NewLine Rhine Pivot Series User manual

1. When you receive your Newline shower check contents for any freight damage.

2. Advise Newline on 0508 639 5463 if any damage has occurred or a defect

identied within 8 hours of receiving the goods so this can be rectied.

3. Do not proceed with installation until resolved.

Important!

May 2020

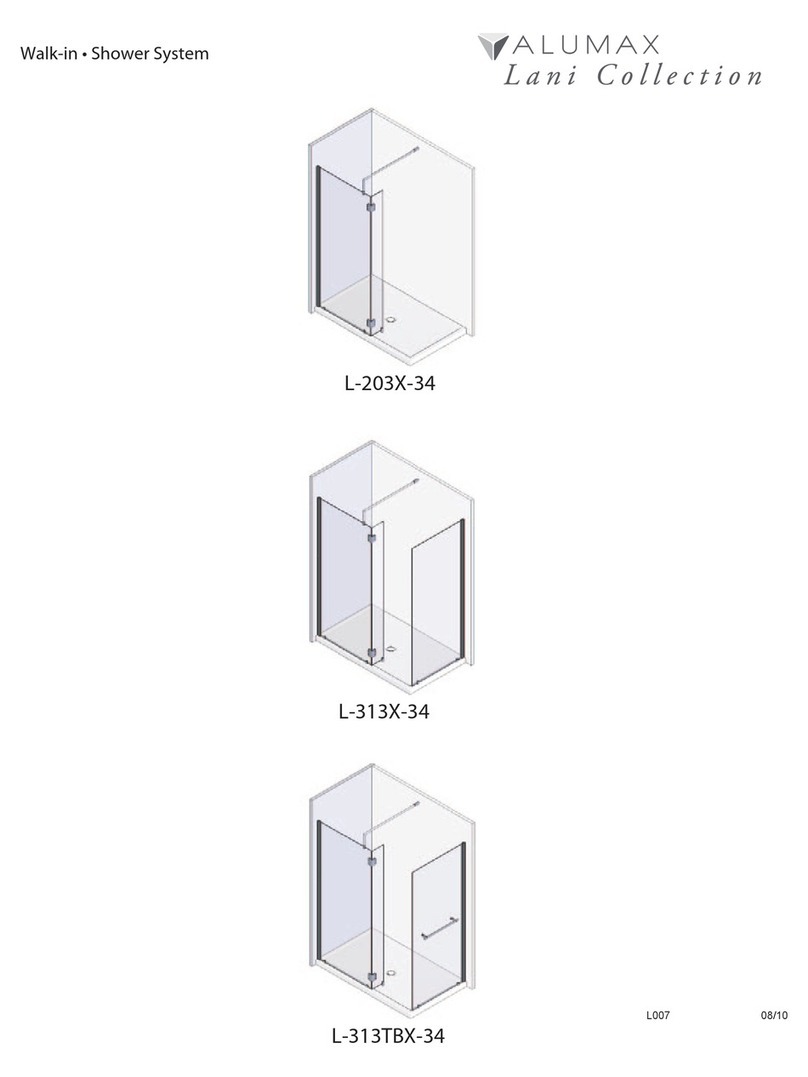

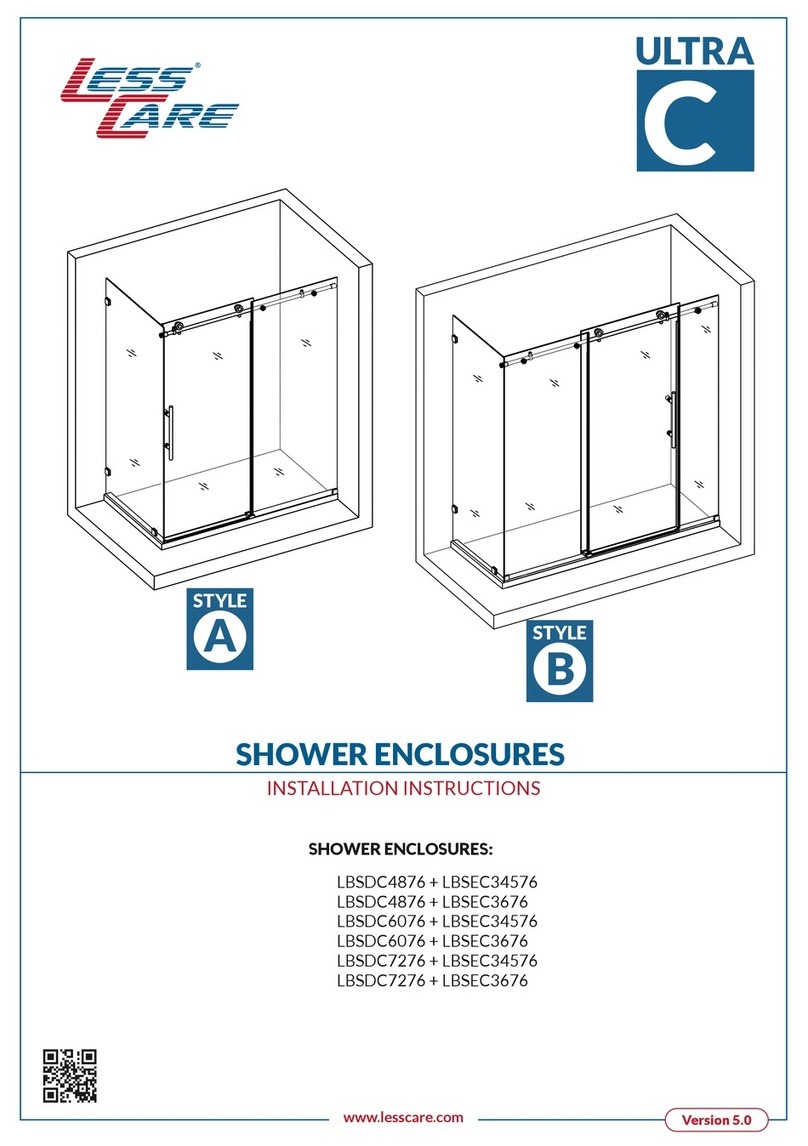

INCLUDES: 2-SIDED SHOWERS AND 3-SIDED ALCOVE DOORS

Rhine Pivot

Low Prole Tray Series

INSTRUCTION MANUAL

2

Page 3 Prep and layout tables for all pivot doors

Page 4 - 7 2-Sided shower

Page 8 - 12 3-Sided Alcove shower

NEWLINE RECOMMENDS A SKILLED TRADESMAN ACQUAINTED WITH

SHOWER INSTALLATIONS TO ENSURE THE VERY BEST OUTCOME.

PIVOT DOOR SETS 2-SIDED & ALCOVE APPLICATIONS

WARRANTY

Faulty goods are covered under warranty. Visit www.newline.co.nz for warranty information.

Breakages incurred during construction are not covered under warranty.

Installations must conform to the instructions to be covered by the warranty.

INSTRUCTIONS

Tray and liner instructions: Come with the specic tray supplied

Shower waste and supply fittings: Must be installed by a registered plumber.

HEALTH AND SAFETY

Toughened Glass:

• Do not rework precut glass panels. Cutting or altering a glass panel will cause it to explode without warning.

• Unpack all glass assemblies. Stand glass on soft packaging on the oor and against a wall. Care must be taken

not to strike any edge or corner against a hard surface as this will chip and destroy the glass panel.

Installation:

• Glass panels and assemblies are heavy. Two man lifting is recommend for handling and installation.

• Determine positioning of wiring and piping within wall cavities before shower installation. Mark their positions to

ensure electrical and piping areas are avoided.

• Wear appropriate protective clothing and eye protection during installation.

MATERIALS REQUIRED

Sika Silaex NG translucent silicone.

TOOLS REQUIRED

AFTERCARE

The shower must be squeegeed down after each shower. Thoroughly clean weekly with a microber cloth, mild

detergent and water. Rinse with clean water and squeegee and wiped dry.

NOTE: ACRYLIC TRAY & LINER - Detailed Instructions for both are packed with shower tray.

INDEX

3

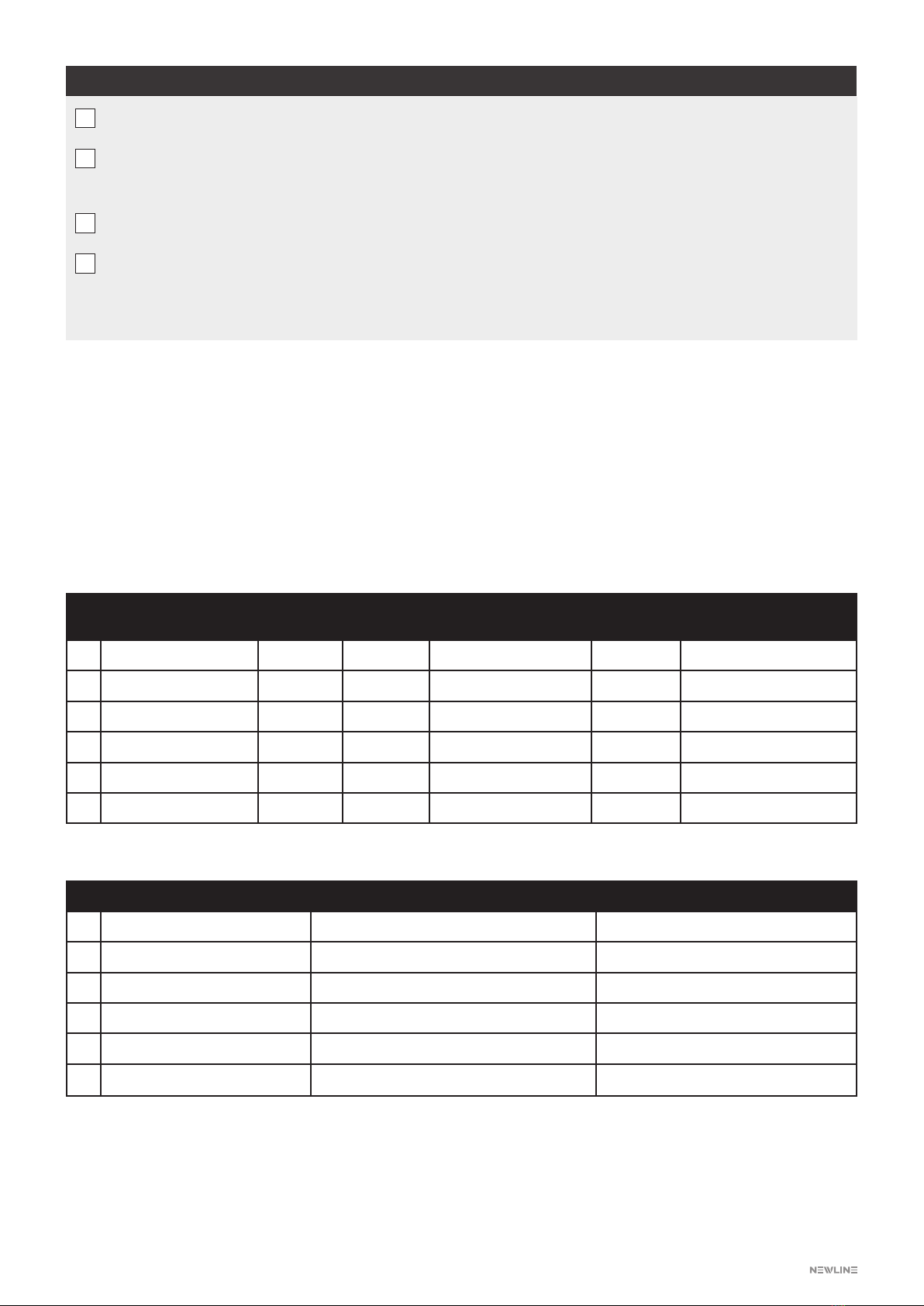

BEFORE YOU START: READ NOTES OF TABLE A & B LAYOUTS

Check TABLE A for layout of 2-Sided shower

• Identify the size of shower you are working with.

• The door set has shared adjustment points: Wall and corner post positions.

• Walls bowed or leaning inwards: Check adjustment available and use Min to Max Table B if your case requires

this.

Note: 3-Sided shower table is on page 9.

2-Sided Shower: Ensure the oor is level and the walls are plumb and at.

Position all framing for solid xing for the shower tray, shower and plumbing ttings. Wall proles

require a stud centred 20mm back from tray outside edge.

Ensure all plumbing items have been installed prior to the lining being attached.

Alcove Shower: The shower tray must be a rm t to the framing prior securing the walls. Floors

must be level and at. Walls also must also be plumb and at. Two walls multiply errors and limit the

potential to t the acrylic liner and shower screen.

PREPARATION CHECKLIST

DOOR SET

TRAY SIZE

CORNER

POST

ADJUSTMENT

WALL

ADJUSTMENT RETURN PANEL

TRAY SIZE

WALL

ADJUSTMENT TRAY EDGE TO WALL

CHANNEL

1 750mm 0 2 915mm 17 15mm

2 820mm 5 10 820mm 413mm

3915mm 6 13 750mm 4 13mm

4915mm 0 11 915mm 11 21mm

51000mm 0 4 1000mm 4 13mm

61200mm 0 2 915mm* 12 20mm

DOOR & RETURN DOOR SET RETURN PANEL

1 750mm x 900mm Min 720mm — Max 740mm Min 870mm — Max 888mm

2820mm x 820mm Min 778mm — Max 794mm Min 790mm — Max 805mm

3900mm x 750mm Min 870mm — Max 890mm Min 720mm — Max 738mm

4900mm x 900mm Min 870mm — Max 890mm Min 870mm — Max 888mm

51000mm x 1000mm Min 970mm — Max 990mm Min 970mm — Max 988mm

61200mm x 900mm Min 1165mm — Max 1185mm Min 870mm — Max 888mm

Walls out of plumb will not allow for full Max/Min options.

TABLE A: LOW PROFILE TRAY 40mm High

TABLE B: MIN TO MAX PIVOT SHOWER RANGE (LH column number ties up to Table A)

4

11

09

10

12

12

Wall Channel K7119 Back Door Seal K7072 Back Door Seal Stop

K4000

Pivot Block K2004

Handle

Replacement Screw Pack - 2 & 3-Sided Chrome & White K2271

4x35mm Screws Screw Caps 4x10mm screwsWall Plug (Concrete)

Return Panel 1200 Door

All doorsexcept1200

Lower door seals

K6808

20 PCS8 PCS8 PCS 12 PCS

PIVOT 2-SIDED SHOWER

COMPONENT LIST

5

1

Apply silicone

bead down back

of channel prior to

fastening.

Mark wall prole.

Acrylic Shower Layout

Ensure you read

“BEFORE YOU START”

section on page 3.

Refer to Page 3

Table A & B will give

measurements for your

specic installation.

B

Fasten wall proles for return and

door panels.

A

6

2

Fit return panel.

12

A

• Connect door set to

return panel.

• NOTE: Table on page

3 will show suggested

corner post position for

your specic shower

install.

• Fasten this join parallel

at corner.

• Corner post must be

plumb for alignment of

magnetic seal.

B

• Finally adjust shower door in wall

proles and square up door to

frame.

• Drill and fasten door frame and

return panel to wall proles.

3B

Ø3.2mm

A

7

4

5

Apply silicone to

join as indicated.

Seal the join

between wall prole

and frame. 150mm

up from base on

both sides.

8

4x35mm Screws Screw Caps

16 PCS

4x10mm screws

Lower Door Seals

K6808

Wall Plug (Concrete)

Replacement Screw Pack - Chrome & White K2271

Wall Channel K7102 Back Door Seal K7072 Back Door Seal Stop

K4000

Pivot Block K2004

Handle

1200 Door

All doors except 1200

8 PCS 8 PCS 8 PCS

09

07

08

10

PIVOT 3-SIDED ALCOVE SHOWER

COMPONENT LIST: 3-SIDED ALCOVE

9

Wall Channel Adjustment: Pivot 3-Sided Alcove Shower Table

Includes Low Prole (L/P) Tray applications

Walls out of plumb will not allow for full minimum / maximum

options.

1

Fit seal to back of door

channel and fasten

end caps (04) to top

and bottom.

Back of Door

Position of wall proles to

door frame.

2

NOMINAL TRAY

SIZE

TRAY TYPE TRAY ACTUAL WIDTH

(+/- 1mm)

LINER TO LINER

MEASUREMENT

SCREEN MIN-MAX EXTENSION AT WALL

2-SIDES OF FRAME

810 L/P 812mm 786mm 769mm - 784mm 8.5mm

900 L/P 902mm 876mm 860mm - 890mm 8mm

1000 L/P 1002mm 976mm 960mm - 990mm 8mm

1200 L/P 1202mm 1176mm 1155mm - 1185mm 10.5mm

04

10

3

Layout

Mark wall prole holes both sides.

Predrill liner with 2mm bit.

B

A

Fasten wall proles.

Apply silicone

bead down back

of channel prior

to fastening.

08

09

11

4

5

Fasten door frame to wall proles. Door seal full width of door. Notch out

glass ange by 12mm each end of door.

Trim each side of pivot.

1. Plumb and square up door to frame.

2. Adjust evenly to both wall proles.

08

09

12

6Apply silicone to outer join as indicated.

Seal the join between

wall prole and frame,

150mm up from base

on both sides.

CONTACT

Freephone: 0508 639 5463 Phone: 09 444 2053 Fax: 09 443 0044

Email: [email protected] www.newline.co.nz

Table of contents

Other NewLine Shower Cabin manuals

Popular Shower Cabin manuals by other brands

ERLIT

ERLIT Eclipse ER 5709P Installation and operation instruction

Omnires

Omnires Bronx S2050 Installation and maintenance instructions

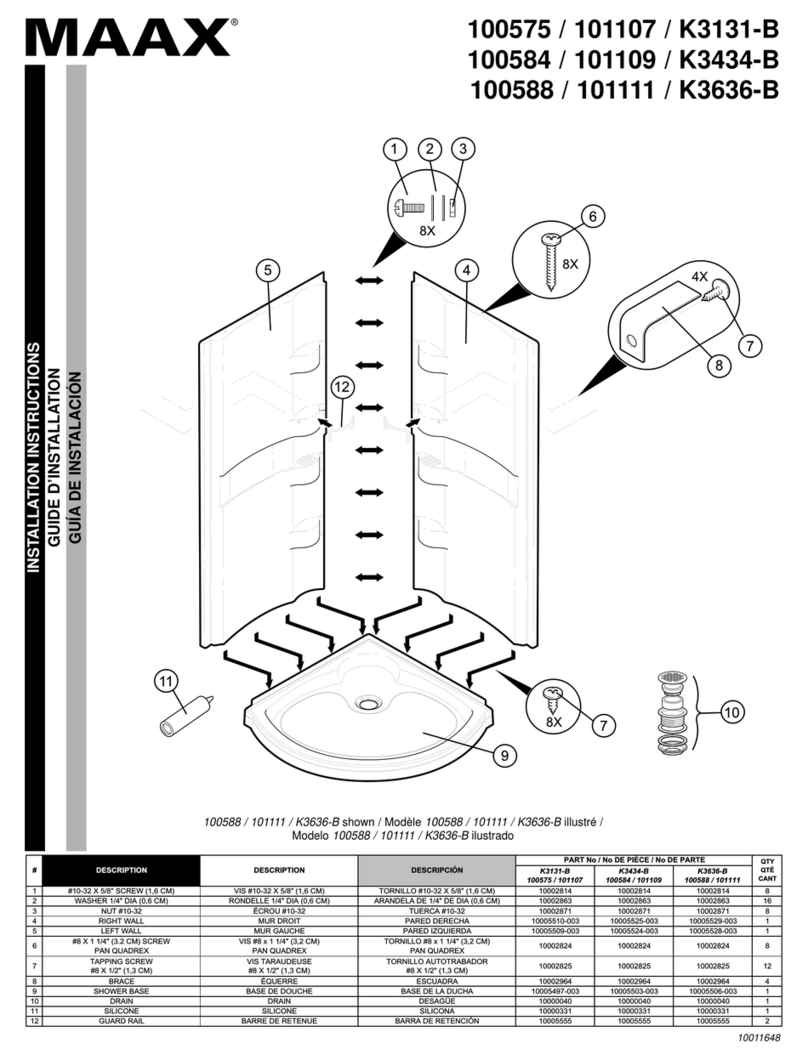

MAAX

MAAX K3131-B installation instructions

Sanotechnik

Sanotechnik PR150 Mounting instruction

OVE

OVE EMILY SWIFT 36 instruction manual

Dreamline

Dreamline ENIGMA-X installation instructions