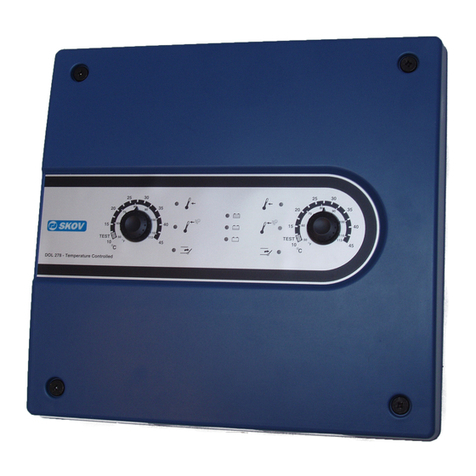

DOL 43X cULus

Technical User Guide

1 Product survey ...............................................................................................................................................5

2 Mounting guide...............................................................................................................................................6

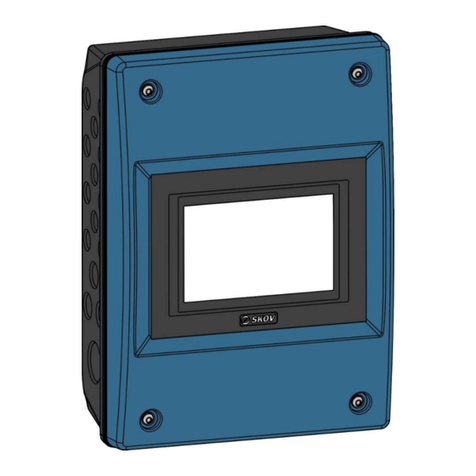

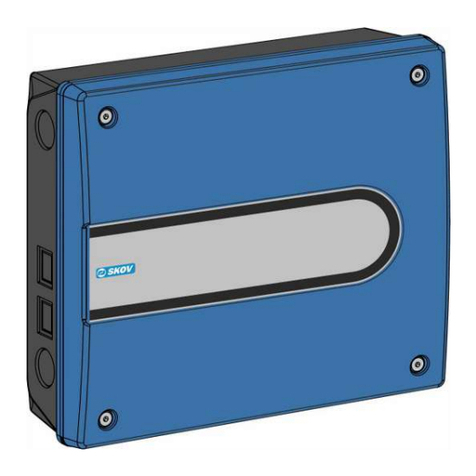

2.1 Mounting of house controller ................................................................................................... 6

3 Installation guide ............................................................................................................................................7

3.1 Electrical connection................................................................................................................. 7

3.1.1 Connection of cables ................................................................................................................... 7

3.2 Positioning of jumper ................................................................................................................ 7

3.3 Setting CAN address ................................................................................................................. 8

3.4 Setting CAN termination jumpers ............................................................................................9

3.5 Setting CAN protocol jumper.................................................................................................. 10

3.6 Overview of connection terminals ......................................................................................... 11

3.6.1 Power supply (-K1.1) ................................................................................................................. 11

3.6.2 Main module (-K1.2) .................................................................................................................. 11

3.6.3 I/O module (-K1.3) ..................................................................................................................... 11

3.6.4 Loop modules (-K1.5) and (-K1.6) ............................................................................................. 11

3.6.5 Power supply (K1.7)................................................................................................................... 11

3.7 Supply voltage for I/O module / main module....................................................................... 12

4 Technical data...............................................................................................................................................13

4.1 Dimensioned sketch ................................................................................................................ 15