Contents

1. Important User Information ......................................................................................4

1.1 Safety .................................................................................................................................... 4

1.2 Product Design ...................................................................................................................... 4

1.3 Compatibility .......................................................................................................................... 4

1.4 Disclaimer.............................................................................................................................. 4

2. Installation .................................................................................................................5

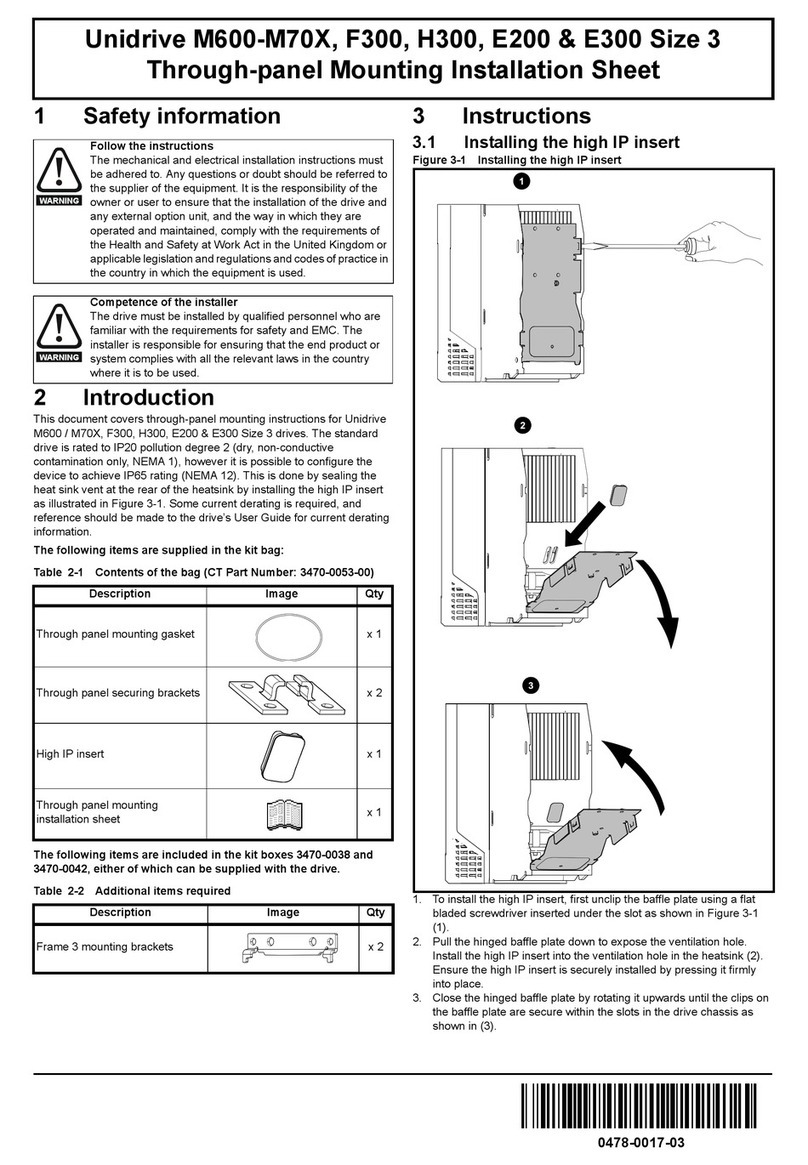

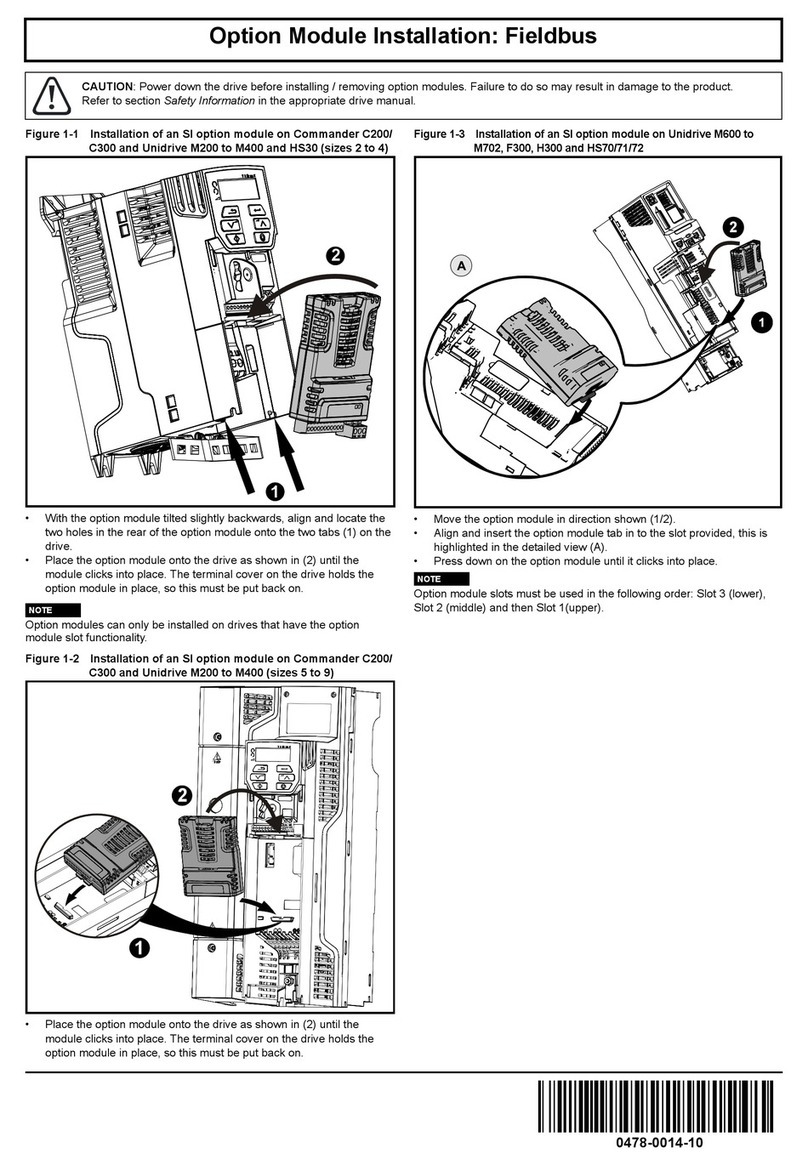

2.1 Installation Procedure ............................................................................................................ 5

3. Connection.................................................................................................................6

3.1 Soft Starter Connection.......................................................................................................... 6

3.2 Network Connection............................................................................................................... 6

3.3 Network Establishment .......................................................................................................... 7

3.4 Communication Protocols ...................................................................................................... 7

3.5 Addressing............................................................................................................................. 7

4. Device Configuration ................................................................................................8

4.1 Ethernet Device Configuration Tool ....................................................................................... 8

5. Operation .................................................................................................................10

5.1 Device Classification............................................................................................................ 10

5.2Master Configuration............................................................................................................ 10

5.3 LEDs.................................................................................................................................... 10

6. Packet Structures....................................................................................................11

6.1 Ensuring Safe and Successful Control................................................................................. 11

6.2 Control Commands (Write Only) .......................................................................................... 11

6.3 Status Commands (Read Only) ........................................................................................... 12

6.4 Parameter Management (Read/write) .................................................................................. 17

6.5 Examples............................................................................................................................. 18

7. Network Design .......................................................................................................19

7.1 Star Topology ...................................................................................................................... 19

7.2 Line Topology ...................................................................................................................... 19

7.3 Ring Topology...................................................................................................................... 20

7.4 Combined Topologies .......................................................................................................... 20

8. Specifications ..........................................................................................................21

Profinet Module: User Guide 3

Issue: B www.nidec.com