that the reported original CO2 value is 500ppm, the calibration is reduced by 100ppm, and the reported value is 400ppm

SetGlobalCalibrateReq: Calibration reduction by 100ppm,Multiplier =0x0001,Divisor = 0x0001,DeltValue = 0xFF9C

Downlink: 01060000010001FF9C0000

Device return:8106000000000000000000

(4) GetGlobalCalibrateReq:

Downlink:0206000000000000000000

Device return:82060000010001FF9C0000

(5)ClearGlobalCalibrateReq (Clear calibration value: reported value returns to 500ppm)

Downlink: 0300000000000000000000

Device return:8300000000000000000000

12

6. Installation

The waterproof breathable film inside the product is waterproof but not waterproof against steam. Therefore, in order to prevent water

vapor from condensing inside the body, it should not be used in high humidity and steam environments.

6-1 Precautions for use of dust sensor

The sensor is made of water-resistant, dust-proof, and impact resistant materials. However, precision instruments need to be

carefully used and maintained to avoid impact and use in harsh environments such as corrosive liquids or gases.

The air inlet of the sensor shall not be blocked or polluted.

The electrolyte leakage will cause damage. Do not disassemble the sensor at will.

Do not use it when the shell is damaged or deformed.

The sensor shall avoid contact with organic solvents (including silicone rubber and other adhesives), coatings, agents, and fuel oils.

It is not recommended to use non-standard methods to test the sensor, and vertical air intake must be avoided. For example, put

the sensor directly on the concentrated ammonia, spray cigarettes towards the sensor, approach the sensor after the lighter is lit,

exhale towards the sensor, and close the sensor to alcohol. Because the regional concentration can be as high as tens of thousands

of ppm when liquid ammonia or alcohol volatilizes, and the carbon dioxide concentration in human breath can be as high as 40000

ppm, which will damage the sensor.

After being used for a long time in a high-concentration gas environment (it is prohibited to store and use it in a high-concentration

acid gas for a long time), it is slow to recover to the initial state.

When the sensor is stored, the working electrode and the reference electrode should be in a short circuit state.

The sensor is not allowed to be hot-plugged. The sensor must be plugged in after the power is turned off, otherwise, the sensor

may be damaged or abnormal phenomena may occur.

Please pay attention to whether there are requirements for limiting the use of wireless communication devices in this situation. If

there are such restrictions, please do not use this device. For example, during aircraft flight and landing, gas stations, gas stations

or other places with flammable and explosive materials.

6-2. Precautions for use of TVOC sensor

The installation place shall be far away from chemical corrosion environment.

The sensor and wire shall be far away from high-voltage electricity, heat source, etc.

The sensor belongs to precision instrument and should be stored in a dry, ventilated and normal temperature indoor environment.

The sensor is a precision device. Please do not disassemble it when using it to avoid product damage.

13

6-3 Precautions for outdoor installation

According to Enclosure Protection Class

This standard is equivalent to IEC 60529:2001 Degrees of Protection Provided by Enclosures

The test method of IP65 waterproof grade is:

spray the device in all directions under 12.5L/min water flow for 3min, and the internal electronic function is normal.

The test method of IP67 waterproof grade is:

the device is immersed in 1m deep water for 30min, and the internal electronic function is normal.

IP65, dust-proof and to prevent damage caused by water from nozzles in all directions from invading electrical appliances. It can be

used in general indoor environment and sheltered outdoor environment.

It is not suitable for use in environments with high water pressure,high temperatureand high humidity, such as long time direct sunlight

outdoors and possible direct exposure to rainstorm. If it is really necessary to install in harsh environments, it is recommended to add

sunscreen and rainproof shields when installing.

Case I (face down with LED and buttons) Case II (installed under the rain shield)

14

7. Important Maintenance Instruction

Kindly pay attention to the following in order to achieve the best maintenance of the product:

• Keep the device dry. Rain, moisture and various liquids or water may contain minerals that can corrode electronic circuits. In case the

device is wet, please dry it completely.

• Do not use or store in dusty or dirty areas. This way can damage its detachable parts and electronic components.

• Do not store in excessive heat place. High temperatures can shorten the life of electronic devices, destroy batteries, and deform or

melt some plastic parts.

• Do not store in excessive cold place. Otherwise, when the temperature rises to normal temperature, moisture will form inside which

will destroy the board.

• Do not throw, knock or shake the device. Treating device roughly can destroy internal circuit boards and delicate structures.

• Do not wash with strong chemicals, detergents or strong detergents.

• Do not paint the device. Smudges can make debris block detachable parts up and affect normal operation.

• Do not throw the battery into the fire to prevent the battery from exploding. Damaged batteries may also explode.

All the above suggestions apply equally to your device, batteries and accessories.

If any device is not operating properly, please take it to the nearest authorized service facility for repairing.

This manual suits for next models

20

Table of contents

Other netvox Accessories manuals

netvox

netvox RA0711 User manual

netvox

netvox ZB11A1 User manual

netvox

netvox ZB11C1 User manual

netvox

netvox R809A User manual

netvox

netvox R313WA User manual

netvox

netvox R816B01 User manual

netvox

netvox R718B1 Series User manual

netvox

netvox R718PB15 User manual

netvox

netvox Z311C User manual

netvox

netvox R718X User manual

netvox

netvox R72632A User manual

netvox

netvox R311B User manual

netvox

netvox R718LB User manual

netvox

netvox R718PA Series User manual

netvox

netvox R816B User manual

netvox

netvox R718PG-AS923 User manual

netvox

netvox R311G User manual

netvox

netvox R816B User manual

netvox

netvox R718CN2 User manual

netvox

netvox R718PA11 User manual