Nippon MA-3000 User manual

1

.

Inspection

i

No.

704-2010-01

MA-3000

Service Manual

Document No. NIC-704-2010-01 Date of Issue

Jan. 16, 2014

Management Dept.

Page 1/

MA-3000

SERVICE MANUAL

Nippon Instruments Corporation

Service Department

Date Written By Checked By Approved By

1st edition Jan. 15, 2014 Kotake Daito Noda

1

.

Inspection

ii

No.

704-2010-01

MA-3000

Service Manual Document No. NIC-704-2010-01 Date of Issue

Jan. 15, 2014

Management Dept.

Page 2/

Revision History

Ver.

Revision

Date Reason for Revision Written By

Approved By

01

Jan. 15,

2014 First edition issued Kotake Noda

1

.

Inspection

iii

No.

704-2010-01

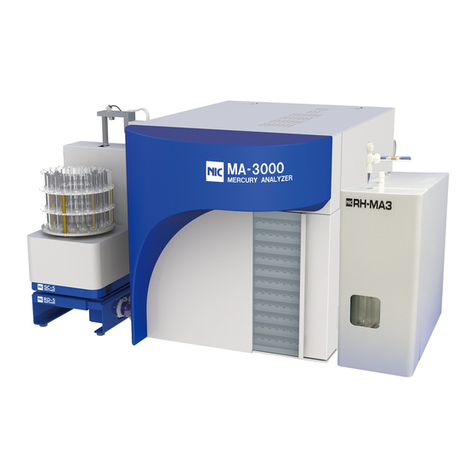

FULL-AUTOMATIC HEAT-VAPORIZATION MERCURY ANALYZER

MERCURY MA-3000 SERVICE MANUAL

Contents

SERVICE MANUAL..............................................................................................................1

1.Inspection........................................................................................................................4

1.1. Removal of cabinet covers.....................................................................................5

1.2. Cell cleaning...........................................................................................................8

1.3. Replacement of joint.............................................................................................12

1.4. Dismounting the sample heating tube ..................................................................13

1.5. Mounting the sample heating tube .......................................................................15

1.6. Overall operation check of sample changer .........................................................18

1.7. Procedure for leak check......................................................................................23

1.8. Inspection.............................................................................................................28

2. Replacement work........................................................................................................29

2.1 Replacement procedure of H1 heater .......................................................................30

2.2 Adjustment procedure of H1 heater...........................................................................33

2.3 Replacement procedure for H2 heater......................................................................34

2.5 Replacement procedure of thermocouple for H3 heater ...........................................39

2.6 Replacement procedure of SSR................................................................................41

3. Sample changer and its relatives................................................................................44

3.1 Recovery procedure for the MA-3000 sample changer error ....................................44

3.2 Function check of each sensor..................................................................................47

3.3 Replacement procedure of boat taking Boat handling poker.....................................49

3.4 Adjustment of sample changer (Vertical axis, Y-axis)................................................52

3.5 Adjustment of sample changer (Horizontal axis, X-axis)...........................................55

3.6 Adjustment of sample changer (Lift axis) ..................................................................56

・ Replacement of lift motor.........................................................................................57

4. About high level pollution............................................................................................58

1

.

Inspection

1

No.

704-2010-01

Inspection

Since extensive improvement has been carried out for the MA-3000, its structure after the

improvement differs from that before the improvement.

Instruments with serial numbers 10740001 to 12740140 are referred to as the Version I type,

and those with serial numbers 13740141 and later are referred to as the Version II type for

convenience.

・List of time-change components for MA-3000

Sample heating tube MA-3 W139-1360-01 1

Mercury collection tube (gold nanoparticles) W139-1341-00 1

Teflon joint 6 mm dia. N-41663 1

Different diameter union tee 516165 1

*When the system has the option.

Different diameter union cross 516166

Teflon joint FLW-30-3U-S 1

Different diameter union elbow 3-4 FLW-30-4RUE3-S 1

Inlet O-ring P-022A DPN-P-022A-7075 1

In/out rod O-ring 24A DPN-P-024A-7075 1

Teflon tube (3 mm dia. ×2 mm dia.) S1037-0202-00 60 cm

Activated carbon case (for exhaust) W139-1120-01 1 set

MA-3000 sample boat set (10 pcs.) S1106-6100-00 1 set

1

.

Inspection

2

No.

704-2010-01

1.1.

Removal of cabinet covers

①Top cover

・Version I type

With the instrument turned off, remove the

ring latches and remove the top cover.

・Version II type

With the instrument turned off, remove the

ring latches.

* The M3 screws in the upper part of the

rear are for transportation. Remove them

after installation.

1

.

Inspection

3

No.

704-2010-01

②Removal of right side panel

・Type A or B

Remove the fixing screws for

transportation.

・Type C

Remove the knurled screw in the rear.

Remove the two knurled screws and

remove the side panel.

Remove the M3 screw fixing the right side

panel, and remove the side panel.

1

.

Inspection

4

No.

704-2010-01

③Removal of left side panel

・Type A or B

Remove the fixing screws for

transportation.

・Type C

Remove the knurled screw in the rear.

Remove the two knurled screws and

remove the side panel.

Remove the M3 screw fixing the left

side panel, and remove the side panel.

1

.

Inspection

5

No.

704-2010-01

1.2.

Cell cleaning

(1) Preparation of components

(2) Removal

Remove the top cover and remove the cover of the optical system from its case. Then,

remove the cell retainers, loosen the joint and the screws fixing the optical system,

and remove the cell unit.

MA-3000 (Version I type) MA-3000 (Version II type)

* If the 1 mm cell, branch pipe or O-ring has a crease or breakage, replace it.

If not replaced, it will cause a leak.

No.

Name Comp. No. Qty Remark

1 Phillips screwdriver (02) - 1 Tool

2 Phillips screwdriver (01) 1 Accessory

3 Coin 1 Tool

4 Beaker (500 mL) 1 For cleaning

5 10% nitric acid 500 mL For cleaning

6 Distilled water 1 L For cleaning

7 Alcohol (ethanol etc.) 100 mL For cleaning

8 Cotton waste 1 box For cleaning

9 Rubber glove 1 set For cleaning

1

.

Inspection

6

No.

704-2010-01

(3) Disassembly of component

Disassemble the cell unit and divide it into metal components and other.

* When it is impossible to remove the cell window, it can be removed by soaking it in

water. Do not give a strong shock.

(4) Cleaning of components

Clean up the metal components using alcohol, and wipe them.

Wash the other parts using neutral detergent and nitric acid.

Wash them using neutral detergent for 30 minutes with ultrasonic washer, or soak

for five hours without it. Discard cleaning fluid, rinse the components well using

distilled water and dry them.

Rinse the components well, and wash with nitric acid as well. Then rinse well the

items with distilled water and dry them.

1

.

Inspection

7

No.

704-2010-01

(5) Reassembly

・Version I type ・Version II type

*The order of the packing and glass are different in the Version I type and Version II type.

Version I type ・Version II type

Reassemble the cell unit. (Take care not to mistake the position packing(s) and O-

ring(s).)

Keep in mind that the screw will break if the connection of the 200-mm cell

and the 1-mm cell is fastened too much tightly. Fixing of components

(6) Attach the cell unit, tighten the screws fixing the optical system and finally retighten

the joint.

(7) After the power is turned on and all heaters are stabilized, adjust the voltages for the

optical system.

(It takes at least one hour to stabilize the temperature in the instrument.)

1

.

Inspection

8

No.

704-2010-01

(8) Gain adjustment*

(9) Make the gain adjustment only when the shift of the voltage is large after

replacing cells, and cleaning photoelectric tubes, lens and half-mirrors.

Version I type

Adjust SIG1, SIG2 and REF to about 3 using

the trimmers 20 minutes after switching on the

power supply. And then tune them to 3.0 +/-0.2

1 hour or more after.

*Adjustment of them if this is not possible, then change the resistance.

Turn off the power and unplug the connector of the optical system.

Remove the screws that secure the phototube of SIG2 and SIG1.

Remove the board and change the resistance.

If you wish to double its current

value, replace the resistor with the

twice resistance-value .

1

.

Inspection

9

No.

704-2010-01

Version II type.

* Use the automatic gain adjustment function for the Version II type.

・Before the adjustment, record the constants of the current offset information and gain

information.

・Push the “AUTO” button to make the automatic gain adjustment.

・If the difference from the constant before the alteration is abnormally large after the

automatic adjustment is made, make an adjustment again. If the difference from the

original constant is 50 or more, the adjustment will be regarded as no good.

③

1

.

Inspection

10

No.

704-2010-01

1.3.

Replacement of joint

(1) Preparation of components

(2) If the joint connected to a Teflon tube is tightened too strongly, it will be damaged. If

a cap nut, especially one made of stainless steel, is tightened sl, the thread may be

damaged and an accident in which a leak does not stop may occur. (The photographs

below show defective components.)

(3) Tightening Procedure

In the case of a joint and a Teflon tube, tighten them manually and then tighten them

furthermore by one turn.

In the case of a joint and a glass tube, tighten them manually and then tighten them

furthermore by a 1/6 turn.

(4) Loosen a stainless steel cap nut without removing it when disconnecting a pipe. If it

is removed, attach it while keeping the joint parallel to the cap and making sure of the

engaging of the screws.

(5) To tighten the loosened 6 mm dia. joint (connection of the collection tube and the

sample heating tube), tighten it with the one side fixed using long-nose pliers.

No.

Name Comp. No. Qty Remark

①

Joint - 1 Tool

②

Long-nose pliers 2 Tool

③

Monkey wrench (small) 1 Tool

1

.

Inspection

11

No.

704-2010-01

1.4.

Dismounting the sample heating tube

Warning Carry out maintenance of the heated sections only after the

power switch has been turned OFF and the heater has cooled

down to room temperature or it could result in burns.

Remove the top cover and open the front

cover. (Locked when the power is ON)

Open the front cover and turn ON the power

of the MA-3000.

Turn OFF the MA-3000 after the sample

changer operates, and the Z axis moves

towards you and stopped.

Loosen the Teflon joint at the sample inlet.

Unscrew 4 knurled screws holding the

sample heating tube retainer and the pipe

heater cover, and remove the retainer and

the cover.

Loosen the joint connecting the mercury

collection tube and the cell.

Loosen 2 box nuts of the reducing T joint on

the side of the mercury collection tube and

on the side of the detector to remove the

joint.

*

The joint would be a cross joint in the case

an optional unit is supplied.

1

.

Inspection

12

No.

704-2010-01

Loosen the 4 panel fasteners on the inlet

shaft on both the left and right sides with a

Phillips screw driver (No.2) and open the

door to the right.

Remove the 3 screws that fix the sample

inlet.

Remove the sample heating tube.

Remove the 3 flat head screws on the

sample inlet and slowly turn sample heating

tube and mercury collecting tube to pull

them out.

Unscrew 3 screws with a hex wrench and

pull out the sample heating tube. Also

remove the box nuts of the Teflon joint.

1

.

Inspection

13

No.

704-2010-01

1.5.

Mounting the sample heating tube

Make sure that the O-ring is not damaged

when assembling the sample inlet.

Place the O-ring in the center of the sample

inlet retainer and pass the branch tube

through the sample inlet ring.

Do not confuse the head and tail of the ring.

Install the sample heating tube in the

retainer.

Insert the tube and tighten the screws.

(Tighten the 3 screws gradually in an

alternative manner until there is no

clearance.)

Install the Teflon joint and the mercury

collection tube to the sample heating tube.

Disassemble the Teflon joint, pass the

sample heating tube through the box nut,

washer, O-ring and joint in this order and

tighten the nut.

Here, do not insert the joint too deep so that

the position can be easily adjusted later.

* The thread on the Teflon joint is easily

damaged. Ensure to verify that the nut

turns smoothly. If the box nut does not

correctly engage the thread, it could result

in leaking.

Wipe the outside of the sample heating tube

and the mercury collection tube with alcohol.

1

.

Inspection

14

No.

704-2010-01

Insert the sample heating tube.

Slowly insert the sample heating tube into

the sample inlet while twisting it gently to the

left and right.

* Pushing it too forcefully could result in the

heater being deformed.

Pass the mercury collection tube through the

H3 heater and push it until the sample inlet

touches the reducing joint.

Adjust the position of the mercury collection

tube. Align the end of the heater and the

dent of the mercury collection tube. Adjust

the position by adjusting the insertion depth

of the Teflon joint.

Tighten the Teflon joint securely. In particular,

the reducing joint must be tightened lightly

with a hand at first and then re-tightened with

a wrench by about ½ turn.

* The joint may be broken if excessively

tightened.

Fix the mounting piece of the sample heating

tube in place.

Tighten the screws with the supplied hex

wrench.

Close the door of the sample inlet shaft.

Gradually tighten the panel fasteners with a

Phillips driver (No.2). Tighten all of the 4

screws lightly and then the re-tighten them

little by little.

1

.

Inspection

15

No.

704-2010-01

⑪Connect the elbow joint to the branch pipe

on the sample inlet.

⑫Install the pipe heater cover and sample

heater tube retainer. Close the front cover

and install the top cover.

⑬Turn ON the power of the MA-3000 and

perform the check of flow path to make sure

that there is no leak.

1

.

Inspection

16

No.

704-2010-01

1. .

Check of sample changer

(1) Select [run] - [maintenance] on the menu bar to open the “Maintenance” screen, and

select the “BC” tab. Then, click BC ADJUST and make the operation check of the sample

changer.

It is possible to specify the tray number and boat number at (1) and (2), respectively.

*

A number can be changed only when it is displayed in black.

Items (3) and (4) show operation to be carried out when (5) or (6) is selected.

Item (5) is used for operation in the direction to insert a boat.

Item (6) is used for operation in the direction to return a boat.

①Ready state

Put a boat on Tray No. 1 and set it to the

MA-3000.

①

②

③

④

⑤

⑥

Other manuals for MA-3000

1

Table of contents

Other Nippon Measuring Instrument manuals

Nippon

Nippon RA-4500 User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon WA-5A User manual

Nippon

Nippon MA-3 Solo User manual

Nippon

Nippon Hi-Lutor User manual

Nippon

Nippon Mercury/PE-1 User manual

Nippon

Nippon MA-3000 User manual

Nippon

Nippon EMP-3 User manual

Nippon

Nippon AQUA User manual

Nippon

Nippon MA-3 Solo User manual

Popular Measuring Instrument manuals by other brands

M-Sure

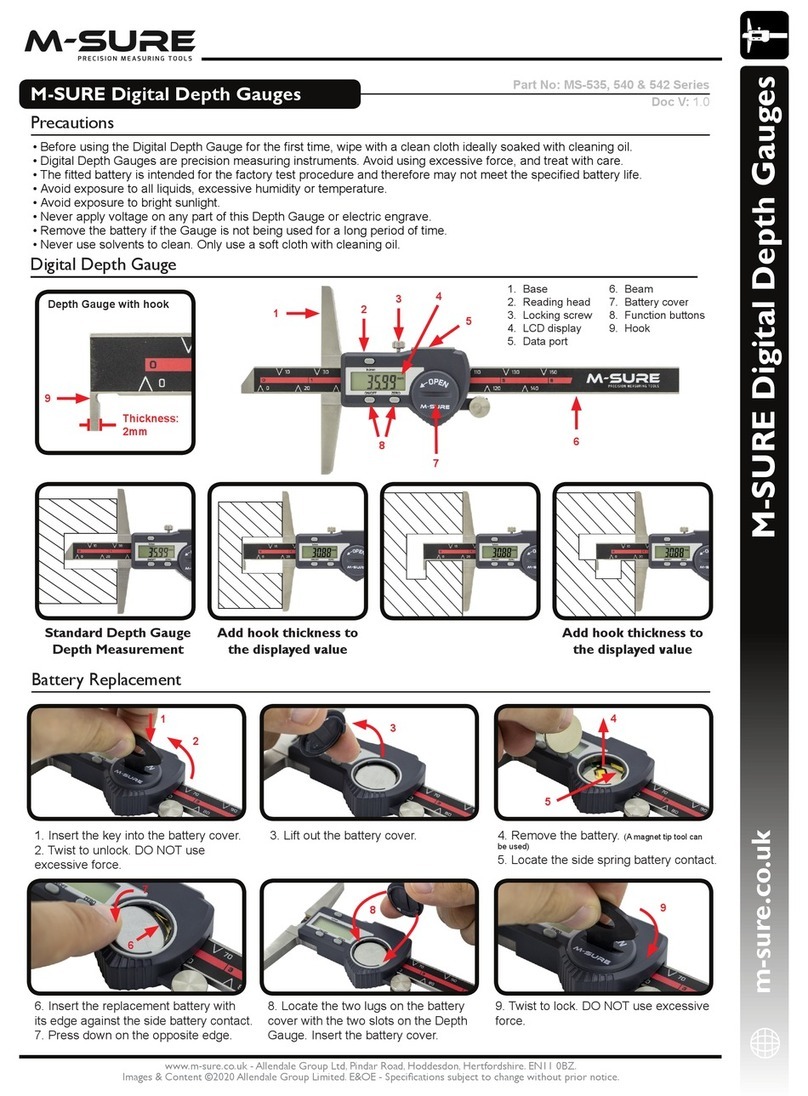

M-Sure MS-535 Series quick start guide

Komshine

Komshine KFI-40 user manual

TDE Instruments

TDE Instruments Digalox DPM72-MPPV-USB instruction manual

agratronix

agratronix MT-PRO+ Operator's manual

ATS

ATS ATS-FM-M Instructional manual

BEG

BEG LUXOMAT Indoor 180N-R/2W-UK Installation and operating instruction