1

1. Installation to the Start of Operation

2. Unit Model

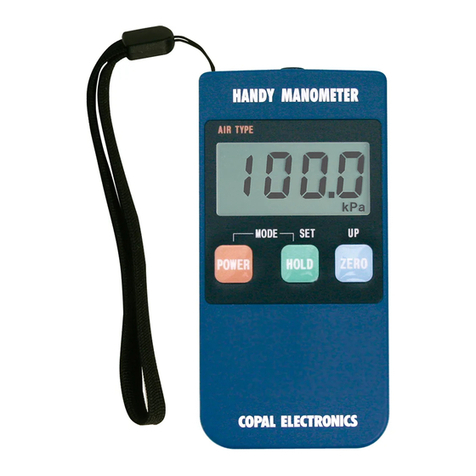

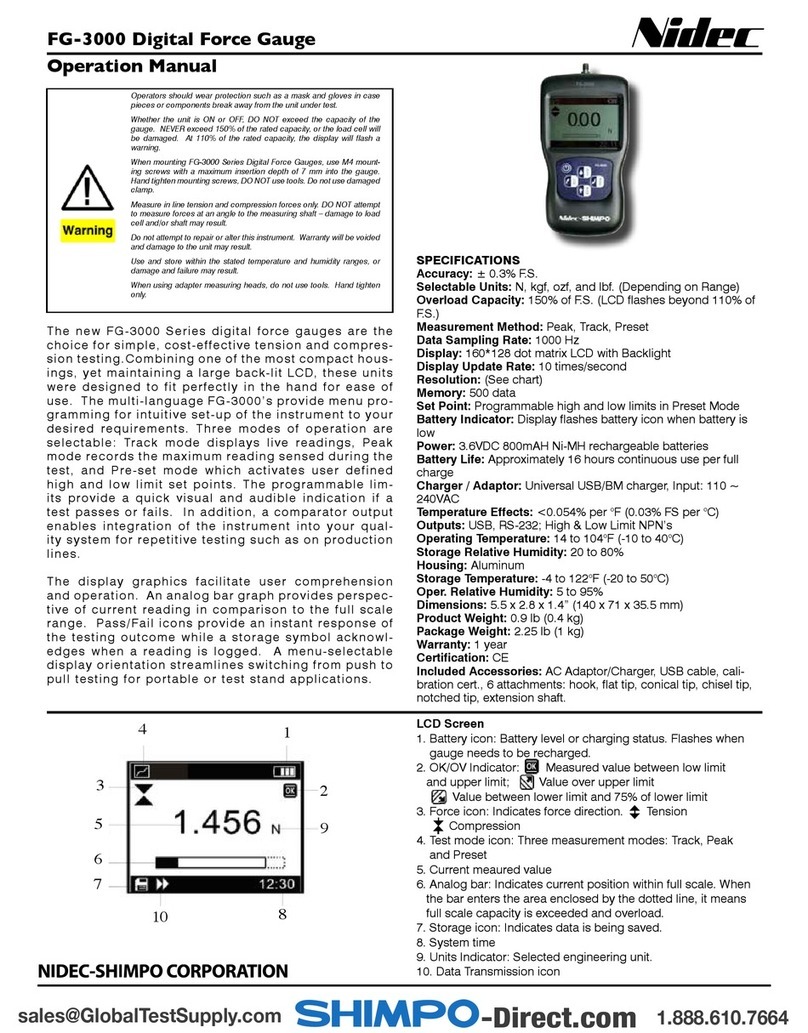

3. Specications

4. Component Part Names and Functions

5. External Dimensions

6. Installation to the Panel

7. Wiring to Power Source and Sensors (DT-501XA/DT-501XD)

8. Wiring to Power Source and Sensors (DT-501FA)

9. Basic Setting Procedure

10. Keys to be Used for Various Settings and Their Applications

11. Teaching Function Settings

12. About Mode

13.

When You Select Mode 1 (Digital Tachometer Mode) for Measurement

14.

When You Select Mode 2 (Elapsed Timecounter Mode) for Measurement

15.

When You Select Mode 3 (Time Width Meter Mode) for Measurement

16.

When You Select Mode 4 (Flowmeter Mode) for Measurement

17.

Setting Method of Functions (Excluding in the Test Mode, Common in Each Mode)

18. Comparator Function

19. Memory Function

20. Test Mode (Function to Check if the Unit is Operating Normally)

21. Error Display

22. Parameter List

23. Function List

24. Option -FVT/-FVC

25. Option -BCD

26. Option -TRT

27. Option -CPT

28. DT-501X / DT-501F series model list

CAUTION

Precautions before use

Power

●Be sure to use the unit under the specied voltage (AC power

specications: 85 - 264VAC / DC power specications: 10.8 - 25.2VDC).

●Inverter power source cannot be used.

Input signal wire

●Connection wiring from sensors shall not be kept in the same or parallel conduit or

cable as the power source, power or high voltage cables. If you fail to separate the

wiring, noise may be superimposed on the signal wire, resulting in malfunctions.

●

Use shielded wire for input power connections with the shortest possible metal conduit.

Terminal

●

Check that the screws have not come loose due to vibrations after a certain period of time.

Operating environment

●Do not install the unit in the following places or conditions.

●●Places exposed to direct sunlight, or places where the ambient temperature

exceeds a range of 0 - 45ºC.

●●Places where the relative humidity percentage exceeds a range of 35 - 85%, or

places subject to condensation due to rapid change in humidity.

●●Places subject to corrosive and/or combustible gases.

●●Places subject to a large amount of dust, salinity, and/or ferric substance.

●●Places susceptible to noise (including static electricity).

98211B

!

!

INDEX

Digital Tachometer

2

2

3

3

4

4

5

6

6

6

7

8

8

10

12

14

16

17

18

19

19

20

21

23

25

27

27

28

After reading, be sure to store this manual in a safe,

convenient place where operators can always refer to it easily.

Thank you for purchasing SHIMPO's Digital Tachometer DT-501X/

DT-501F. For instructions on how to use this product properly

and optimally for a long period of time, please be sure to read this

manual thoroughly before use.

When you purchase the product with optional equipment:

Please refer to the operation manual of the optional equipment.

Before operation, maintenance and inspection, please

carefully read this instruction manual and follow it

for proper use.

DT-501X/DT-501F

Standard input series Dierential input series

Instruction Manual

Digital Tachometer/ Elapsed timecounter/ Time width meter/ Flowmeter

Electric Shock.

Be sure to turn the power OFF when wiring as well as

inspecting the unit.

DO NOT block the ventilation holes on the side of the main unit.

DO NOT put any foreign objects or materials inside the unit

through these holes.

DO NOT touch the unit with wet (or sweaty) hands when

inspecting or for wiring.

Failure to do so could result in electric shock.

Failure to follow this could result in abnormal heat generation

and/or malfunctions.

Failure to do this could result in electric shock.

Before operation, maintenance and inspection, please carefully read this instruction

manual and follow it for proper use. Please carefully read all information related to

this unit and safety, and precautions before use.

● We are not responsible for damages resulting from negligence through failure to

follow the instructions set out in this manual.

●

We are not responsible for damages resulting from earthquake and/or re unrelated

to us, actions by third parties, or any other accidents, intentional or through

customer negligence, as well as from accidents caused by misuse or improper use

under abnormal conditions.

●For information regarding assurance provisions, please read the attached warranty

certicate.

WARNING Improper use may result in serious injuries.

CAUTION Improper use may result in minor injuries or

property damage.

DANGER

Improper use by neglecting the following

precautions may result in the potential

for re, serious injuries, and/or death.

Safety Requirements

Be sure to observe

!

!

!

●Limited Warranty

This instruction manual categorizes safety precautions as “DANGER”, “WARNING”,

and “CAUTION”. Each of them is an important description related to safety. Be sure

to observe.

5

10

15

20

25

30