- 5 -

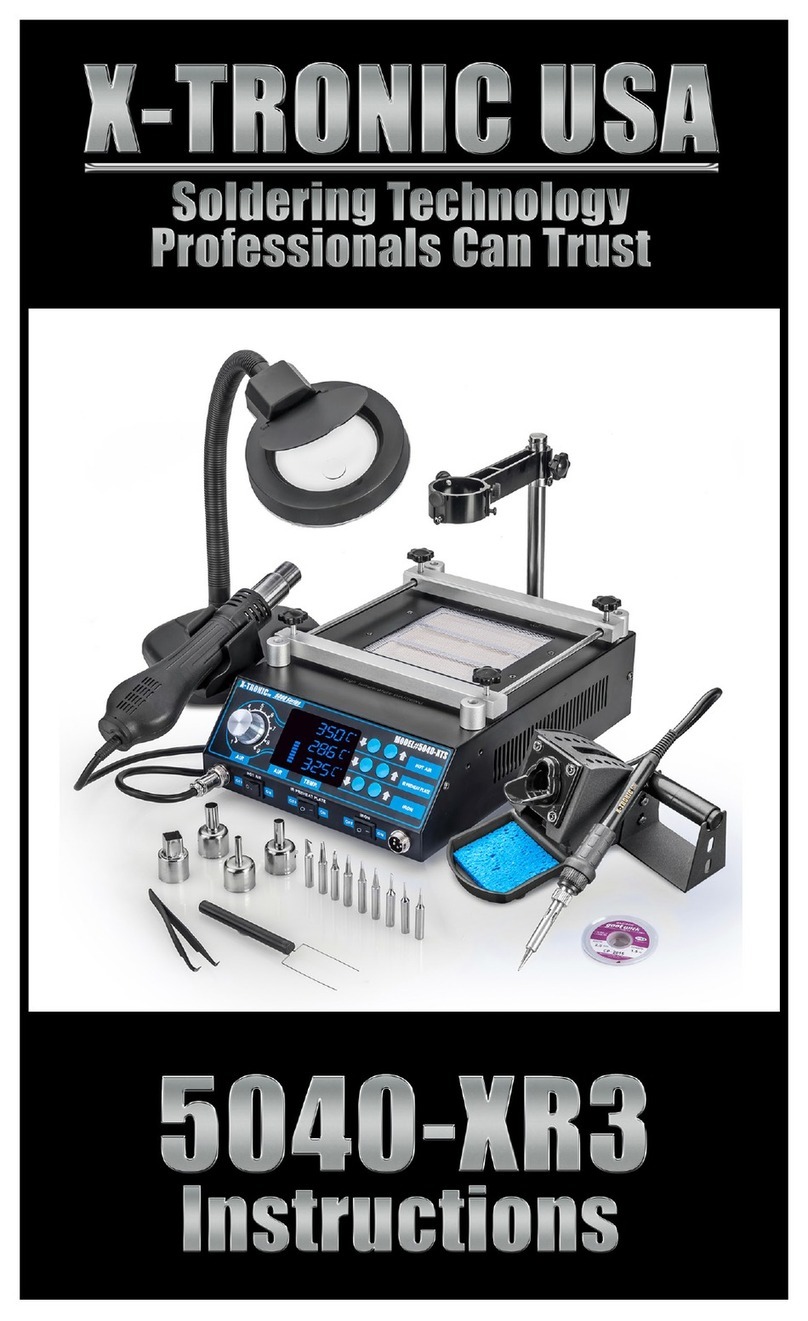

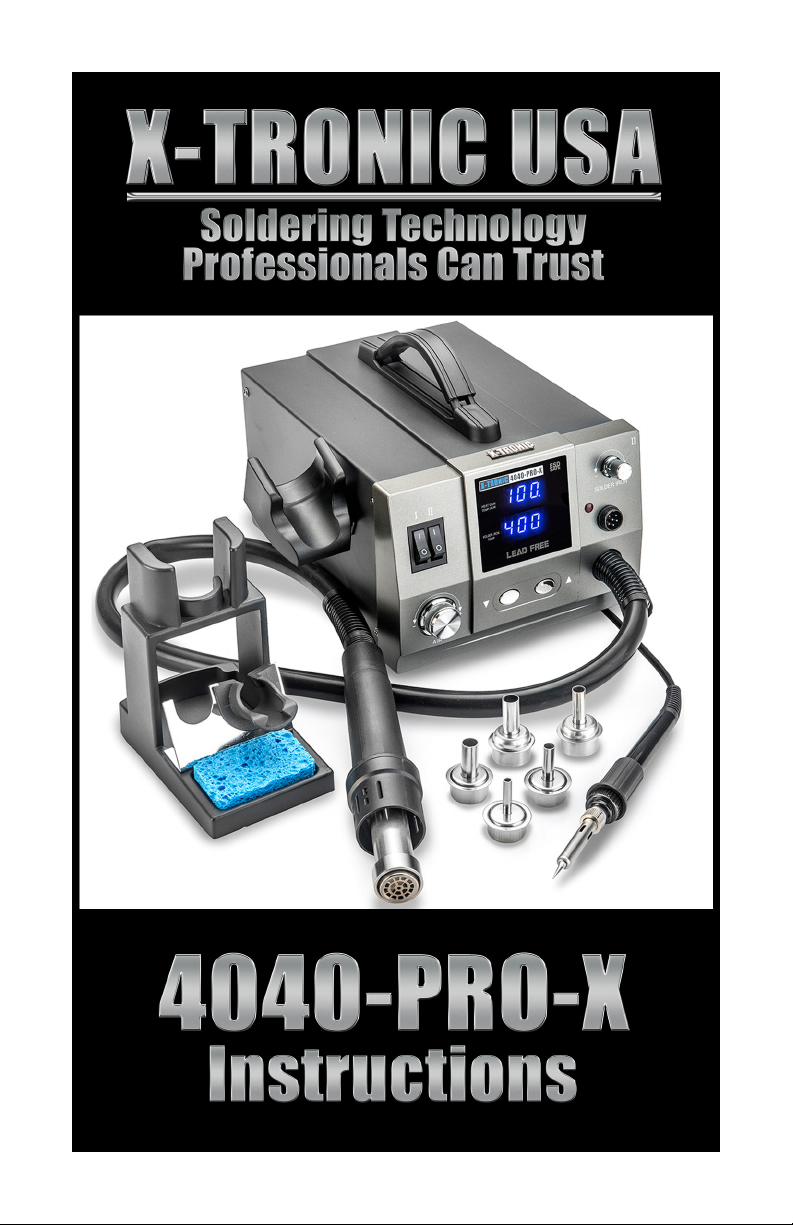

HOT AIR GUN

1. The top display will show “SLP” when the hot air gun is in its holder

and in sleep/standby mode.

2. Push the Hot Air Temperature Adjustment Buttons (▲ or ▼ ) in the

middle unit to set the hot air gun temperature. The hot air gun can

be set between 212°F ~ 932°F / 100°C ~ 500°C.

3. Turn the Air Flow Control Knob to adjust the airflow for the hot air

gun. This can be set from 20 - 100.

CAUTION

When using a temperature higher than 300°C on the hot air gun the

air flow should be set at 45 or higher. This will prevent damage to

the hot air gun and increase the life of the heating element.

4. When the hot air gun is removed from the holder it will start

blowing air and ramp up to the programmed temperature and air

speed quickly.

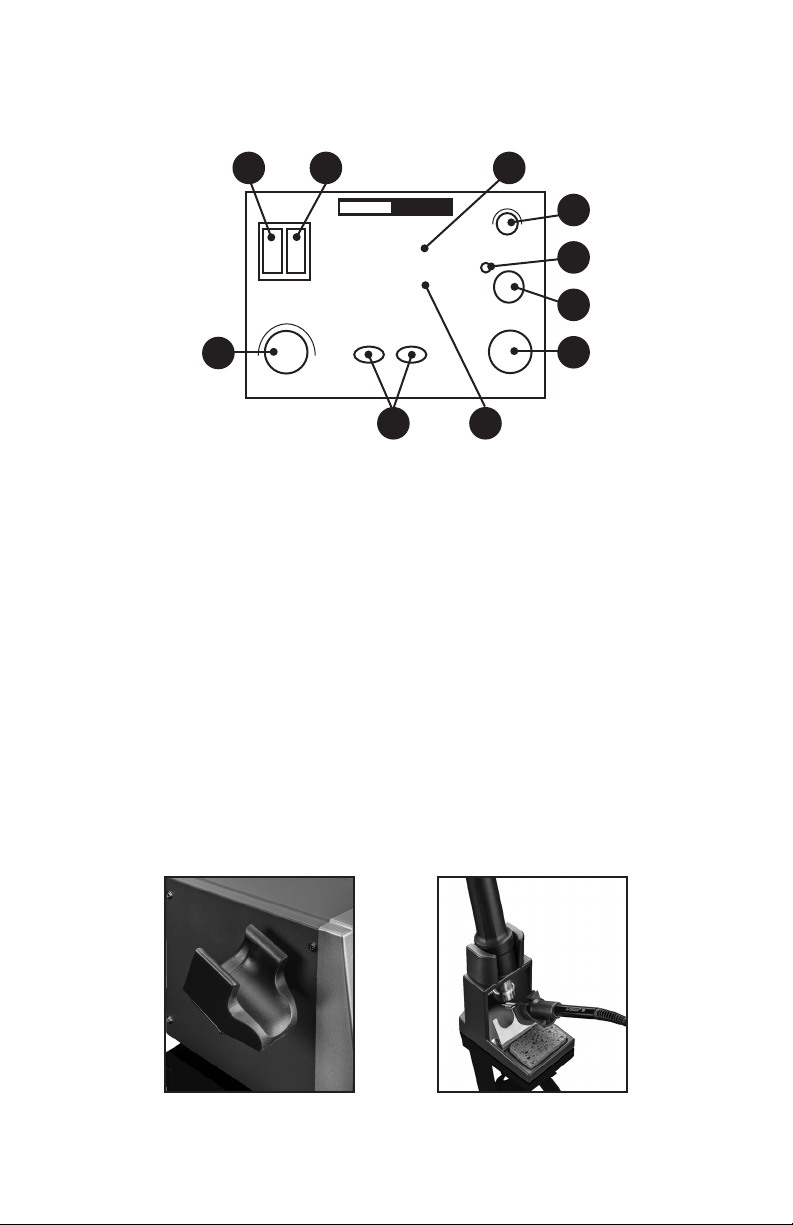

5. When the hot air gun is not in use always place it back in the side

holder or in the vertical position in the upright tower holder. When

the hot air gun is placed in one of these holders, it will start going

into the Auto Cool Down and Sleep/Standy mode immediately. The

hot air gun will continue blowing air until the temperature gets back

down to 100°C and then the airflow will stop and the hot air gun will

go into sleep/standby mode.

Note: When the hot air gun is initially returned to either of these holders,

the air flow may increase noticeably while the hot air gun is

cooling down and going into sleep/standby mode. This is a safety

feature built into the unit.

6. When the hot air gun is removed again from either of these holders

it will start blowing air and ramp up to the programmed temperature

and air speed again quickly.

7. To turn the hot air gun off, turn off the II power switch on the front

of the unit.

Note: Do not unplug the unit or shut off the Main Power Switch on

the back of the unit until you have placed the hot air gun in the

holder and it has cooled down and the air has stopped blowing

automatically - this allows a full cool down of the hot air gun.

When the unit is not in operation and has fully cooled down, turn the unit

off with the power switch located on the back of the unit and unplug from

the outlet.