Nippon RA-4500 User manual

Fully-automatic Reducing Vaporization

Mercury Analyzer

RA-4500

Instruction Manual

NIC-600-2202-17

Nippon Instruments Corporation

NIC-600-2202-17

RA-4500

RA-4500

Instruction Manual

Table of Contents

1. INTRODUCTION............................................................................................................. 1

1.1. Safety precautions................................................................................................... 1

1.1.1. Meaning of safety alert symbols....................................................................... 1

1.1.2. Installation precautions..................................................................................... 1

1.1.3. Handling precautions........................................................................................ 1

2. OVERVIEW OF THE INSTRUMENT.............................................................................. 2

2.1. Measurement principle............................................................................................. 2

2.2. Part names and functions........................................................................................ 3

2.2.1. Front.................................................................................................................. 3

2.2.2. Left side ............................................................................................................ 4

2.2.3. Right side.......................................................................................................... 5

2.3. Measurement flow.................................................................................................... 6

2.3.1. Purge line.......................................................................................................... 7

2.3.2. Measuring line .................................................................................................. 8

2.3.3. Blowing line....................................................................................................... 9

2.4. Operation sequence............................................................................................... 10

2.4.1. Without Pretreatment (Method 1)....................................................................11

2.4.2. With Pretreatment (Method 3)........................................................................ 12

2.4.3. With Pretreatment (only sample) (Method 5)................................................. 13

3. INSTALLATION AND CONNECTIONS........................................................................ 15

3.1. Installation of the instrument.................................................................................. 15

3.2. Installing RA4Win................................................................................................... 16

3.2.1. Installing RA4Win ........................................................................................... 17

3.2.2. Making the network settings........................................................................... 18

3.2.3. Setup of IP address (network adapter)........................................................... 18

3.2.4. How to uninstall............................................................................................... 20

4. STARTUP AND ENDING OPERATION ....................................................................... 21

4.1. Startup.................................................................................................................... 21

4.1.1. Starting the RA-4500 ...................................................................................... 21

4.1.2. Starting the control software........................................................................... 21

4.1.3. Self-check....................................................................................................... 22

4.1.4. Filling reagents................................................................................................ 22

4.2. Ending operation.................................................................................................... 24

4.2.1. Reagent discharge.......................................................................................... 24

4.2.2. Closing the control software........................................................................... 25

4.2.3. Shutting down the instrument......................................................................... 25

5. PREPARATION OF REAGENTS ................................................................................. 26

5.1. Preparation of reagents ......................................................................................... 26

5.2. Preparation of standard solution............................................................................ 27

6. MEASUREMENT.......................................................................................................... 28

6.1. Setting the Measurement Condition...................................................................... 29

6.2. Setting the table conditions.................................................................................... 29

6.3. Registering the calibration curve information ........................................................ 30

6.4. Registering unknown samples............................................................................... 31

NIC-600-2202-17

RA-4500

6.5. Setting the samples in place.................................................................................. 32

6.6. Starting a measurement......................................................................................... 32

6.7. Stopping a measurement....................................................................................... 34

6.8. Reviewing a calibration curve................................................................................ 35

6.9. Reviewing the measurement results...................................................................... 36

6.10. Data saving............................................................................................................ 36

6.11. Printing................................................................................................................... 37

7. CONTROL SOFTWARE RA4WIN................................................................................ 38

7.1. Main screens.......................................................................................................... 38

7.1.1. Table window.................................................................................................. 39

7.1.2. Calibration curve (Calib) window.................................................................... 43

7.1.3. Control screen ................................................................................................ 44

7.1.4. Analysis screen............................................................................................... 45

7.2. List of icons and their function............................................................................... 46

7.2.1. Icons ............................................................................................................... 46

7.3. File menu commands............................................................................................. 47

7.3.1. New ....................................................................................................... 47

7.3.2. Open ..................................................................................................... 48

7.3.3. Save ....................................................................................................... 48

7.3.4. Page Setup..................................................................................................... 49

7.3.5. Print Preview ...................................................................................... 50

7.3.6. Printing............................................................................................................ 50

7.3.7. Quit ......................................................................................................... 52

7.4. Edit menu commands............................................................................................ 52

7.4.1. Copy................................................................................................................ 52

7.4.2. Cut .................................................................................................................. 52

7.4.3. Paste............................................................................................................... 52

7.4.4. Remove........................................................................................................... 53

7.4.5. Insert............................................................................................................... 53

7.4.6. Move............................................................................................................... 53

7.4.7. Save as csv file............................................................................................... 53

7.4.8. Save as jpg file ............................................................................................... 53

7.4.9. Add Data......................................................................................................... 53

7.5. Run menu commands............................................................................................ 54

7.5.1. Turn Tray ............................................................................................... 54

7.5.2. Lift Move ................................................................................................. 54

7.5.3. Start ........................................................................................................ 55

7.5.4. Stop ........................................................................................................ 55

7.5.5. Emergency ............................................................................................ 55

7.5.6. Reset............................................................................................................... 55

7.5.7. Measurement Conditions................................................................................ 56

7.5.8. Self-check....................................................................................................... 61

7.5.9. Leak check...................................................................................................... 63

7.5.10. Start and Lamp-off.......................................................................................... 64

7.5.11. Maintenance................................................................................................... 65

7.6. Table menu commands.......................................................................................... 70

NIC-600-2202-17

RA-4500

7.6.1. Memo Setup.................................................................................................... 70

7.6.2. Table Conditions ................................................................................. 71

7.6.3. Statistics (S) ........................................................................................ 74

7.6.4. Registration of sample name (R).................................................................... 77

7.6.5. Table column initialization (I) .......................................................................... 78

7.7. System menu commands ...................................................................................... 79

7.7.1. Setup of IPAddress(RA4/RA4Win)................................................................ 79

7.7.2. Setup of IPAddress(RA4Win)........................................................................ 80

7.7.3. Setup............................................................................................................... 81

7.7.4. Color Scheme Setup....................................................................................... 83

7.7.5. Firmware Update............................................................................................ 84

7.8. Window menu commands...................................................................................... 86

7.8.1. Screen change (Control Screen) .......................................................... 86

7.8.2. Screen change (Analysis Screen) ........................................................ 86

7.8.3. Usual and Precision/Management Change.................................................... 86

7.8.4. Screen Arrangement Initialization................................................................... 87

7.8.5. Sequence Log and Error History Labeling ..................................................... 87

7.9. Help menu.............................................................................................................. 89

7.9.1. Version information......................................................................................... 89

8. SELF-PRECISION MANAGEMENT............................................................................. 90

9. TEMPERATURE CALIBRATION FUNCTION.............................................................. 94

10. MAINTENANCE .......................................................................................................... 98

10.1 Daily inspection...................................................................................................... 98

10.2 Yearly inspection and replacement parts................................................................ 100

10.3 Error and warning ................................................................................................ 101

10.4 Recovery from power failure................................................................................ 103

10.5 Corrective actions................................................................................................ 104

10.5.1 Abnormal blank value................................................................................... 104

10.5.2 Poor sensitivity.............................................................................................. 105

10.5.3 Leakage........................................................................................................ 105

10.6 Replacing the parts.............................................................................................. 106

10.6.1 Removing the turntable................................................................................. 106

10.6.2 Replacing the reaction tube.......................................................................... 107

10.6.3 Replacing the reagent pump tube.................................................................110

10.6.4 Replacing the reagent tube ...........................................................................111

10.6.5 Replacing the tubes inside the detector........................................................113

10.6.6 Replacing the cap and bubbler......................................................................114

10.6.7 Replacing the lamp........................................................................................116

10.7 Cleaning method...................................................................................................117

10.7.1 Cleaning the reagent tube.............................................................................117

10.7.2 Cleaning the cap, bubbler, light absorption cell, and dehumidifier tube........117

11. CALCULATION............................................................................................................118

11.1 Conversion of reagent amounts............................................................................118

11.2 How to determine a calibration curve.................................................................. 120

11.2.1 Linear equations........................................................................................... 120

11.2.2 Cubic equations............................................................................................ 120

11.3 Standard addition................................................................................................. 122

NIC-600-2202-17

RA-4500

12. SPECIFICATIONS ...................................................................................................... 123

12.1. Component specifications.................................................................................... 123

12.1.1. Detecting unit................................................................................................ 123

12.1.2. Sample pretreatment & reduction unit.......................................................... 123

12.1.3. Reagent dispensing unit............................................................................... 124

12.1.4. Data processing system............................................................................... 124

12.2. Installation specifications..................................................................................... 125

12.2.1. Installation environment................................................................................ 125

12.2.2. Power supply specifications ......................................................................... 125

13. CONTACT................................................................................................................... 126

NIC-600-2202-17

1. Introduction

RA-4500

1

1. Introduction

1.1. Safety precautions

1.1.1. Meaning of safety alert symbols

Warning

Indicates that incorrect handling could result in the death or severe injury

to the operator.

Caution

Indicates that incorrect handling could result in moderate or minor injury

to the operator, or damage to property.

1.1.2. Installation precautions

Warning

•Ensure to connect the protective grounding to prevent electric shock.

1.1.3. Handling precautions

Warning

•Shut Off the power supply before starting any maintenance. Otherwise, it could

result in electric shock.

•Keep your hands away from the auto sampler during measuring operation, or they

could be caught in a moving part, and thus leading to injury as well as damage to

the instrument.

•When using a reagent, be sure to wear protective equipment and properly ventilate

the work area. Reagents to be used in this instrument contain acutely toxic

substances and corrosive substances.

Caution

•Do not touch any sample tubes or the sample table during and shortly after the

heating operation, or you may suffer burns because of its high temperature. Wait

until they cool down to around the room temperature before proceeding with work.

•Be careful when touching or handling any glass parts because they could have

been damaged during work. Failure to observe this may cause injury.

•Be sure to use the instrument within the specifications, or it may break down.

2. Overview of the instrument

NIC-600-2202-17

RA-4500

2

2. Overview of the instrument

The RA-4500 is a fully automatic mercury analyzer which carries out the wet

decomposition of samples such as drinking water and soil extracts, and then measures its

mercury content utilizing cold vapor atomic absorption spectroscopy.

It is capable of ultrahigh sensitivity measurement with a small quantity of samples. Since

the system determines an undecomposed sample, even less-experienced personnel can

perform the correct measurement.

2.1. Measurement principle

The instrument adds sulfuric acid, nitric acid, and potassium permanganate to the sample,

and after confirming that the potassium permanganate remains vermilion, adds potassium

peroxodisulfate. When this solution is heated, the mercury compounds in the solution are

oxidized and broken down into divalent mercury ion (Hg2+).

After leaving the solution standing to cool, the instrument adds a hydroxylammonium

chloride solution to remove excess potassium permanganate. When it adds a stannous

chloride (II) solution to this sample subjected to wet pretreatment, the divalent mercury ion

(Hg2+) is reduced to zero-valent metallic mercury and turns into mercury gas by bubbling.

Hg2++SnCl2→Hg0↑

After removing the acid mist and water vapor generated by bubbling with the electronic

cooling unit, the instrument measures the absorbance of mercury at 253.7 nm which is the

first absorption wavelength.

It measures the known mercury amount, creates a calibration curve, and then calculates the

mercury amount from the absorbance.

NIC-600-2202-17

2. Overview of the instrument

RA-4500

3

2.2. Part names and functions

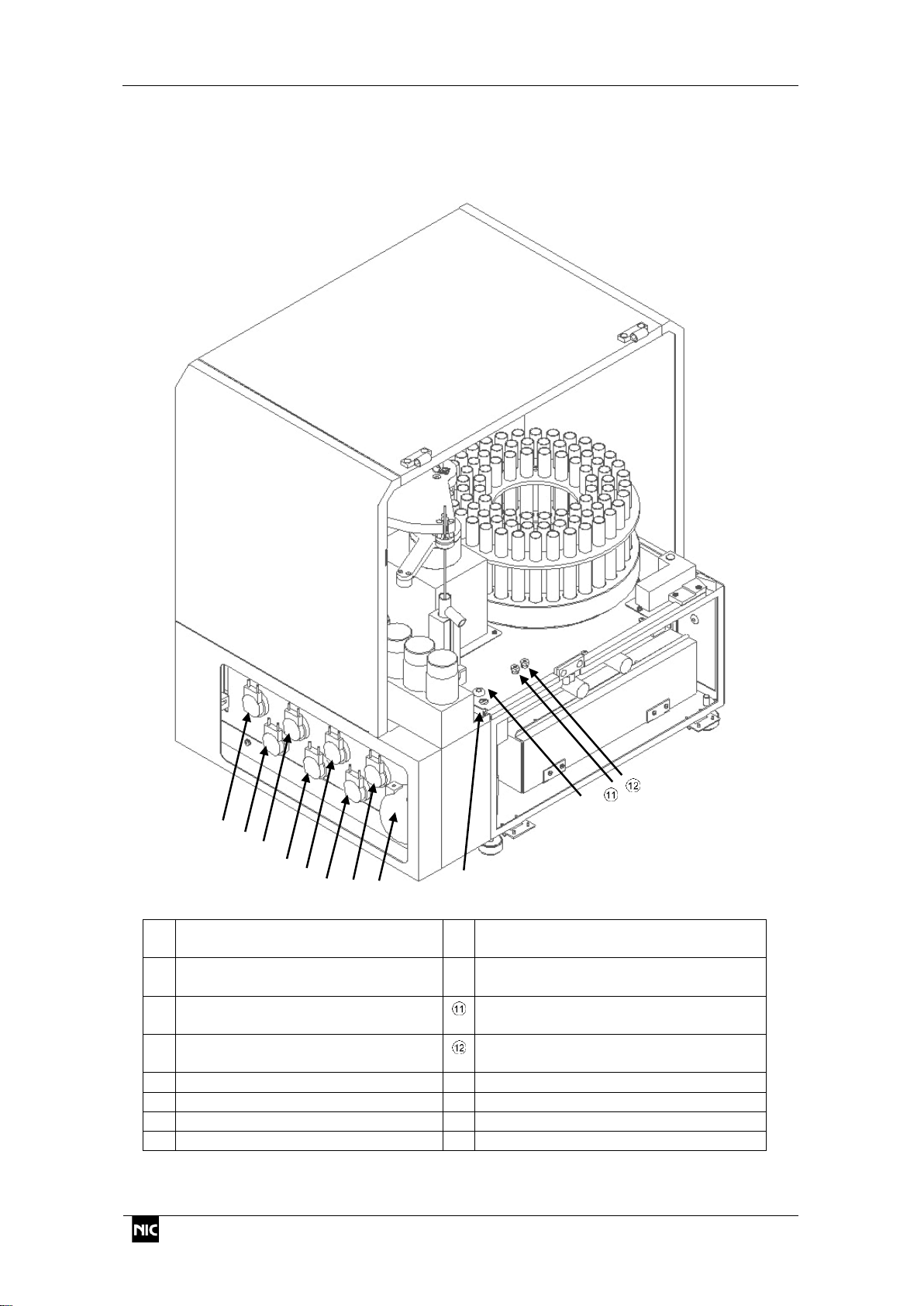

2.2.1. Front

Dispensing cap

Optical system

Measuring cap

V3 valve

Color sensor

V1 valve

Reagent stand

Flow sensor

Rinse container

Door lock

Dehumidifier

Heating table

V2 valve

Sample tube

Drain tank

Dispensing arm

2. Overview of the instrument

NIC-600-2202-17

RA-4500

4

2.2.2. Left side

Air pump

Opening for drawing out the effluent

hose

Reagent pump P1

Grommet for (transparent) reaction

tube

Reagent pump P2

Connection port for (green) reaction

tube

Reagent pump P3

Connection port for (yellow) reaction

tube

Reagent pump P4

Reagent pump P5

Reagent pump P6

Rinse pump P7

NIC-600-2202-17

2. Overview of the instrument

RA-4500

5

2.2.3. Right side

Connectors to optional units.

Cooling fan

Main switch

Main power connector

Power connector for duct fan

LAN cable port

RS-232C port

Ventilation fan (with filter)

Duct fan

2. Overview of the instrument

NIC-600-2202-17

RA-4500

6

2.3. Measurement flow

The instrument drips a reagent for pretreatment using the reagent pumps P1 to P4 and

drips a reducing agent using the reagent pumps P5 and P6.

After the dripping reagents, it turns the rotor using the stirrer located under the turntable to

stir the sample.

Carrier gas is introduced into the purge line, measuring line, or blowing line by the

switching V1, V2 and V3. The bubbler is washed in the rinse bottle after measurement.

Cell

Yellow

Activated

carbon case

Mercury

lamp

Sample tube

Rinse bottle

Air pump

V1

V3

V

s

V2

V

R

H

2

SO

4

KMnO

4

HNO

3

P1

P2

P3

P4

K

2

S

2

O

8

HONH

3

Cl

SnCl

2

P5

P6

P7

DW

スターラー

Effluent bottle

Cap

Bubbler

Stirrer

Dehumidifier

section

Drain tank

Green

NIC-600-2202-17

2. Overview of the instrument

RA-4500

7

2.3.1. Purge line

Before starting measurement, the instrument replaces the gas in the absorption cell and

measuring line.

The valves V3 and V2 turn ON, and the carrier gas flows through the channel shown in

the figure below.

Bubbler

Mercury

lamp

Activated

carbon case

Air pump

Rinse bottle

V1

V3

V

s

V2

V

R

H

2

SO

4

KMnO

4

HNO

3

P1

P2

P3

P4

K

2

S

2

O

8

HONH

3

Cl

SnCl

2

P5

P6

P7

DW

Sample tube

Effluent bottle

Cap

Yellow

Cell

Dehumidifier

section

Drain tank

Green

2. Overview of the instrument

NIC-600-2202-17

RA-4500

8

2.3.2. Measuring line

After dripping stannous chloride (II) into the sample, the instrument carries out bubbling in

the sample tube to gasify mercury, and measures its absorbance in the cell.

The valves V1, V2 and V3 turn ON, and the carrier gas flows through the channel shown

in the figure below.

* Bubbling does not occur when there is a leak in the line.

Bubbler

Cap

Rinse bottle

Mercury

lamp

Air pump

Activated

carbon case

Sample tube

V1

V3

V

s

V2

V

R

H

2

SO

4

KMnO

4

HNO

3

P1

P2

P3

P4

K

2

S

2

O

8

HONH

3

Cl

SnCl

2

P5

P6

P7

DW

Effluent bottle

Yellow

Cell

Dehumidifier

section

Drain tank

Green

NIC-600-2202-17

2. Overview of the instrument

RA-4500

9

2.3.3. Blowing line

This line is a channel used to purge chlorine gas after bubbler cleaning in the rinse bottle

or after dripping a hydroxylammonium chloride solution. The instrument uses this channel to

drip the water accumulated in the dehumidifier tube, into the drain tank.

The air pump runs with all of the valves V1, V2 and V3 set to OFF, which allows the carrier

gas to flow through the channel shown in the figure below.

Mercury

lamp

Activated

carbon case

Sample tube

Bubbler

Cap

Dehumidifier

section

Rinse bottle

V1

V3

V

s

V2

V

R

H

2

SO

4

KMnO

4

HNO

3

P1

P2

P3

P4

K

2

S

2

O

8

HONH

3

Cl

SnCl

2

P5

P6

P7

DW

Effluent bottle

Yellow

Cell

Drain tank

Air pump

Green

2. Overview of the instrument

NIC-600-2202-17

RA-4500

10

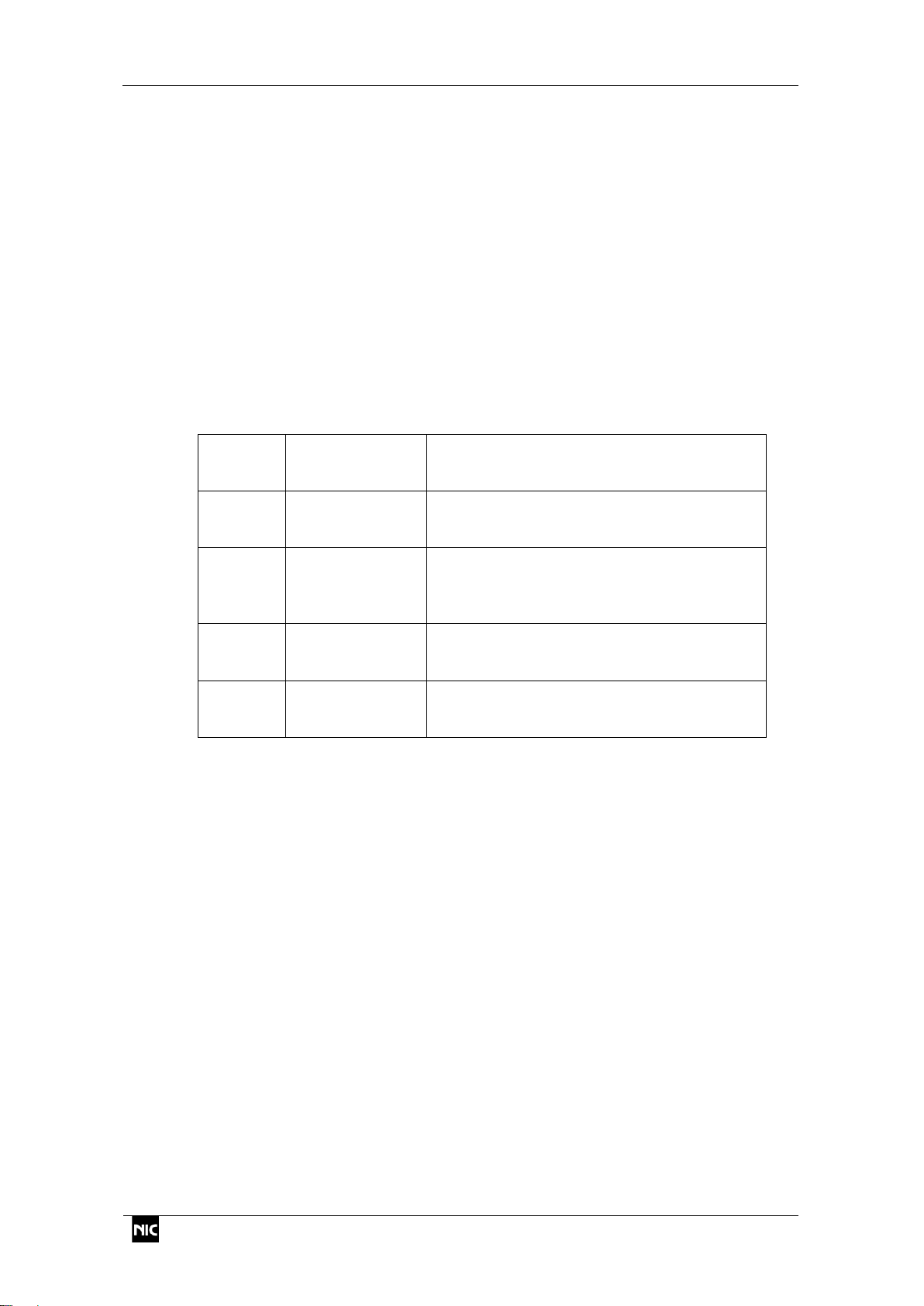

2.4. Operation sequence

The following three patterns of operation sequence are available depending on the

Pretreatment setting in the Measurement Condition window.

Pretreatment Without : Neither standard samples nor unknown samples

are pretreated.

Pretreatment With : Both standard samples and unknown samples are

pretreated under the same conditions.

Pretreatment Sample Only : Standard samples are measured by the

“Pretreatment Without” option, and unknown

samples are measured by the “Pretreatment With”

option.

The following four measurement methods 1-5 were registered before shipping the product.

Method1

Pretreatment

Without

For samples that contain no interfering

ingredients (Prepared as per JIS-K0102

“Testing methods for industrial wastewater”)

Method2

Pretreatment

With

For river water and drinking water

(Prepared as per Ministry of Health, Labour

and Welfare notice No. 261)

Method3

Pretreatment

With

For environmental samples that involve

water contamination

(Prepared as per Appendix 2 of Notification

No. 59 of the Ministry of Environment)

Method4

Pretreatment

Sample Only

For industrial wastewater samples

(Prepared as per JIS-K0102 “Testing

methods for industrial wastewater”)

Method5

Pretreatment

Sample Only

For absorption solution of stack gas

(Prepared as per No. 94 of the Ministry of

Environment)

* The amount of reagents can be changed freely, as long as the total setup amount is lower

than 10 mL.

* Changing the reagent concentration could damage or block a tube.

* If pretreatment is carried out, addition of the sample is not allowed. When starting the

decomposition of an unknown sample after checking the calibration curve with “sample

only” option, do not put a check in the unknown sample in the SMP tab.

NIC-600-2202-17

2. Overview of the instrument

RA-4500

11

2.4.1. Without Pretreatment (Method 1)

* The same sequence is used in the Method 4 for measurement of standard samples,

except that no sample addition is allowed.

Repeat the cycle for all samples

Start

In the Method 1 (unpretreated samples), the sample may be

added during measurement.

* In this method, the system does not carry out the Sample

presence check.

* The door lock is also disabled.

End

Reagent dispensing

Sample presence check

Sulfuric acid (1+1) (Normally 0.9 mL)

10% stannous chloride solution

(Normally 0.5 mL)

Measurement (Normally 120 sec.)

Output of measurement results

Bubbler cleaning (Normally 7 sec.)

2. Overview of the instrument

NIC-600-2202-17

RA-4500

12

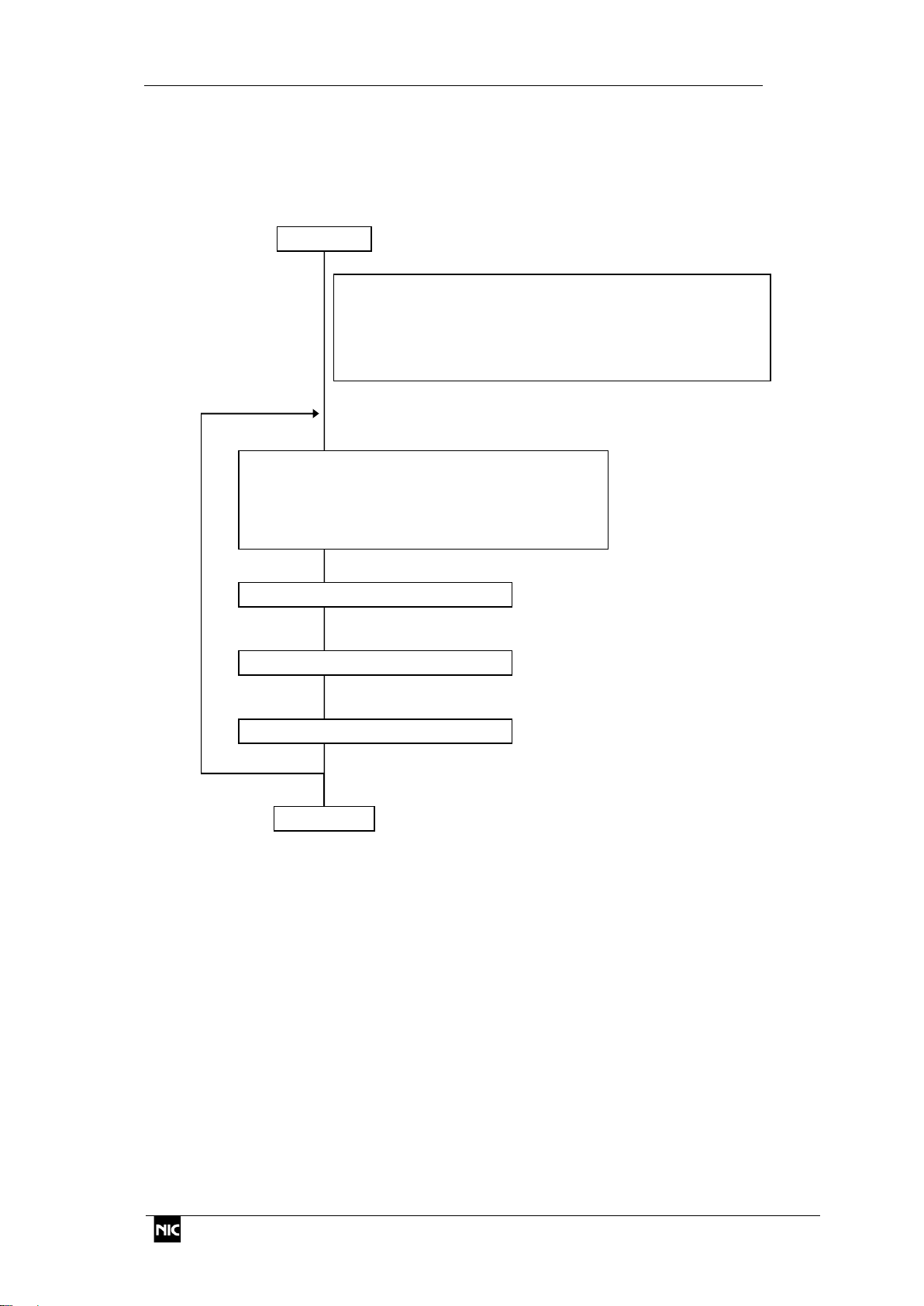

2.4.2. With Pretreatment (Method 3)

Start

End

Reagent dispensing (Carried out for all samples to be measured)

Nitric acid (1+3) (Normally 0.5 mL)

Sulfuric acid (1+1) (Normally 0.5 mL)

5% potassium permanganate solution (Normally 0.5 mL)

Letting it stand

Reagent dispensed period is memorized for each sample; and after a lapse of 15

minutes, color check starts.

* It is possible to make settings of starting color check after dispensing all reagents.

Color check (1)

If the solution is vermilion, a 3% potassium peroxodisulfate solution (normally 0.5

mL) will be dripped into it.

If the vermilion disappears, a potassium permanganate solution will be added in

the sample and then returned to "Letting it stand" step.

* If the amount of P1 reagent is set to more than 0.7mL and P1 reagent is to be

added to all 80 samples again, the amount of reagent will not be enough.

Heating (Normally 95°C for 2 hours)

Cooling (Normally for 60 min.) If the sample temperature exceeds 40°C after the

preset time, it will be cooled down to 40°C or less.

Reagent dispensing

1.0% hydroxylammonium chloride solution (Normally 2.5 mL)

Stirring, and chlorine gas purging

10% stannous chloride solution (Normally 0.4 mL)

Bubbler cleaning (Normally 7 sec.)

Measurement (Normally 120 sec.)

Presence check for all samples

* If no sample is detected for a checked item, the confirmation message appears.

Color check (2)

Check of residual permanganate ion (Normally disabled)

Output of measurement results

NIC-600-2202-17

2. Overview of the instrument

RA-4500

13

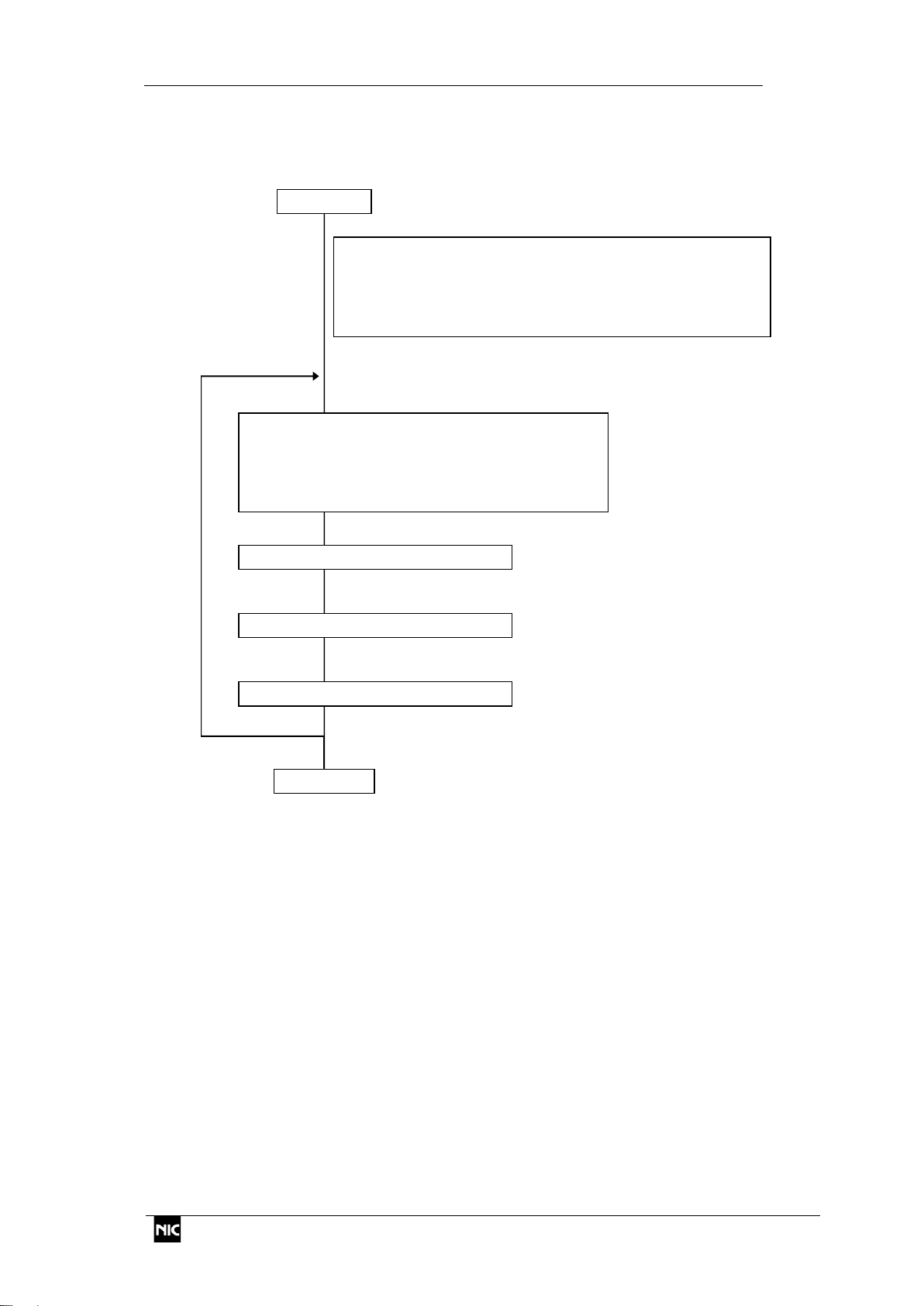

2.4.3. With Pretreatment (only sample) (Method 5)

Repeat the cycle for all samples

Start

* The sample presence check can be used in method2-4 as

an auxiliary function, but it cannot be used in method5

because these samples have the color of potassium

permanganate solution.

End

Reagent dispensing

Sample presence check

Sulfuric acid (1+1) (Normally 0.6 mL)

10% stannous chloride solution

(Normally 0.3 mL)

Measurement (Normally 120 sec.)

Output of measurement results

Bubbler cleaning (Normally 7 sec.)

2. Overview of the instrument

NIC-600-2202-17

RA-4500

14

Start

End

Letting it stand

Reagent dispensed period is memorized for each sample; and after a lapse of 15

minutes, color check starts.

* It is possible to make settings of starting color check after dispensing all reagents.

Color check (1)

If the solution is vermilion, a 3% potassium peroxodisulfate solution (normally 0.5

mL) will be dripped into it.

If the vermilion disappears, a potassium permanganate solution will be added in

the sample and then returned to "Letting it stand" step.

* If the amount of P1 reagent is set to more than 0.7mL and P1 reagent is to be

added to all 80 samples again, the amount of reagent will not be enough.

Heating (Normally 95°C for 1 hours)

Cooling (Normally for 60 min.) If the sample temperature exceeds 40°C after the

preset time, it will be cooled down to 40°C or less.

Reagent dispensing

1.5% hydroxylammonium chloride solution (Normally 2.7 mL)

* It is the concentration the when absorption solution is diluted to 300mL.

If dilution rate is different, only change the concentration and keep the

reagentamount to 2.7mL.

Stirring, and chlorine gas purging

10% stannous chloride solution (Normally 0.5 mL)

Bubbler cleaning (Normally 7 sec.)

Measurement (Normally 120 sec.)

Color check (2)

Check of residual permanganate ion (Normally disabled)

Output of measurement results

Reagent dispensing (This operation is not carried out in the default setting)

* If the sample is at neutral pH due to the dilution of the absorption solution etc.,it

is better to add sulfuric acid (1+1).

NIC-600-2202-17

3. Installation and connections

RA-4500

15

3. Installation and connections

3.1. Installation of the instrument

(1) Place the RA-4500 at the installation position.

(2) Connect the duct hose to the exhaust fan.

(3) Connect the power cable and LAN cable (straight cable) to each connector on

the back.

(4) Set the instrument in place, and adjust the adjuster bolts to prevent wobbles.

(5) Place the effluent tank on the left side of the instrument, and tighten the cap.

* Ensure that the tube does not get in contact

with the liquid inside.

(6) Connect the LAN cable to the PC.

(7) Connect the power cable to the power outlet.

* Be sure to connect it to a grounded outlet.

Table of contents

Other Nippon Measuring Instrument manuals

Nippon

Nippon MA-3 Solo User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon MA-3000 User manual

Nippon

Nippon Mercury/PE-1 User manual

Nippon

Nippon AQUA User manual

Nippon

Nippon Hi-Lutor User manual

Nippon

Nippon MA-3 Solo User manual

Nippon

Nippon MA-3000 User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon WA-5A User manual