8– English

English

INSTALLATION: COMPONENT ASSEMBLY AND CONNECTION

––– STEP 5 –––

IMPORTANT!

- For correct system operation it is necessary to supply mechanical

stops, on the ground or wall, positioned at the maximum Opening and

Closing points of the door. Note - These end stops are not included in

the kit and do not form part of the Mhouse product range.

WARNINGS

• Incorrect installation may cause serious physical injury to those

working on or using the system.

• Before starting automation assembly, carry out the preliminary

checks as described in STEP 3.

• All installation operations must be performed with the power

supply disconnected. If the system is equipped with a PR1 buffer

battery, it must be disconnected.

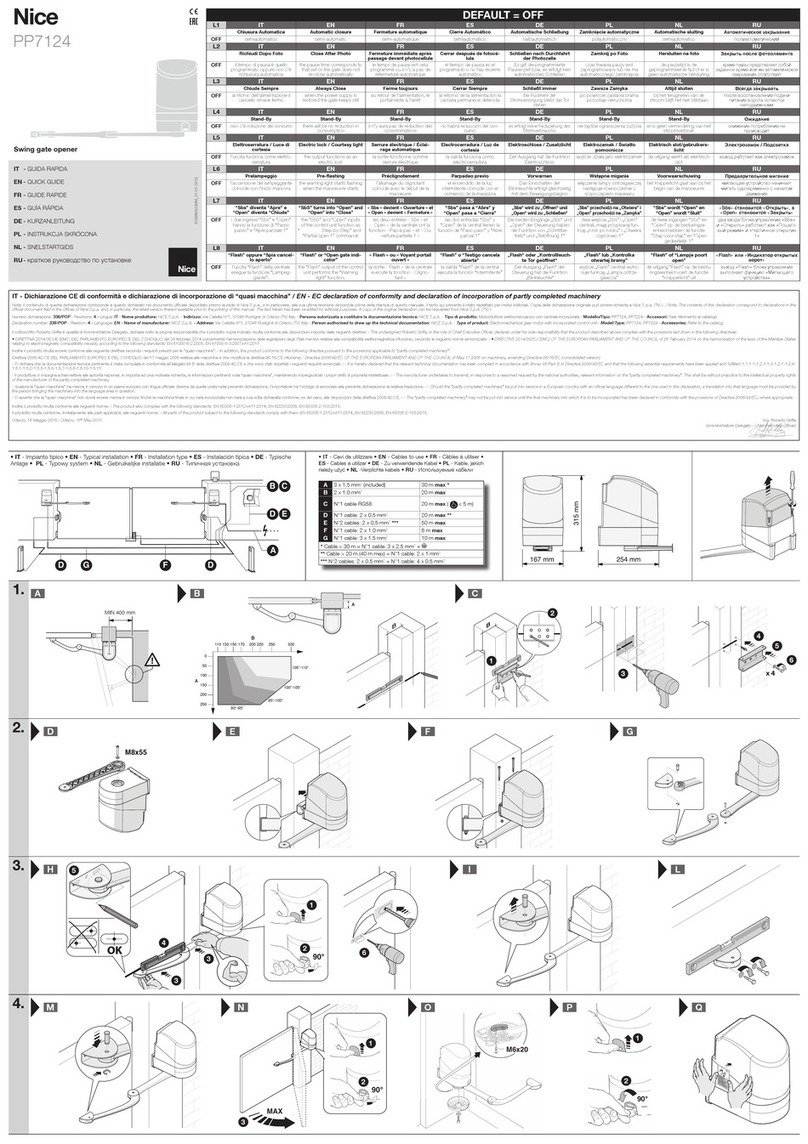

5.1 - GEARMOTOR INSTALLATION ON RACKLESS GATES

Ifthesurfaceitistorestonalreadyexists,thegearmotormustbemount-

eddirectlyontothatsurfaceusingappropriatemeans,e.g.expansion

bolts.Otherwise,proceedasfollows:

01. Digasuitablysizedfoundationpitinrelationtothepositionofthe

installation;seethedimensionsgivening.2;

02. Prepare one or two ducts for routing the cables as indicated in g.5.

N.B.: make sure the tubes are 50 cm longer than the nominal rating;

03. Assemble the two anchoring devices onto the foundation plate, plac-

ingonenutunderandoneovertheplate;thenutundertheplate

must be tightened as in g.6 so that the threaded section protrudes

byaround36mmabovetheplate;

04. Before pouring the concrete, prepare the foundation plate with its

stampedside(sprocketside)towardsthegateandfollowingtheindi-

cations of g.7;thenroutethecableductingthroughthehole;

05. Now pour the concrete and settle the plate as shown in point 04,

makingsureitisparalleltothegateandperfectlylevel(g.8).Wait

fortheconcretetosetfully;

06. Whentheconcretehassetsufciently(afterafewdays),removethe

2uppermostnutsasthesearenolongerrequired;

07. Shortenthecableductingbyaround30/40mm;

08. Remove the nut cover on the gearmotor(g.9);

09. Placethegearmotorontheplate,makingsureitisperfectlyparallel

to the gate, then hand tighten the 2 provided locknuts and washers

(g.10).Fullytightendownthenuts;

10. Manuallyreleasethegearmotor,asexplainedin11.3-Usageguide;

11. Movethegatetothefullyopenpositionbyhand,andpositionthe

rstsectionoftherackabovethegearmotor'ssprocket.Therack

mustprotrudeoverthesprocket'saxisbytheamountshowning.

11 (motortotheleft)org.12(motortotheright);i.e.,theamount

requiredforthestopbrackets;

Important!–Leavea1mmgapbetweentherack(allsections)and

sprocket (g.13),sothattheweightofthegateisnotbornebythemotor.

12. Nowmounttheothersectionsofrackonebyone:tokeeptherack

levelwiththesprocket,simplytracethemountingholewhentheslot

isinlinewiththeaxisofthesprocket(g.14).Repeatforallmounting

positions;

13. Afteryouhaveinstalledthelastsectionofrack,cutoffanyexcess

length;therackmustnotprotrudebeyondthegateitself;

14. Openandclosethegatebyhandafewtimestocheckthattherack

runssmoothlyoverthesprocket;

15. Roughlypositionthetwolimitswitchbrackets[A]ontherack(g.

15),movethegatebyhandandsecuretheminplace.

16. Securethelimitswitchbrackets:

a)movethegatebyhandtotheopenposition,stoppingatleast2-3

cmbeforethemechanicalstop.

b) slide the limit switch bracket along the rack in the opening direc-

tionuntilthelimitswitchtrips.Nowmovethebracketatleast2cm

furtherandlockitontotherackwiththeprovidedcaptivebolts.

c)repeattheoperationwiththeclosedpositionlimitswitch.

17. Manuallylockthegearmotor,asexplainedin11.3-Usageguide;

Youcannowmaketheelectricalhookup,seechapter6.

5.2 - GEARMOTOR INSTALLATION ON GATES WITH PRE-

EXISTING RACK

Ifthesurfaceitistorestonalreadyexists,thegearmotormustbemount-

eddirectlyontothatsurfaceusingappropriatemeans,e.g.expansion

bolts.Otherwise,proceedasfollows:

Warnings

–Beforemountingthegearmotor,checkthattheexistingrackiscompat-

iblewiththesprocket'soveralldimensions,seeg.16.

–Checkthattherack'spitchisabout12mm.

01. Digasuitablysizedfoundationpitinrelationtothepositionofthe

installation;seethedimensionsgivening.2;Important! – The

foundationplatemustbelocated77mmawayfromtherack.

02. Prepare one or two ducts for routing the cables as indicated in g.5.

N.B.: make sure the tubes are 50 cm longer than the nominal rating;

03. Assemble the two anchoring devices onto the foundation plate, plac-

ingonenutunderandoneovertheplate;thenutundertheplate

must be tightened as in g.6 so that the threaded section protrudes

abovetheplatebyaround36mm;

04. Before pouring the concrete, prepare the foundation plate with its

stampedside(sprocketside)towardsthegateandfollowingtheindi-

cations of g.17;thenroutethecableductingthroughthehole;

05. Now pour the concrete and settle the plate as shown in point 04,

makingsureitisparalleltothegateandperfectlylevel(g.8).Wait

fortheconcretetosetfully;

06. Whentheconcretehassetsufciently(afterafewdays),removethe

2uppermostnutsasthesearenolongerrequired;

07. Shortenthecableductingbyaround30/40mm;

08. Remove the nut cover on the gearmotor(g.9);

09. Place the gearmotor onto the foundation plate to facilitate its insertion

undertherack(g.18).Handtightenthe2locknutswiththeirwash-

ers;

10. Ifnecessary,adjusttheheightofthegearmotor(maximumadjust-

ment10mm),withthe4captivebolts(g.19).Important! – Leave

at least a 1 mm gap between the rack and sprocket, so that the

weightofthegateisnotbornebythemotor.

We advise mounting the gearmotor without the captive bolts, so that

itismorestablysupportedbytheplate;

11. Checkthatthegearmotorisperfectlyparallelwiththegate,thenfully

tightendownthe2locknutstoxittothefoundationplate;

12. Manuallyreleasethegearmotor,asexplainedin11.3-Usageguide;

13. Openandclosethegatebyhandafewtimestocheckthattherack

runssmoothlyoverthesprocket;

14. Fit the limit switch brackets [A](g.15):

a)movethegatebyhandtotheopenposition,stoppingatleast2-3

cmbeforethemechanicalstop.

b) slide the limit switch bracket along the rack in the opening direc-

tionuntilthelimitswitchtrips.Nowmovethebracketatleast2cm

furtherandlockitontotherackwiththeprovidedcaptivebolts.

c)repeattheoperationwiththeclosedpositionlimitswitch.

15. Manuallylockthegearmotor,asexplainedin11.3-Usageguide;

Youcannowmaketheelectricalhookup,seeSTEP6.