Nippon MA-3 Solo User manual

Thermal Vaporization

Mercury Analyzer

MA-3 Solo

Simplified Manual

NIC-TD-0000092-00

Nippon Instruments Corporation

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 1

1. Precautions for Use

1.1. Safety Precaution

For the safe use of this product, observe the following precaution:

In no event shall Nippon Instruments Corporation, Inc. be liable for any direct,

indirect, punitive, incidental, special consequential damages, to property or life,

whatsoever arising out of or connected with the use or misuse of our products.

Meanings of Safety Alert Symbols

Danger

Indicates that incorrect handling could result immediately in death or

severe injury to the operator.

Warning

Indicates that incorrect handling could result in death or severe injury

to the operator.

Caution

Indicates that incorrect handling could result in moderate or minor

injury to the operator or damage to property.

Cautions Concerning Installation

Danger

Do not put any inflammable or combustible around the instrument.

Otherwise, a fire may result.

Warning

If there is any risk of generation of any harmful gasses such as

halogen, sulfur and selenium during decomposition by heating, please

be sure to vent the exhaust gas.

Caution

Be sure to use the supplied power cable.

If another cable is used, it may cause a failure.

Observe installation requirements and power specifications.

Otherwise, a failure may result.

Install the instrument on a horizontal working table with sufficient

strength.

Otherwise, a failure or a minor injury caused by an overturn or a

fall may result.

Secure space of 150 mm or more in the rear for hot exhaust

(general exhaust) from the rear upper part of the instrument and

work space to turn on or off the instrument.

Be sure to avoid a room for using an organic chlorine solvent or a

halogen reagent such as potassium iodide.

Also avoid a room into which the gas of the above-mentioned

reagent may flow.

Such substances become the cause of trouble such as the

sensitivity fall of the instrument.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

2 Nippon Instruments Corporation

Cautions Concerning Handling

Warning

The area near the inlet is hot.

Put on protectors such as heat-resistant gloves, and take care not

to get burned.

Never disable the solenoid lock manually during a measurement

because it is very dangerous.

When handling a sample boat or a mercury collector tube for a

measurement or the like, take care not to get burned.

When handling, put on protectors such as heat-resistant gloves,

and use boat tongs.

Hot exhaust (general exhaust) is discharged from the rear upper

part of the instrument.

Take care not to get burned.

When touching the instrument for maintenance, make sure that it

has been cooled sufficiently.

When touching, put on protectors such as heat-resistant gloves.

Otherwise, you may get burned.

When the instrument is turned off, the surface temperature can be

high due to the heat from the heater.

Be cautious about burn injuries and do not place anything on the

instrument.

Take care that there is no dust on the filter of the fan in the rear.

If the filter is clogged, it will cause the abnormal temperature rise

of the instrument, which is very dangerous.

Before using a reagent, procure and administer the safety data

sheet (SDS).

Disconnect the power cable from the instrument before

maintenance work.

Otherwise, an electric shock or a failure caused by a short circuit

may result.

Do not measure directly sample decomposed using nitric acid.

Otherwise, the activated carbon filter on the exhaust side may

generate heat.

Dilute nitric acid to 5 wt% or less.

Caution

Do not disassemble or modify the instrument without permission.

Otherwise, a failure may result.

Use the instrument after reading this document carefully.

Otherwise, a failure caused by an operational mistake may occur.

Observe the range of specifications. If the instrument is used out

of the specification range, a failure may occur.

When touching a glass component, take care not to suffer an

injury such as cutting a hand.

Use neutral detergent to clean the holder exclusively for the

collector tube that is used for the measurement of the mercury

collector tube, and put on (heat-resistant) gloves or the like when

touching it so that oil does not stick to it.

Otherwise, it will rust and deteriorate sooner.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 3

Cautions Concerning Storage

Caution

After the termination of a measurement, be sure to remove water in

the drain bottle and humidification bottle.

Otherwise, the sample heating tube in the instrument may absorb

moisture and be clogged.

Also when the instrument is not used for a long time, the sample

heating tube in the instrument may absorb moisture in the air and

be clogged.

Start up the instrument every two weeks or remove the sample

heating tube and keep it in a desiccator or the like so that it does

not absorb moisture.

2. Installation and Connection

(1) Put the MA-3 Solo and PC in the installation position.

(2) Connect the power cable to the AC inlet in the rear of the MA-3 Solo.

(3) Connect the power cable to an outlet with the ground.

(4) Connect the MA-3 Solo and the PC using a USB cable.

(5) Connect the exhaust port in the rear of the instrument to a draft or the like.

3. Necessities for Measurement

1) Deionized water

2) Standard mercury solution (Examples: 1 ppm, 0.1 ppm, 0.01 ppm)

3) Micropipette (up to 200 L) (measuring of liquid sample such as standard solution)

4) Electronic balance (that can measure 0.1 mg)

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

4 Nippon Instruments Corporation

4. Startup of the Instrument

4.1. Startup of MA-3 Solo

(1) Make sure that the supplied power cable has been connected to an outlet with the

ground, and turn on the power switch in the rear of the MA-3 Solo.

The status display lamp in the front of the MA-3 Solo blinks at intervals of 1 sec.

(2) Start the control and analysis software “MA3SoloWin” installed in the PC by

double-clicking.

(3) “OFFLINE”, “INITIALIZE” and “CONFIRM” appear in that order on the status bar in

the lower left part of the PC screen, and the following window is displayed in the

center of the screen.

Click one of the displayed items.

* When the ordinary measurement is to be made, we recommend that the

instrument check be made.

4.2. Self Check

The self diagnostics of the instrument is carried out before starting a measurement.

1) Click the “Self Check” tab in the upper left part of the screen.

2) Click in the upper left part of the screen, and the instrument check will start.

* It is also possible to carry out the instrument check according to the procedure

described in “4.1 Startup of MA-3 Solo”.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 5

3) Enter the peak height of the absorbance used as the threshold for the blank check

of the instrument, and click “START”.

* Reference values of the peak heights of the absorbance and the quantities of

mercury are as follows:

Reference Values of Peak Heights of Absorbances and Quantities of Mercury

Low Range

High Range

Peak Height of

Absorbance

Mercury

Quantity

(ng)

Peak Height of

Absorbance

Mercury

Quantity

(ng)

0.0001

0.06

0.0001

0.5

0.0005

0.3

0.0002

1

0.0015

1

0.002

10

4) Some items in the instrument check must be carried out manually. Carry out the

procedure according to the instructions on the screen.

5) When dust has stuck to the filter of the fan in the rear, carry out the instrument

cooling, turn off the power and clean the filter.

* Do not apply strong force to the filter.

If it is deformed, it may touch the fan in the rear.

6) Pull the drain bottle out ofthe instrument, loosen the lid and then dispose of effluent

collected in the drain bottle.

After the disposal, attach the bottle in the procedure reverse to that for the removal.

* When closing the lid, make sure that the packing has not been deformed.

If the packing has been deformed, a leak may occur.

Turn clockwise: To open

Turn counter-clockwise: To close

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

6 Nippon Instruments Corporation

7) Pull the humidification bottle out of theinstrument, loosen the lid and then pour pure

water into the humidification bottle.

After pouring pure water, attach the bottle in the procedure reverse to that for the

removal.

* When closing the lid, make sure that the packing has not been deformed.

If the packing has been deformed, a leak may occur.

8) Pull up the knob of the flow adjustment valve to disable the lock.

While looking at the screen, turn the knob to adjust the flow rate to 0.18 to 0.22

L/min.

After the adjustment, push the knob to lock it.

9) Instrument check items after (8) are automatically carried out.

10) When all items for the instrument check have been completed with “OK”, any

abnormality has not been found in the instrument.

If “NG” is displayed in the instrument check, carry out maintenance work according

to MA-3 Solo Instruction Manual.

* The purgetolower the blank value canbe carried out easilybyusing the “PURGE”

function written in MA-3 Solo Instruction Manual.

Turn clockwise: To open

Turn counter-clockwise: To close

Turn clockwise to decrease the flow rate.

Turn counterclockwise to increase the flow

rate.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 7

5. Preparation for Measurement

5.1. Blank Process of Sample Boat

By heat-treating a sample boat to remove a very small quantity of mercury before a

measurement, a precise measurement can be made.

Carry out the heat treatment of a sample boat according to (1) or (2) described below.

When the blank process is completed, leave the sample boat to cool and retain it in an

airtight container.

1) Measure an empty boat using the MA-3 Solo main unit repeatedly to make sure that

the blank value has been stabilized.

2) Put a boat in a heat-resistant ceramic container such as a crucible, and heat it at

750C for three hours or so using an electric furnace.

* If possible, use different boats for high concentrations and for low concentrations.

Especially when liquid sample is measured, mercury that has soaked into the

boat starts to melt gradually, and a measurement value becomes high.

* To clean a dirty sample boat, soak it in neutral detergent for immersion cleaning,

and carry out ultrasonic cleaning for 30 minutes or more.

Then, remove sticking dirt using a swab, a brush or the like, and soak the boat

in nitric acid solution of 1% or so.

Rinse it sufficiently using pure water and dry it at 100C or so for two hours.

* If a sample splashes on a boat tray at the time of sample dispensing or waiting,

the boat tray will be contaminated and the next measurement will be affected.

Use a clean tray. When it is dirty, wash it with water.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

8 Nippon Instruments Corporation

5.2. Blank Process of Mercury Collector Tube (Gas Measurement Option)

Before using a mercury collector tube for gas measurement, heat-treat it using an

electric furnace or the like to lower the blank value.

* Do not use a mercurycollector tube that has discolored wool even after the procedure

described below.

The capability to collect mercury may have decreased.

(1) Wipe off dirt on a mercury collector tube.

Wipe the inside using a swab or the like soaked with a little ethanol.

(2) Put mercury collector tubes on a heat-resistant ceramic pan or the like, and heat

them at 700C for 30 minutes or more using an electric furnace.

* Take care because quartz tubes may break easily because of devitrification if

sodium, calcium or the like adheres to them.

(3) When the temperature in the electric furnace has lowered and it is possible to take

out the tubes, take them out using a flat trowel, tongs or the like while protecting

yourself using heat-resistant gloves or the like, and cool the tubes.

* Take sufficient care not to get burned, and follow the instruction manual of the

electric furnace when taking out the tubes.

* If a heat-resistant ceramic pan is cooled rapidly, it may break.

(4) Leave the tubes to cool them sufficiently and then retain them in an airtightcontainer.

(5) Conduct a sampling inspection and check a blank value. (An inspection of one out

of 10 tubes is recommended.)

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 9

6. Measurement Operation

6.1. Setup of Measurement Condition

Click and set information for the measurement range, blank check and cooling

time.

(1) Measurement Range

The range is switched to LOW or HIGH according to a measured mercury

quantity.

The measurement range of the LOW range is 0 to 1000 ng (linear range: 0 to 100

ng), and that of the HIGH range is 0 to 10000 ng (linear range: 0 to 1000 ng).

(2) STD Method

Select the method for calibration curve measurement.

* Each method can be changed from the input of “Measurement” screen or table

of “Analysis” screen.

(3) Blank Check

When high-concentration sample is measured using the unknown sample

measurement, this function automatically carries out the blank value lowering of

the instrument before the next sample is measured.

To use the blank check, select “ENABLE”and enter each information.

When the blank check functions, the line of “Blank Check” is automatically added

to the table.

(1)

(2)

(3)

(4)

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

10 Nippon Instruments Corporation

(4) Cooling Time

Set the cooling times of the H1 and H3 during a measurement. (60 to 600 sec.)

For safety, the boat in/out rod is locked and it is impossible to unload the sample

boat until the preset cooling time passes.

* Although it is possible to unload the sample boat after the completion of a

measurement, the cooling of the H1 continues.

* Even when the cooling time is long enough, a sample boat after cooling is hot as

shown below, and you may get burned.

6.2. Setup of Table Condition

Click and set the contents of a memo written at the time of printing, calibration

curve table and unknown sample table.

No.

Item

Description

1

Height/Area

Set an analysis mode for the absorbance (ABS).

Usually, select AREA(integration analysis).

When a peak is small and dispersion is large in the case of

AREA, use the HEIGHT analysis.

2

Calibration Curve Selection

Set the type of a calibration curve.

* Usually, select “+Blank”for the intercept.

3

Sample Type

Select the type of an unknown sample.

When the sample type is changed, units and items to be

displayed are change.

1

2

3

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 11

6.3. Creation of Calibration Curve

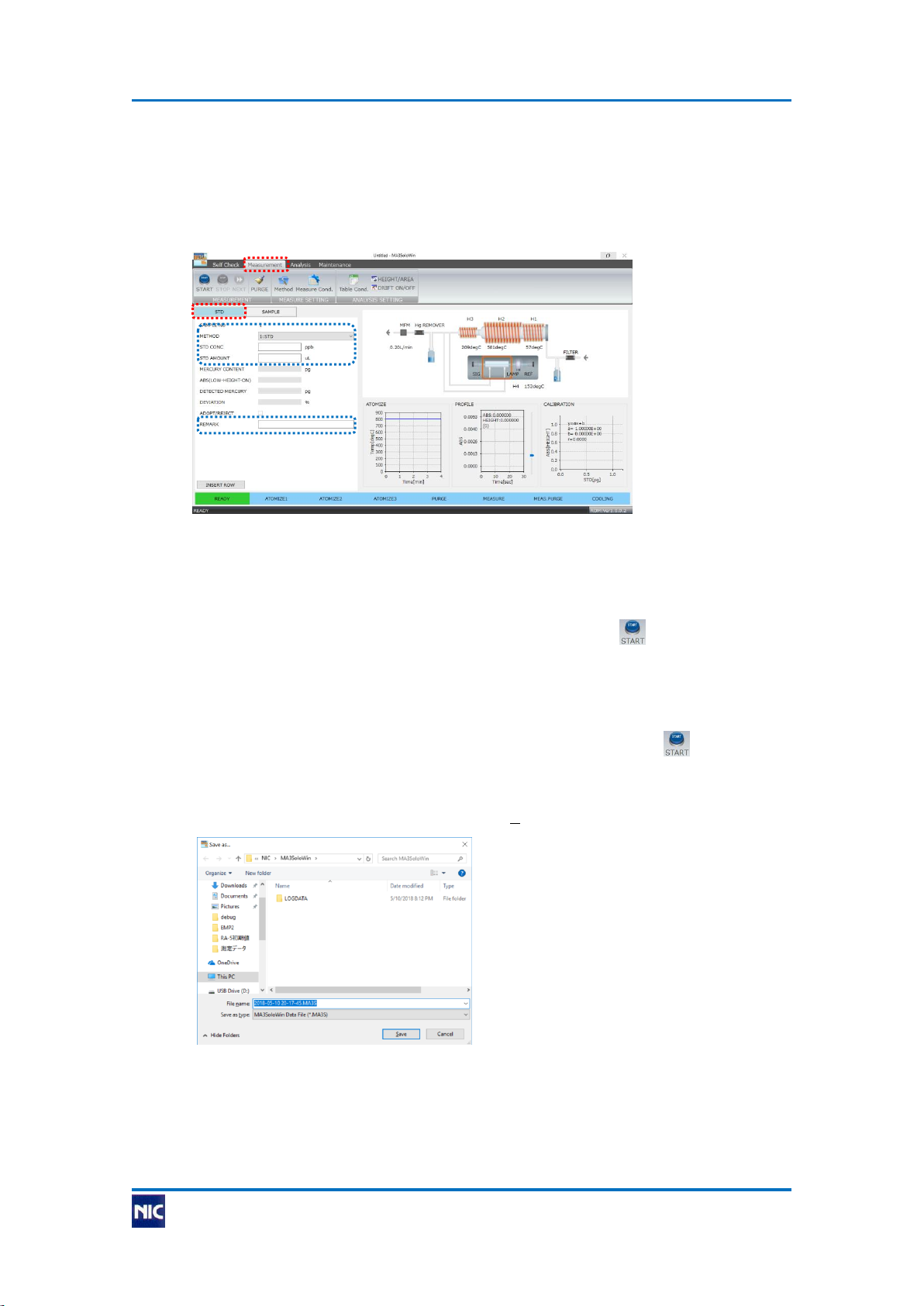

(1) Click the “Measurement”tab in the upper left part of the screen, and then click the

“STD”button.

(2) Enter “STD CONC”, “STD AMOUNT”, etc. on the following screen:

* It is also possible to enter information similarly using the table displayed when

“Analysis”in the upper left part of the screen is clicked.

(3) After the sample is set the sample heating furnace, click the “Measurement”or

“Analysis”tab in the upper left part of the screen, and click in the upper left

part of the screen to start a measurement.

* When operation is carried out on the “Analysis”tab, make sure that check marks

have been placed for samples to be measured, and then click .

(4) In the case of the first measurement, the following screen appears. Set a folder for

file saving, enter a file name and then click “Save”.

Step (1)

Step (2)

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

12 Nippon Instruments Corporation

* After a measurement starts, the solenoid lock operates as safety measures and

it is impossible to open the inlet.

* During a measurement, the status display lamp blinks at intervals of 0.1 sec.

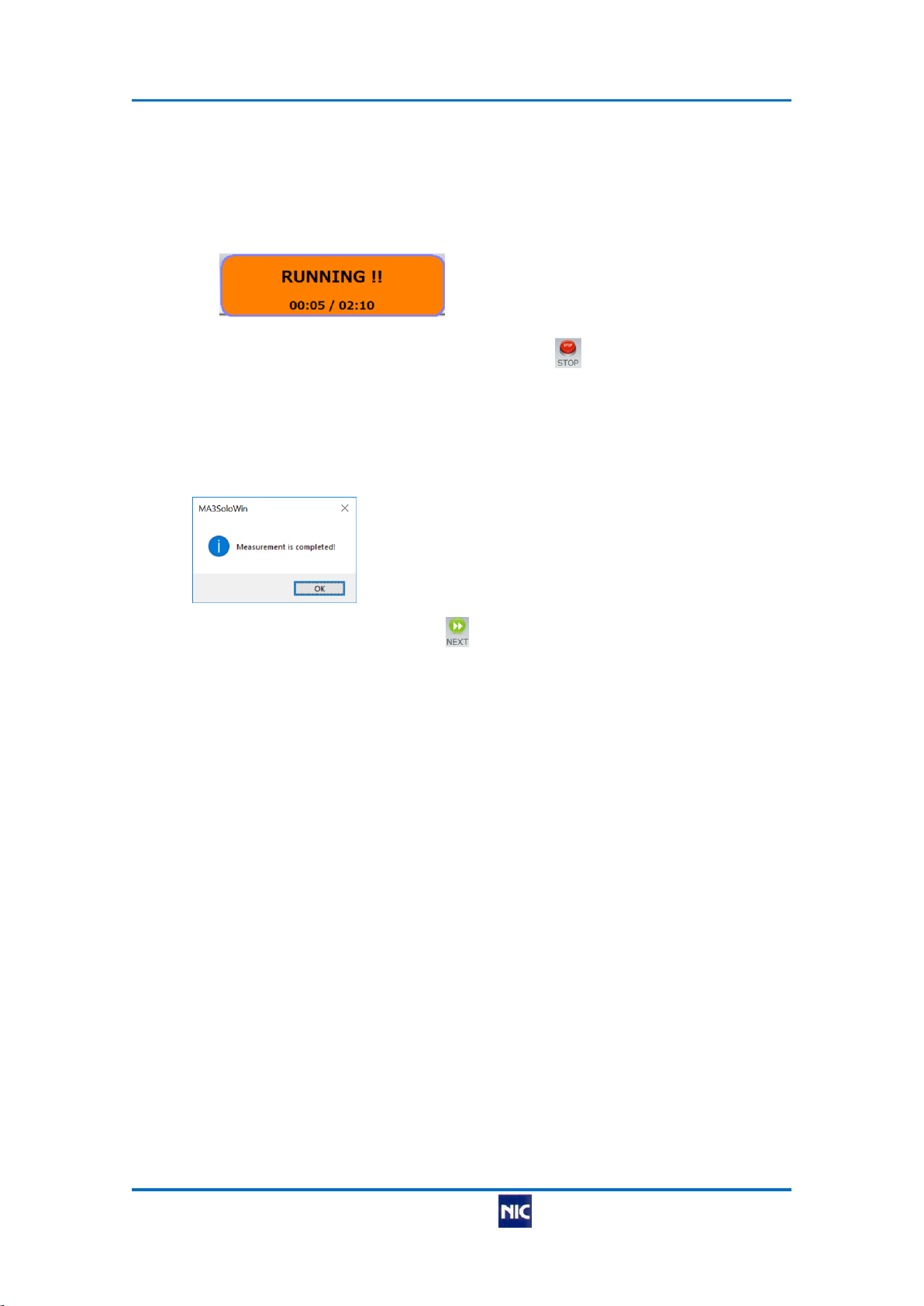

Also, the following window will pop up.

(5) When you want to suspend a measurement, click in the upper left of the

screen. The cooling starts immediately.

After the cooling is completed, the solenoid lock is disabled.

(6) When a measurement is completed, the following screen appears:

Also, the finishing sound will be played at the end of measurement.

(7) To measure the next sample, click .

Information on the next sample appears and the heating profile and theABS profile

are cleared.

* When the sample boat used for the measurement is to be used again, use it

after cooling it at room temperature for 10 minutes or more.

If sample is poured at a high temperature, the bumping or mercury leak may

occur.

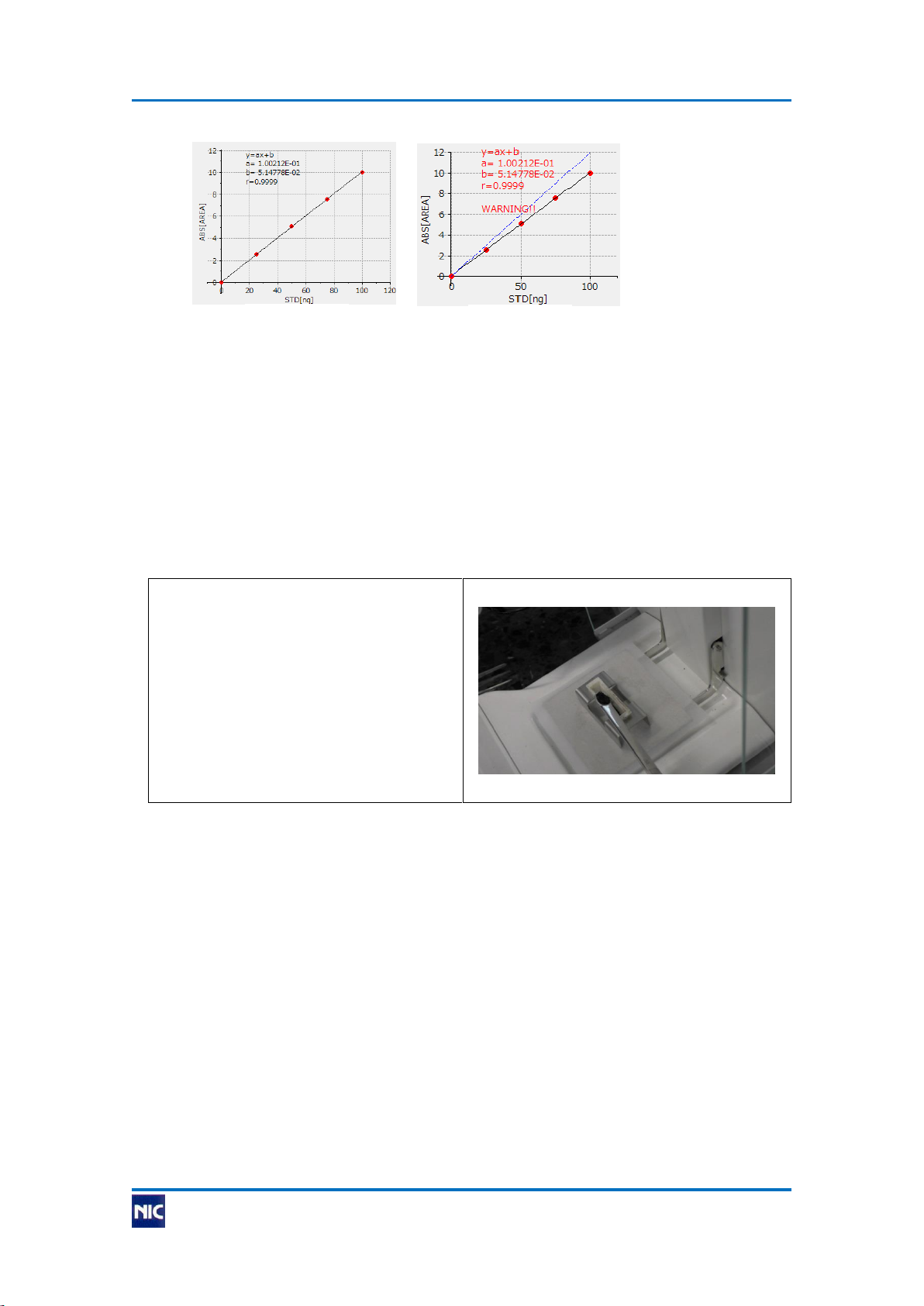

(8) Check the calibration curve on the “Analysis”screen.

If a calibration curve is abnormal, the color of characters will turn red and

“WARNING”will appear. In that case, make sure whether or not there is any

abnormality in the setup of standard values, standard mercury solutions or the

instrument.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 13

It is also possible using the table to check detected values, deviations and peak

profiles in measurement results.

When the “ox”field of an abnormal data item is clicked and “x”is placed, it is not

adopted and is excluded from a calculation and printing.

6.4. Unknown Sample Measurement

(1) Put sample on a sample boat. In the case of liquid sample, measure it using a

micropipette or the like. In the case of solid sample, measure it using a balance.

Example: Measuring of Sample Weight

(1) Put a sample boat on a boat mount using

boat tongs.

(2) Put the boat mount with the sample boat

on a balance.

(3) Eliminate a tare.

(4) While taking care not to spill sample, put it

in the sample boat and record the weight.

* In the case of the measurement of a very small quantity of mercury, an abnormal

value may occur because of contamination. When handling a sample boat, take

measures such as using disposable gloves and clean boat tongs.

* In the case of the measurement of liquid sample, put an appropriate quantity of

sample on the sample boat using a micropipette or the like after putthe sampleboat

on the boat in/out rod.

Normal

Abnormal

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

14 Nippon Instruments Corporation

* When using an additive, put it in a boat before measuring sample.

In the case of highly volatile liquid sample,

put an additive so that its height becomes

the same as or higher than that of the

liquid surface.

If it is necessary to prevent fusion, put an

additive up to such a level that the bottom

surface is covered.

When you want to suppress sudden

combustion and bumping, make an

additive soaked with sample uniformly and

cover the sample with the additive.

(2) Click the “Measurement”tab in the upper left part of the screen, and then click the

“SAMPLE”button.

Register sample names, sample volumes, etc.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 15

Six types of method have been registered in the initial condition, and it is possible

to register and use up to 16 types of methods for the same measurement.

* At first, make a measurement using 50 L or so of liquid sample or 50 mg or so

of solid sample.

The sample volume can be increased only when standard mercury solution is

measured after a sample measurement and the recovery is 95 to 105%.

* When a large quantity of sample containing a halogen, sulfur or the like

plentifully is measured, the instrument sensitivity may lower.

In that case, make a measurement using a sample volume less than 50 L or

50 mg.

* When sensitivity has lowered, it may be recovered by measuring water

repeatedly. By measuring 200 Lor so of standard mercury solution repeatedly,

sensitivity recovery and sensitivity checking can be carried out simultaneously.

* For other sample measurements, consult with the agency or us.

Sample Type

Method

Upper limit

Volume of

Sample

Remark

Standard Solution

1 STD

200 L

Biotic Sample

(Solid Sample Such As

Fish, Meat or Plant)

2 SOLID,

HEAVY OIL

200 mg

Soil

200 mg

Coal

100 mg

Heavy Oil

50 mg

The additive B is used.

Lake Water, Tap Water

3 AQUEOUS

LIQUID

200 L

Seawater, Effluent

200 L

The additive B may be used.

Crude Oil

200 L

The additive B is used.

65 L Mercury Collector

Tube

4 COLLECTOR

TUBE

-

Used for the mercury collector tube

measurement.

A dedicated holder (option) is

necessary.

-

15 PURGE

-

Used to lower the blank value of the

instrument or a sample boat.

* Do not use this for the blank value

lowering of a mercury collector tube.

Since the temperature is too high, this

becomes the cause of the

deterioration of a mercury collector

tube.

-

16 TEST

-

Used to check the instrument status.

(3) Measure the sample according to “6.3 Creation of Calibration Curve”.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

16 Nippon Instruments Corporation

(4) After the termination of a measurement, check the measurement result on the

“Analysis”screen, and determine whether to adopt or reject the data.

By clicking on the “Analysis”screen, the result of a statistical calculation can

be checked.

* When the recovery of standard mercury solution after a sample measurement is

90% or less, the sensitivitymay have lowered because of the poor decomposition

of a sample.

Decrease a sample quantity and reconsider a method.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 17

7. Printing

1) Click in the upper left part of the screen.

2) Click on the printing menu.

3) Place check marks for items to be printed, and click the “Print Preview”button to

check the printing contents.

Set the printing direction, header, footer, etc. using “Page Setup.

* The scale of a printing profile is interlocked with the profile scale on the “Analysis”

screen.

Set the scale and the number of displayed profiles for each of a standard sample

and an unknown sample.

* The width of each column is interlocked with the setup on the table screen. When

the column width atthe time of printing is narrow, make an adjustment on the table

screen.

When the column width is set to zero, that column is not printed.

4) Click the “Print”button to start printing.

Step (1)

Step (2)

Scale

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

18 Nippon Instruments Corporation

8. Shutdown

(1) Click in the upper right part to terminate “MA-3SoloWin”.

*When you carry out maintenance work or move the instrumentafter the termination

of a measurement, lower the temperature of the instrument sufficiently according

to MA-3 Solo Instruction Manual before starting the work.

(2) Terminate Windows and turn off the PC and printer.

(3) Turn off the power switch in the rear of the MA-3 Solo.

* When MA-3 Solo is turned off, the solenoid lock will be locked for the safety.

(4) Discard effluent in the drain bottle and pure water in the humidification bottle.

(5) To remove the sample heating tube, refer to MA-3 Solo Instruction Manual.

9. Error and Warning

Even when a warning message has been displayed, a measurement operation is

possible. However, when an error message has been displayed, it is impossible to start

a measurement.

Remove the cause of the error, restart the instrument and then start a measurement.

If the error status is not canceled even after measures are taken, an electric failure may

be the cause.

Consult with the agency or us.

Simplified Manual:Thermal Vaporization MercuryAnalyzer MA-3 Solo NIC-TD-0000092-00

Nippon Instruments Corporation 19

10. Contact

Nippon Instruments Corporation

URL http://www.hg-nic.com

E-mail hg[email protected]

Technical Service Group

14-8 Akaoji-cho Takatsuki-shi, Osaka, 569-1146 Japan

Phone: +81-72-693-6820

Fax: +81-72-694-0663

Other manuals for MA-3 Solo

1

Table of contents

Other Nippon Measuring Instrument manuals

Nippon

Nippon MA-3000 RD-5+SC-5 User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon AQUA User manual

Nippon

Nippon MA-3000 User manual

Nippon

Nippon RA-4500 User manual

Nippon

Nippon Mercury/PE-1 User manual

Nippon

Nippon WA-5A User manual

Nippon

Nippon MA-3000 User manual

Nippon

Nippon MA-3 Solo User manual

Popular Measuring Instrument manuals by other brands

Associated Research

Associated Research MEG CHEK 2100 owner's manual

Hydreka

Hydreka ODEON user manual

Raycus

Raycus RFL-C30000XZ user guide

CS Instruments

CS Instruments DP 400 mobil Installation and operating instructions

InnotechRV

InnotechRV TPMS-400 Quick setup instructions

Liebert

Liebert Liqui-tect MC68HC16Z1 user manual