New lift A6 PL 0 10 2.2 User manual

Manual

A6

Safety Monitoring Device

PL 0 10 2.2

A6_EN.DE05/01

Publisher NEW LIFT Steuerungsbau GmbH

Lochhamer Schlag 8

D- 82166 Gräfelfing

Germany

Tel.: +49 (0) 89 / 8 98 66 - 0

Fax: +49 (0) 89 / 8 98 66 - 3 00

Doc. No. A6_BA.EN05/01

Date of issue 05/01

Copyright © 1999, NEW LIFT Steuerungsbau GmbH

All rights including those of copying and reproduction of parts of this de-

scription and of the translation are reserved by the publisher.

No part of this description may be reproduced in any form or copied with an

electronic replication system without the written permission of the publish-

er.

Contents

A6_BA.EN05/01 3

1 About this Manual ...............................................................................................5

1.1 General........................................................................................................................... 5

1.2 Signs and symbols used........................................................................................ 6

2 General Safety Regulations..........................................................................7

2.1 Intended use................................................................................................................ 7

2.2 Safety regulations......................................................................................................7

3 Important Facts about your A6 Safety Monitoring Device.....9

3.1 Working principle...................................................................................................... 9

3.2 LEDs and terminals................................................................................................ 10

3.3 Dimensions and technical data......................................................................... 12

4 Installation and Commissioning............................................................. 15

4.1 Mounting and Wiring the A6 Safety Monitoring Device........................... 16

Mounting the A6 Safety Monitoring Device ..................................................................... 16

Wiring the A6 Safety Monitoring Device.......................................................................... 16

4.2 Commissioning the A6 Safety Monitoring Device..................................... 17

5 Troubleshooting and Servicing............................................................... 19

5.1 Troubleshooting....................................................................................................... 19

5.2 Servicing..................................................................................................................... 19

6 Declarations of Conformity......................................................................... 21

Contents

4A6_BA.EN05/01

1 About this manual

A6_BA.EN05/01 5

1 About this manual

Please read this manual carefully before installing, commissioning or ser-

vicing the A6Safety Monitoring Device. Alsosee chapter 2 „General Safety

Regulations“.

1.1 General

This manualcontains important information forsafe and properinstallation,

commissioning and servicing of the A6 Safety Monitoring Device.

Following these instructions will help to:

- prevent danger

- avoid repair costs and standstill

- increase the reliability and lifespan of the A6 Safety Monitoring Device

and the lift system.

Local, national and on-site regulations regarding health and safety and pro-

tection of the environment must be taken into account in addition to this

manual.

This manual only describes the NEW LIFT A6 Safety Monitoring Device of

the lift system.

One copy of this manual must be given to the engineer when installing and

commissioning the A6 Safety Monitoring Device. It must be placed in the

controller cabinet after commissioning.The factory test logs of the A6 Safe-

ty circuit remain with NEW LIFT.

Please refer to the respective manufacturer’s or supplier’s documentation

for information about all other components of your lift system.

1 About this manual

6A6_BA.EN05/01

1.2 Signs and symbols used

The following signs and symbols are used:

Symbol

Activity Symbol:

Activities described after this symbol must be carried out in the given or-

der.

Warning sign High voltage

This sign marks activities with danger of electric shock with pos-

sibly fatal consequences.

2 General Safety Regulations

A6_BA.EN05/01 7

2 General Safety Regulations

All important safety regulations are summarized in this chapter.

All persons performing installation, commissioning or servicing work

on the A6 Safety Monitoring Device must read this chapter and follow

its regulations.

All installation, commissioning or servicing work on the A6 Safety Monitor-

ing Device must be performed by or supervised by a qualified electrician.

A qualified electrician has appropriate training and knowledge of regula-

tions that allow him to judge the quality of the work performed and spot pos-

sible dangers.

Laws, regulations, guidelines and standards that apply in the country of op-

eration must be followed in addition to the safety regulations mentioned in

this manual.

2.1 Intended Use

The A6 Safety Monitoring Device according to EN 81-1/-2, 14.1.2.3 and

TRA 264.2 is only intended for use as a control element in hydraulic and

cable lifts to enable the following functions of the lift:

- Landing andrelevelling the carwithopen carand shaftdoors (according

to EN 81-1/81-2, 14.2.1.2 and TRA 265.1).

- Ramp control (according to EN81-1, 14.2.1.5 / EN81-2, 14.2.1.4 and

TRA 266.3)

The A6 Safety Monitoring Device is used to override the door and locking

switches (safety switches) in the unlocking zone.

2.2 Safety Regulations

General The instructions of the lift manufacturer and the instructions in this manual

must be followed during installation, commissioning and servicing of the lift

system.

Alcohol and drugs must not be consumed before and during installation

and commissioning.

2 General Safety Regulations

8A6_BA.EN05/01

Electricity Danger to life! Do not touch live parts while working on electrical equip-

ment.

Regulations for installing and operating electrical equipment (VDE 0100)

and regulations of local utilities must be followed.

The specified distances between different electrical assemblies must be

controlled and maintained.

All installation work must be carried out with the system shut down and off

circuit.

All cables and wires must be installed with sufficient strain relief.

Working in the shaft When using the car for an assembly platform, regulations from VGB 35

“Building hoists” apply for the entire lift system.

Troubleshooting and

Servicing The A6 Safety Monitoring Device must not be tampered with or repaired.

A faulty A6 Safety Monitoring Device must be replaced. The replaced A6

Safety Monitoring Device must be returned to NEW LIFT for quality control

and documentation.

Waste Disposal Faulty parts that cannot be repaired must be disposed of in an environmen-

tally acceptable manner in accordance with the governing environment

protection laws. Separate the different materials (plastic, metal, electronic

components) and recycle them.

3 Important Facts about your A6 Safety Monitoring Device

A6_BA.EN05/01 9

3 Important Facts about your A6 Safety Monitoring

Device

The A6 Safety Monitoring Device according to EN 81-1/-2, 14.1.2.3 and

TRA 264.2 is only intended for use as a control element in hydraulic and

cable lifts to enable the following functions of the lift:

- Landing andrelevelling the carwithopen carand shaftdoors (according

to EN 81-1/81-2, 14.2.1.2 and TRA 265.1).

- Ramp control (according to EN81-1, 14.2.1.5 / EN81-2, 14.2.1.4 and

TRA 266.3)

The A6 Safety Monitoring Device is used to override the door and locking

switches (safety switches) in the unlocking zone.

A type verification certificate from the German TÜV and an EC Declaration

of Conformity are available (see “Declarations of Conformity” on page 21).

3.1 Working Principle

Abb. 3.1 Diagram of working principle

lift controller A6 Safety Monitoring Device

+24V,GND power supply

door zone enable

+24V

door zone signal

override

safety circuit

error signalshut down

sensor A

sensor B

GND

external

error signal

A6002.cdr

3 Important Facts about your A6 Safety Monitoring Device

10 A6_BA.EN05/01

The A6 Safety Monitoring Device is a stand-alone relay circuit to override

the door andlocking switches in the unlocking zone of the shaft doors. The

car position is continuously monitored with two non-equivalent sensors

(magnet switches on the car).

If the controller enables the zone circuit (while landing on a level or during

adjustment) and the car is in the unlocking zone (sensor A closed, sensor

B open), the A6 Safety Monitoring Device sends a zone signal to the con-

troller and closes the contacts to override the door and locking switches.

If the car leaves the unlocking zone or the controller does not enable the

zone circuit, the zone signal and the door and locking switch override are

deactivated.

If the position ofsensor A and sensor B is not non-equivalent for more than

1 second, the lift controller system is shut down by the issuing of an error

signal. The shut down lift can only be reactivated by cycling the lift control-

ler system OFF and ON.

3.2 LEDs and Terminals

Abb. 3.2 LEDs and terminals of the A6 Safety Monitoring Device

A6003.cdr

Sicherheitsschaltung

A6

Zonenfehler

Zonenmeldung

K202

K201

K200

24V DC

PL 0 10 2.2

505

506

507

508

509

510

511

512

513

514

515

516

517

518

519

501

502

503

504

NEW

3 Important Facts about your A6 Safety Monitoring Device

A6_BA.EN05/01 11

LEDs

Terminals

LED Col-

our State Description

Zonenfehler red on Sensor A/B not non-equivalent

or A6 SafetyMonitoring Device

faulty

Zonenmel-

dung green on Sensor A closed

Sensor B open

24V DC green on Power supply

K202 red on out of zone

K201 red on out of zone

K200 green on in zone

A6 Description

501 Error signal for shutting down the system (input)

502 Error signal for shutting down the system (output)

503 Override door locking equipment (input)

504 Override door locking equipment (output)

505 External error signal (isolated input)

506 External error signal (isolated output)

507 Zone signal (isolated input)

508 Zone signal (isolated output)

509 NC

510 GND emergency power supply

511 + 6 - 24 V emergency power supply

512 + zone indicator EN81-2, 12.9.3 and TRA 228.5

513 - zone indicator EN81-2, 12.9.3 and TRA 228.5

514 Zone enable (input + 24 V DC)

515 Sensor B

516 Sensor A

517 GND

518 GND (power supply)

519 + 24 V DC (power supply)

3 Important Facts about your A6 Safety Monitoring Device

12 A6_BA.EN05/01

3.3 Dimensions and Technical Data

Dimensions

Abb. 3.3 Dimensions of the A6 Safety Monitoring Device

A6004.cdr

top-hat rail mounting lock

3 Important Facts about your A6 Safety Monitoring Device

A6_BA.EN05/01 13

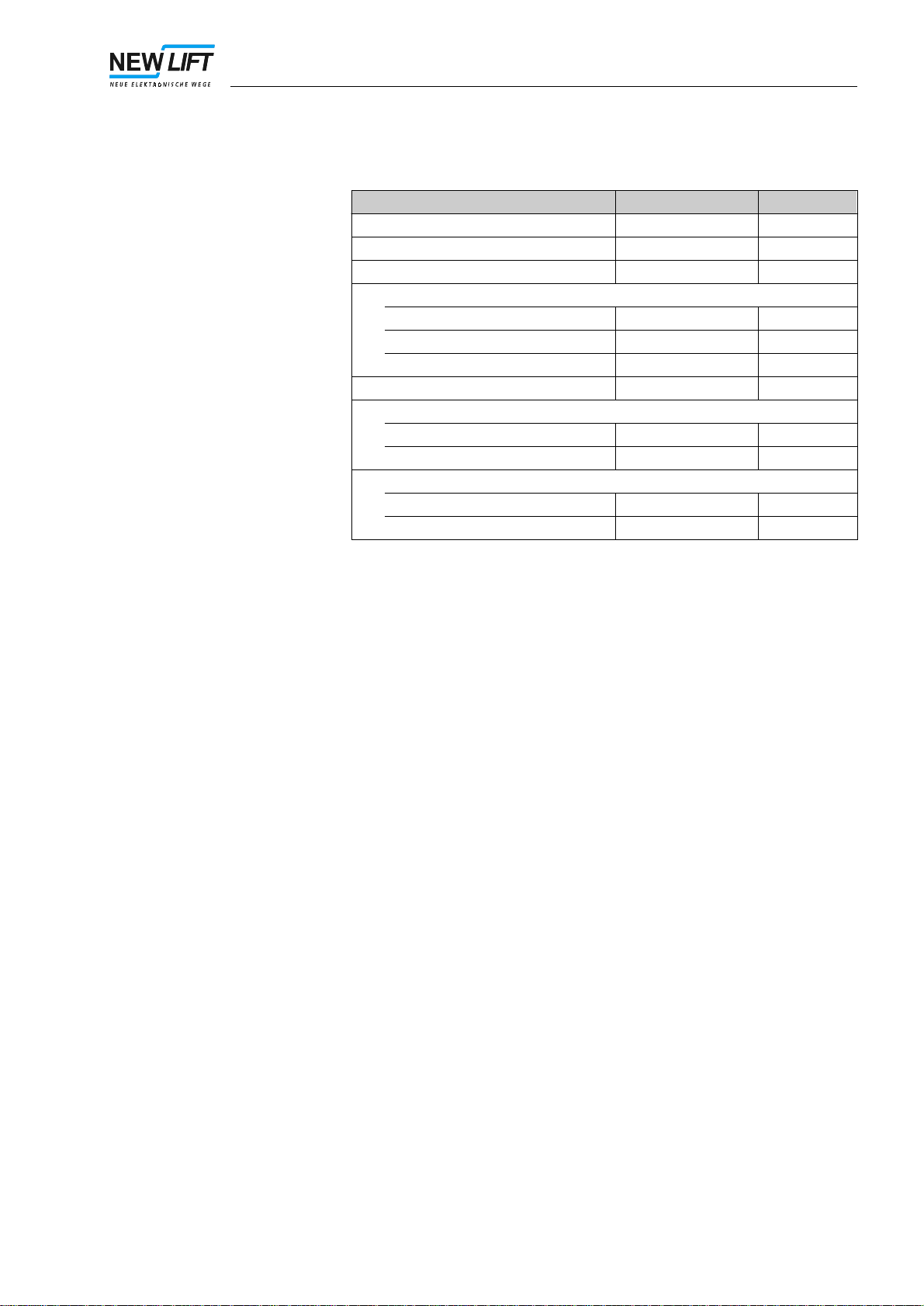

Technical data Description Value Unit

Signal voltage 24 ±10% V DC

Power consumption 200 mA

Fusing the safety circuit C2

Output limits

Voltage 250 V

Current 4 A

Capacity 800 VA

Length x width x height 100 x 75 x 110 mm

Temperature range

Storage / transport -20 - +70 °C

Operation ±0 - +60 °C

Relative humidity

Storage / transport 5 - 95 %

Operation 15 - 85 %

3 Important Facts about your A6 Safety Monitoring Device

14 A6_BA.EN05/01

Notes

4 Installation and Commissioning

A6_BA.EN05/01 15

4 Installation and Commissioning

All important information for installing and commissioning the A6 Safety

Monitoring Device is described in this section. On-site circumstances may

require a different order of assembly than the one suggested here.

If the A6 Safety Monitoring Device is part of a lift controller system supplied

by NEW LIFT, it is delivered in the wired controller cabinet and installation

is to be carried out following the instructions of your lift controller.

Abb. 4.1 Recommended order of installation and commissioning of

the A6 Safety Monitoring Device.

Mounting the

A6 Safety Monitoring Device

A6005.cdr

Wiring the

A6 Safety Monitoring Device

Mounting the

magnet swichtes sensor A/B

Connecting the

magnet swichtes sensor A/B

to the A6 Safety Monitoring

Device

Commissioning the

the lift controller and

the A6 Safety Monitoring

Device

Operating test of the

A6 Safety Monitoring Device

4 Installation and Commissioning

16 A6_BA.EN05/01

4.1 Mounting and Wiring the A6 Safety Monitoring Device

The A6 Safety Monitoring Device must be mounted in a controller cabinet

rated as IP54 and fused with C2 (safety circuit) and 0.5 A (+ 24 V DC).

Control engineering regulations according to VDE 0100 must be fol-

lowed when mounting and wiring the A6 Safety Monitoring Device in

the controller cabinet.

Mounting the A6 Safety Monitoring Device

The A6 Safety Monitoring Device is snapped onto a top-hat rail DIN EN

50022 in the controller cabinet or fastened to the supporting plate with two

screws. (See fig. “Dimensions of the A6 Safety Monitoring Device” on page

12.)

Wiring the A6 Safety Monitoring Device

The A6 Safety Monitoring Device is wired according to the documentation

of the lift controller used.

All signal voltage wires must be at least 0,5 mm2and all wires of the safety

circuit (501, 502, 503, 504) at least 1,0 mm2.

WARNING!

Electric hazard due to live wires and parts.

Death or serious injury.

Make sure system is off circuit.

All installation work on electrical parts must be carried out with the

system shut down and off circuit.

4 Installation and Commissioning

A6_BA.EN05/01 17

4.2 Commissioning the A6 Safety Monitoring Device

The shaft components are connected to the A6 Safety Monitoring Device

according to the instructions of the controller manufacturer after installing

the controller cabinet in the machine room.

With NEW LIFT controls, the A6 Safety Monitoring Device is always mount-

ed and wired in the controller cabinet.

Requirements - Safety circuit in operation

- Control in operation

- Awareness of all possible dangers in the shaft and how to avoid them.

- Installation and wiring of the A6 Safety Monitoring Device and sensors

A and B completed.

Sensor switching points The sensor switching points must be adjusted so that in the zone area sen-

sor A is closed and sensor B open. The zone area is ±0,2 m (±0,35 m) from

the levelling position with symmetrical switching points.

Commissioning The A6 Safety Monitoring Device must be commissioned together with the

lift controller system used. The commissioning instructions of your control-

ler manufacturer will give you more information.

WARNING!

Electric hazard due to live wires and parts.

Death or serious injury.

Make sure system is off circuit.

All installation work on electrical parts must be carried out with the

system shut down and off circuit.

4 Installation and Commissioning

18 A6_BA.EN05/01

Operating Test The following checks must be carried out:

- in the zone (car is at rest)

Disconnect terminal 516 (sensor A). The zone errorLEDmust illumi-

nate within 1 second maximum.

- while the car is moving

Disconnect terminal 515 (sensor B) while the car is still at rest, then

start moving the car. When leaving the zone area, the zone error

LED must illuminate within 1 second maximum and the car must

come to rest at the next stop.

5 Troubleshooting and Servicing

A6_BA.EN05/01 19

5 Troubleshooting and Servicing

5.1 Troubleshooting

An error signal is sent when faults occur with the A6 Safety Monitoring De-

vice or with sensors A and B.

Requirements for

trouble-free operation - Power supply (24 V ±10%) on terminals 518 and 519

- The controller has enabled the A6 Safety Monitoring Device

- Sensors A and B are non-equivalent.

Malfunctions

If all requirements for trouble-free operation are met and the A6 Safety

Monitoring Device is still malfunctioning, it must be replaced.

The replaced A6 Safety Monitoring Device must be returned to NEW

LIFT. The A6 Safety Monitoring Device must not be opened or re-

paired.

5.2 Servicing

An operating test of the A6 Safety Monitoring Device (see page 18) is rec-

ommended when routinely servicing the lift system.

Other than that the A6 Safety Monitoring Device requires no servicing.

WARNING!

Electric hazard due to live wires and parts.

Death or serious injury.

Make sure system is off circuit.

All installation work on electrical parts must be carried out with the

system shut down and off circuit.

5 Troubleshooting and Servicing

20 A6_BA.EN05/01

Notes

Table of contents

Other New lift Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Megger

Megger DLRO100EB manual

CGOLDENWALL

CGOLDENWALL NDJ-5S user manual

Horiba Scientific

Horiba Scientific LAQUA DS-71 Quick manual

Itm

Itm Oakton 450 Series Operation instructions

Tektronix

Tektronix TLA7S08 Declassification and security instructions

Agilent Technologies

Agilent Technologies OmniBER OTN Series Performance Verification Manual

Velleman

Velleman DEM400 user manual

Maxwell Digital Multimeters

Maxwell Digital Multimeters 25603 user manual

DEELAT

DEELAT D1140772 user manual

Endress+Hauser

Endress+Hauser Deltapilot S FMB70 Functional safety manual

Bender

Bender LIM2000-1NL quick start guide

York Survey Supply

York Survey Supply 343000 operating instructions