English

English – 3

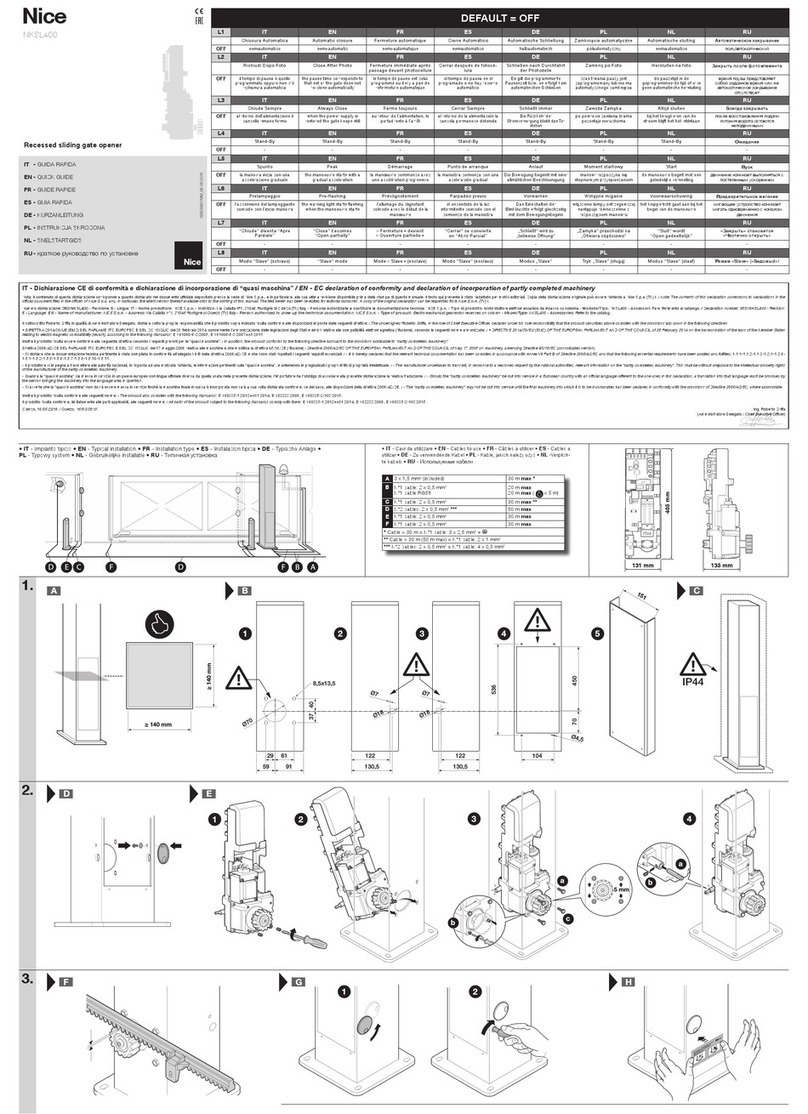

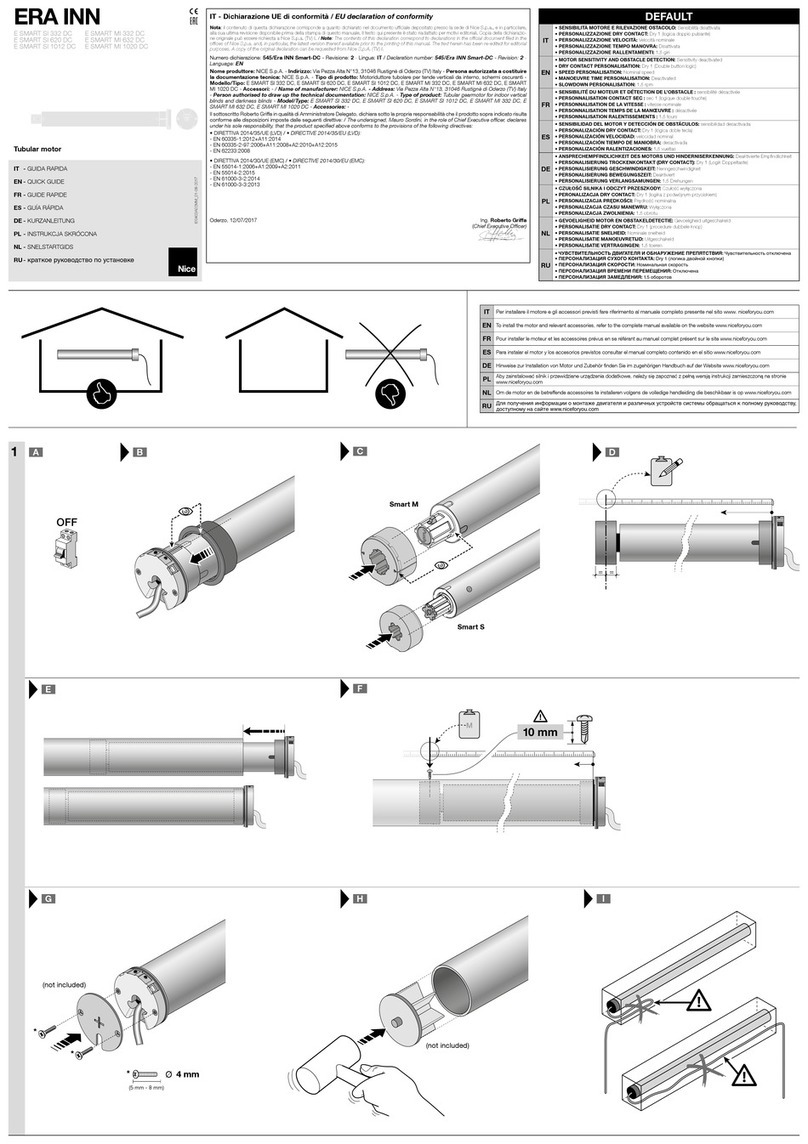

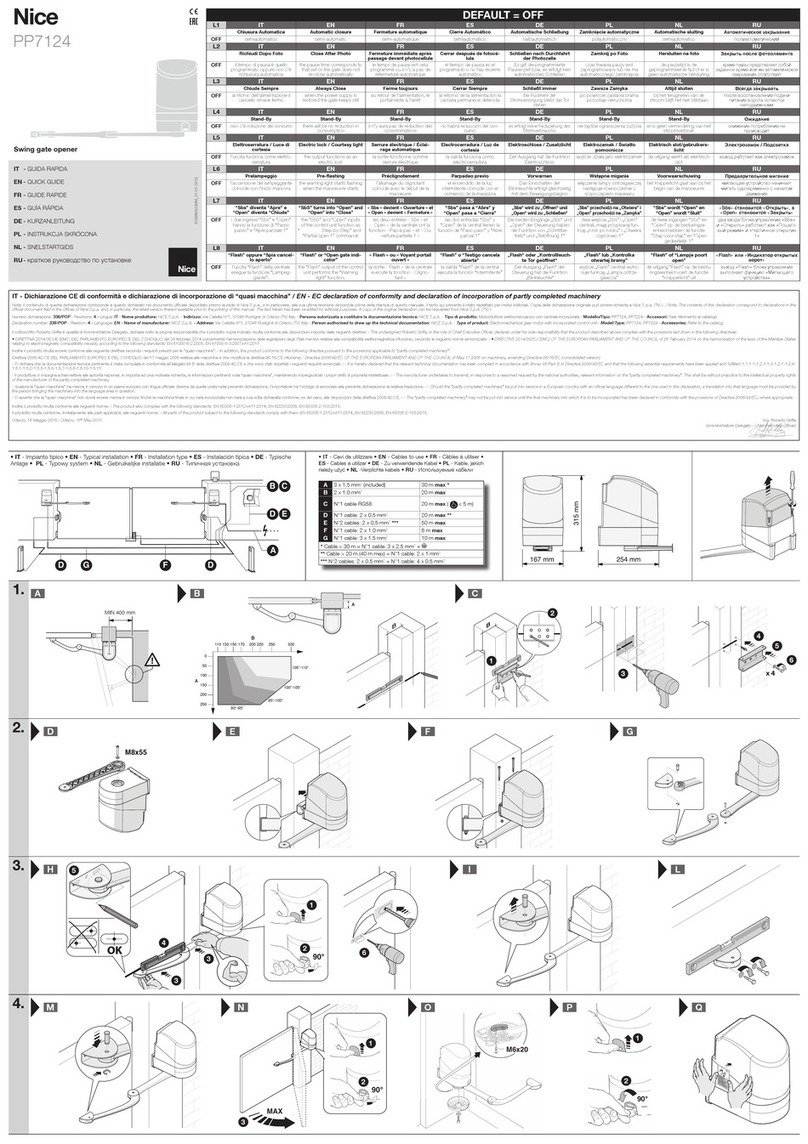

KNOWLEDGE OF THE PRODUCT AND PREPARATION FOR INSTALLATION

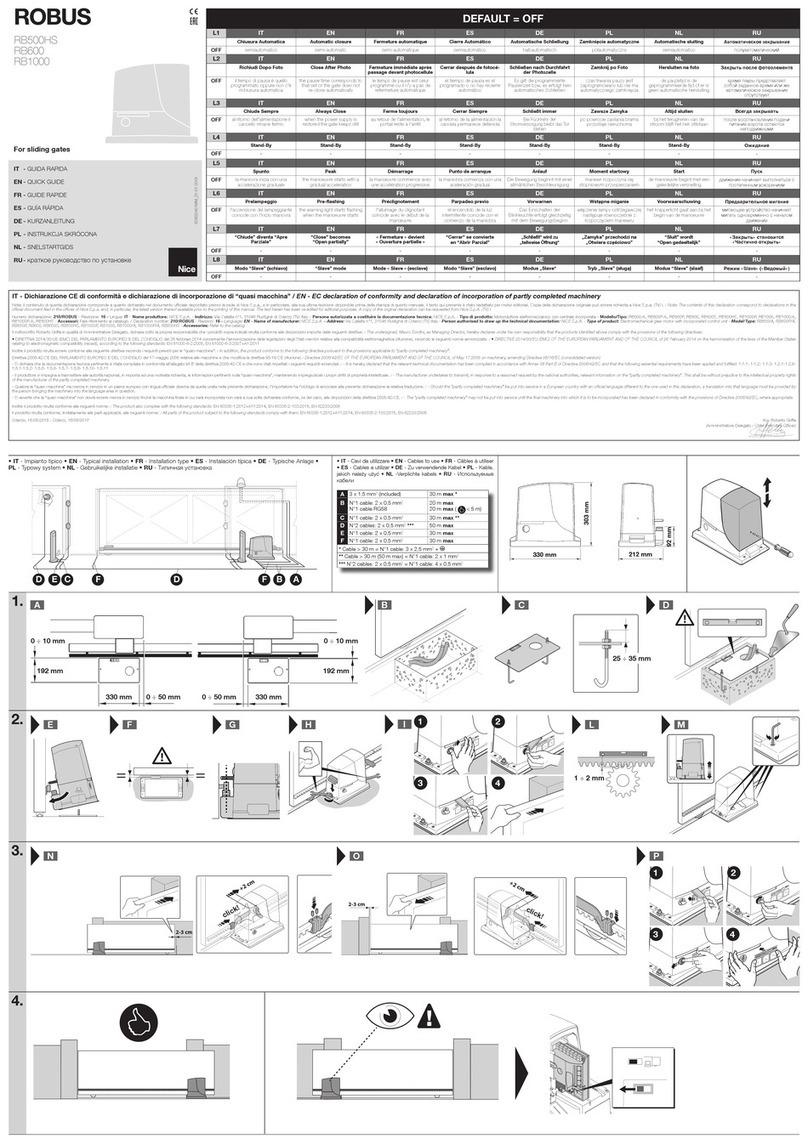

––– STEP 3 –––

3.1 - CHECK SUITABILITY OF GATE TO BE AUTOMATED

AND OF THE ENVIRONMENT

•Ensurethatthemechanicalstructureofthegateissuitableforauto-

mationandcomplieswithlocalstandards.Toverifythis,refertothe

technicaldataonthelabelofthegate.Important - This product cannot

automateagatethatisnotalreadysecureandefcient;moreover,it

cannotresolvedefectscausedbyimproperinstallationofthegateor

fromitspoormaintenance.

•Manuallymovethegateleavesinthetwodirections(open/closed)and

make sure that the movement takes place with a constant friction at

everypointinitscourse(thereshouldbenopointsthatrequiremore

effortnorless).

•Ifthereisanaccessdoorinthegate,orwithintherangeofmovement

of the gate, make sure that it does not obstruct normal travel and, if

necessary,provideanappropriateinterlocksystem.

•Makesurethatthegateisnotonaslope,i.e.thattheleafdoesnot

movebyitselfwhenitismanuallymovedtoanyposition.

•Ensurethattheenvironmentinwhichthegearmotoristobeinstalled

hassufcientspacetobeabletoperformthemanualmanoeuvreof

releasingthegearmotor.

•Makesurethatthesurfacesselectedfortheinstallationofthedevic-

es,arestrongandcanensureastableattachment;forthephotocells,

chooseaatsurfacethatcanensureacorrectalignmentofthepair(Tx

andRx).

•Ensurethatalldevicestobeinstalledareinashelteredlocationand

protectedagainsttheriskofaccidentalimpact.

•Ensure that the area surrounding the automation does not contain

deviceswhichproductpersistentradiointerference.Thesecandisturb

anddistortsystemfunctionality.

•Checkthedimensionallimitsbyreferringtog.2.

•Checkthatthereissufcientspace,evenwiththegateintheopenposi-

tion(g.3).

•Check,accordingtotheopeningangleoftheleaves,thatyoucanmeet

the limits in g.4and the graph in g.5).

•Therearsupportbracketcanbemountedinvariousways(g.10):the

amount“C” mayvarybetween53mmand176mm.Usuallyitisaround

150mm.

•Theamount“D”isavaluethatyoucaneasilymeasureonthegate.

•Theamount“A”isthesumof“C”and“D”.

•Basedonthevalueof“A”,andthegateopeningangle,inGraph 2 you

canobtainthevalueof“B”.Forexample:if“A”is150mmandthegate

openingangleis100°,thevalueof“B”isintheregionof150mm.

We advise you to choose “A” and “B” values which are similar

to one another. By doing this, you are assured of a regular leave

movement, and minor stress to the gearmotor.

3.2 - PRODUCT APPLICATION LIMITS

Before proceeding with installation perform the following checks in the

suggested order and check their compliance with both the data in this

paragraphandthetechnicaldatainthechapter“Producttechnicalspeci-

cations”:

1- Check that the gate leaves have dimensions and weights which fall

withinthefollowinglimits:

- maximum length 2.2 m

- maximum weight 250 kg

- opening angle of up to 120°

Theshapeofthegateandtheclimaticconditions(forexampleastrong

wind)canreducethesemaximumvalues.Inthiscase,itisnecessaryto

measure the torque required to move the leaves in the harshest condi-

tions,andcompareitwiththedatareportedinthetechnicalspecica-

tions.

2- Checkthemeasurementsofthetotalsizeofthegearmotor(g.2).

Note - These measurements also serve as a reference to calculate

the space that the foundation excavation will require for the passage

of the raceways for the electrical cables.

3- Checkthattheestimatedmaximumnumberofdailycycles(para-

graph3.2.1)iscompatiblewiththeintendeduse.

4- Checkthattheestimateddurabilityiscompatiblewiththeintended

use(seeparagraph3.3).

5- Makesureyoucancomplywithallthelimitations,conditionsand

warningsinthismanual.

NOTE TO MANUAL

•Thismanualdescribes how to implement a complete and opti-

malautomation,likethatshowning.6,usingalltheMhouse

devices which form part of the automation system known as

“WG2W”. Some devices and accessories mentioned in this man-

ual are optional and may not be present in the kit. For a com-

plete overview, see the Mhouse product catalogue or visit www.

niceforyou.com.

•Thismanualisdesignedasastep-by-step guide. Therefore, for

the safety and ease of assembly and programming work, we

advice you to carry out all the operations described in the same

order in which they are presented.

––– STEP 2 –––

2.1 - PRODUCT DESCRIPTION AND INTENDED USE

Thedevicesinthiskit,plusotheraccessories(someoptionalandsome

notincluded),togetherformtheautomationsystemcalled“WS2W”,

designedforautomationofahingedgatefor“residential”use.All uses

other than the intended use described and use in environmental

conditions other than those described in this manual should be

consideredimproperandforbidden!

The main part of the automation consists of a control unit and two elec-

tromechanicalgearmotors.Eachgearmotorisprovidedwitha24Vdirect

currentmotorandareductionunitwithwormscrews;itisequippedwith

amechanicalreleaseandkeywhichallowsyoutomanuallymovethe

gateintheeventofalackofpowersupply.

The command control unit manages the operation of all of the automa-

tion, and is made up of an electronic board and an integrated radio receiv-

er,toreceivecommandssentbytheuserviathetransmitter.Itcanstore

upto256GTX4transmitters,andupto20wirelessdevices.

TheinnovativeMhousePower&FreeSystemallowsthecontrolunitto

directthePH100WphotocellsandtheFL100Washingindicator,without

wiredconnections.Howeveritispossibletoconnectotherdevices,using

a single cable with two electrical conductors, on the inputs assigned to

opening(Open)andstopping(Stop).Thecontrolunitcanbepoweredby

axedelectricalnetwork(230V)or,alternatively,bysolarenergyviathe

PFsolarpowersystemfrom the Mhouse line.

Ifpoweredfromthegrid,itcanhostabufferbattery(mod.PR1,option-

alaccessory)whichensuresthattheautomationcanexecutecertain

manoeuvres,duringthehoursfollowingalossofpower(electricalblack-

out).Itishoweveralwayspossibletomovethegatemanually,byrst

releasingthegearmotorusingtheappropriatekey(seechapter11.3-

Usageguide).

2.2 - DEVICES REQUIRED TO CREATE A FULL SYSTEM

The g.1showsallthedevicesrequiredtocreateafullsystem,suchas

that shown in g.6.

Thedevicesshowning.1are:

A- 2 electromechanical WS1SK gearmotors, complete with mounting

brackets

B-3releasekeys

C-1pairofPH100Wphotocells(madeupofaTXandanRX)

D- 2 GTX4 radio transmitters

E-1FL100Washingindicator

F- 1 CL2W command control unit

G- Metal hardware

Note:

- Some devices and accessories mentioned in this manual are option-

alandmaynotbepresentinthekit.Foracompleteoverview,seethe

Mhouseproductcatalogueorvisitwww.niceforyou.com.

- The end stops are not included in the kit and do not form part of the

Mhouseproductrange.