Contents

Contents.........................................................................................................................................2

Figure table ....................................................................................................................................2

Before starting................................................................................................................................4

Electrical connection....................................................................................................................... 5

Installing Compact S.......................................................................................................................6

Condensation drain/water trap........................................................................................................9

Water connection.......................................................................................................................... 10

Supplementary heating element DHW.......................................................................................... 10

Duct connection.............................................................................................................................11

Electrical heating element............................................................................................................. 12

Start-up and configuration of CTS 602 controls............................................................................ 13

Startup......................................................................................................................................13

CTS 602 configuration .............................................................................................................. 13

Activating the Mainmenu/submenu menu.................................................................................. 13

Activating the SERVICE menu.................................................................................................. 14

Inlet heating.............................................................................................................................. 15

Hotwater ...................................................................................................................................16

Air quality.................................................................................................................................. 17

Air exchange............................................................................................................................. 18

Defrost......................................................................................................................................19

Temp. control............................................................................................................................ 20

Inlet control............................................................................................................................... 21

Room control ............................................................................................................................ 22

Restart......................................................................................................................................23

Preset....................................................................................................................................... 24

Manual......................................................................................................................................25

Modbus..................................................................................................................................... 26

Datalog .....................................................................................................................................27

Fault finding.................................................................................................................................. 28

Maintenance................................................................................................................................. 29

Energy saving............................................................................................................................... 31

Accessories / spare parts ............................................................................................................. 32

Recycling of this HVAC equipment ............................................................................................... 33

Figure table

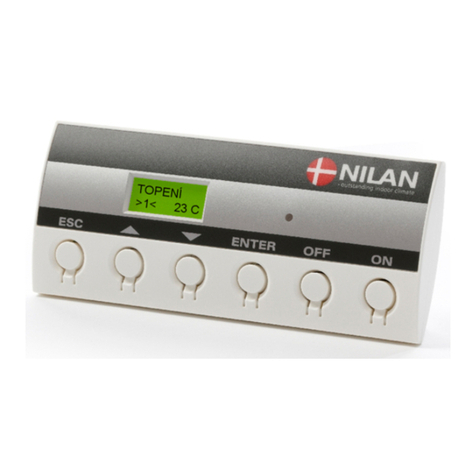

Figur 1: CTS 602 Control Panel...................................................................................................... 5

Figur 2: Duct Connections..............................................................................................................6

Figur 3: Sketch of Compact S......................................................................................................... 7

Figur 4: Location of temperature sensors ....................................................................................... 8

Figur 5: Location of sacrificial anode............................................................................................. 10

Figur 6: Water connections........................................................................................................... 10

Figur 7: Flexible connection.......................................................................................................... 10

Figur 8: Insulation of ducting..........................................................................................................11

Figur 9: Headlines in the service menu......................................................................................... 14

Figur 10: The "inlet heating" Menu................................................................................................ 15

Figur 11: The "Hotwater" Menu..................................................................................................... 16

Figur 12: The "Air quality" Menu ................................................................................................... 17

Figur 13: The "Air exchange" Menu.............................................................................................. 18

Figur 14: The "Defrost" Menu ....................................................................................................... 19

Figur 15: The "Temp. control" Menu.............................................................................................. 20

Figur 16: The "Inlet control" Menu................................................................................................. 21

Figur 17: The "Room control" Menu.............................................................................................. 22