ABS/SET

MIN

mm

CAL

ZERO/ON

ABS/SET

MIN CAL

ZERO/ON

ABS

mm

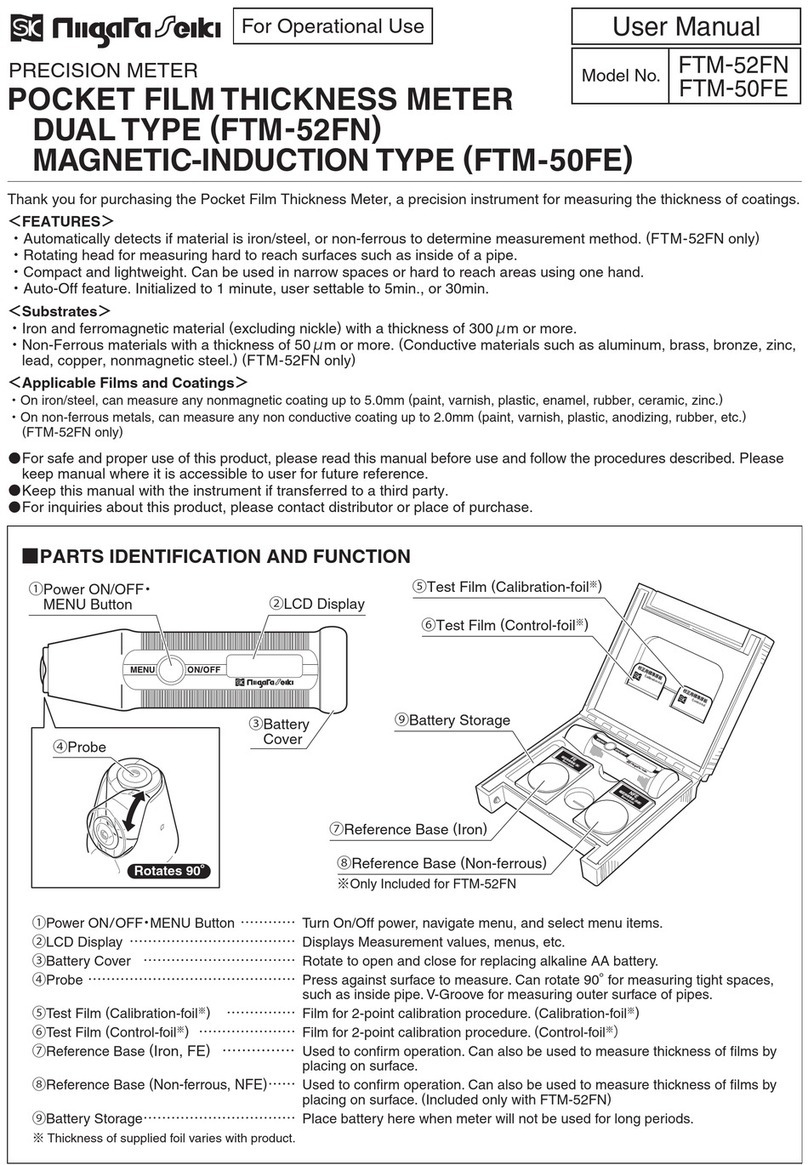

Protective Cover

Grip

LCD Display

[ZERO/ON]

Button

[CAL]Button

[MIN]Button

[ABS/SET]

Button

Clamp

Screw

Spacer

Clamp

Screw

※Not including quantization error (±1 count)

This is a precision instrument, use care not to drop

or mishandle.

Please do not disassemble or modify.

Keep instrument away from water and oil.

Use only with supplied Extension Rods and Washers.

Keep instrument away from direct sunlight and

high temperatures such as in a car, near a stove

or heat source.

After use, remove dust and cutting chips and

apply rust preventative oil to components

including Extension Rods, and Extension

Washers. When not in use store in original case.

This product is for measuring inside diameter; use

only as directed. Improper use may cause

accident or injury.

Avoid using in locations with high electric fields,

such as near fluorescent lights or switching power

supplies, as it may cause erroneous reading to

display on LCD.

①Remove the protective cover by

unscrewing the two screws which hold the

cover in place.

※To reattach the protective cover, please refer to

the section: “Attaching the Protective Cover”

②Loosen the Clamp Screw and insert the

Digital Indicator into the gauge body.

Tighten Clamp Screw to secure.

※After attaching to body, press the

[ZERO/ON]Button to turn on power. Check

for proper operation by pressing on the

Probe Tip. If the LCD display reading does

not change, readjust the insertion depth of

the indicator.

③Choose combination of Rod and Washer (CDI-18D only) applicable

for desired measurement range.

When using the Protective Cover, please attach using

the following procedure.

①Loosen the Clamp Screw and remove Clamp and

Spacer from shaft. (Figure: 1)

②Without removing the Rod or Washers, follow the

“Assembly” procedure to reattach the Indicator and

Clamp without the Spacer.

③Mount the Protective Cover to the Indicator and attach

with the 2 mounting screws. (Figure: 2)

●

●

●

●

●

●

●

●

●

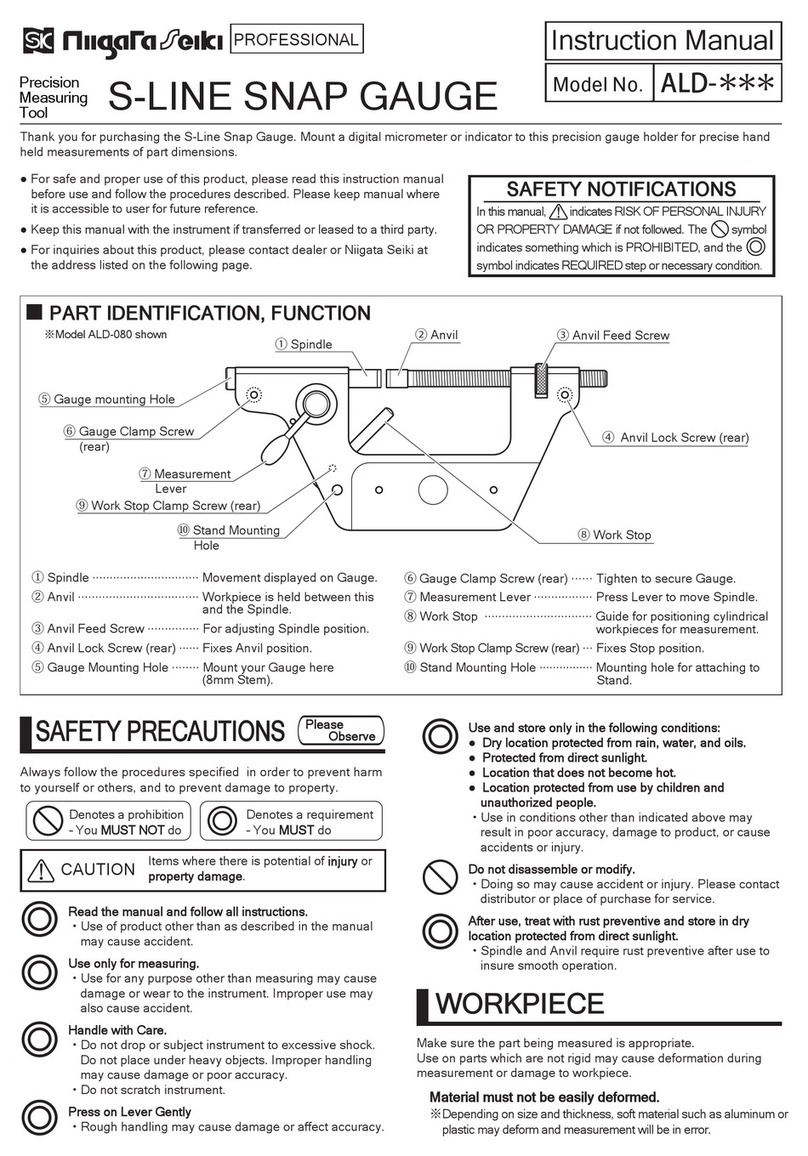

■PART IDENTIFICATION

■ASSEMBLY

■

SPECIFICATIONS

■

BATTERY REPLACEMENT

Indicator

Screws

Spacer

Clamp

Screw

(Figure: 1)

(Figure: 2)

Model No.

Measurement Range

Resolution

Wide Range Accuracy

Adjacent Error

Repeat Accuracy

Extension Washer

Weight

*

*

*

※

※

※

Single Probe Measuring Range

(mm)

(mm)

(µm)

(µm)

(µm)

(mm)

(mm)

(g)

CDI-10D

6-10

12

5

0.6

0.5

CDI - 18D

10-18

0.002

3

0.8

250 270

Extension

Rod

Shaft

Measurement

Head Probe Tip

(CDI-18D)

(CDI-10D)

Length below grip-100mm

Extension

Rod

Measurement

Head Guide

Probe

Tip

Spanner

Spanner

Nut

1. Using the Spanner, loosen the nut

below the Measurement Head.

2. Attach the Extension Rod and

secure by tightening the nut.

Attach Extension Rod and Extension

Washer to Measurement Head and

secure with the supplied Spanner.

Extension Rod:

8.5mm

Extension

Rod: 14mm

Extension

Washer: 0.5mm

+

Example: CDI-10D For 8.5mm Measurement

Example: CDI-18D For 14.5mm Measurement

●

●

●

Extension Rods

CDI-10D........6, 6.5, 7, 7.5, 8, 8.5, 9, 9.5, 10 mm (9 pieces)

CDI-18D........10, 11, 12, 13, 14, 15, 16, 17, 18 mm (9 pieces)

Spanner ........ 1

Battery...........CR2032 Lithium Battery (Included for testing)

Extension Washer 0.5mm

(CDI-18D)

Extension Rod

(CDI-10D) (CDI-18D)

Spanner

(CDI-10D) (CDI-18D)

※1

Digital Indicator

※2

INSTRUCTION MANUAL

Model No. : CDI-10D / CDI-18D <combined>

DIGITAL BORE GAUGE

※1: This button not used.

※2: “0.01” Indicates bar graph display units. Bar graph display

will increase or decrease by one bar for each 0.01mm

change in measured value.

Thank you for purchasing the Digital Bore Gauge.

Please read this manual thoroughly before use for proper operation.

:With supplied Digital Indicator.

*

ACCESSORIES

NOTICE

Open battery door using the tabs

on either side. Insert battery with

“+” side facing downward. Push in

door to replace.

Only use CR2032 Lithium Battery.

Caution

Length below

grip-50mm

Battery

Door

Battery

(CR2032)

Attaching the Protective Cover

Protective

Cover

RemoveRemove

Insert

Attach

※Spanner shape may vary

from above drawing,

however function will not

be affected.