Nickel-Electro Clifton Range SM-1 User manual

High quality products at aordable prices

SPIROMETER SM-1

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

Dear Customer

The Clifton Range® is part of Nickel-Electro Ltd a family rm based in Weston-Super-

Mare which was incorporated as a limited company in 1941 but its roots can be traced

back to 1935 when the business rst started. Now in its 3rd generation of family

members, the company prides itself on being a strongly established, independant

British manufacturer.

Thank you for purchasing this piece of Clifton Range® temperature control equipment.

To get the best performance from your equipment and for your own safety please read

these instructions carefully before use.

GENERAL NOTES

1. Always follow good teaching and safety practice. CLEAPPS October 2005 report

recommends a Risk Assessment is produced.

2. Spirometers should only be used under the direct supervision of a teacher who is

experienced in their correct use. Teachers are reminded that they have a special

responsbility when pupils are used as the subject of experiments. Investigations

involving unusual ventilation of the lungs can be dangerous to epileptics,

ashmatics or children suering from bronchial disorders.

3. When using spirometers for gas analysis be aware of the possible consequences

of hyperventilation or of holding the breath. If the experiment requires a supply of

oxygen it must be of medical quality.

4. In experiments where indication soda-lime is used to absorb the expired carbon

dioxide, the spirometer oat must be lled with medical grade oxygen. Contact

BOC Healthcare for further information.

5. A kymograph or datalogger system is required to record results. We recommend a

Logit from Grien Education or a Data Harvester from Scientic and Chemical with

neccessary motion sensor tted to logger.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

INTRODUCTION

The Clifton Spirometer can be used for investigating tidal volumes, respiratory rate, pul-

monary ventilation, reserve volumes and vital capacity. Oxygen consumption can also

be measured which is useful in metabolic rate studies.

The spirometer essentially consistts of a counterbalanced oat, sealed by water which

contains oxygen. A system of valves and tubing enables the subject to breathe this oxy-

gen, thus causing the oat to move up and down. Indicating soda-lime can be incorpo-

rated into the circuit to absorb carbon dioxide from the expired breath.

A simple level control enables the subject to be connected either to the atmosphere or

to the oat for recording. A container for soda lime crystals is tted which can be used

to absorb carbon dioxide. The spirometer is designed to oer minimum resistance to air

ow. This means greater comfort for the user and more realistic results.

The spirometer enables rate of breathing, volumes of breaths and consumption of oxy-

gen to be monitored. It has a scale calibrated in litres, which can be read against the

water level, enabling readings to be taken directly, or it can be tted with a pen arm al-

lowing the attachment of a bre tipped pen or used in conjunction with a Kymograph or

electronic data logger system to record results.

Recommended data loggers: Logit from Grin Education or Data Harvester from Scien-

tic and Chemical with neccessary motion sensor tted to logger for recording results.

LOCATION

The product must be placed on a smooth, level and sturdy work surface, indoors. Use in

a ventilated room. Suitable for use in ambient temperatures 5°C to 40°C with a maximum

humidity 80% (temperature 31°C) decreasing to 50% (temperature 40°C). Mains

uctuations are not to exceed +/-10% of the normal supply. This product is designed for

educational use.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

UNPACKING

Remove the product from its packaging and retain over the warranty period. Contents

consist of:

• Spirometer Body

• Float Assembly

• Pen Arm Assembly

• Nylon Net Bag

• Corrugated Tube (x2)

• Snapper Clip (x2)

• Mouth Piece

• Nose Clip

• Instruction Manual

SETTING UP (SEE APPENDIX A FOR FURTHER INFORMATION)

1. Place the oat in position, ensuring that the pivot pins are correctly located in the

dimples( top of the tank).

2. Screw the counter balance weight fully into the back of the oat support but do not

adjust the oat until the chamber has been lled with water.

3. Connect the exible hoses to the ports of the Spirometer. When new these may be a

tight t (lubricate with water). Fit the clips to secure. Note the way the valves in the

T piece operates and connect the corugated hoses to the T piece so that expired air

enters the spirometer via the port labelled IN and expired air from the oat leaves

via the port labelled OUT. DO NOT use oil or grease as a lubricant anywhere in the

system as oxygen can form explosive compounds with these materials.

4. Immerse the mouth piece into sterilizing solution. Spare mouth pieces are available

from your distributor (BX0612 Disposable Mouth Piece).

5. If the results are to be recorded on a kymograph, t the pen arm and clamp a ne

bre tipped pen into the holder. Arrange the kymograph so that the pen writes

properly over the full height of the chart. If the full spirometer capacity of 7 litres is

to be used, a chart and 200mm is required. When tted 10mm of vertical movement

of the pen corresponds to approx 500ml change in volume in the spirometer.

6. Fill the tank with water almost to the very top.

7. Calibrate the recording device to known volume of air for the “Suggested

Investigations”.

8. Ensure the oat is in the lowest position, set the valve to ATMOSPHERE. The

kymograph should produce a continuous horizontal lineand dataloggers will record

zero motion. This corresponds to zero volume.

9. To introduce a measured volume of air, ll a ask with an accurately measured

volume of water (500ml). Mark the level of water on the neck of the ask. Empty

the water, t a two hole bung with one tube connected to the oxygen inlet of the

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

spirometer and the other to the water tap. Fill the ask to the mark and air will be

despatched from the ask into the spirometer. Close the clip and empty the ask.

10. A second line or reading should appear above zero volume line which should provide

a scale e.g 500ml air volume = height ?mm. This is the basis for dening the scale.

11. Set the valve to SPIROMETER and adjust the weight so that the oat comes to rest

in the mid position.

12. If oxygen consumption is to be measured ll the nylon net bag with coarse soda

lime and place it in the container (front view, right hand side of the tank, unscrew

the wing nut and remove the cap).

13. Ensure there are no gaps between the net bag and the walls of the container.

Replace the cover and tighten.

14. Gently press down on the oat to expel the air and turn the valve to ATMOSPHERE.

15. Connect the medical grade oxygen supply to the oxygen inlet (container, adjacent

to the wing nut tube) using pressure tubing.

16. Slowly turn on the oxygen supply. Oxygen will ow into the unit and raise the oat.

When it contains about 2 litres turn o the supply set the valve to SPIROMETER and

press down on the oat. This forces the oxygen out through the mouthpiece and

ushes the air out of the system. Do not allow oxygen to be discharged near a naked

ame.

17. Repeat the process, lling and ushing and then close o the oxygen supply and

turn the valve to ATMOSPHERE. If the cylinder is to be removed ensure a tube and

clip are left closing the oxygen inlet.

OPERATING INSTRUCTIONS

1. A two way valve is tted. When this valve is set to ATMOSPHERE the breath-

ing tubes are open to the atmosphere and the spirometer is closed. The subject

therefore breathes normal atmospheric air. This position should be used when the

subjects rst use the spirometer to enable them to become accustomed to it.

2. When the valve is set to SPIROMETER the subject takes in the oxygen contained

under the oat, causing the oat to fall. The expired gases pass through the soda

lime contained before returning to the oat. The soda lime absorbs the carbon di-

oxide from the expired gases. The valve is set to this position when the spirometer

is in normal use.

Medical grade oxygen cylinder must only be used for respiration

purposes. Before using soda lime dust should be removed from it by

pouring the soda lime from one container to another in the open air.

!

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

3. Select a subject. To enable some degree of standardisation the subject should be

rested for 30 minutes and should not have eaten a meal for the previous 2 hours.

4. Fit a sterilised mouthpiece to the T piece, seat the subject comfortably and place

the mouthpiece and nose clip in position.

5. Allow thw subject to become accustomed to breathing through the tubes and

then at the end of an outward breath turn the valve to SPIROMETER and begin

recording.

Suggested Investigation 1

Normal tidal volume, respiratory rate and pulmonary ventilation.

1. Allow the subject to breathe normally through the mouthpiece (they should not

be able to see the trace).

2. Continue recording the trace for one minute or until its completed whichever is

shorter.

3. Normal tidal volume: is given by the amplitude of the trace.

4. Respiratory rate: the number of breathes per minute or more formally the number

of movements indicative of inspiration and expiration is usually determined by

counting the number of times the chart rises or falls per minute.

#Newborns: average 44 breathes/minute

#Infants: average 20-40 breathes/minute

#Preschool children: 20-30 breathes/minute

#Older children: 16-25 breathes/minute

#Adults: 14-18 breathes/minute

5. Pulmonary ventilation: is the volume of air moved and is found by multplying aver-

age tidal volume by respiratory rate.

Suggested Investigation 2

Reserve volumes and vital capacity

1. After a normal breath ask the subject to take the deepest possible inward breath

and the the deepest possible outward breath.

2. These peaks give the inspiratory and expiratory: reserve volume.

3. The total volume from maximum to minimum is the vital capacity.

Suggested Investigation 3

Oxygen Consumption

1. Seat the subject comfortably and allow them to breathe normally through the

mouthpiece.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

2. As medical grade oxygen is consumed and respiratory carbon dioxide is removed

from expired breathe the volume falls progressively. The slope on the trace indi-

cates the rate at which oxygen is consumed.

3. Continue until half the oxygen has been used or for two minutes whichever occurs

rst.

4. Draw a straight line linking the upper or lower extremities of the trace for the sec-

tion under examination. It is convenient if the lines extends over the length of the

chart corresponding to one minute. Measure the vertical change in this time. This

corresponds to the volume of oxygen consumed in one minute. The investigation

can be repeated during and after exercise and it is interesting to compare.

CARE AND MAINTENANCE

Please ensure that the washing agent and sanitizing agent are BSI

accredited and approved by the H&S department.

Outside Surfaces: Wipe with a soft cloth or sponge soaked in warm soapy water.

Inside Surfaces: Can be descaled to maintain in an as new condition. Descale by adding

1 litre of vinegar to water and leave for an hour. Empty and brush the lime away. Rinse

thoroughly afterwards.

The stainless steel crevice free tank should provide years of valuable service and is

resistant to chloride containing solutions but it is important to avoid high concentrations

of halogens- particularly chloride. Halogen deposits may show as rust which can be

cleaned o with nitric acid (10%) on a cloth. WEAR PROTECTIVE EQUIPMENT!

Bar Keepers Friend® can be used as a stainless steel cleanser to remove unsightly mineral

deposits.

EXTERIOR ANTI BACTERIAL PAINTED SURFACES

The spirometer should be cleaned at regular intervals by wiping external surfaces with

a cloth or sponge soaked in warm water with a mild detergent. DO NOT USE STRONG

SOLVENTS OR SOLUTIONS CONTAINING CHLORINATED HYDROCARBONS, ESTERS,

KETONES OR ABRASIVE CLEANERS AS THIS MAY DAMAGE THE BUILT IN ANTI BACTERIAL

PROPERTIES.

The “anti-bacterial” paint nish inhibits the growth of bacteria. It has been tested by

independant specialist houses using internationally recognised test methods and

proven to be eective against a wide range if bacteria including Escherichia Coli and

Staphylococcus Aureus (MRSA).

!

We recognise hygenic coatings are part of a controlled approach to a cleaner working

environment. Within the paint formulation is an active ingredient with proven anti-

bacterial properties which is maintained throughout its life span. In a laboratory

environment this is one less source of contamination. Unlike detergents the anti-

bacterial paint nish does not oer an instantaneous action, but is intended for long

term general protection against bacterial growth.

Moisture on the painted surface is neccessary for the bacterium to absorb the agent

and be aected by it. The coating is therefore less active in very dry conditions

although moisture in the atmosphere will maintain some activity. Areas where

moisture is trapped are dicult to clean and allow bacteria to proliferate but these

areas are most active for the anti-bacterial coating improving defence against

bacterial growth.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

WARRANTY TERMS AND CONDITIONS

1. Nickel Electro Ltd warrants to the Customer that the product purchased is free

from defects in materials and workmanship.

2. Provided the terms of payment are duly complied with, Nickel Electro Ltd

undertakes to remedy any original defects arising from faulty materials or

workmanship, in any goods manufactured/supplied by Nickel Electro Ltd, which

under proper and normal conditions of use, may develop within a period of one

years from the date of delivery.

3. In the case of components which by their nature of application have an

unpredictable life, this guarantee shall only be to the extend of the guarantee

given by the manufacturers of these articles.

4. Nickel Electro Ltd will accept no liability, where in the opinion of the company

the defect has been caused by damage due to the Customers failure to follow

operating instructions, correct installation, wear and tear, or damage due to the

use of spare parts other than those spare parts of Nickel Electro Ltd or which are

recommended by Nickel Electro Ltd, the defect has been caused by alterations or

repairs being undertaken by a person(s) other than an authorised representative

of Nickel Electro Ltd.

5. Any damage claim must be in writing, and give the serial number and description

of the goods, order number and date of delivery, and will not apply where any

names or serial numbers or other information which may be attached to or

inscribed upon the goods have been removed, covered up or defaced in any

way.

6. Any goods or parts thereof, which may require repair or replacement, shall be

repaired or replaced (at the discretion of Nickel Electro Ltd) at the works of

Nickel Electro Ltd. The product to be repaired shall be delivered carriage paid

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

back to Nickel Electro Ltd by the customer at the Customer’s risk and expense. Any

such goods or parts will be delivered by Nickel Electro Ltd to the Customer free

within the United Kingdom but if required to be borne by the Customer. All faulty

parts removed from the equipment will become Nickel Electro Ltd’s property. Any

other repairs or work by Nickel Electro Ltd will be carried out under the terms and

conditions for specialist engineers currently in force.

7. In the event of replacement with a new or reconditioned model, the replacement

unit will continue the warranty period of the original equipment.

8. If any goods or parts thereof are returned unnecessarily all cost involved, including a

charge for inspection, handling and the return carriage must be paid by the sender.

In no circumstances shall any of the goods be returned to Nickel Electro Ltd without

its prior written consent.

9. Please retain the original packaging over the warranty period.

NON WARRANTY INFORMATION

Spare parts shall be made available for a period of 3 years after a piece of equipment is

discontinued.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

SPIROMETER INSTALLATION

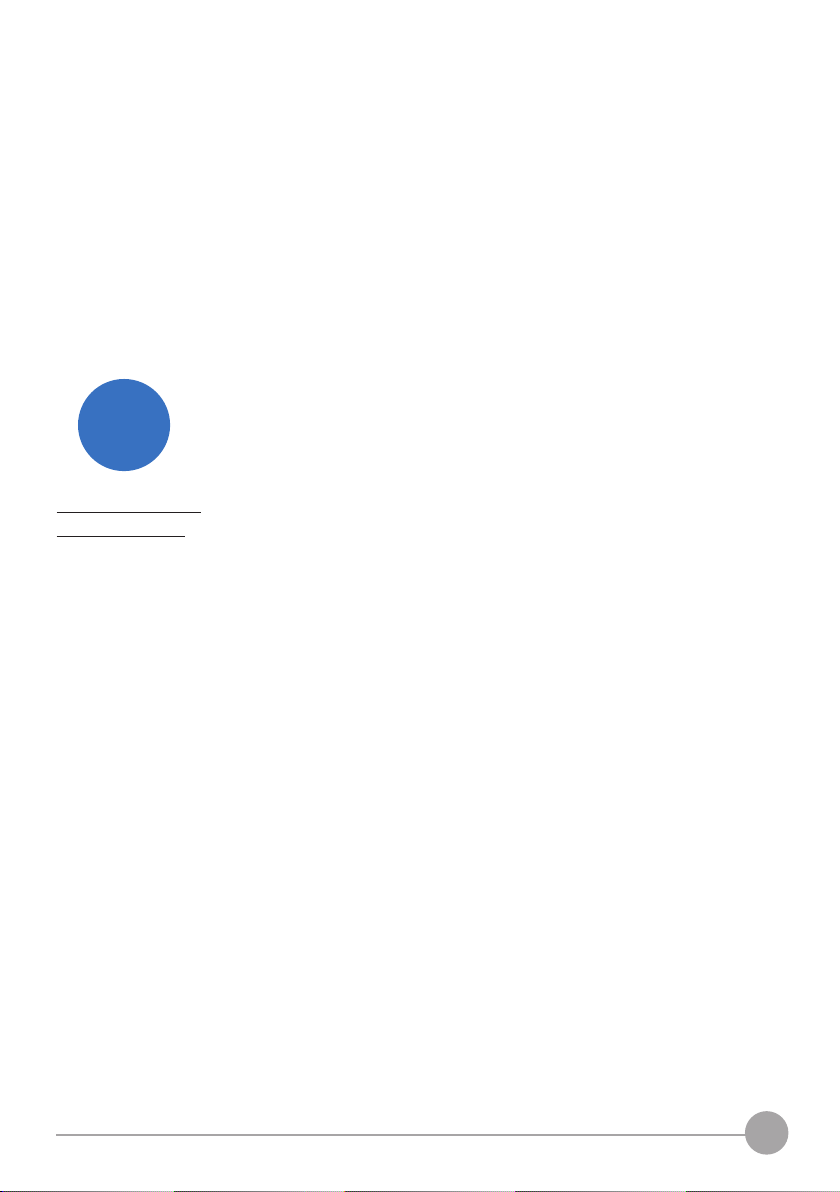

Float assembly and counterweight

1. A rod and counterbalance weight

is supplied. Slide the weight onto

the rod and tighten the thumb

screw. This is the counterweight

assembly for the oat.

2. The large white moulding is the

oat assembly, a metal frame is

tted for the counter weight.

3. The oat has a threaded stud on the metal frame for the counter weight to be

screwed on.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

4. Place the oat assembly into the tank of

the spirometer. On each leg of the frame a

pointed screw is tted. Each one locates into

a dimple on the top rim of the tank. The oat

assembly will “see saw” adjust the counter

balance weight accordingly.

5. In a polythene bag there are a

number of loose parts.

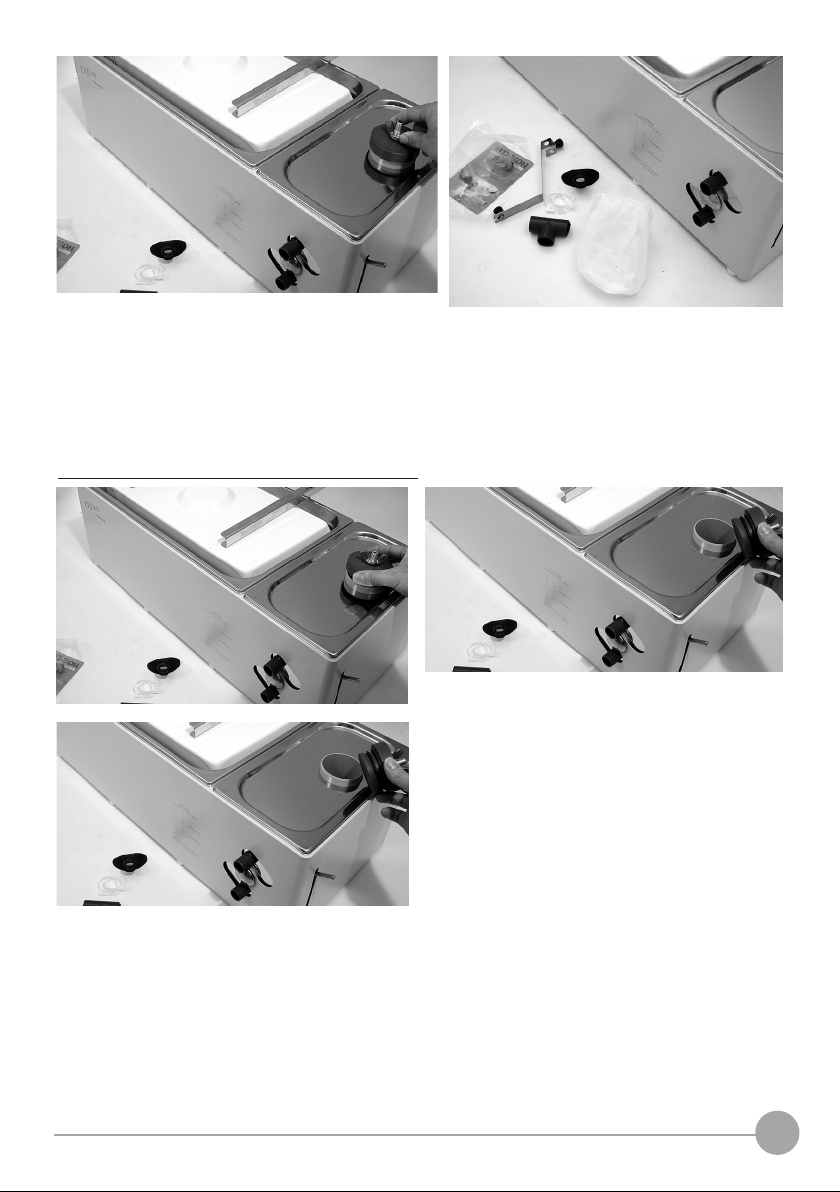

1. Loosen o the wing nut. Twist/slide the

dark grey cap assembly upwards to reveal

a container.

Installing the Nylon Net Bag and Soda Lime

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

2. The net bag should be lled with

coarse soda lime then placed inside the

container.

3. Ret the dark grey plastic cap

assembly by pushing it back into the

top of the container. Tighten the wing

nut to seal the container.

4. Connect the oxygen supply to the

outlet tted in the cap.

Assembling the Flexible Hoses to the Spirometer

1. Place a clip on one end of the hose but

do not fasten.

2. Push the hose fully onto a pipe

outlet and pinch the clip together

for secure tting.

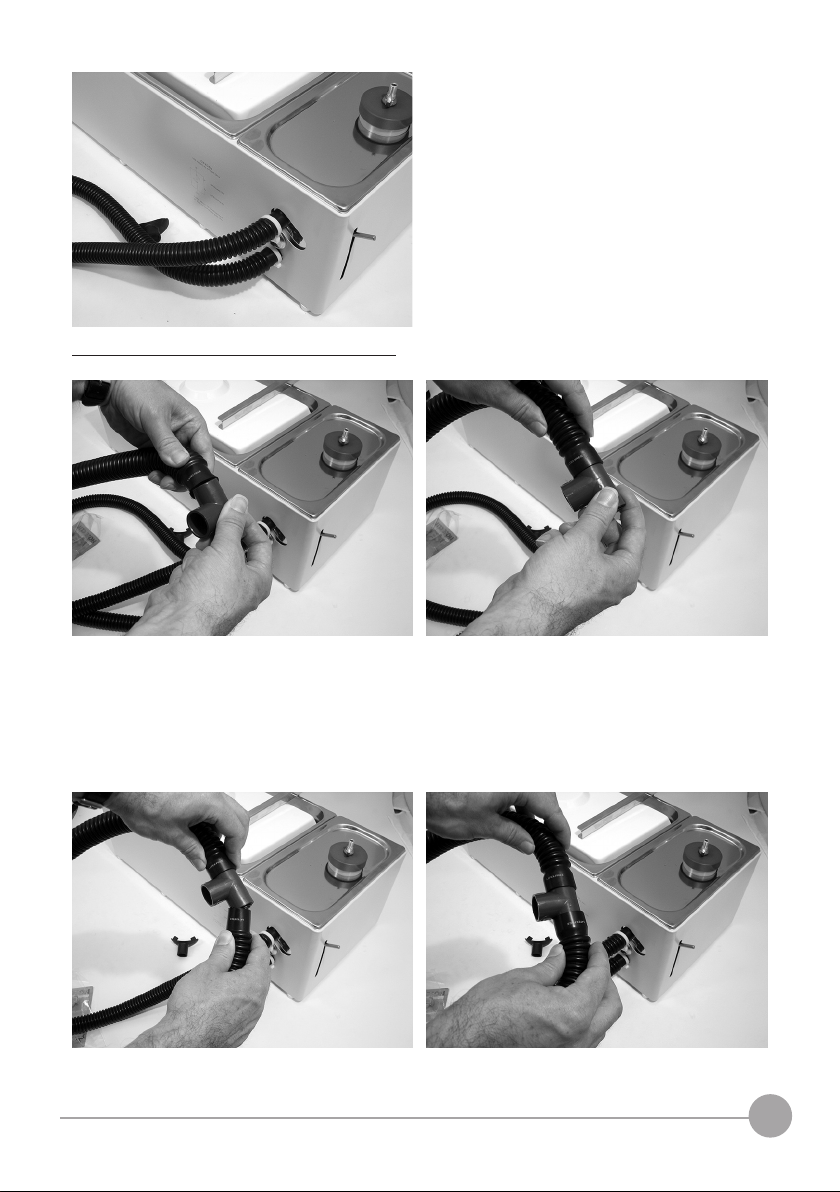

Fitting the T Piece to the Flexible Hoses

Fitting Mouthpieces into the T Piece

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

3. Repeat with the second hose so both

are tted.

1. The T piece is a tight t into the hose

and this is as it should be. Hold the hose

and tilt the T piece back slightly. Push

3/4 of the T piece inside the hose, gently

wiggle and rotate both parts to fully

insert the T piece into the hose end.

2. The hose is now correctly tted onto

the T piece.

3. Repeat the process to t the second

hose.

4. Both hoses are now correctly tted

onto the T piece.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

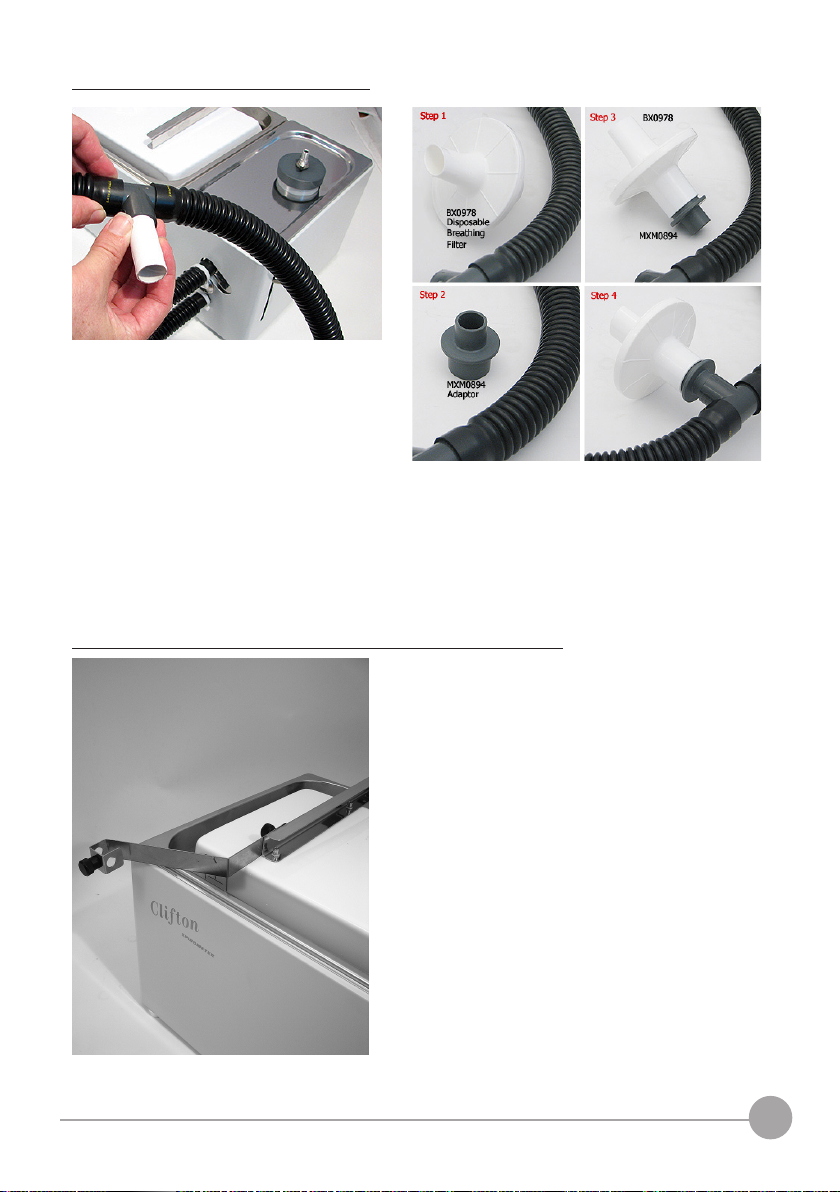

Fitting Mouthpieces into the T Piece

Option1: BX0612 Disposable Mouth

Piece: simply push the tube into the

T piece and hold together whilst

breathing.

Option 2: BX0978 Disposable

Breathing Filter: t the accessory

adaptor MXM0894 into the T piece.

Push the disposable lter into the

adaptor.

Fitting the Pen Arm for Recording Breathing Measurements

1. Fit the “Z” shaped bracket to the oat

assembly. This in conjunction with a motion

sensor and data logger can record pulmonary

ventilation.

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

SPIROMETER SM-1

CLIFTON RANGE® - 1 YEAR WARRANTY

Table of contents

Other Nickel-Electro Laboratory Equipment manuals

Nickel-Electro

Nickel-Electro Clifton Range NE9S Series User manual

Nickel-Electro

Nickel-Electro Clifton RANGE NE2D Series User manual

Nickel-Electro

Nickel-Electro NE4-T Series User manual

Nickel-Electro

Nickel-Electro Clifton 1000ER Series User manual

Nickel-Electro

Nickel-Electro Clifton Range NE4-14D User manual

Nickel-Electro

Nickel-Electro Clifton NE1B Series User manual