2 - Safety information

The following section contains the safety information that you need to be familiar with before servicing a NewTom

GiANO. Additional information are included inside the User Manual under the “Safety warnings” chapter.

2.1 General safety

Follow these rules to ensure general safety:

Observe good housekeeping in the area of the machines during and after maintenance.

When lifting any heavy object:

1. Ensure you can stand safely without slipping.

2. Distribute the weight of the object equally between your feet.

3. Use a slow lifting force. Never move suddenly or twist when you attempt to lift.

4. Lift by standing or by pushing up with your leg muscles; this action removes the strain from the muscles in

your back. Do not attempt to lift any objects that you think are too heavy for you.

Do not perform any action that causes hazards to the customer, or that makes the equipment unsafe.

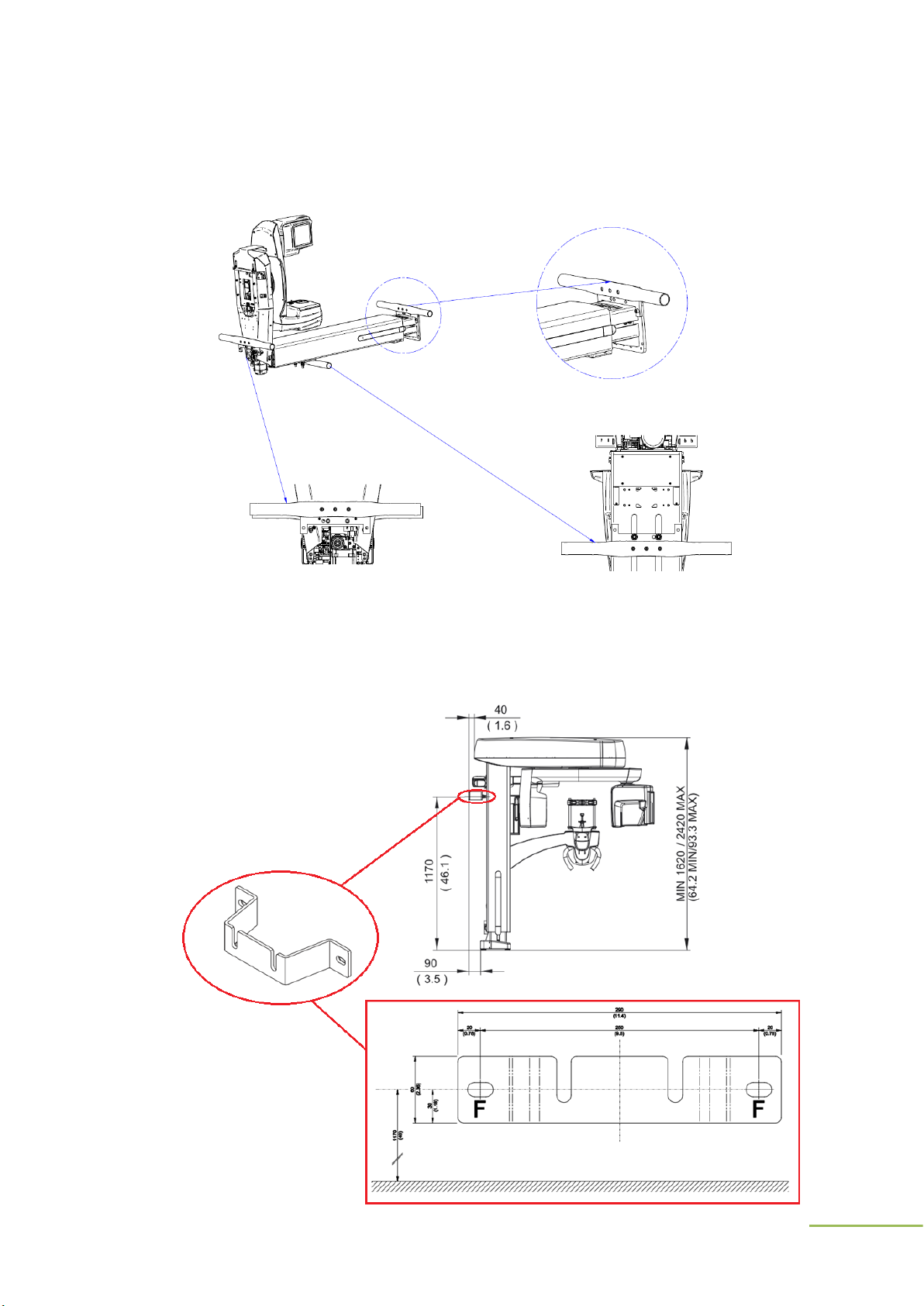

Perform an installation that achieve a optimal use. Care to

obstacles do motorized motion,

mechanical damage of connecting cable,

patient-operator visibility,

device accessibility for maintenance and cleaning, etc...

Before you start the machine, ensure that other service representatives and the customer's personnel are not

in a hazardous position.

Place removed covers and other parts in a safe place, away from all personnel, while you are servicing the

machine.

Keep your tool case away from walk areas so that other people will not trip over it.

Do not wear loose clothing that can be trapped in the moving parts of a machine. Ensure that your sleeves are

fastened or rolled up above your elbows. If your hair is long, fasten it.

Insert the ends of your necktie or scarf inside clothing or fasten it with a nonconductive clip.

Do not wear jewelry, chains, metal-frame eyeglasses, or metal fasteners for your clothing.

Wear safety glasses when you are: hammering, drilling soldering, cutting wire, using solvents, or working in

any other conditions that might be hazardous to your eyes.

Follow all cautions and instructions marked on the equipment.

Do not under any circumstances, remove any Caution, Warning or any other descriptive labels from the device

until the conditions warranting the label are eliminated.

To avoid fire or explosion, do not operate this device in an explosive environment or near flammable

anesthetics.

After service, reinstall all safety shields, guards, labels, and ground wires. Replace any safety device that is

worn or defective.

Reinstall all covers correctly before returning the machine to the customer.

Do not under any circumstances make mechanical or electrical modifications to the equipment. Manufacturer

is not responsible for regulatory compliance of a modified product.

Connect to the device only computers, computer peripherals and cables in compliance to the manufacturer

specifications