SAFETY PRECAUTIONS

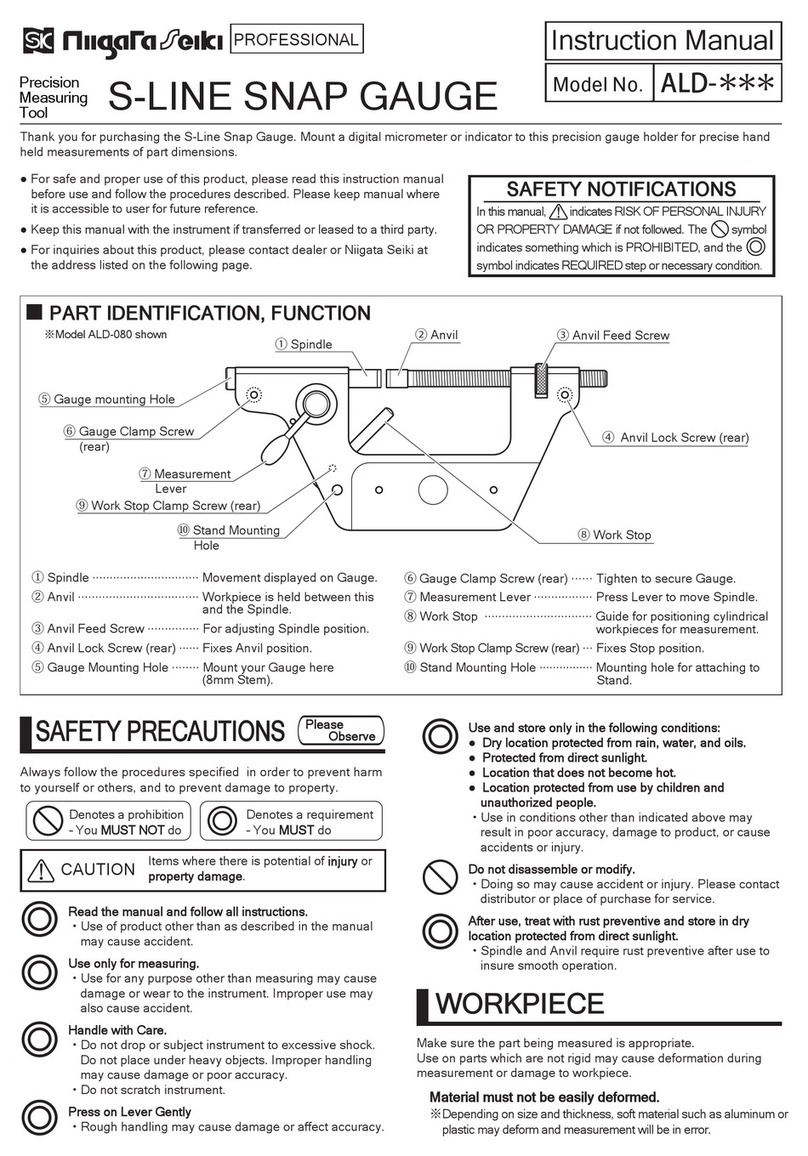

PREPARATION - Mounting

WARNING Indicates risk of personal injury or property damage if not followed.

Please Observe

Always follow the procedures specified below in order to prevent harm to yourself or others, and to

prevent damage to property.

Dial gauge must be securely mounted such as on a comparator stand or magnetic base.

Please follow these guidelines.

■Content marked as follows indicates risk of injury or damage if not followed.

CAUTION

Denotes a prohibition – You MUST NOT do.Denotes a requirement – You MUST do.

■These symbols mark content that must be observed.

Read the manual and follow all instructions.

・Use of product other than as described in the

manual may cause accident.

Use only as indicator Gauge.

・Use for any purpose other than measuring

may damage or wear the instrument.

Improper use may also cause accident.

Use in an environment which meets the

following conditions:

●Temperature within range of 0~40°C、

humidity 30~70% (non-condensing.)

●Location with minimal dust, oil, oil mist,

and protected from direct sunlight.

●Location protected from use by children

and unauthorized people.

・Use in location contrary to the above may

cause poor accuracy, damage to the product,

or may result in accident or injury.

Handle With Care.

・Do not drop or subject to shock, do not place

under heavy objects. Damage may cause

failure or poor accuracy.

Make sure Gauge holder is rigid.

・Holder must be sufficiently secure to prevent deflection

from the weight of the Gauge.

・Holder must be rigid enough to hold Gauge and not to

lift from measurement force.

・Holder support arm should be as short as possible to

prevent deflection.

※Deflection or lifting will cause measurement error such

as origin position error and inaccuracies in measured

reading.

Dial Gauge must only be attached by Stem or Rear Lug.

・Mounting of gauge by other than Stem or Lug will cause

inaccuracy and product damage.

During installation, do not over-tighten the Stem.

・Excessive force on the Stem may cause Spindle to bind.

Do not disassemble or modify.

・It may damage Gauge and cause poor

accuracy

・If Bezel Clamp Screw is removed, internal

components may come loose and become

misaligned causing product failure.

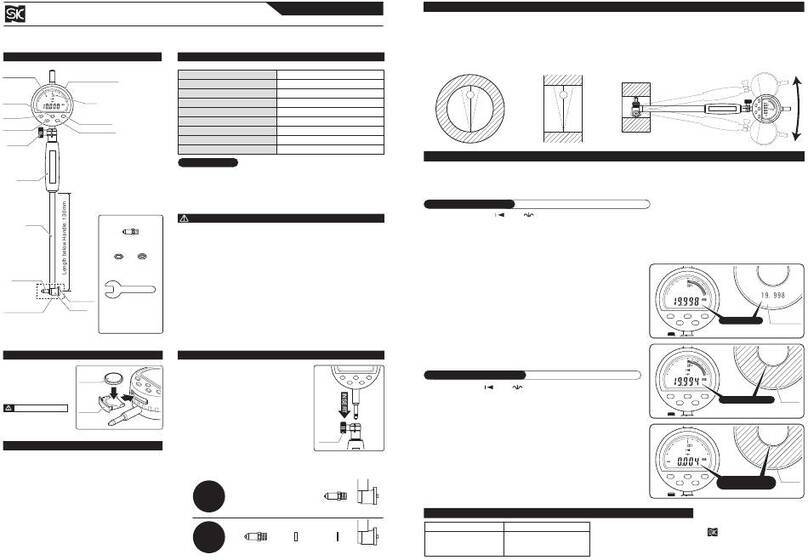

Do not shock Spindle.

・Rapid motion, or lateral force may damage

Gauge and cause poor accuracy.

Gauge Holder

Support Arm

⑦Stem

※Mounting Example

Minimize Length

No Rapid Motion No Lateral Force